Patents

Literature

38results about How to "Reduced moment load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

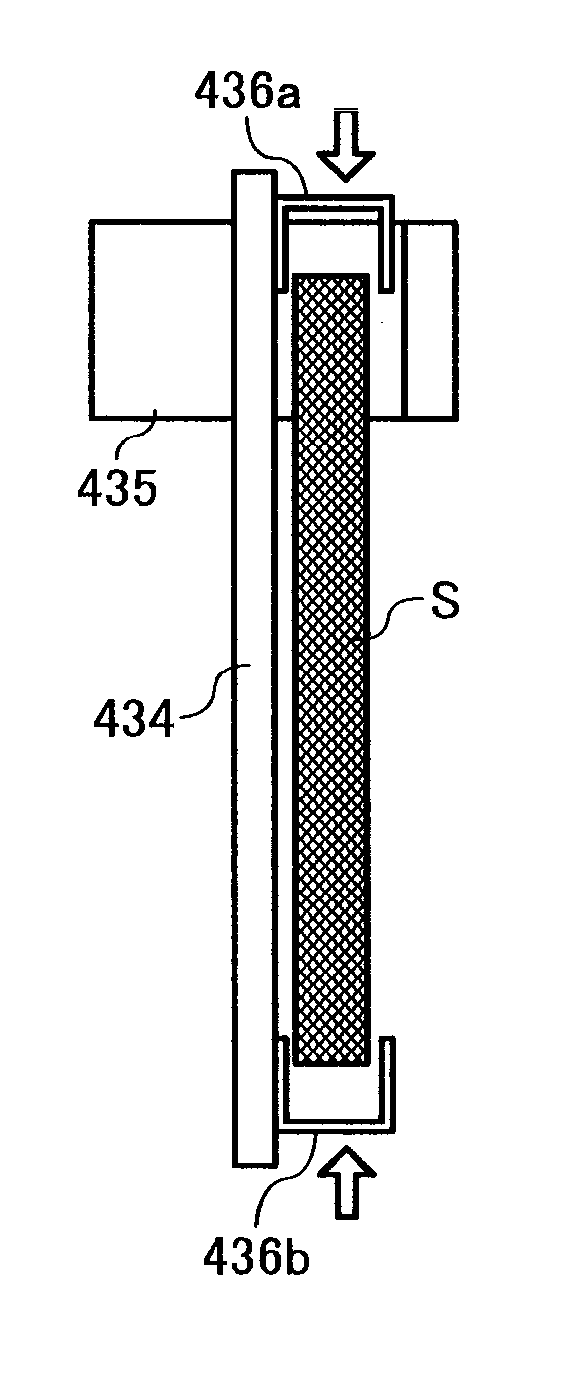

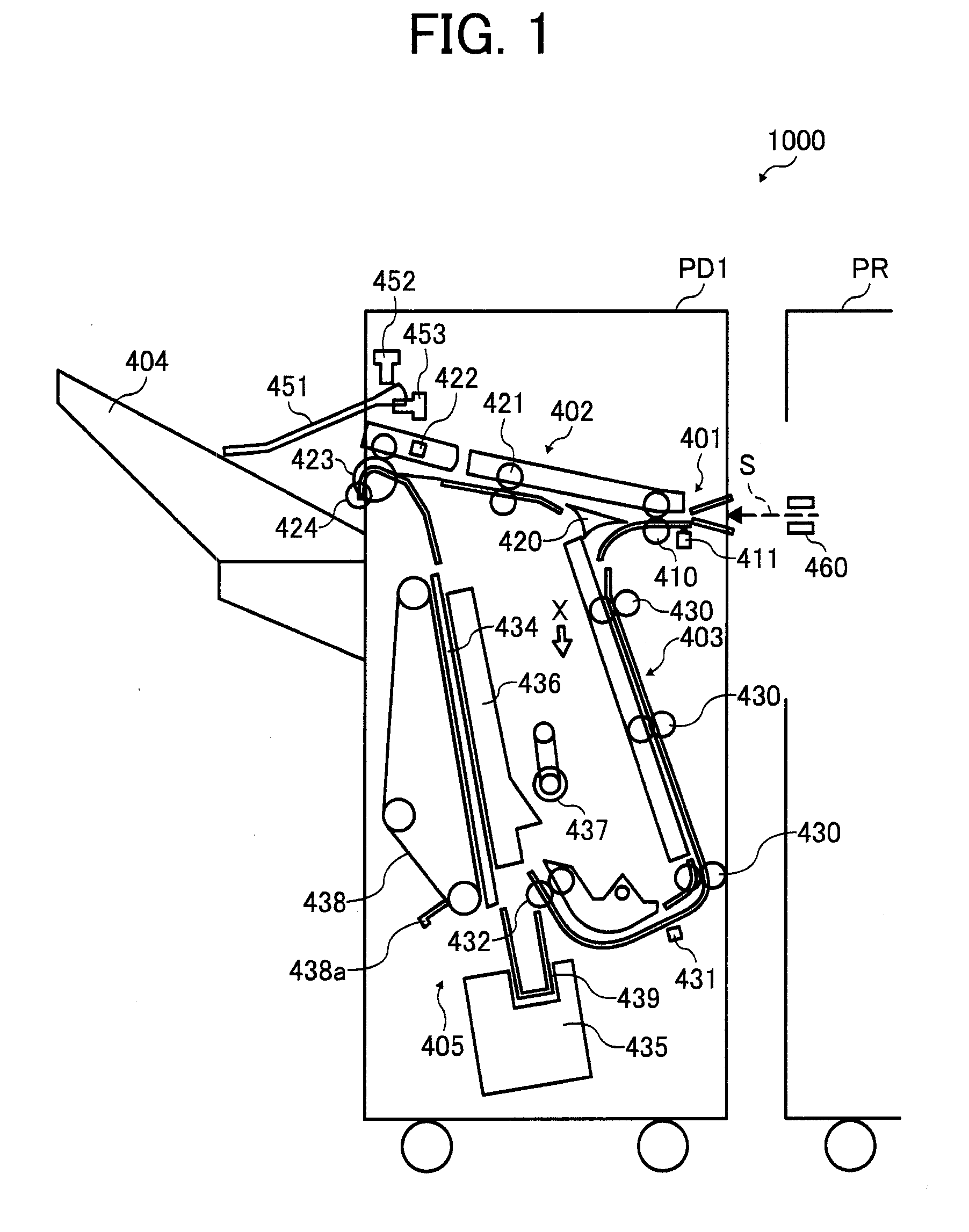

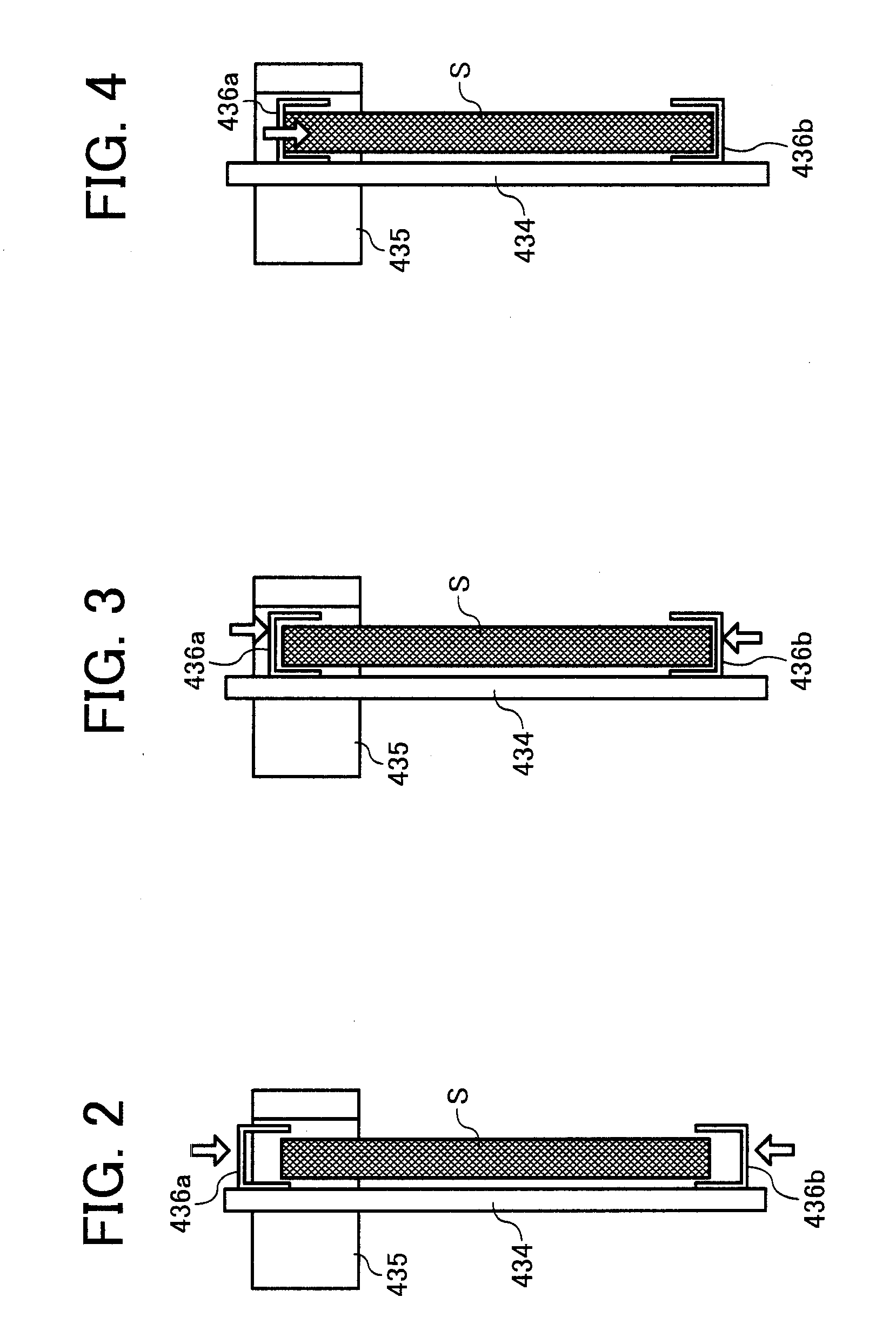

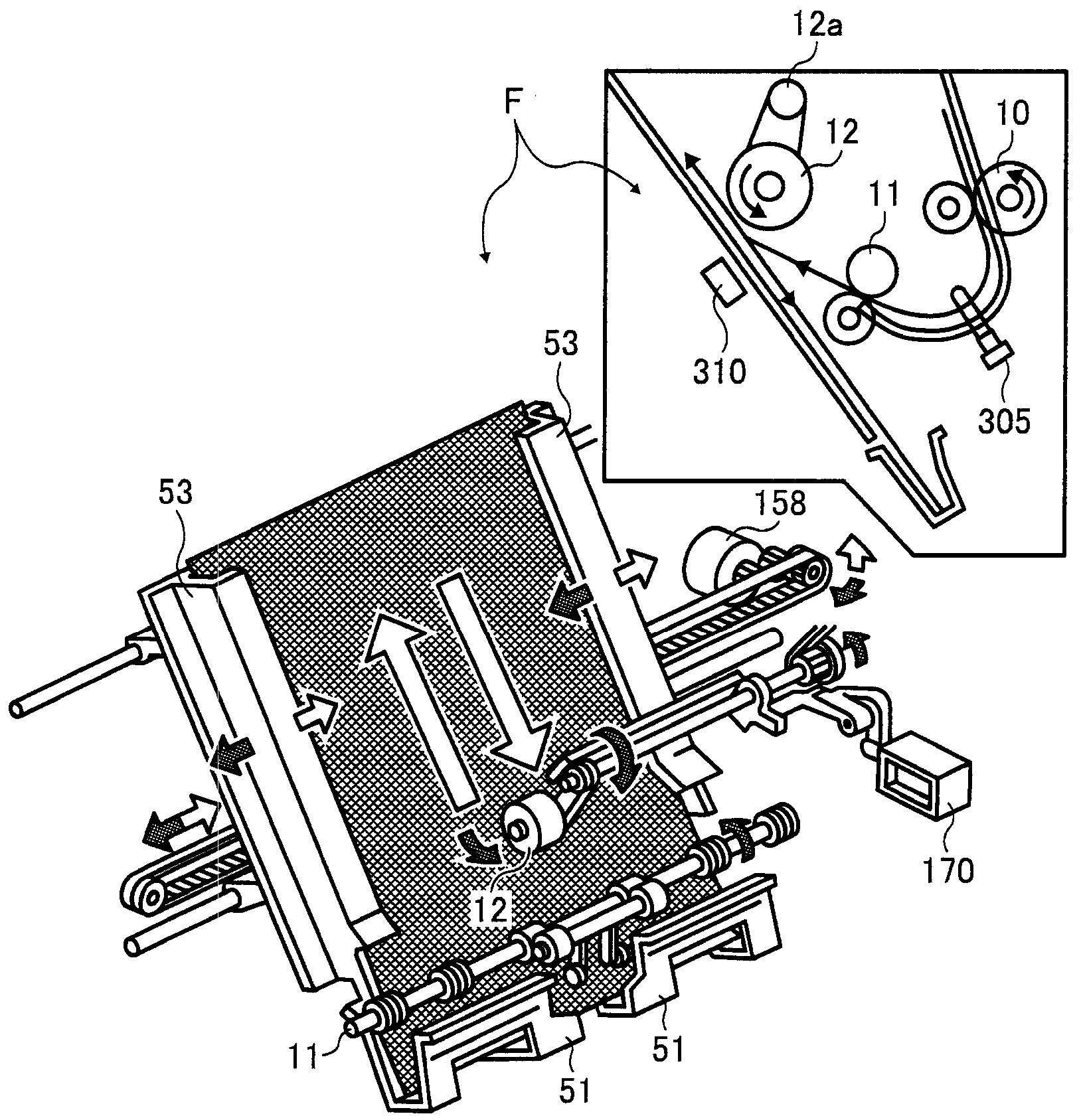

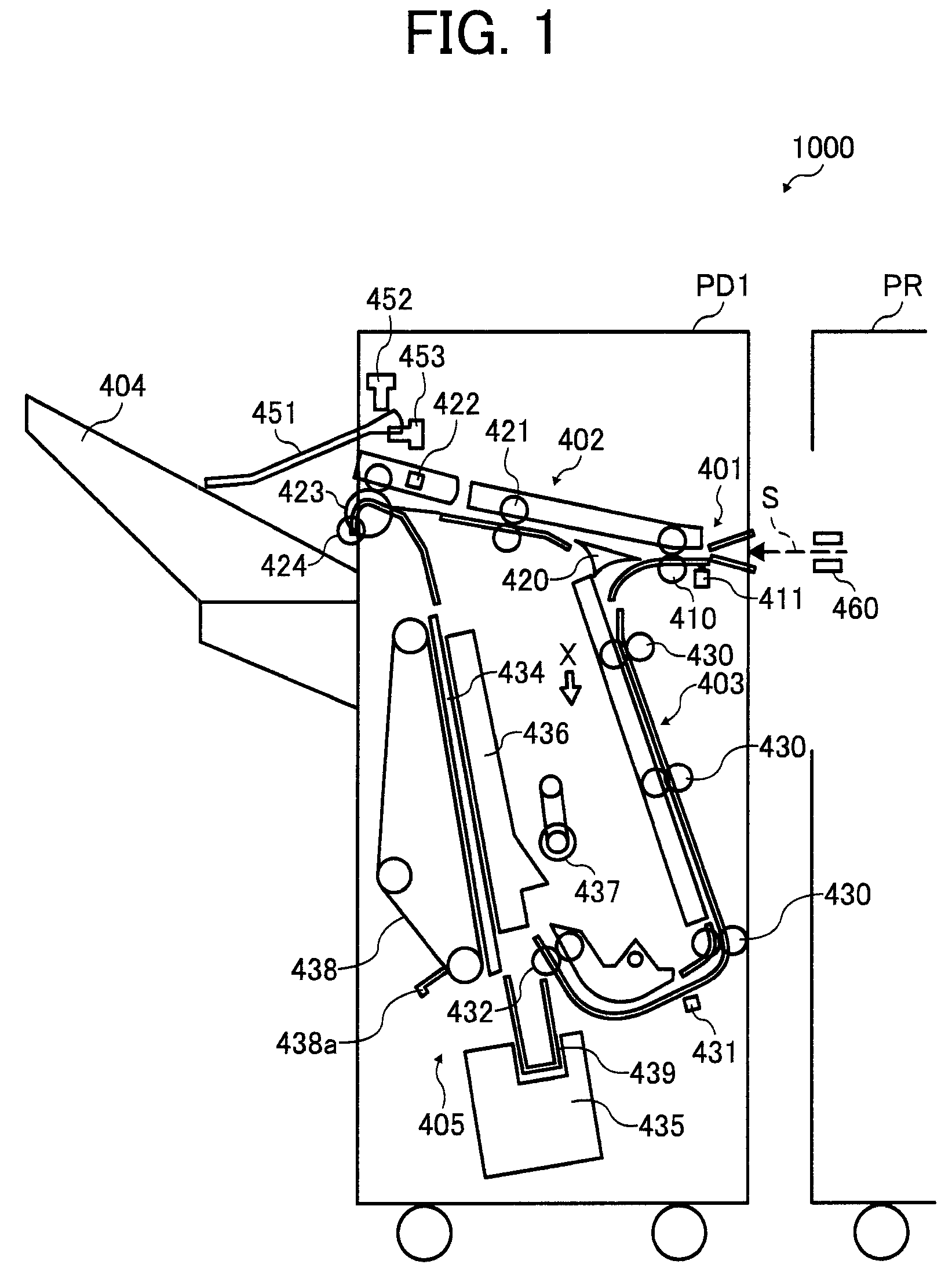

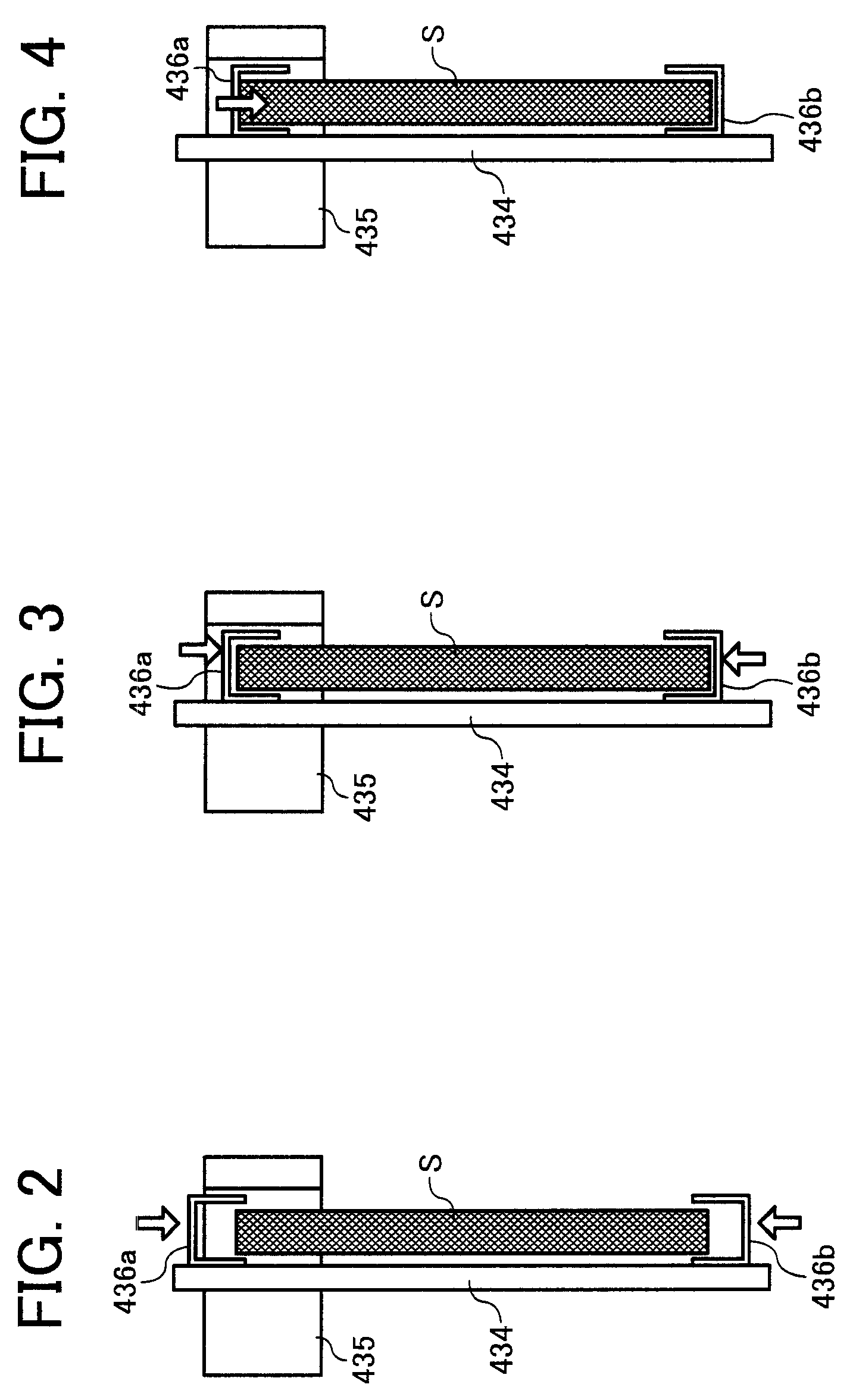

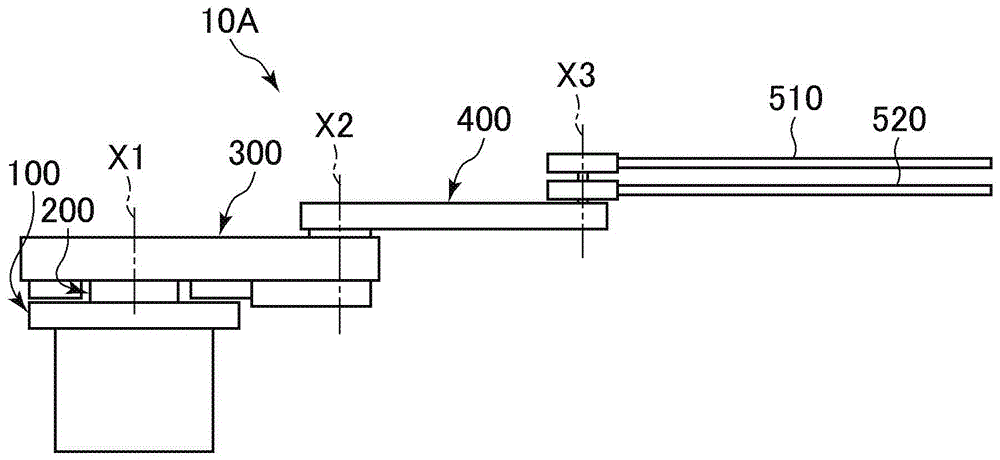

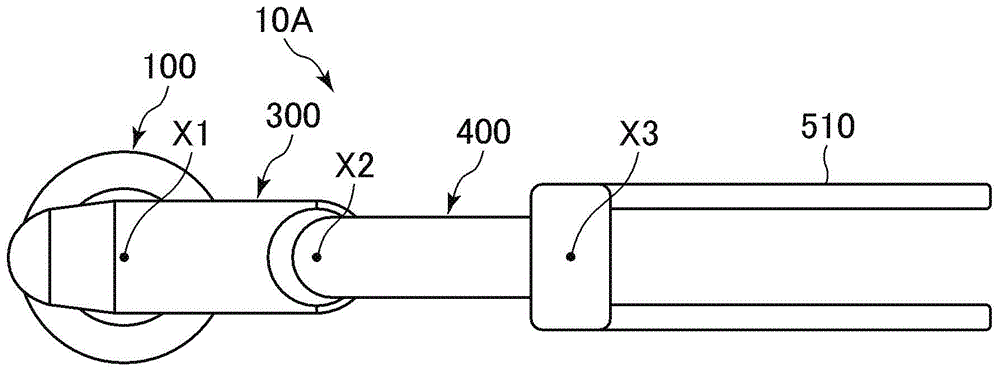

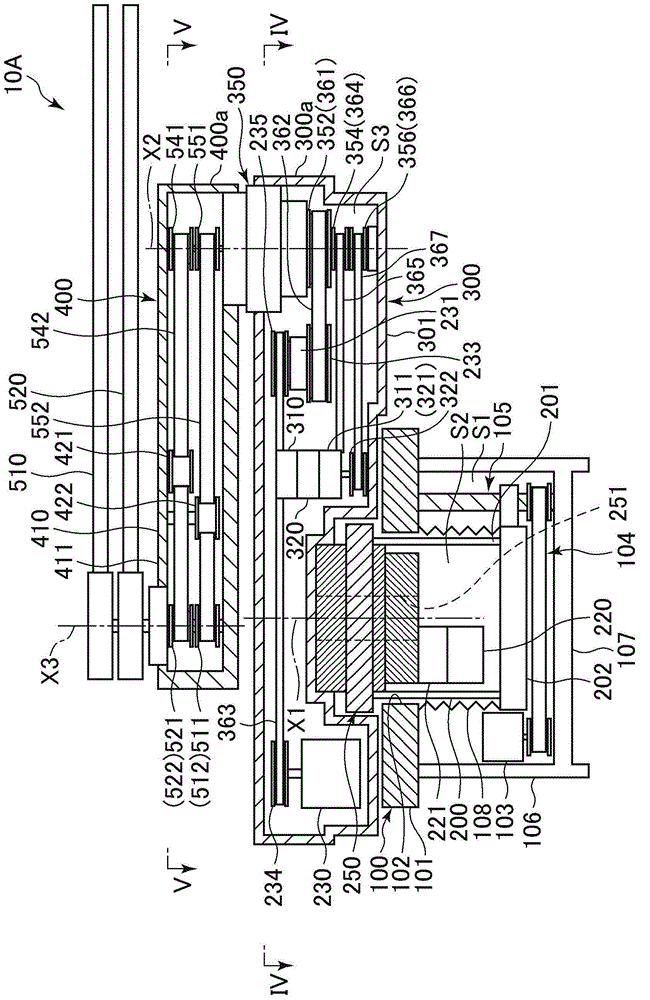

Sheet alignment device, sheet finishing apparatus including the same, and image processing system including the same

ActiveUS20080006993A1Reduced moment loadRegistering devicesFunction indicatorsPaper sheetFixed position

A sheet alignment device, that is included in a sheet finishing apparatus integrally mounted with an image forming apparatus to an image forming system or connected to the image forming apparatus, includes an accommodating unit configured to temporarily accommodate a paper sheet and a paper sheet stack including the paper sheet therein, and a sheet alignment unit configured to align the sheet stack including the paper sheet in a direction perpendicular to a sheet travel direction. The sheet alignment unit has a first alignment member configured to move between a sheet receiving position and a sheet alignment position along the direction perpendicular to the sheet travel direction so as to push the sheet stack and a second alignment member configured to move to a fixed position and remain stationary thereat so as to stop the sheet stack pushed by the first alignment member.

