Original soil strengthen pile sinking method and its construction apparatus

A construction device and a technology for driving piles, which are used in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as uneven subsidence and inclination of buildings, increased construction costs of pile foundations, and unguaranteed pile body strength. , to avoid the waste of resources and financial resources, improve the efficiency of pile driving, and improve the penetration ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

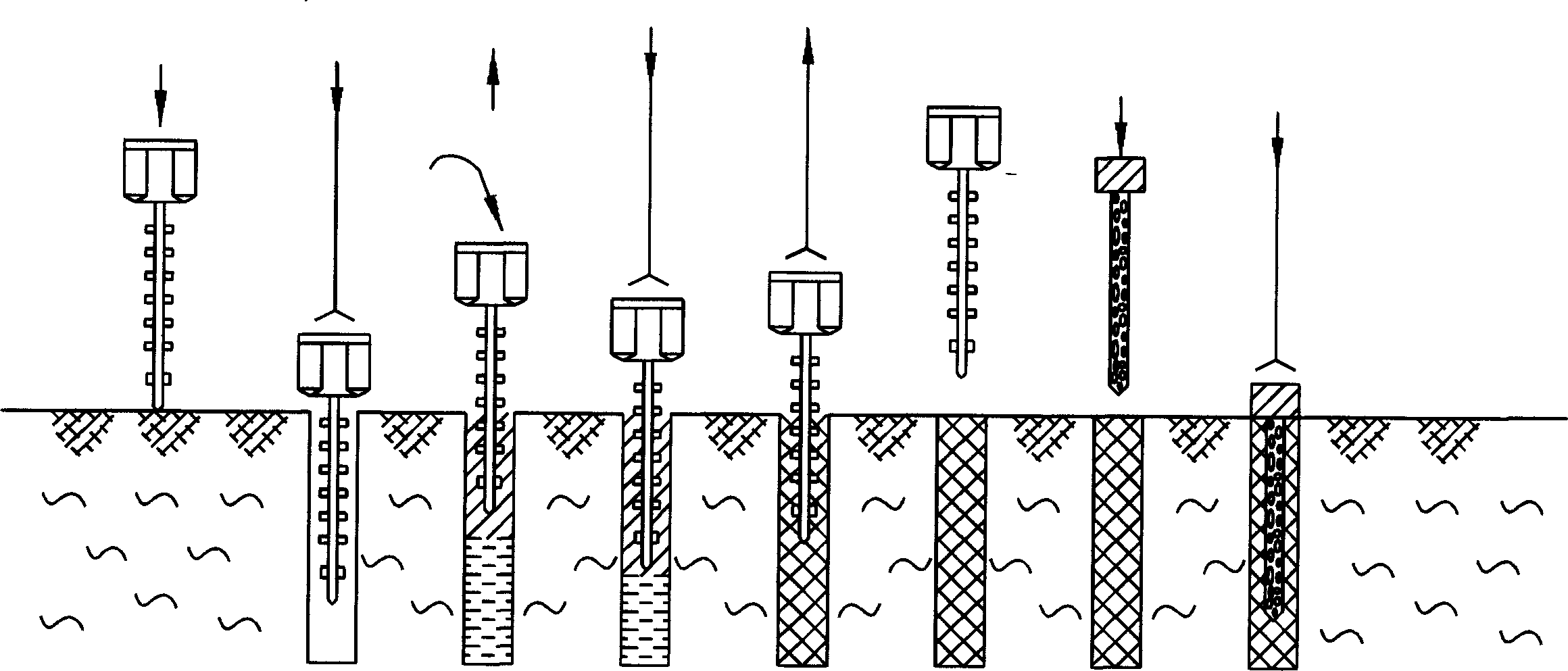

[0014] figure 1 It shows a kind of specific construction process flow diagram of the present invention. The process steps from left to right in the figure are as follows:

[0015] (1) First, move the deep layer mixer to the predetermined reinforcement stirring position of the foundation, position and center, and start the deep layer mixer motor;

[0016] (2) After the rotation speed of the mixing head is normal, it will feed downwards while rotating and stirring, cutting and crushing the soil layer until it reaches the predetermined depth, so as to form a bulky mixing and cutting original soil at the reinforcement mixing position;

[0017] (3) Configure cement slurry (cement content accounts for about 7-15% of the weight of the reinforced soil), lift the mixer slightly, turn on the mortar pump and continue to rotate and lift, and press the cement slurry into the agitator while stirring the slurry. Cut into the original soil until it is lifted to the design height; at this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com