Static pressure type rear support spiral pile based on bionics and construction method thereof

A technology of screw pile and static pressure, which is applied in foundation structure engineering, sheet pile wall, building and other directions, can solve the problems of large soil disturbance, insufficient horizontal bearing capacity of pile foundation, low construction efficiency, etc. The effect of small body disturbance and low construction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

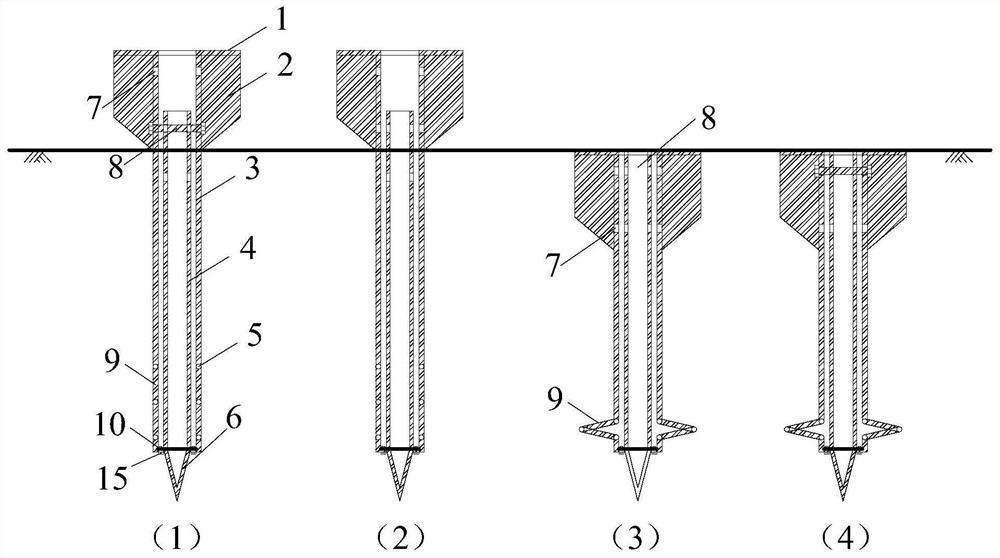

[0050] Embodiment 1 uses a static pressure back-stayed screw pile with a built-in steel pipe and its construction method.