Owner:RICOH KK

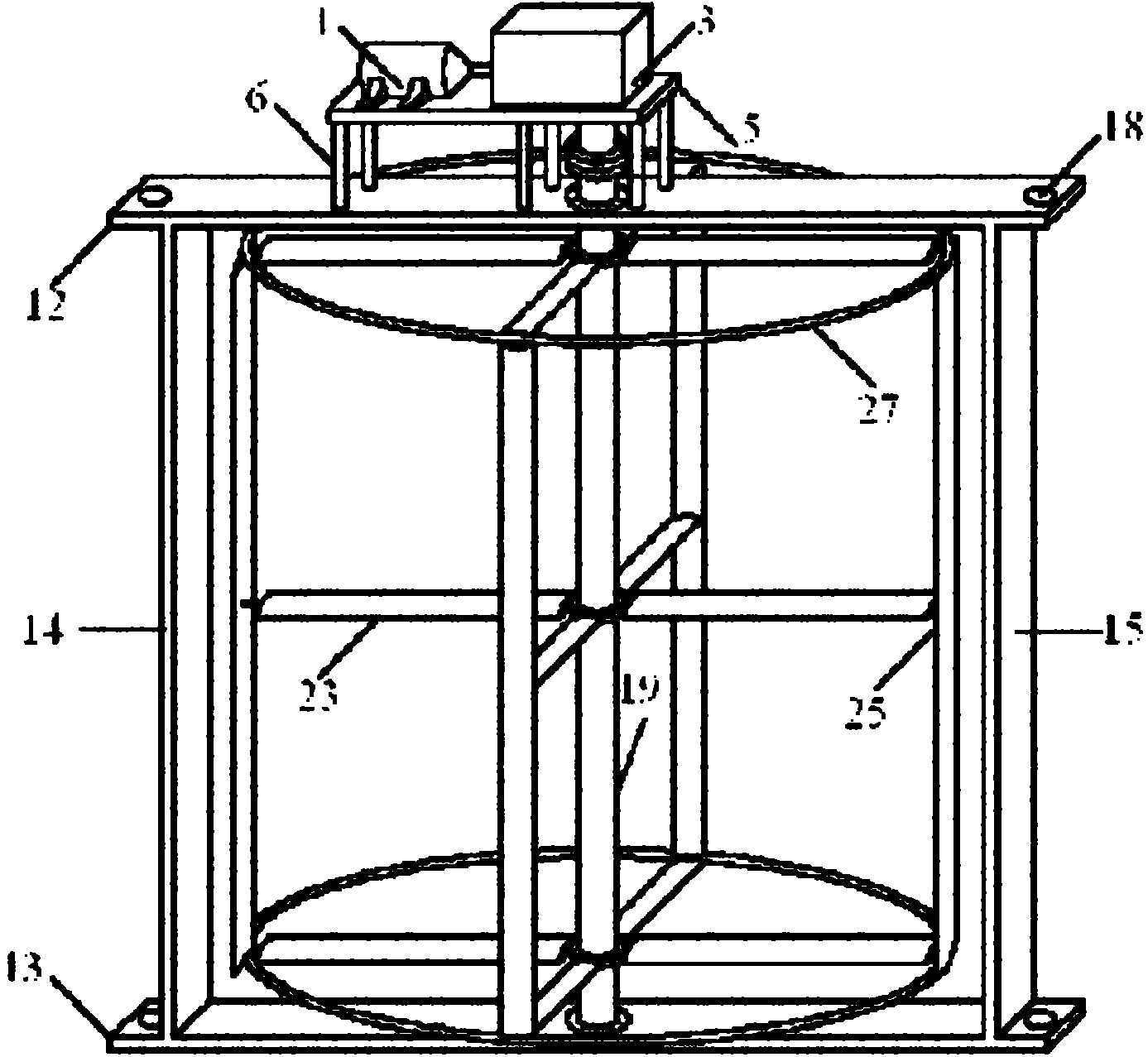

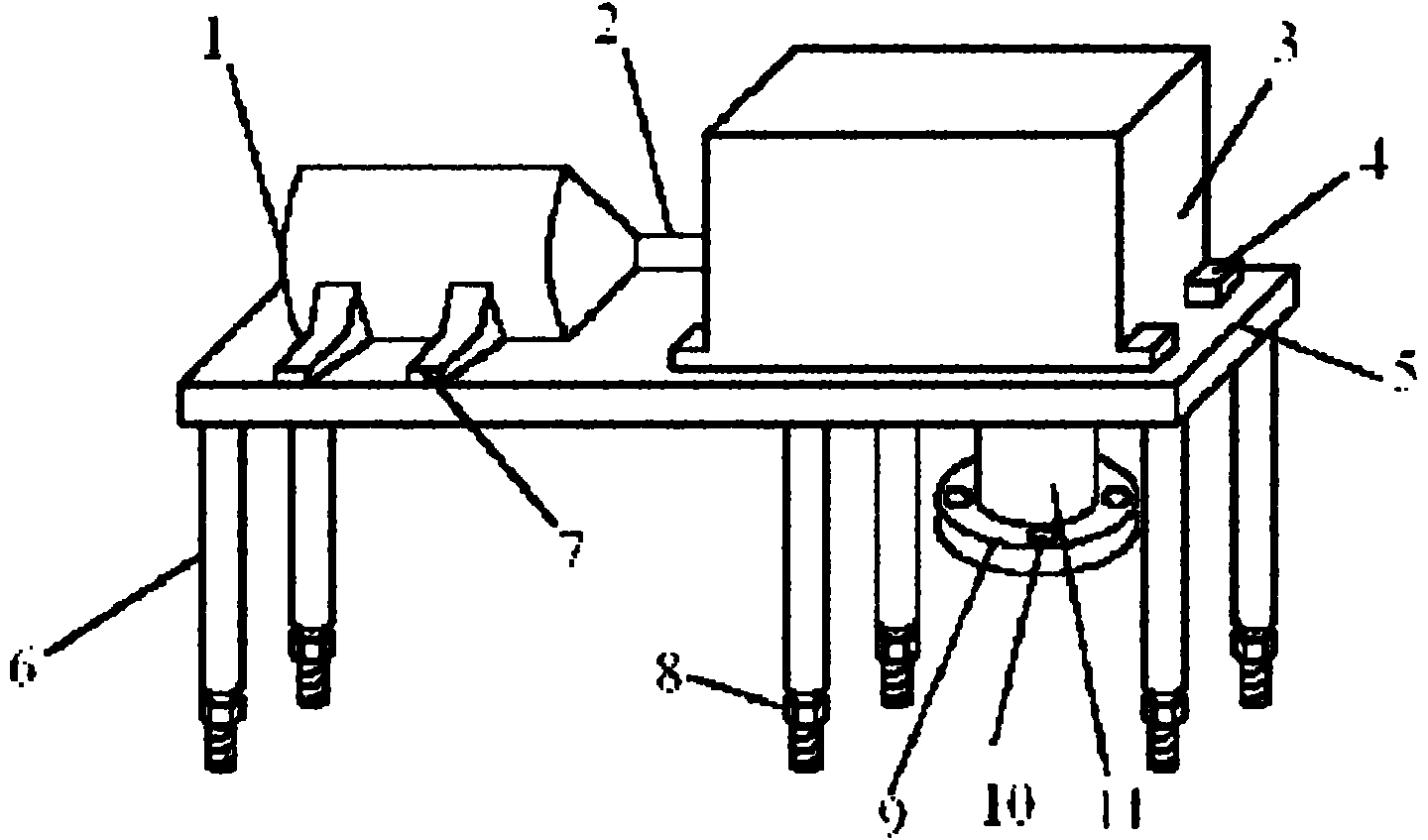

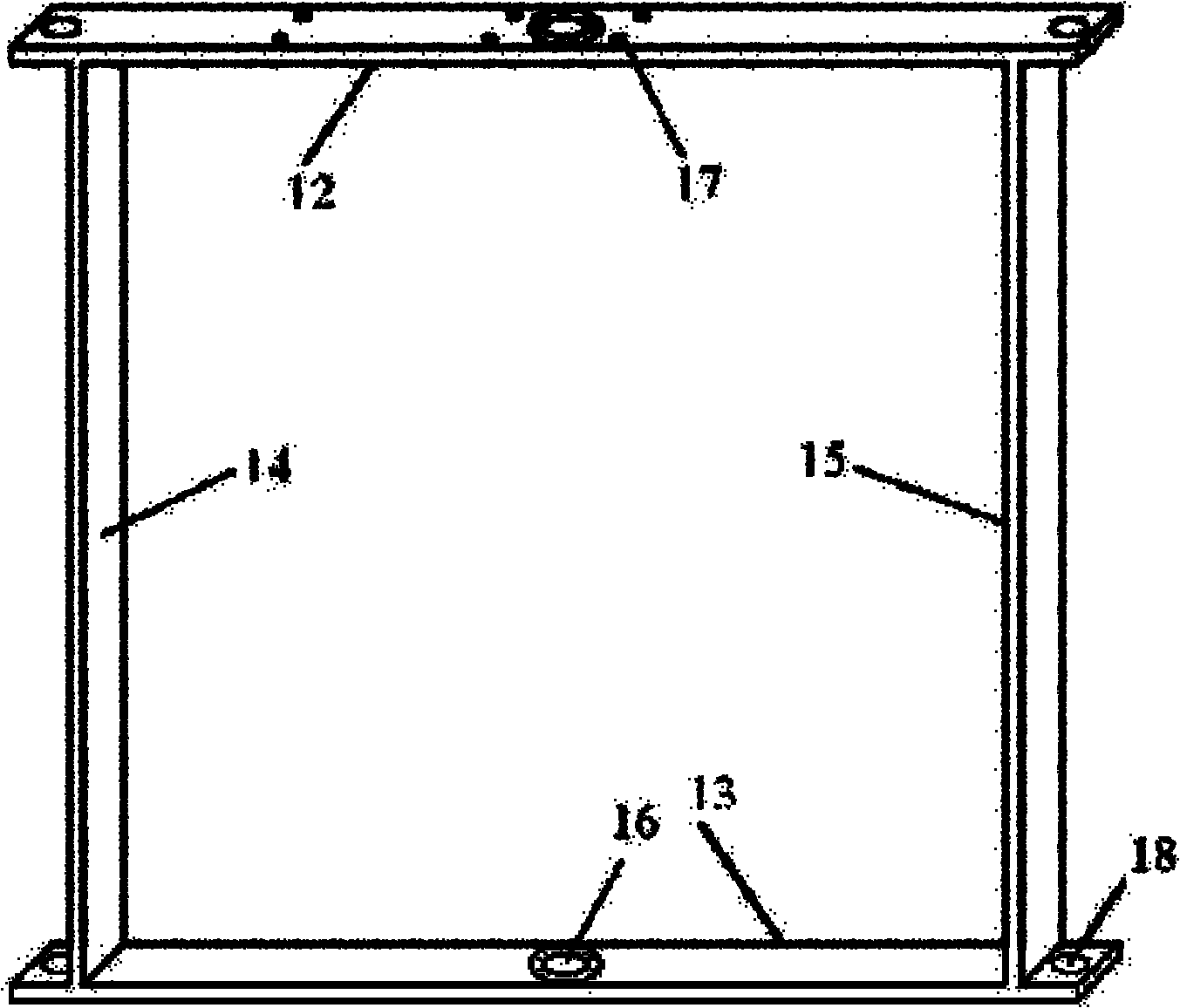

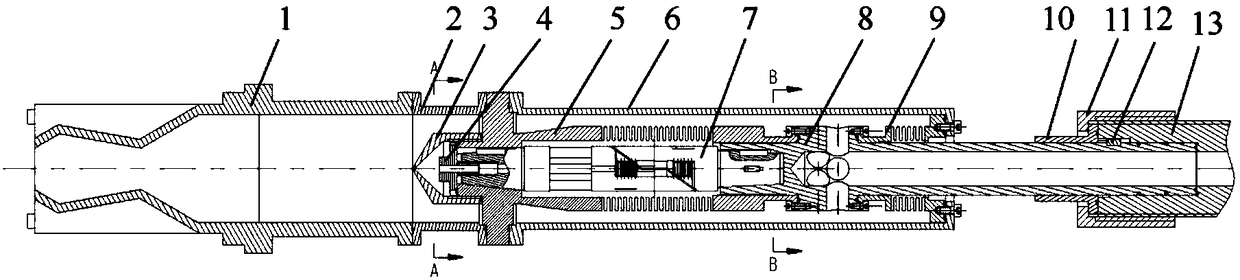

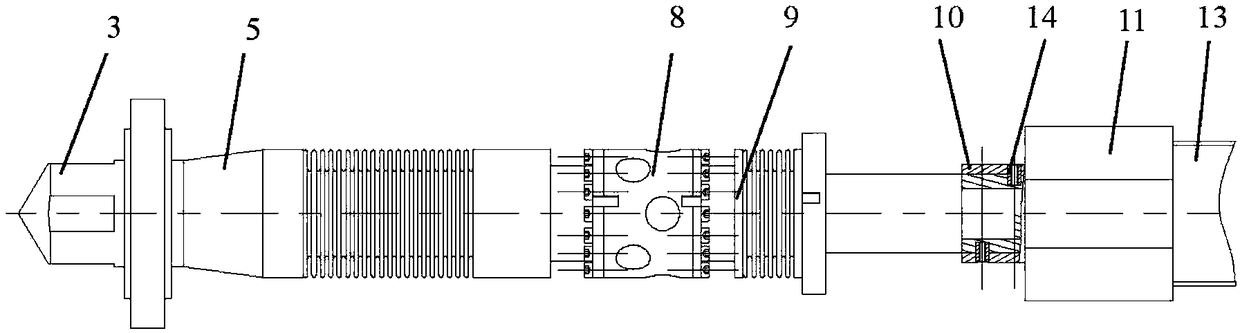

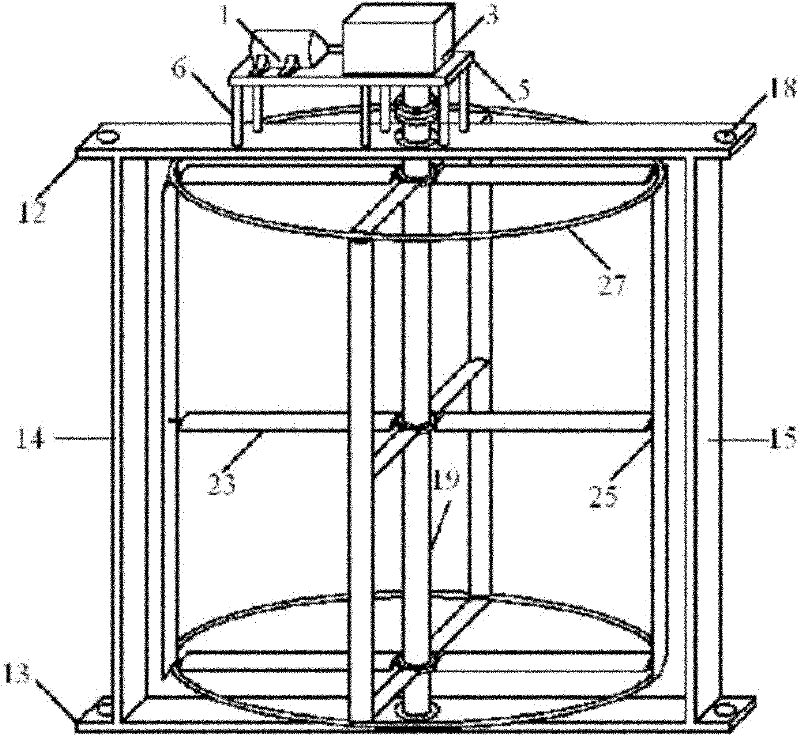

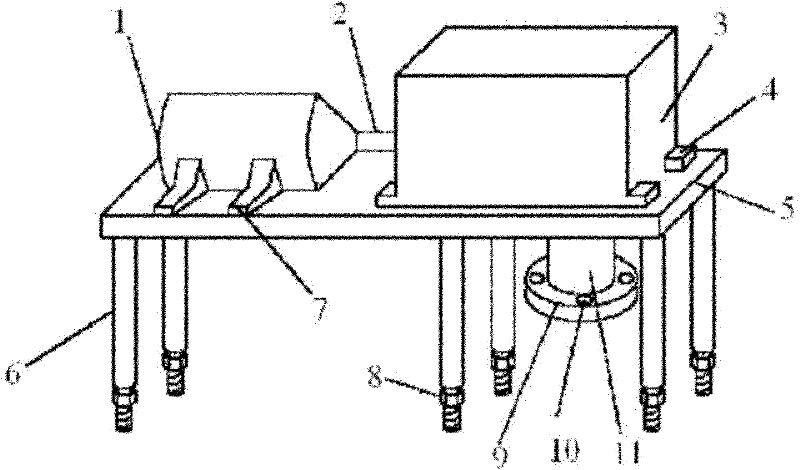

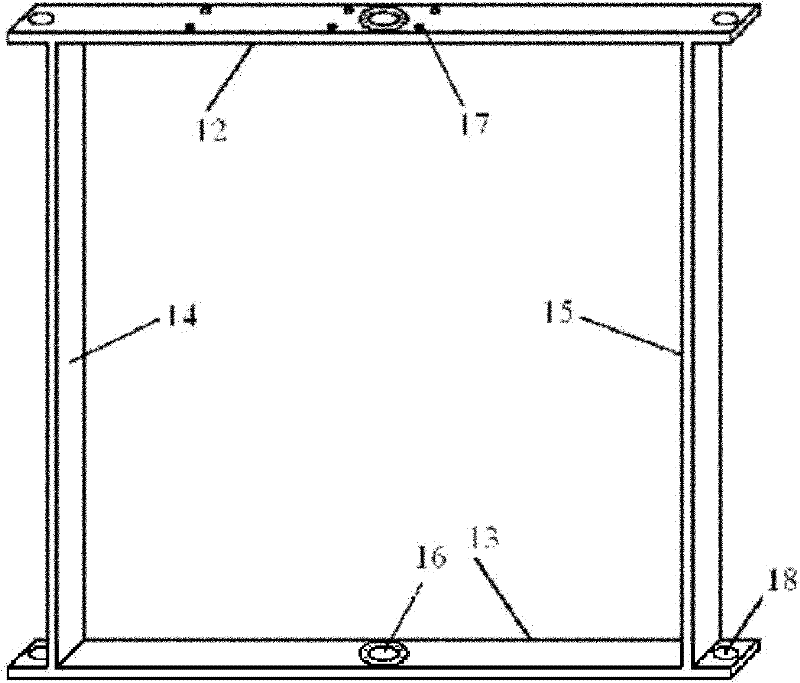

Vertical shaft tidal current generating set

InactiveCN101988463AReduced moment loadReduce frictionFinal product manufactureMachines/enginesImpellerComputer module

The invention provides a vertical shaft tidal current generating set. The vertical shaft tidal current generating set comprises three modules, namely an upper layer platform part, a supporting frame part and an impeller part, wherein the upper layer platform part mainly comprises a generator, a gear box, a horizontal connecting shaft, a supporting platform, a supporting column and a vertical connecting shaft; the supporting frame part is formed by connecting an upper frame plate, a lower frame plate, a left frame plate and a right frame plate; and the impeller part comprises a main shaft, a spoke sleeve, a spoke, a spoke shaft, a blade, a blade shaft, a wheel disk and an adaptive attack angle control device. The invention provides the high-performance vertical shaft tidal current generating set, which has high starting and generating performances and high structural strength, can be developed towards large-scale direction, can be used below a floating platform and above a pile base and a tension leg, is convenient to produce, manufacture, install and debug, and is suitable for engineering application.

Owner:HARBIN ENG UNIV

Sheet alignment device, sheet finishing apparatus including the same, and image processing system including the same

ActiveUS7568688B2Reduced moment loadRegistering devicesFunction indicatorsImaging processingImage formation

A sheet alignment device, that is included in a sheet finishing apparatus integrally mounted with an image forming apparatus to an image forming system or connected to the image forming apparatus, includes an accommodating unit configured to temporarily accommodate a paper sheet and a paper sheet stack including the paper sheet therein, and a sheet alignment unit configured to align the sheet stack including the paper sheet in a direction perpendicular to a sheet travel direction. The sheet alignment unit has a first alignment member configured to move between a sheet receiving position and a sheet alignment position along the direction perpendicular to the sheet travel direction so as to push the sheet stack and a second alignment member configured to move to a fixed position and remain stationary thereat so as to stop the sheet stack pushed by the first alignment member.

