Combined supporting structure for treating dangerous rock mass and construction method thereof

A technology of combined support and dangerous rock mass, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems that the safety and stability of dangerous rock mass cannot be guaranteed, the safety and stability cannot be guaranteed, and the reinforcement treatment measures are single. The effect of low equipment requirements, good economy, and simple design and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

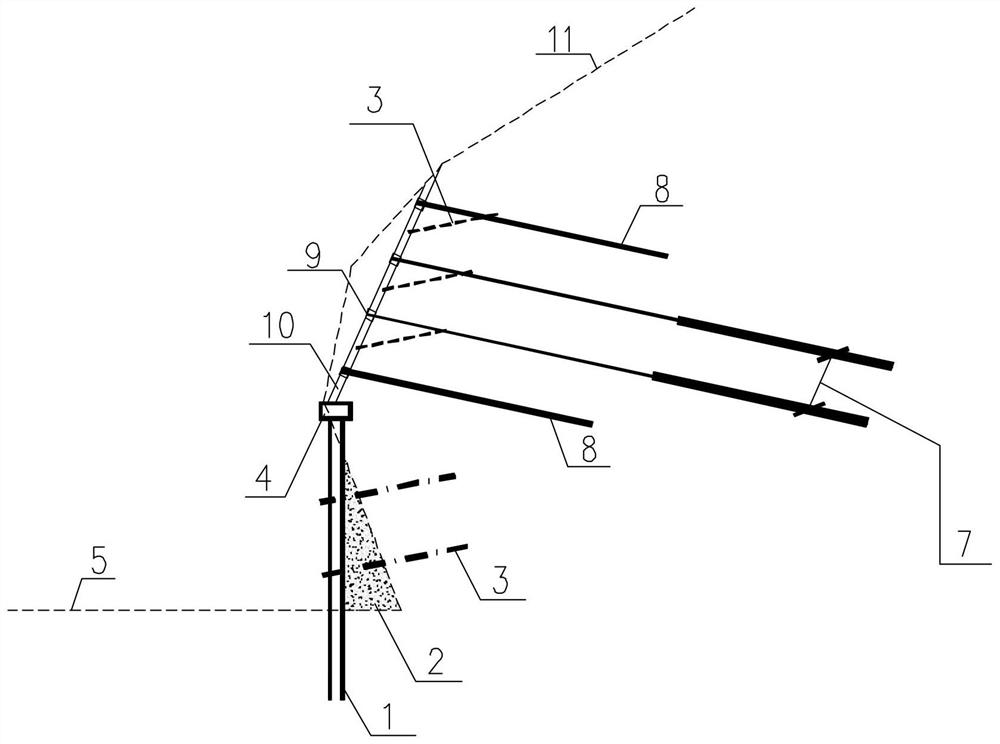

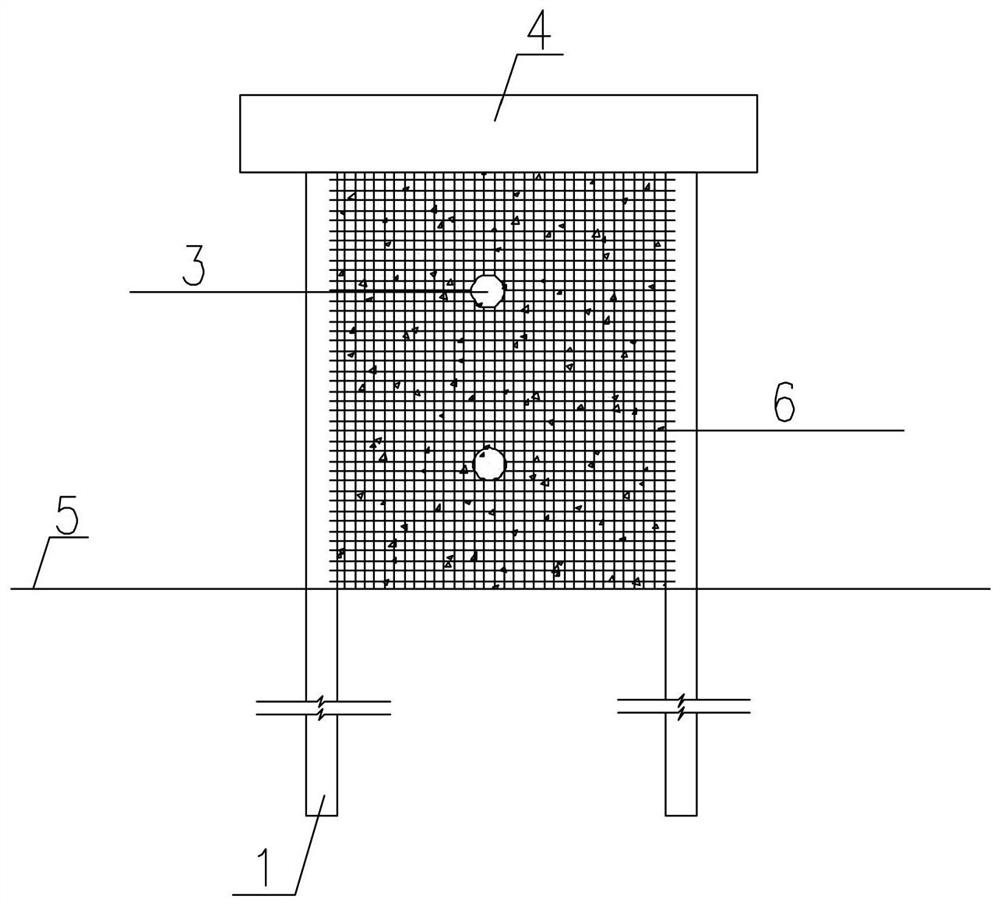

[0026] like figure 1 and figure 2 As shown, the structure of the present invention mainly includes micro steel pipe pile 1, concrete 2, PVC drainage pipe 3, pile top crown beam 4, ground 5, prefabricated concrete baffle 6, prestressed anchor cable 7, prestressed anchor rod 8, Sash girders 9, earth backfill 10, original topographic line 11 of dangerous rock mass and other parts. During specific implementation, a double-row miniature steel pipe pile 1 is designed in the lower dangerous rock mass, including a circular hollow prefabricated steel pipe pile body with a diameter not greater than 300mm, and three steel tendons built in. less than 3m, to ensure that the micro-steel pipe pile 1 has a sufficient length of the embedded section, the top of the micro-steel pipe pile 1 is provided with a pile crown beam 4, and the double row of micro-stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com