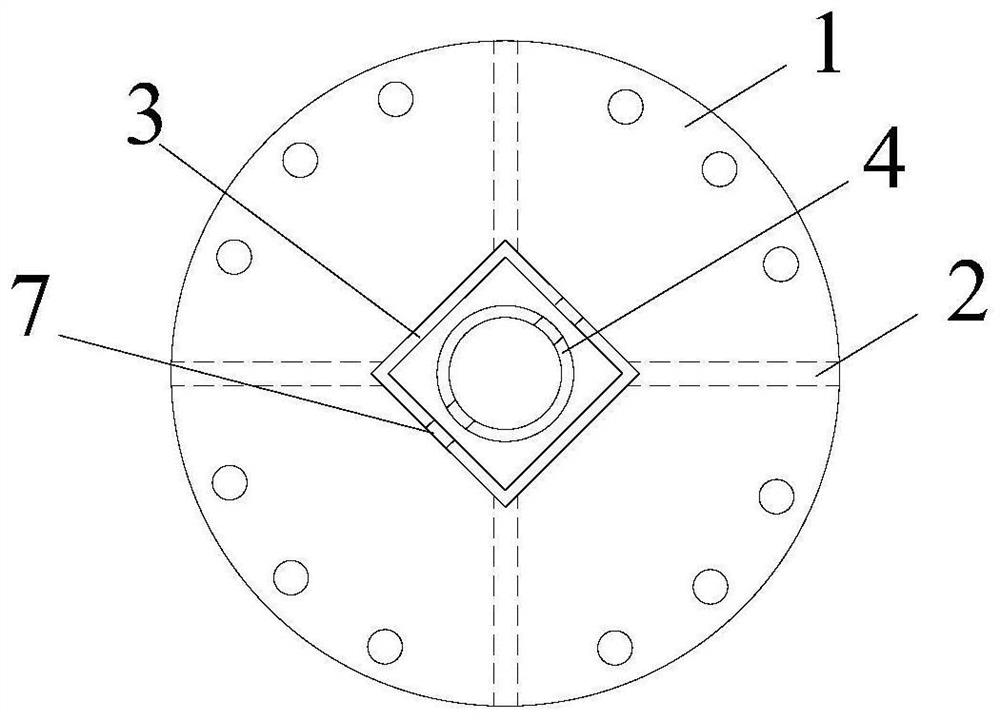

[0051] When the built-in steel pipe 4 is used, the factory prefabricates the built-in steel pipe 4, the pile tip 6, the empennage 2, the outer casing 3, the outer support blade 9 and the flange 1. The built-in steel pipe 4 has a diameter of 76 mm, a length of 1.8 m, and a wall thickness of 8 mm. There are two rows of perforation holes on the upper part of the steel pipe, the first row is 80mm from the top, and the second row is located 50mm above the bottom of the empennage 2; the empennage 2 is composed of four trapezoidal wing plates, and the angle between the wing plates is 90° The plate width is 0.15m, the length of the flange is 0.3m, and the thickness of the flange is 5mm; the pile point 6 is an inverted conical closed pile point, the diameter of the conical bottom surface is 76mm, the angle of the pile point is 30°, and the outer edge of the bottom...

Embodiment 2

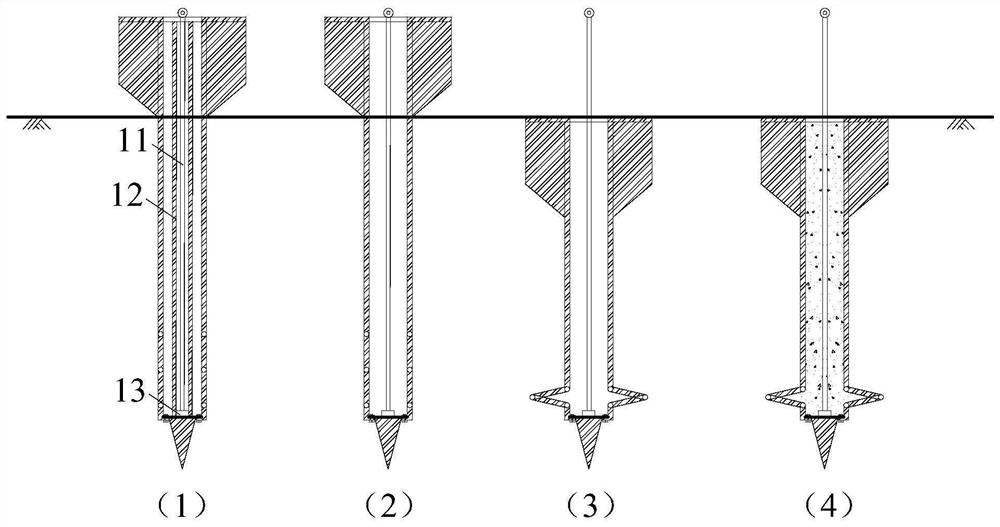

[0056] Finally, move the frame and construct the next static pressure back-supported screw pile until all the pile foundation construction in the site is completed. Embodiment 2: Static pressure back-supported screw pile using flexible anchor rod and its construction method.

[0057] When the flexible anchor rod 11 is used, the flexible anchor rod 11, the pile point 6, the empennage 2, the outer casing 3, the installation sleeve 12, the outer support blade 9 and the flange 2 are prefabricated according to the design requirements. The flexible anchor has a diameter of 10mm and a length of 2.1m. The top of the flexible anchor is equipped with a circular pull ring, the inner diameter is 30mm, the outer diameter is 50mm, and the diameter of the expansion head at the bottom is 50mm. The empennage 2 is composed of three trapezoidal wing plates, the angle between the wing plates is 120o, the width of the wing plates is 0.2m, the length of the wing plates is 0.3m, and the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com