Owner:RICOH KK

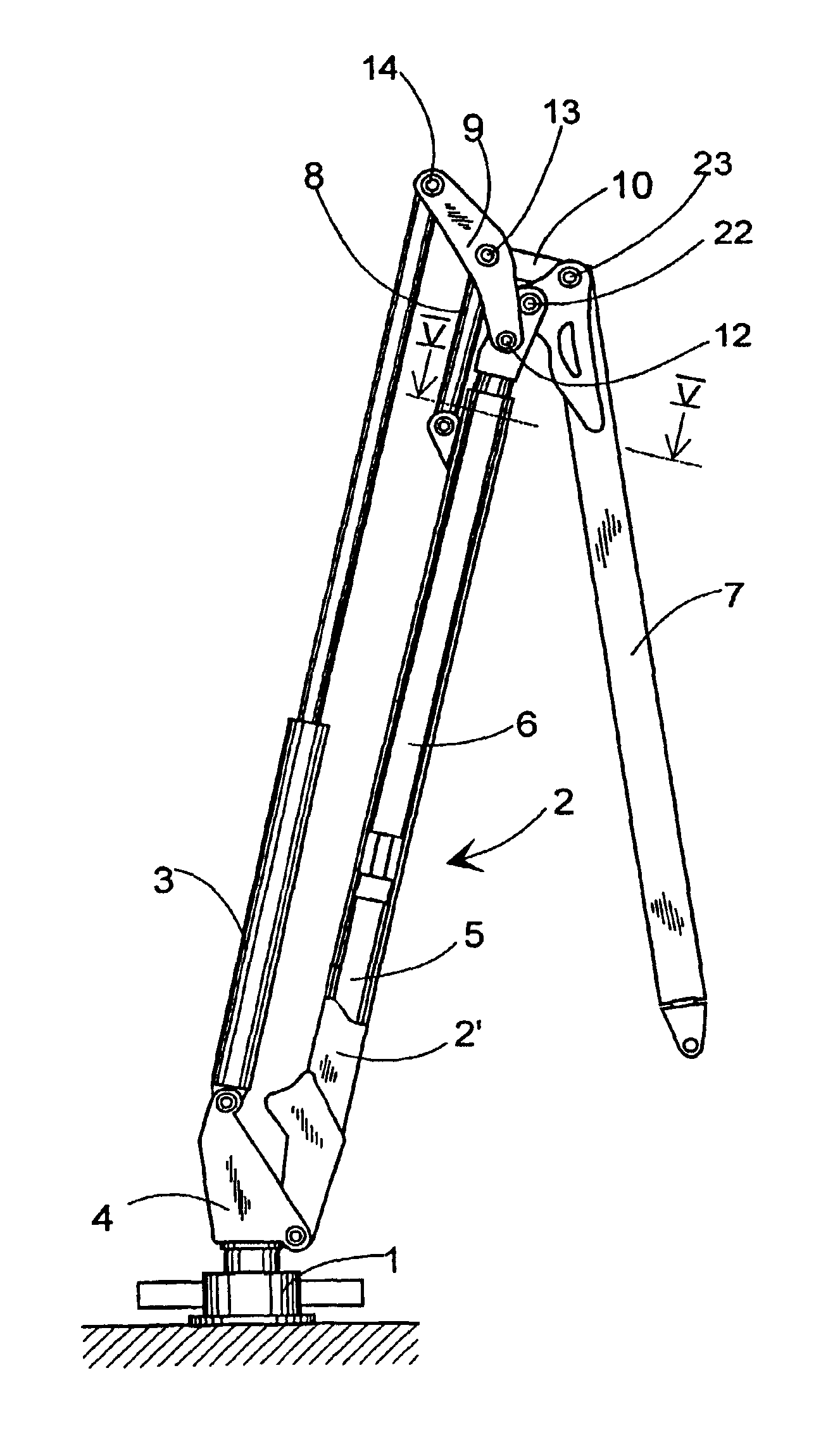

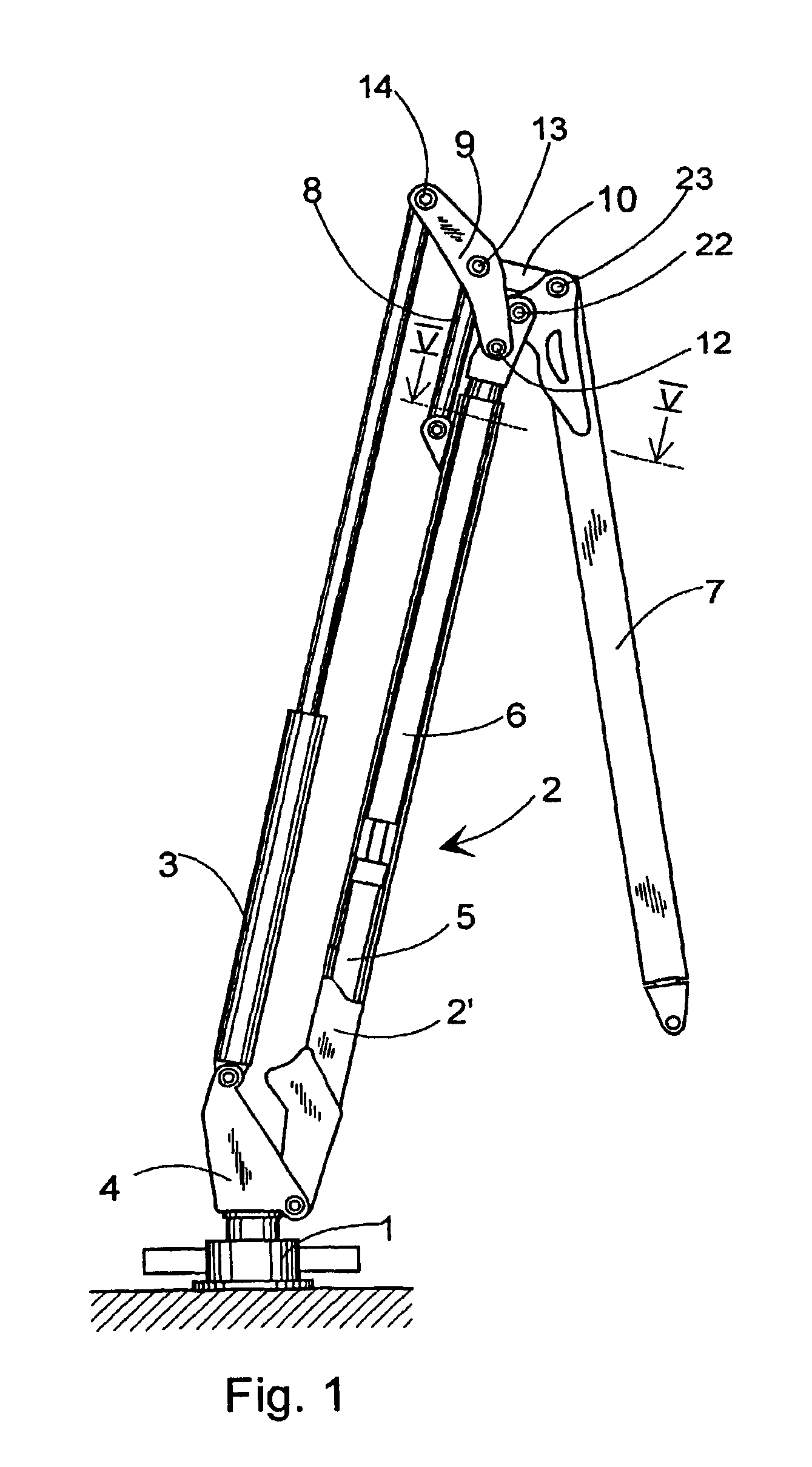

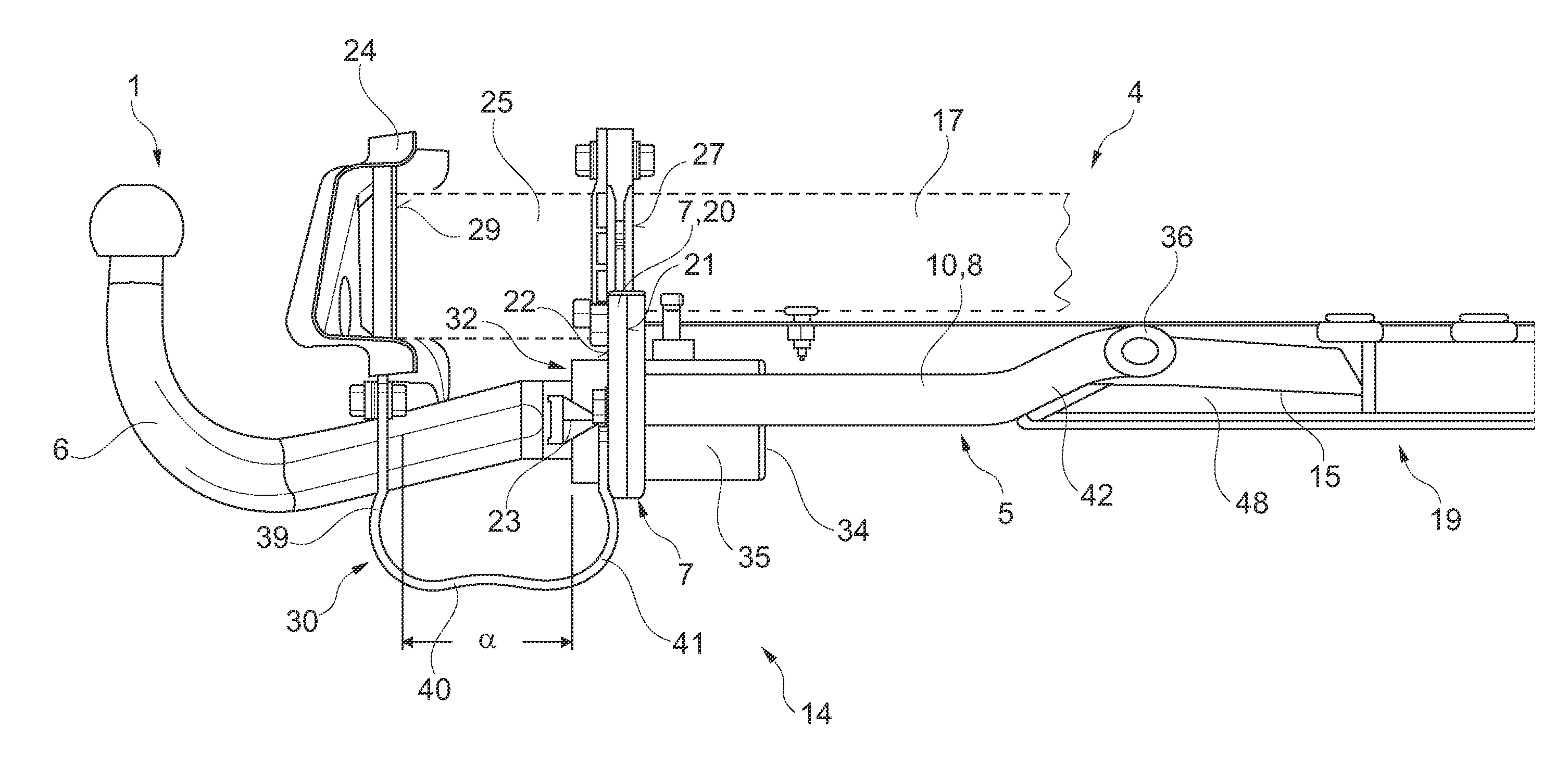

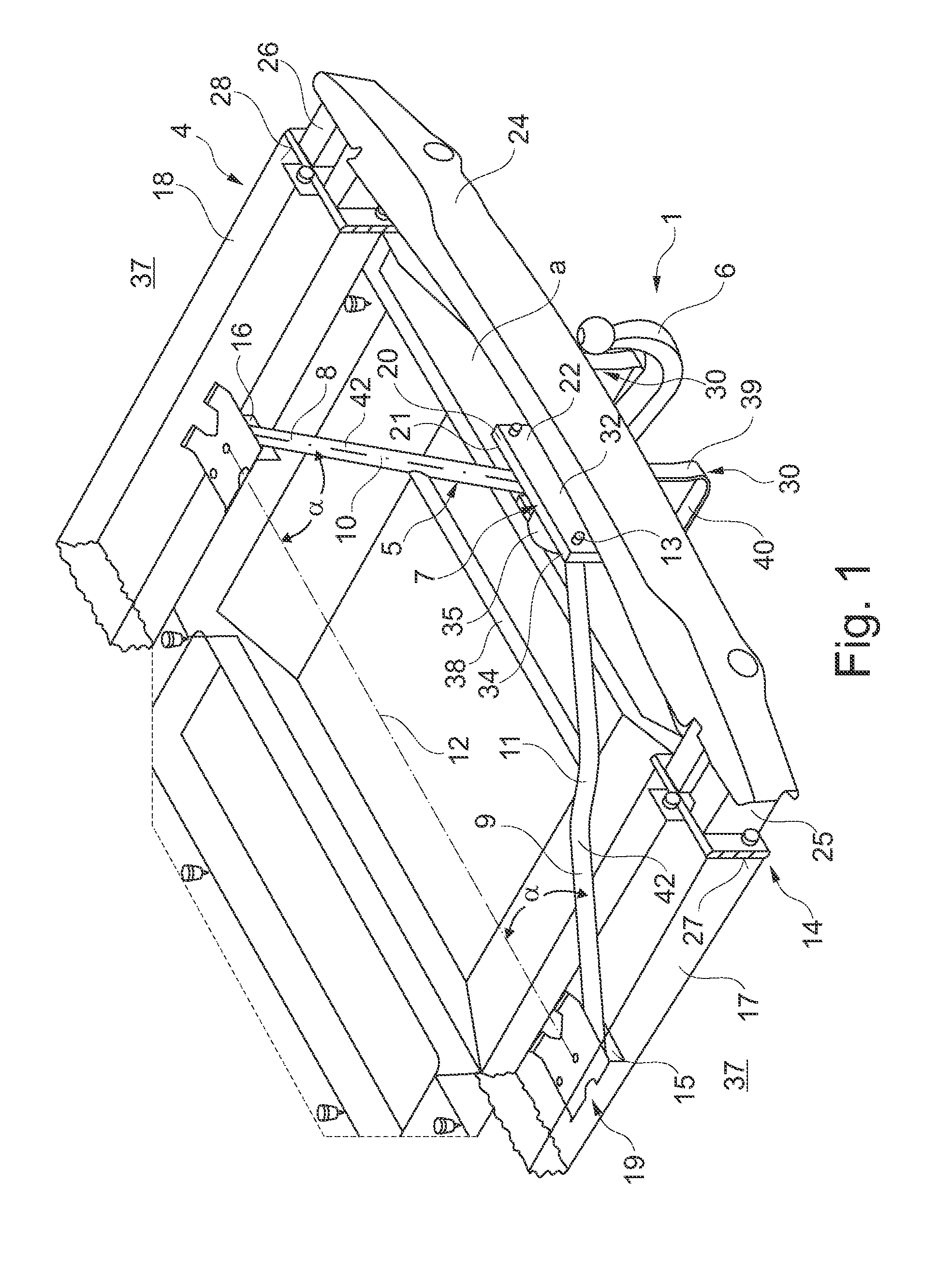

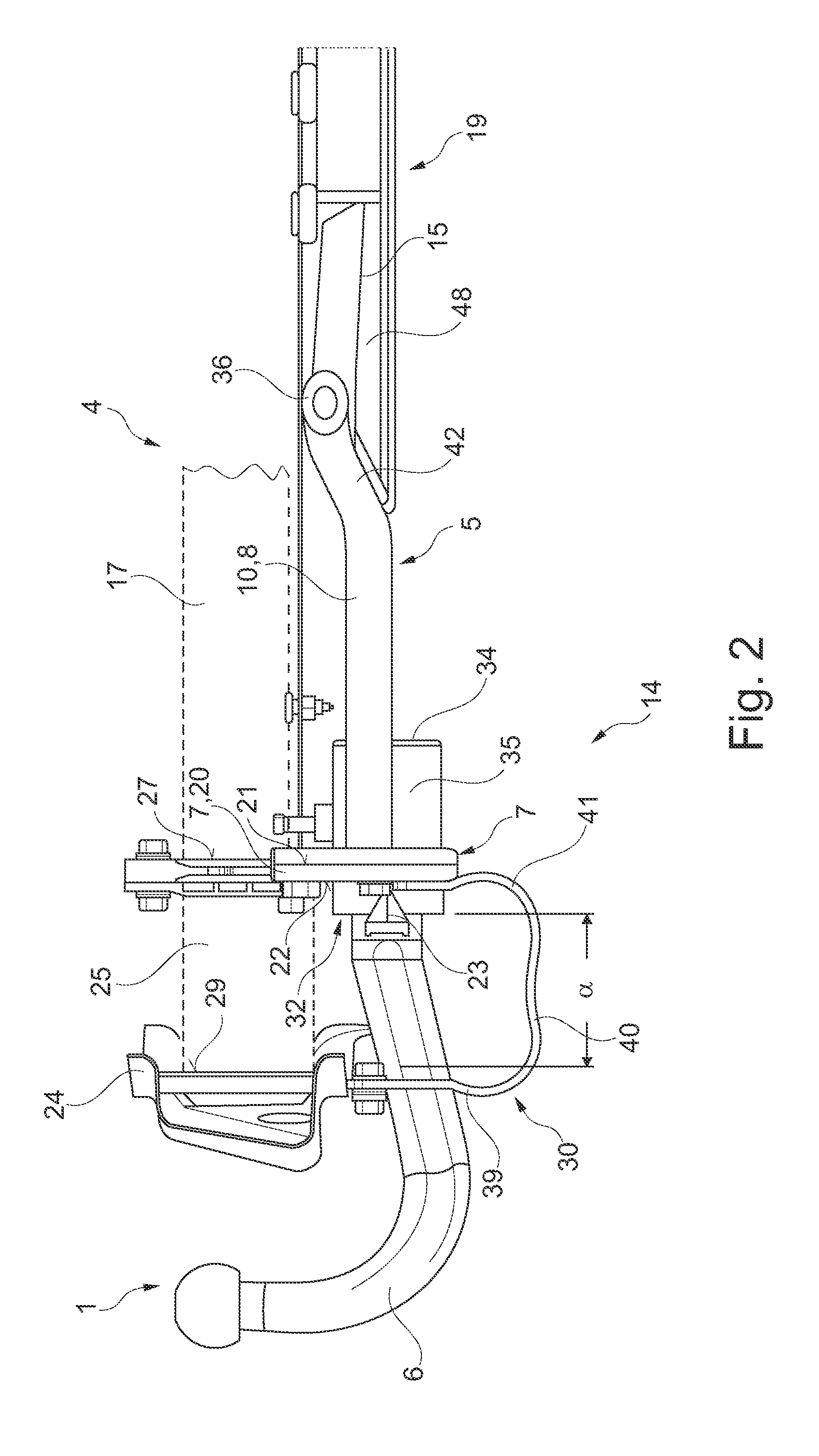

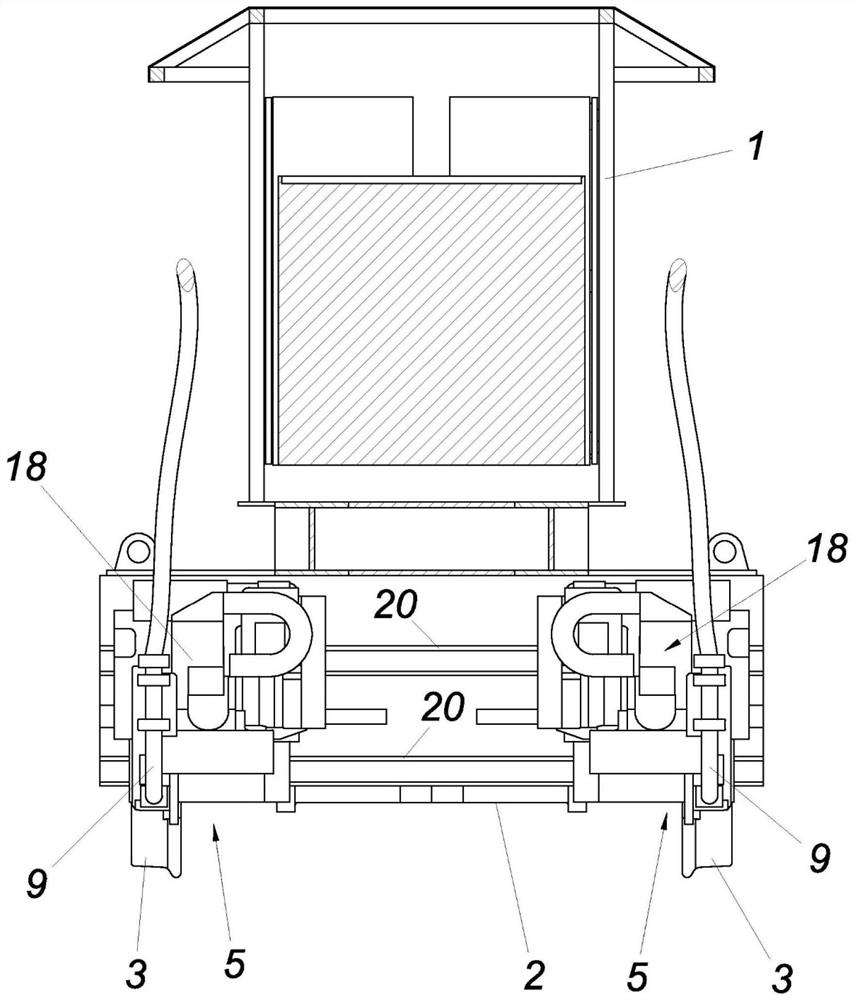

Loader

InactiveUS6860396B2Reduced moment loadEasy to implementMechanical machines/dredgersCranesEngineering

A loader includes a base equipped with a turning device, for attaching the loader to a carrier machine, a telescopic main boom including a frame pivoted on the base, and a telescopic component arranged to move linearly in relation to it and pivoted on the base, a hinged boom pivoted on the main boom, a lifting cylinder pivoted at its first end to the base and at its second end directly or indirectly to the main boom to operate it, an arm directly or indirectly attached to the hinged boom, pivoted to the main boom, a maneuvering cylinder disposed about the main boom between the frame and the telescopic component, the telescopic component is pivoted to the arm operating the hinged boom by the first pivot, the loader includes a link rod pivoted at one end to the frame of the main boom and at the other end to the second pivot of the said arm, which is at a distance from the said first pivot.

