Composite pile structure for iron tower of electric transmission line

A technology of transmission line iron towers and composite piles, which is applied in the direction of basic structure engineering and construction, can solve the problems of large amount of concrete and steel bars, large amount of concrete and steel bars, and low bearing capacity of bearing layer foundation, so as to reduce project cost, The effect of reducing floor space and reducing horizontal displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

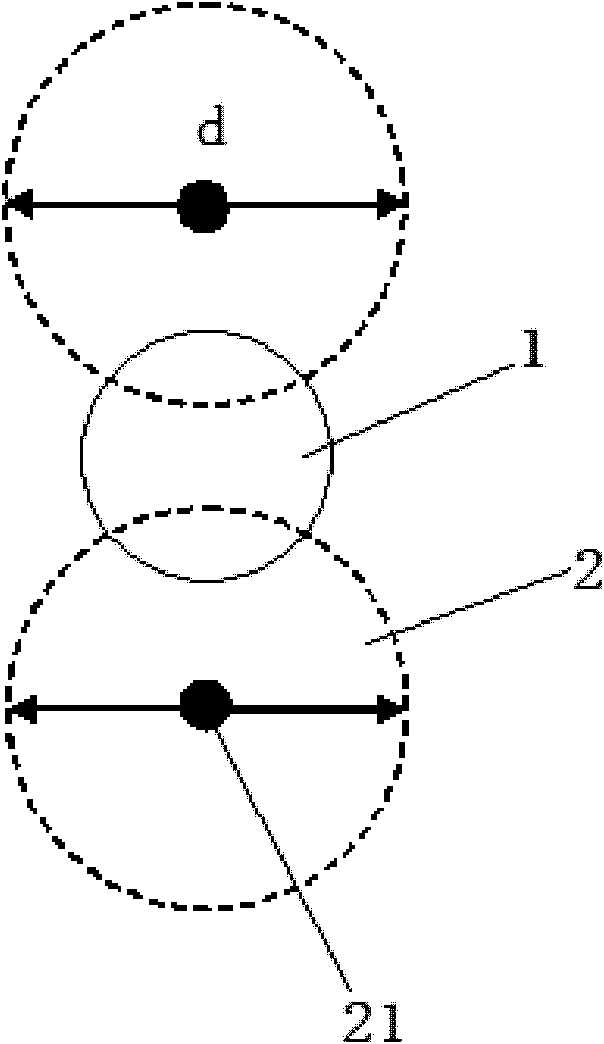

[0020] Such as figure 1 As shown, a composite pile structure for transmission line towers includes a pile body 1 and pile body fasteners 2 , and the pile body fasteners 2 are arranged on both sides of the pile body 1 . There are two pile body fasteners 2, which are arranged symmetrically on both sides of the pile body 1 respectively. The pile body fastener 2 is formed by rotary jet grouting, and the distance between the rotary jet grouting point 21 and the outer surface of the pile body 1 is greater than the grouting radius. The distance between the swirling jet grouting point 21 and the outer surface of the pile is 250mm. The grouting diameter d is 400mm.

[0021] If the pile body 1 is a pressure-resistant pile body, the depth of the pile body fastener 2 is the depth of the pile body plus three times the diameter of the pile body. If the pile body 1 is an uplift pile, the depth of the pile body fastener 2 is the depth of the pile body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com