Cast-in place pile post-grouting construction method for pouring construction

A technology of bored piles and construction methods, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems that the sediment at the bottom of the pile and the mud skin on the pile side cannot be effectively reinforced, and the vertical load drops greatly, and achieves The effect of shortening the number of pile foundations, shortening pile length, and reducing pile diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

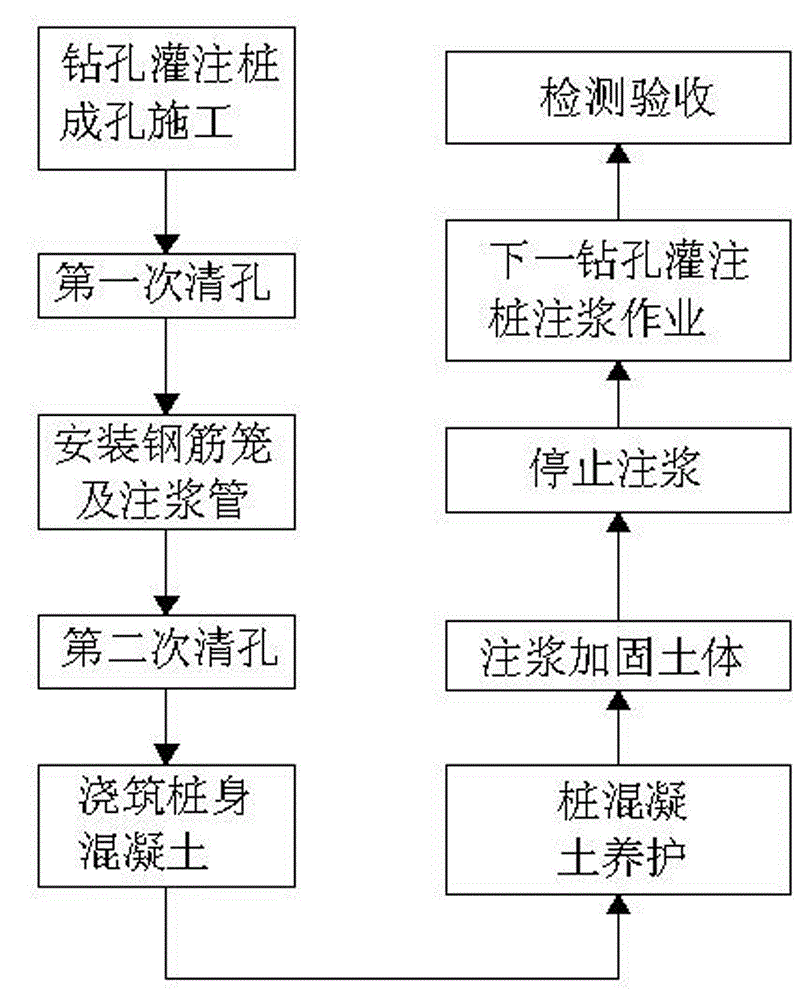

[0040] The present invention proposes a grouting construction method after the bored pile for pouring construction, such as figure 1 shown, including the following steps:

[0041] 1) Hole-forming construction of bored piles: According to the construction process requirements, the bored piles are drilled to form pile holes. During the construction process, the hole depth, diameter and verticality are controlled to understand the condition of the hole wall and the hole wall in time. Internal conditions, whether there are collapsed holes and water leakage, so as to carry out effective technical control during post-grouting construction;

[0042] 2) Cleaning the hole for the first time: After step 1), clean the inside of the pile hole and clean up the residue left during drilling;

[0043] 3) Install reinforcement cages and grouting pipes: hang the assembled reinforcement cages with grouting pipes into the pile holes; strictly control the connection between the grouting pipes and...

Embodiment 2

[0054] This embodiment is further optimized on the basis of the above embodiments. Further, in order to better realize the present invention, the step 3) includes the following steps:

[0055] 3.1) Manufacture and installation of grouting pipe: the grouting pipe is made of steel pipe with a diameter of 25mm~32mm, and the wall thickness of the grouting pipe is greater than or equal to 2.5mm. The grouting pipe is composed of three parts: the pile end grouting device, the middle straight pipe, and the top Joints with threaded buckles, the pile end grouting device is made within 30cm of the bottom of the grouting pipe, and the side wall of the pile end grouting device is provided with grout holes in the shape of a plum blossom. Wrap the completed pile end grouting device with adhesive tape, wrap the outside with lead wire tightly to prevent leakage, and also prevent the concrete grout from blocking the grouting hole of the pile end grouting device of the grouting pipe, affecting th...

Embodiment 3

[0058] This embodiment is further optimized on the basis of the above embodiments. Further, in order to better realize the present invention, in the step 6), when performing pile concrete maintenance, it also includes pressurized water unplugging process, pile pouring Use high-pressure water pressure to pass the grouting pipe within 2~3 days after the completion of the concrete. The water pressure is 2MPa, and the water pressure time is 3~5min. When the pressure exceeds 4MPa, it can be considered that the pipeline is blocked; , indicating that the pipeline has been opened, stop water injection immediately, so as to prevent a large amount of water from pouring into the ground; sooner or later, the uncorking time is particularly critical to the grouting effect. Destroying the concrete strength at the pile end, unplugging the plug too late, and the strength of the concrete wrapping the grouting pipe is too high will cause the adhesive tape of the grouting head to be unopened, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com