Owner:PONSSE

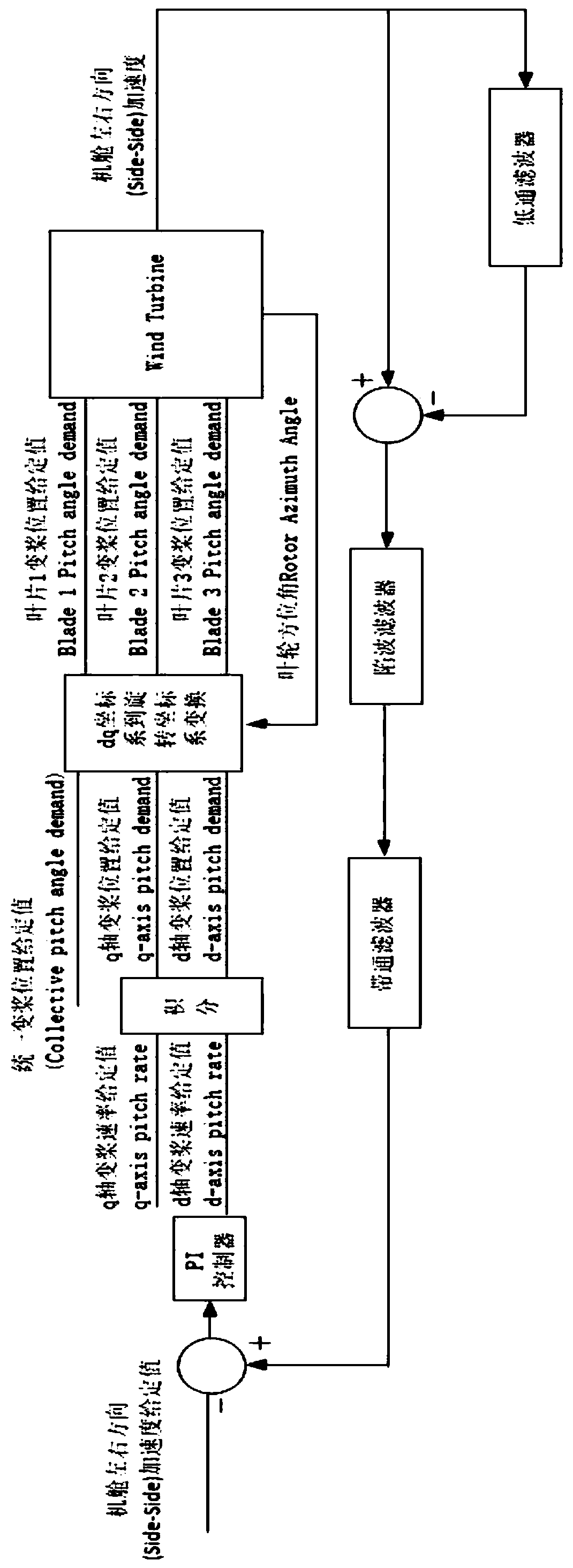

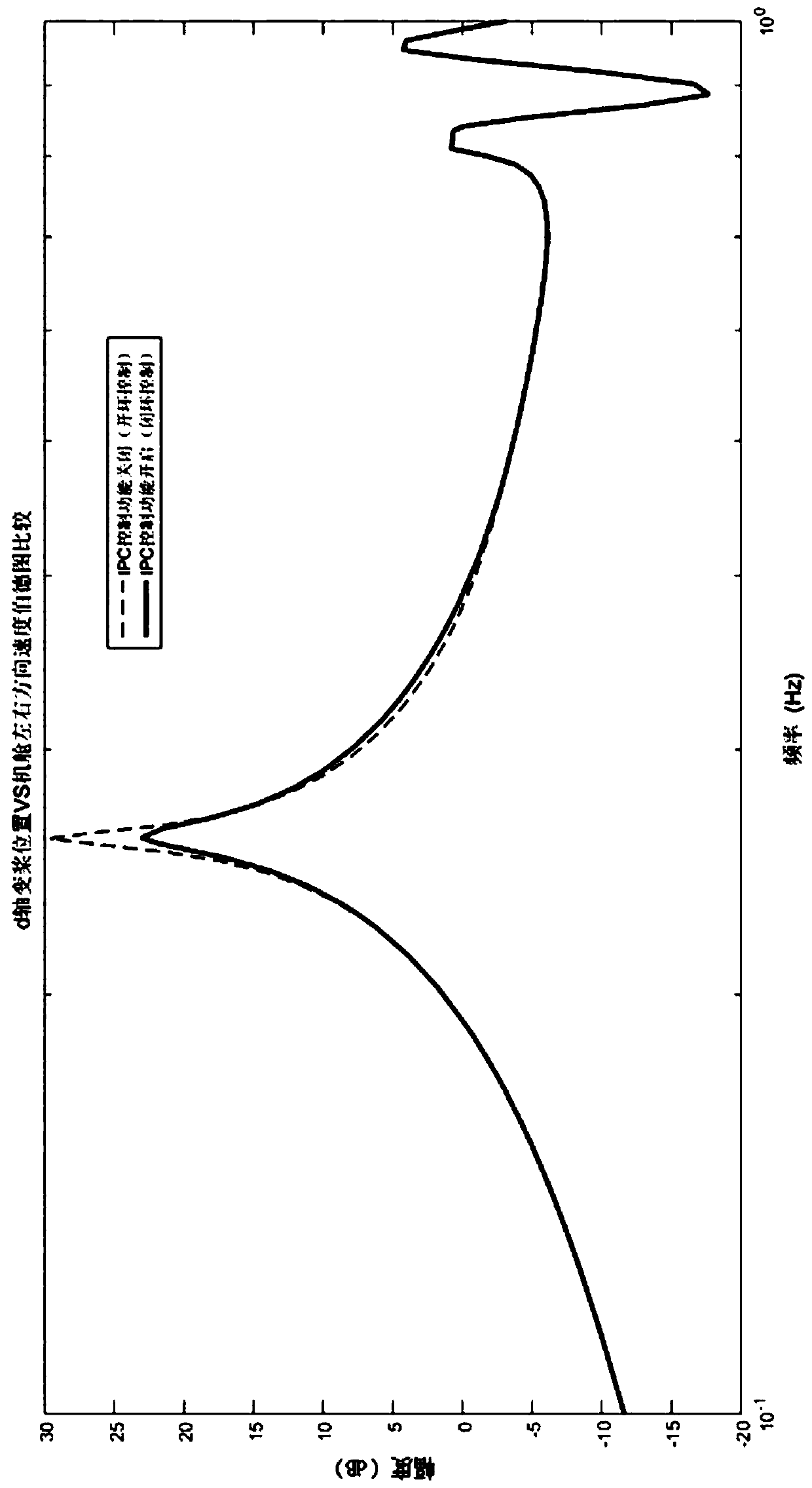

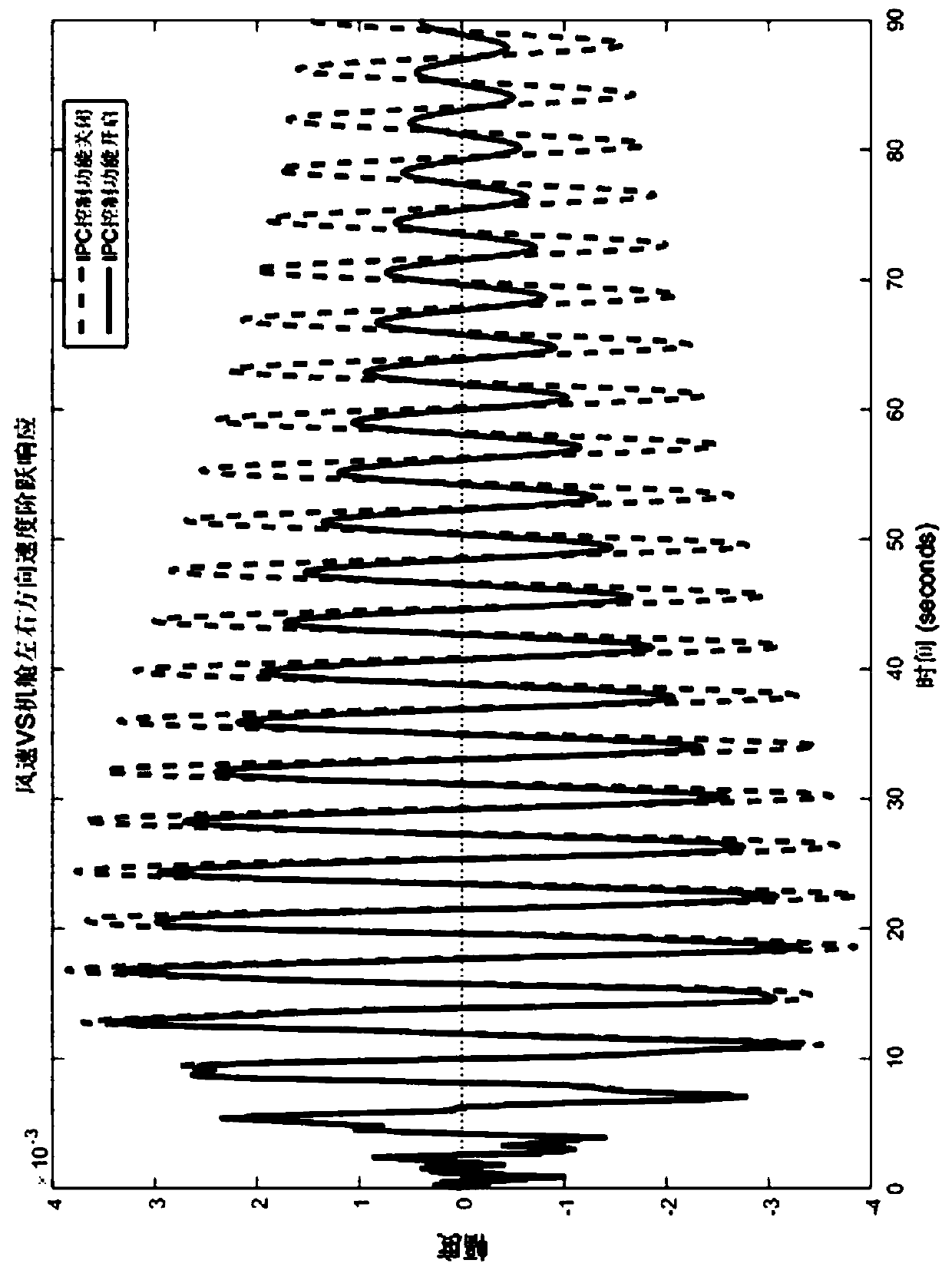

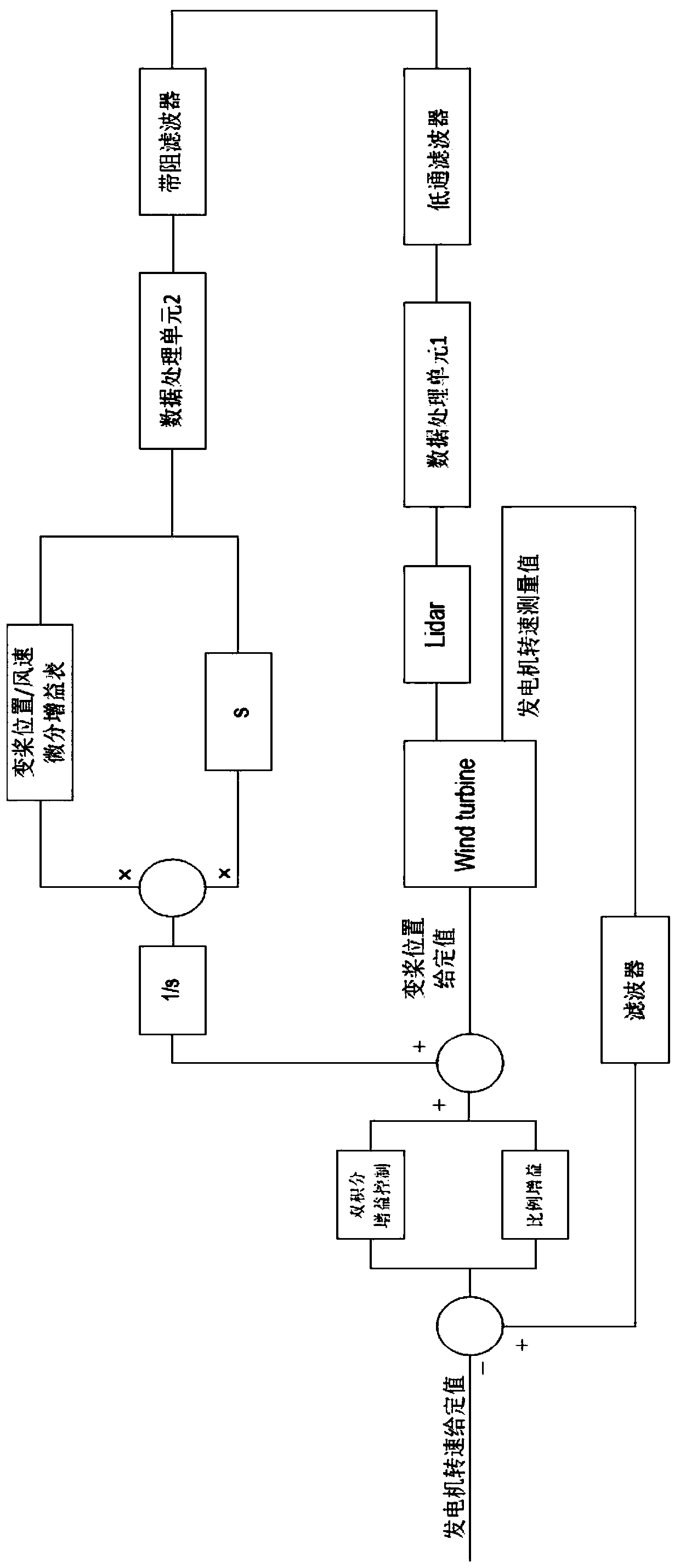

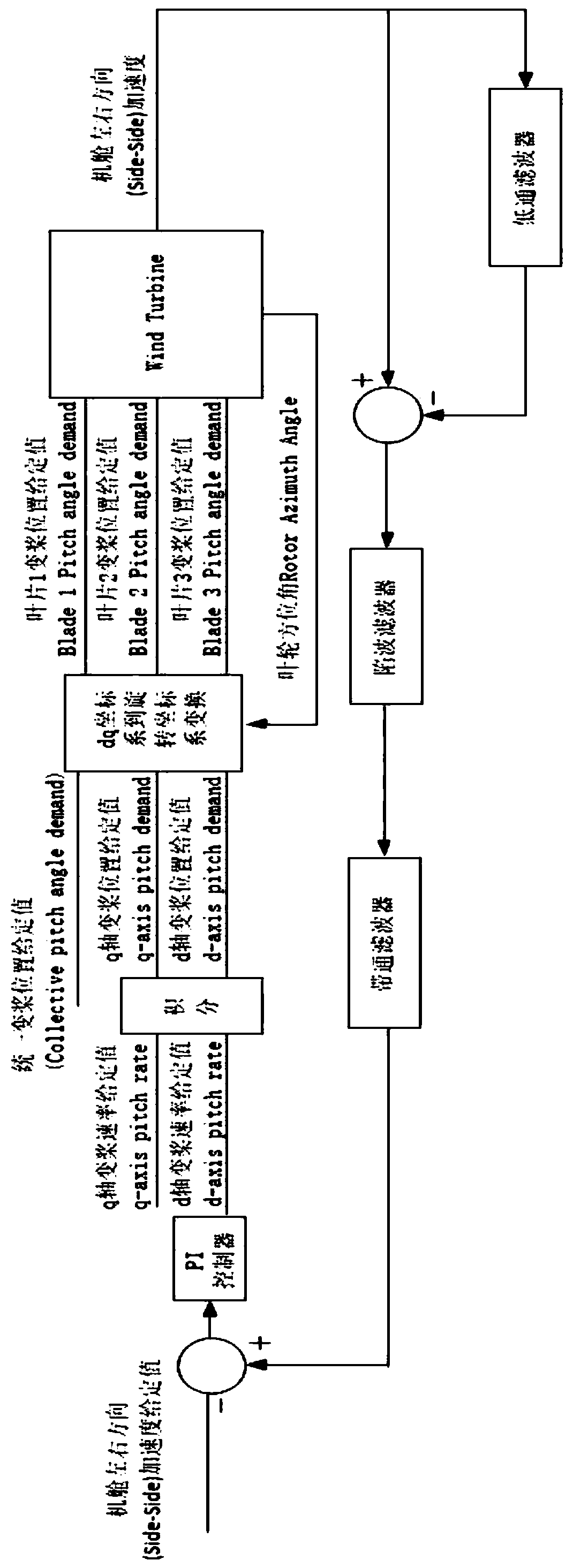

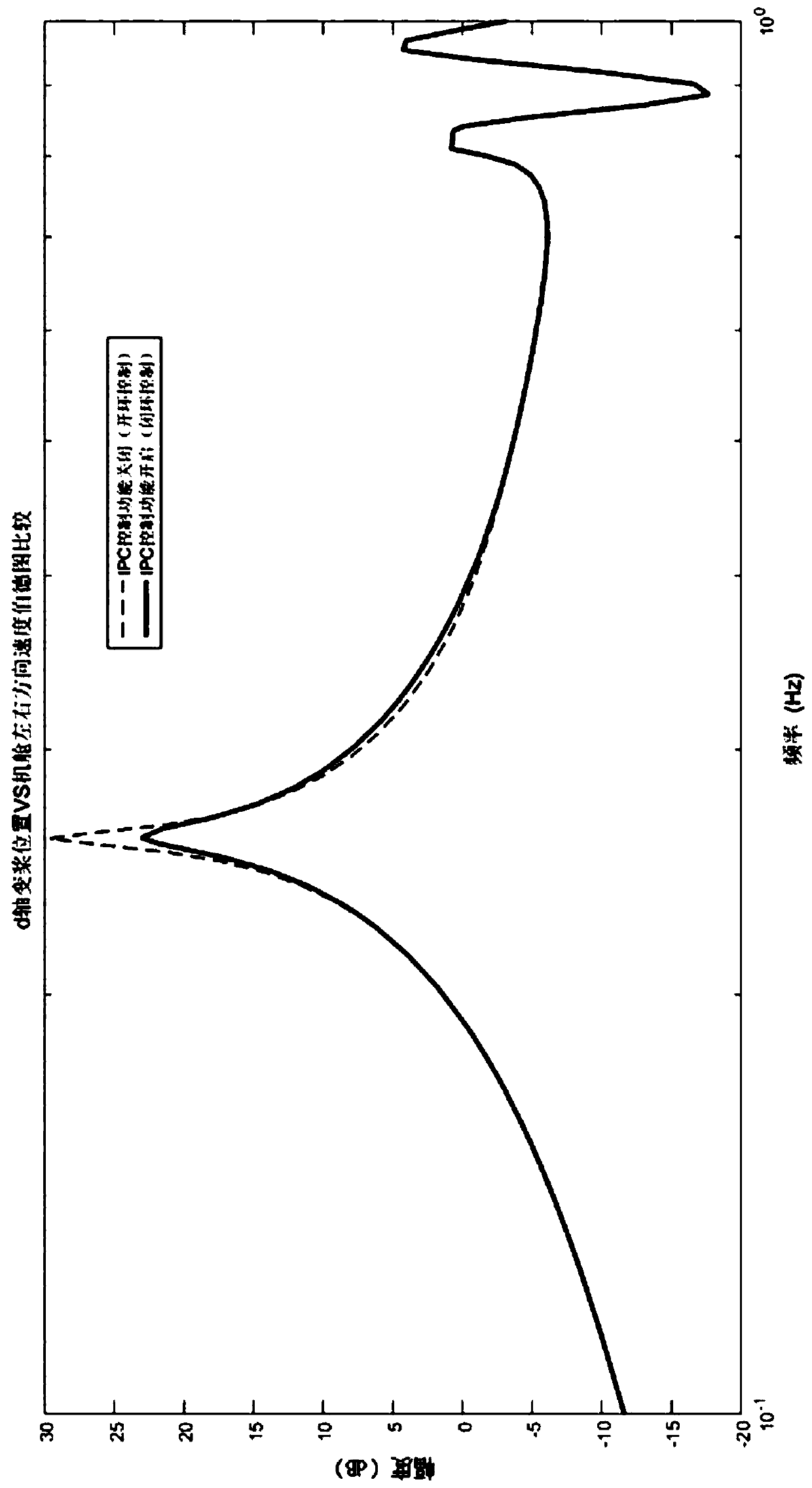

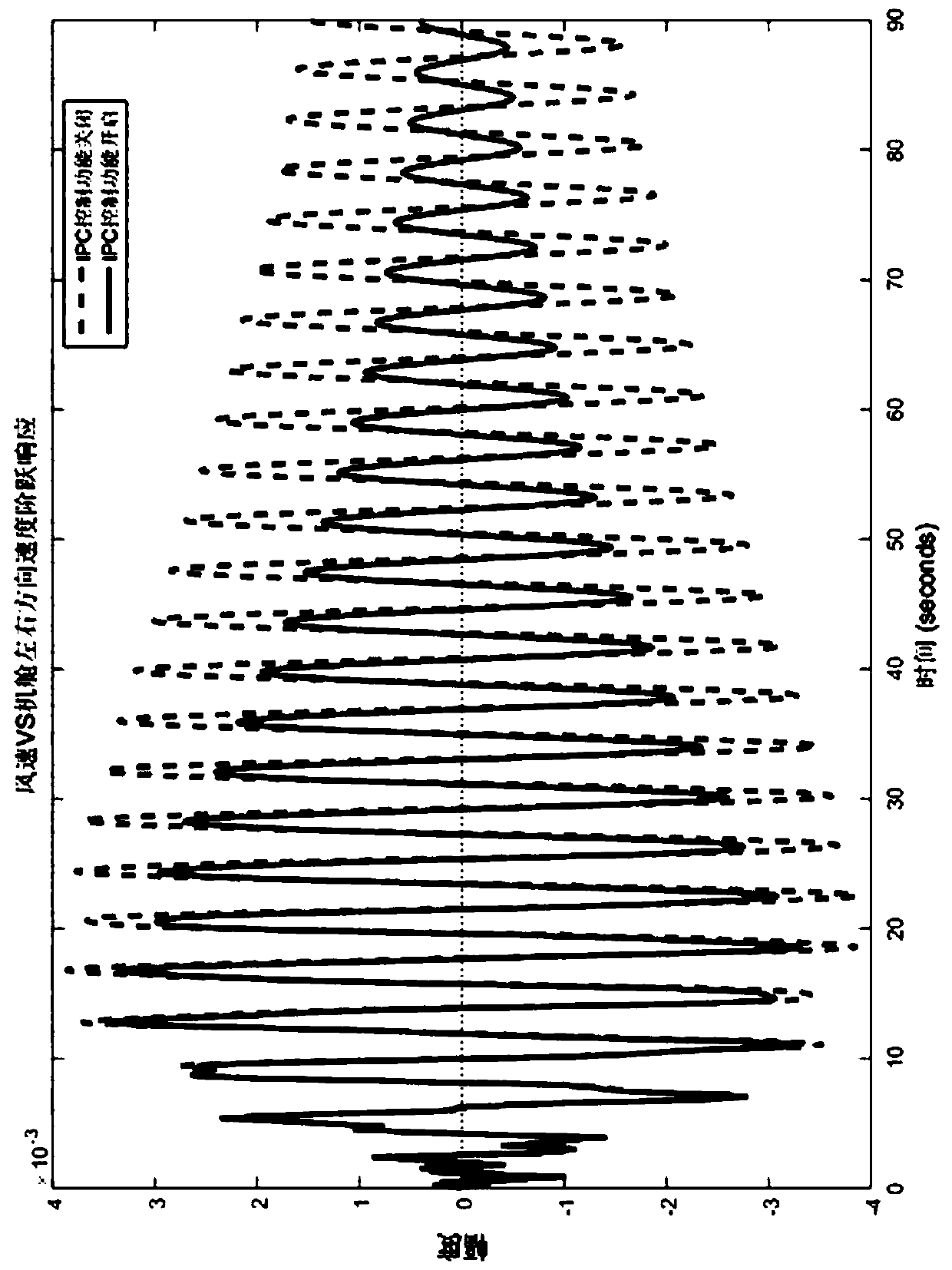

IPC control method for reducing side-side direction vibration and load of wind power tower barrel

ActiveCN110439747AReduced moment loadStable output powerWind motor controlWind motor supports/mountsNacelleRectangular coordinates

The invention discloses an IPC control method for reducing side-side direction vibration and load of a wind power tower barrel. According to the method, a side-side direction acceleration signal of anunbiased engine room is compared with a target value of the side-side direction acceleration signal of the engine room after being filtered by a notch filter and a band-pass filter, the deviation ofthe side-side direction acceleration signal and the target value is processed by a PI controller to obtain a given value of a d-axis variable pitch speed in a dq rectangular coordinate system, and thegiven value of the q-axis variable pitch speed is set in advance; the given value of the d-axis variable pitch speed and the given value of the q-axis variable pitch speed are subjected to integral operation to obtain a given value of a d-axis variable pitch position and a given value of a q-axis variable pitch position respectively; the PI controller is used for acquiring a given value of a uniform pitch position in a power generation mode of a wind generating set, and an absolute value encoder is used for acquiring an azimuth angle of an impeller in the power generation mode of the wind generating set; and through the Park inverse transformation from the dq rectangular coordinate system to a rotating coordinate system, the given values of the variable pitch positions of three blades areobtained, and finally implemented by a variable pitch actuator. The method can effectively reduce the first-order natural frequency vibration and load of the tower barrel in the side-side direction.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Roadway roof supporting method of coal seam roof, soft rock roof or composite roof and for coal mine deep mining

