Solidified soil retaining wall and construction method thereof

A construction method and technology for solidifying soil, which can be used in excavation, artificial islands, water conservancy projects, etc., can solve problems such as large construction costs, and achieve the effects of short construction period, ecological environment protection, and good frost resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

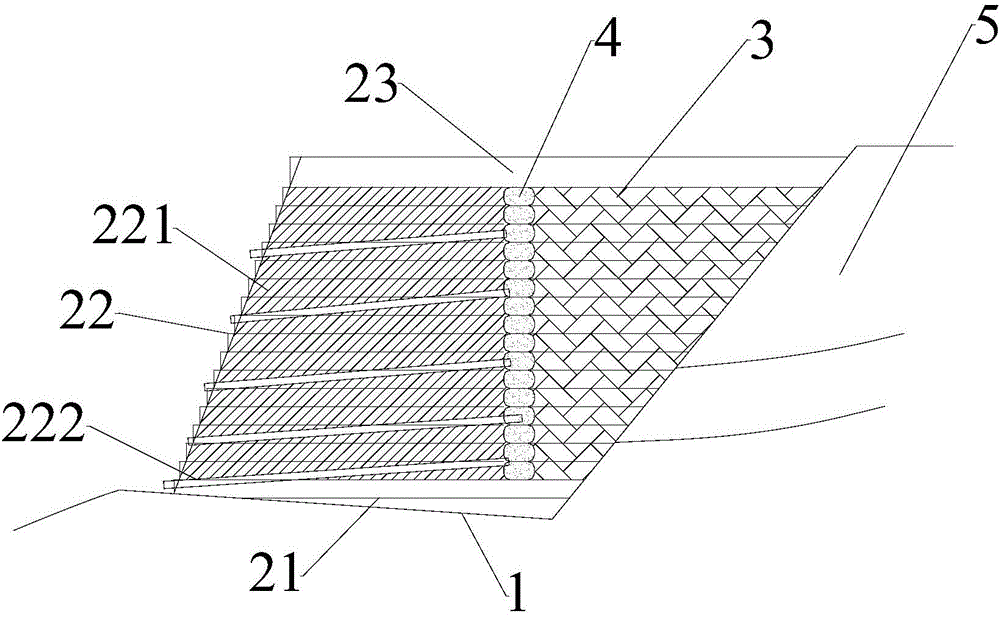

[0045] Please refer to image 3 , a solidified soil retaining wall according to the present invention, comprising a foundation groove 1 arranged near the side slope 5, the foundation groove 1 is divided into a solidified soil mixture laying area and a filling area;

[0046] The solidified soil mixture laying area includes the paving top layer 23, the paving middle layer 22 and the paving bottom layer 21 laid up and down in sequence to form a wall body, and a plurality of drainage pipes 222 are buried obliquely in the body of the wall, and the drainage pipes 222 The water inlet extends into the filling area, the water outlet of the drainage pipe 222 is inclined to the bottom of the foundation tank 1, and a plurality of drainage pipes 222 are arranged up and down; one end of the paving bottom layer 21 touches the top slope 5; the paving middle layer 22 includes a multi-layer solidified soil mixture layer 221, and a filling area is reserved at one end of the paving middle layer 2...

Embodiment 2

[0050] refer to Figure 4 , Figure 4 It is a cross-sectional view of a reinforced retaining wall with solidified soil. The reinforced retaining wall with solidified soil is an improvement based on Embodiment 1, specifically, paving any solidified soil mixture layer 221 and the corresponding plain soil layer 3 in the middle layer 22 Ribs 6 are laid on the upper floor. For the situation that the design height of the retaining wall is relatively high, the ribs 6 can be embedded during the paving process of the solidified soil retaining wall, and the ribs 6 extend to the fill soil behind the wall. The friction between the ribs 6 and the backfill of the wall is used to improve the engineering characteristics of the backfill of the wall, and the solidified soil retaining wall is combined with the reinforced soil to improve the retaining capacity of the retaining wall and increase the stability of the slope 5 .

Embodiment 3

[0052] refer to Figure 5 , Figure 5 It is a cross-sectional view of the solidified soil retaining wall with transverse ribs 7, which is an improvement based on the second embodiment. Specifically, the paving middle layer 22 also includes transverse ribs 7, and each transverse rib 7 It extends to the filling area at a preset vertical distance until it is laid to the side slope 5 , and the ribs 6 are pre-embedded in the transverse ribs 7 . During the layered paving and rolling process of the solidified soil reinforced retaining wall body and the backfill soil, the solidified soil paving operation is extended to the backfill layer at intervals of vertical intervals to form transverse ribs 7 . There is a great friction between the transverse rib 7 and the filling soil behind the wall. The existence of the transverse rib 7 increases the self-weight of the retaining wall at the same time. This type of retaining wall has a strong retaining capacity and can be used for retaining so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com