Ultrathin crystal stone and manufacturing method thereof

A crystalline stone and ultra-thin technology, which is applied in the field of building exterior wall decoration materials, can solve the problems of personnel or other property damage, difficulty in coping with natural climate, and the weight of the material itself, and achieve ultra-thin light weight, high hardness, and good water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

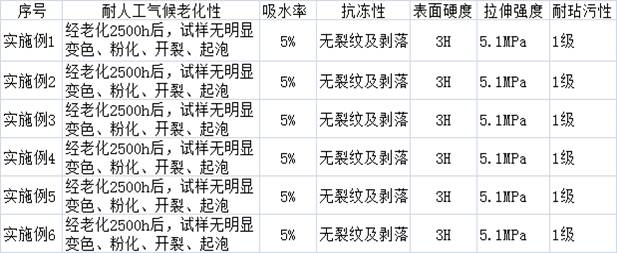

Examples

Embodiment 1

[0033] To prepare crystalline stones, follow these steps:

[0034] S1 preparation of pulp: preparation of raw materials, by weight percentage, cement 20%, fly ash 34%, water 20%, modified silicon solution 1.5%, acrylic emulsion 10%, kaolin 0.5%, magnesium hydroxide 10%, glass fiber filament 0.2%, alkali resistant glass fiber mesh 0.3%, polycarboxylic acid 0.8%, mineral oil 0.5%, calcium formate 1%, iron oxide red 0.4%, iron oxide yellow 0.3%, iron oxide black 0.5%; Add water, modified silicon solution, polycarboxylic acid, mineral oil to the barrel first, add cement, fly ash, kaolin, magnesium hydroxide, glass fiber filament, iron oxide red, iron oxide yellow, iron oxide black, and then add acrylic emulsion, and finally add calcium formate, put all the raw materials in the barrel into a blender, stir for 20 minutes to make the material fully stirred evenly, and the pulp made is called pulp;

[0035] S2 adjust the color and texture of the pulp, and then spray the pulp on the imitat...

Embodiment 2

[0038] To prepare crystalline stones, follow these steps:

[0039]S1 preparation of pulping: preparation of raw materials, by weight percentage, cement 23.2%, fly ash 21%, water 30%, modified silicon solution 1%, acrylic emulsion 12.7%, kaolin 0.3%, magnesium hydroxide 8%, glass fiber filament 0.15%, alkali resistant glass fiber mesh 0.2%, polycarboxylic acid 0.45%, silicone 0.3%, calcium formate O.7%, iron oxide brown 1%, iron oxide yellow 1%; Add water, modified silicon solution, polycarboxylic acid, silicone to the barrel first, add cement, fly ash, kaolin, magnesium hydroxide, glass fiber filament, iron oxide brown, iron oxide yellow, then add acrylic emulsion, and finally add calcium formate, put all the raw materials in the barrel into a mixer, stir for 20 minutes to make the material fully stirred evenly, and the pulp made is called pulp;

[0040] S2 adjusts the color and texture of the pulp, and then sprays the pulp on the simulated wood grain mold, the thickness of the sp...

Embodiment 3

[0043] To prepare crystalline stones, follow these steps:

[0044] S1 preparation of pulping: preparation of raw materials, by weight percentage, cement 26.6%, fly ash 21%, water 25.15%, modified silicon solution 0.6%, acrylic emulsion 20%, kaolin 0.15%, magnesium hydroxide 5%, polyacrylonitrile fiber filament 0.1%, alkali-resistant glass fiber mesh 0.1%, polycarboxylic acid 0.2%, silicon 0.1%, calcium formate O.5%, iron oxide palm 0.5%; Add water, modified silicon solution, polycarboxylic acid, silicone to the barrel first, add cement, fly ash, kaolin, magnesium hydroxide, polyacrylonitrile fiber filament, iron oxide palm, and then add acrylic emulsion, and finally add calcium formate, put all the raw materials in the barrel into a mixer, stir for 20 minutes to make the material fully stirred evenly, and the pulp made is called pulp;

[0045] S2 adjust the color and texture of the pulp, and then spray the pulp on the imitation pine bark mold, spray the thickness of the pulp is 2-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com