InactiveCN104653203AAvoid destructionIncrease frictionMine roof capsTunnel liningEngineeringRock bolt

The invention discloses a roadway roof supporting method of a coal seam roof, a soft rock roof or a composite roof and for coal mine deep mining. The roadway roof supporting method comprises step 1, performing extension anchoring on coal walls through an extended anchor rod, wherein the coal walls are arranged on the bilateral sides of a roadway respectively; step 2, performing composite supporting on a shoulder roof through a shear resistance anchor rod and a shear resistance anchor cable and simultaneously locking a shoulder soft rock roof or a fracture development roof through the anchoring force in the shear resistance anchor rod and the shear resistance anchor cable, wherein the shoulder roof is close to the coal walls which are arranged on the bilateral sides of the roadway respectively; step 3, anchoring the coal seam roof, the soft rock roof or the composite roof on a hard roof through a high strength anchor cable in the middle of the roadway so as to reduce the bending degree and prevent the bending failure. According to the roadway roof supporting method of the coal seam roof, the soft rock roof or the composite roof and for the coal mine deep mining, the different properties of anchor rods are used according to deformation characteristic of different positions of the roadway, the construction is simple and convenient, the construction speed is high, the efficiency is high, the control effect on the soft rock roof, the composite roof and a broken roof during deep mining is good, the bearing capacity of a supporting structure is large, and the repair rate of the roadway is low.

Owner:SHANDONG UNIV OF SCI & TECH +1

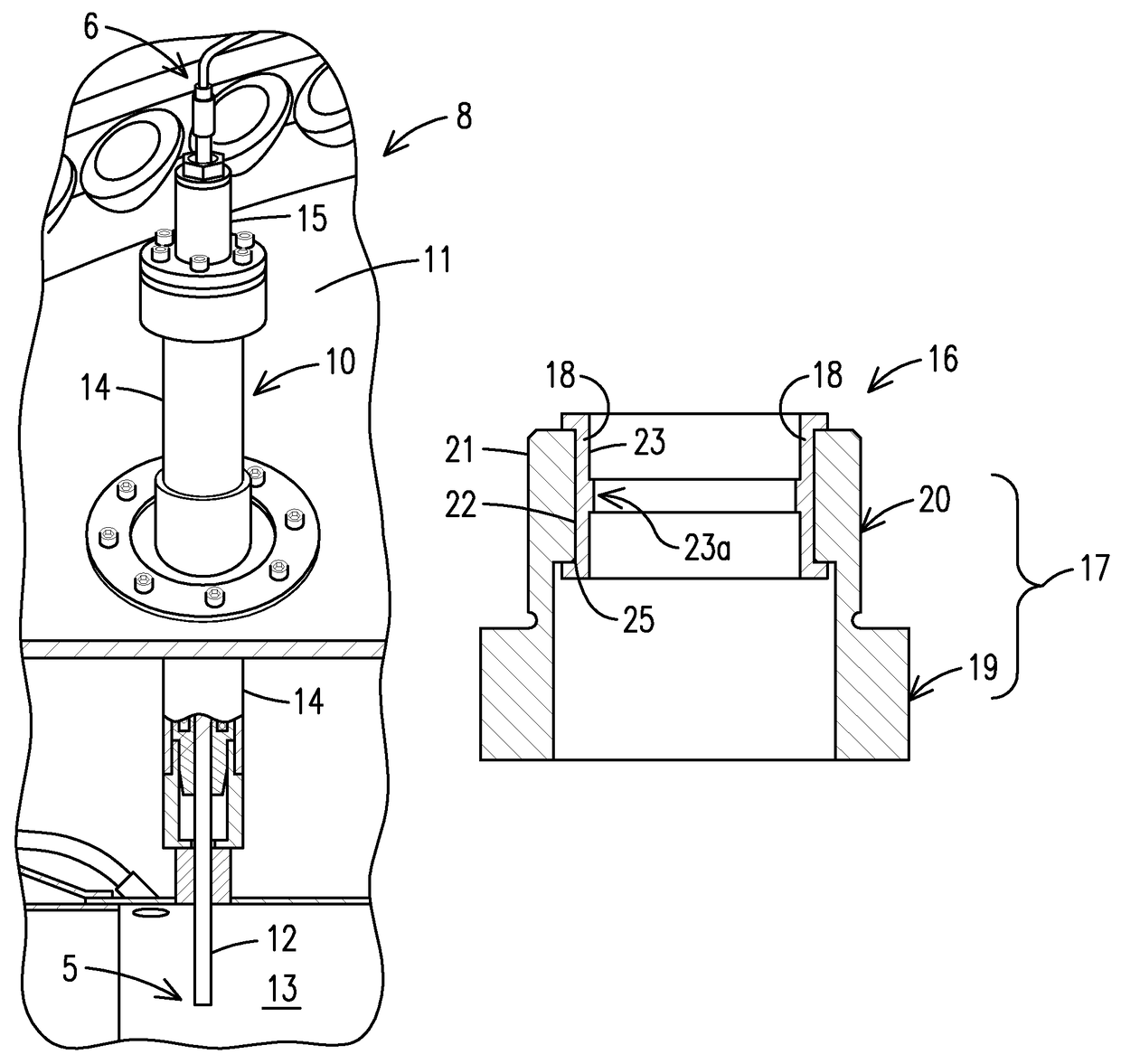

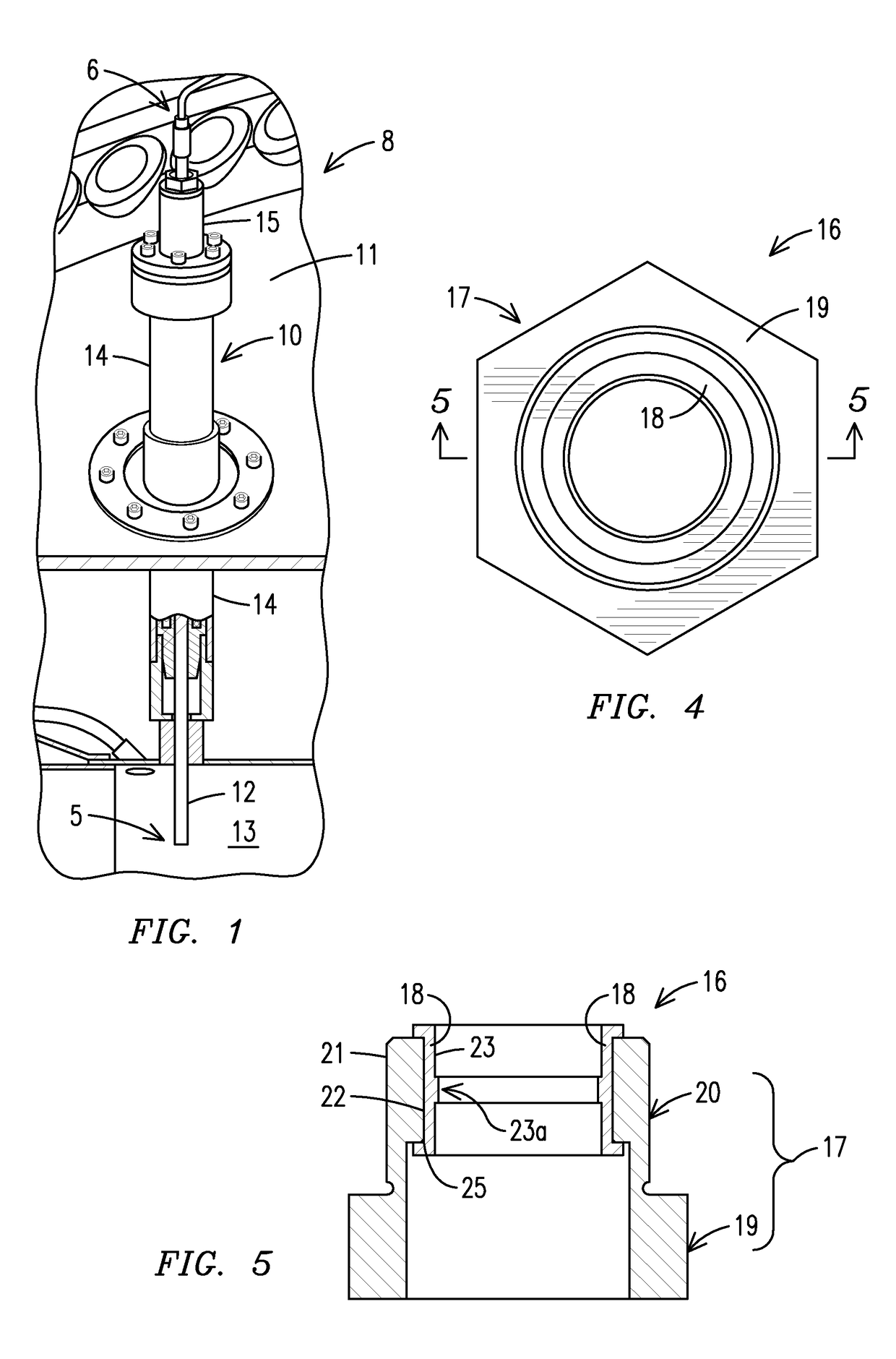

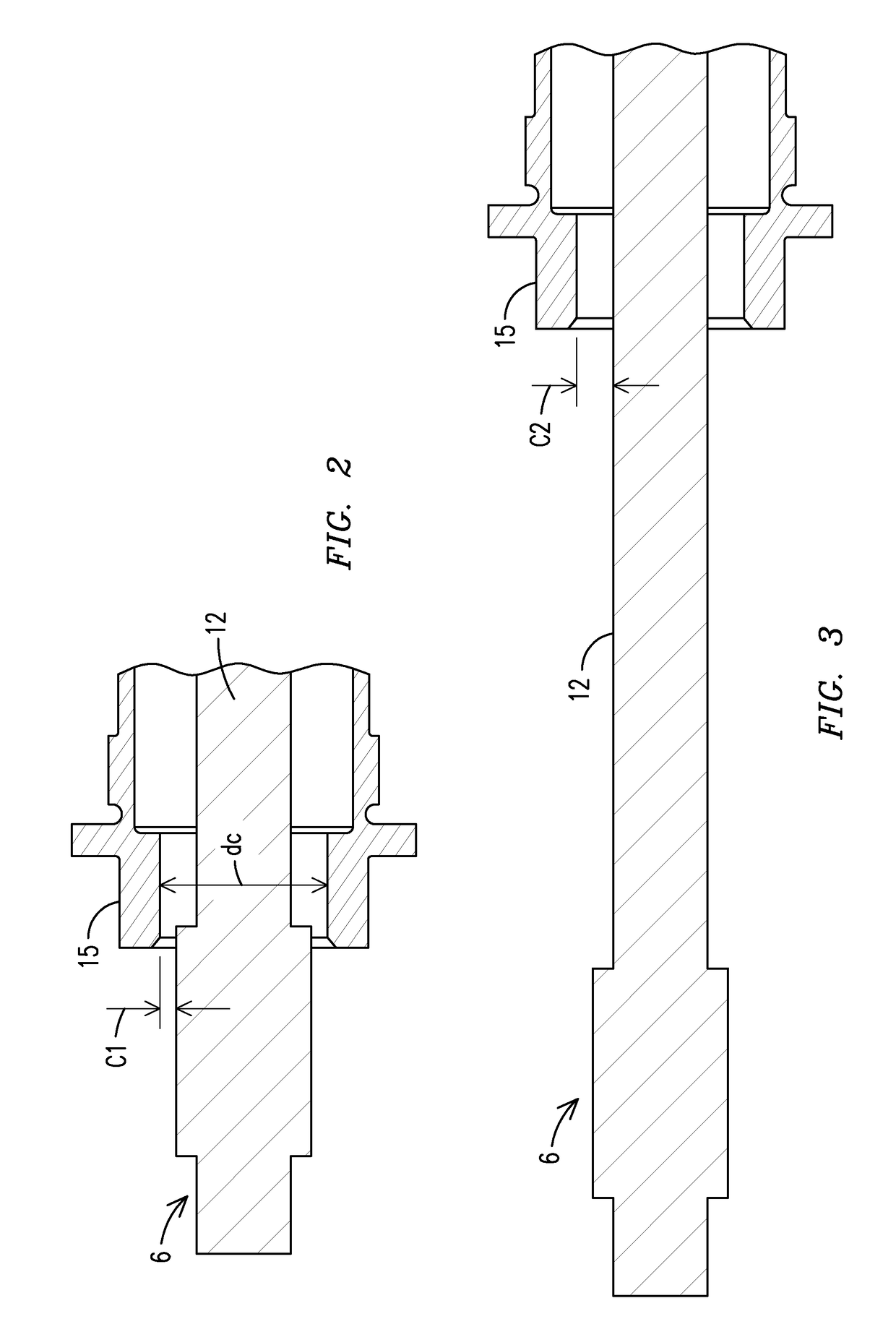

Igniter for a gas turbine

InactiveUS9739204B2Reduced moment loadReduce radial clearanceEngine fuctionsGas turbine plantsEngineeringGuide tube

A gas turbine igniter includes an igniter rod disposed within a guide tube configured for travel between a hot-end region and a cold-end region and a cap connected to the guide tube, the cap defining an access passageway for the igniter rod. An attachment structure is provided for reducing the moment loading at the cold end of the igniter rod. The attachment structure has threaded outer surface configured to engage in a threaded connection with a threaded inner surface of the cap in an end portion of the cap that is proximate to the cold-end region, whereby the attachment structure is attachable to the end portion of the cap via the threaded connection. An inner surface of the attachment structure forms a guide surface for the igniter rod, at a reduced radial clearance with the igniter rod in comparison to the cap, proximate to the cold-end region.

Owner:SIEMENS ENERGY INC

Trailer towing device of a passenger car

A trailer towing device of a passenger car is provided with a traction force transmission linkage and a removable trailer coupling. The removable trailer coupling is releasably fixed on a central nodal element of the transmission linkage. The transmission linkage includes, but is not limited to two force transmission elements that form two legs of a preferentially isosceles triangle. The tip of the triangle is arranged in a rear tail of the passenger car and comprises the central nodal element. The free ends of the legs are releasably connected to side members of the vehicle body in a front tail of the passenger car.

Owner:GM GLOBAL TECH OPERATIONS LLC

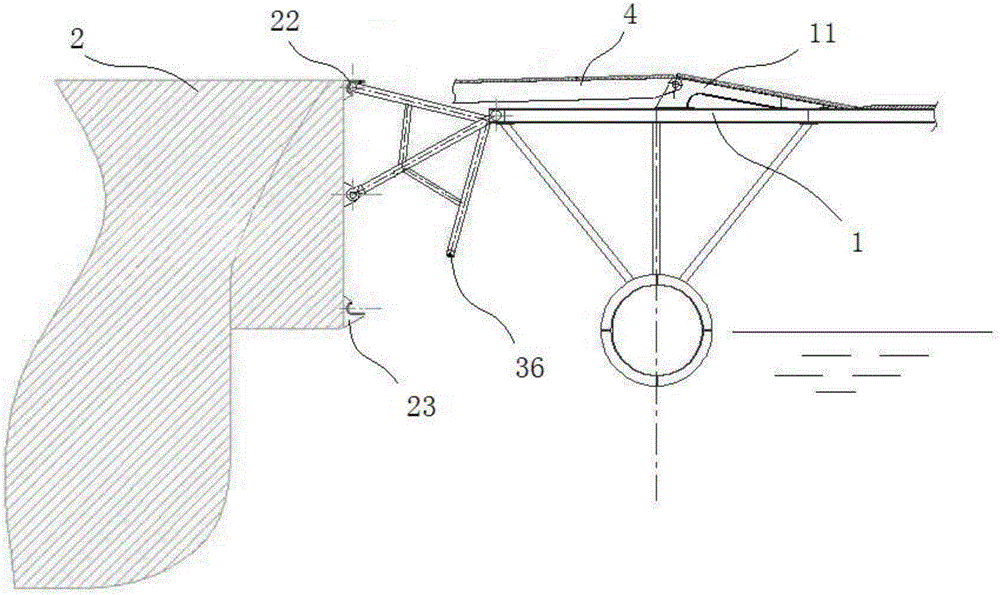

Gangway structure for connecting floating bridge with floating platform

The invention provides a gangway structure for connecting a floating bridge with a floating platform and belongs to the technical field of floating bridge connection. The gangway structure for connecting the floating bridge with the floating platform comprises the floating bridge, the floating platform, footplates, a gangway and supporting limiting frames, wherein the footplates are arranged on the floating bridge and the floating platform; the gangway is hinged between the footplates of the floating platform and the floating bridge; and the supporting limiting frames are hinged on the floating bridge and the floating platform. According to the gangway structure for connecting the floating bridge with the floating platform, as a platform footplate is hinged on a floating bridge platform and the platform footplate is matched with a truss type gangway, the adapted draft difference is great and the adaptation is high; as the supporting limiting frames are arranged and a main support is arranged in the form of a double A-shaped truss, the position of the gangway structure between the floating platform and the floating bridge is effectively limited at a maximum draft difference and at a minimum draft difference so as to ensure that vehicles can safely pass; damage of the bridge body caused by collision between the floating bridge and the floating platform can be avoided; and moreover, the design load of the truss type gangway is reduced, the weight of the structure is reduced and the safety is enhanced.

Owner:708TH RES INST OF CSSC

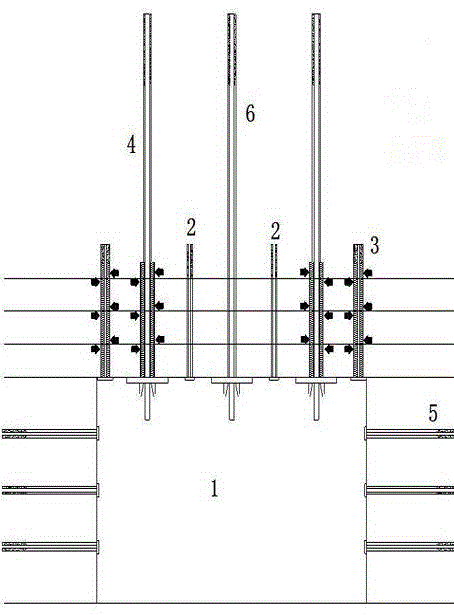

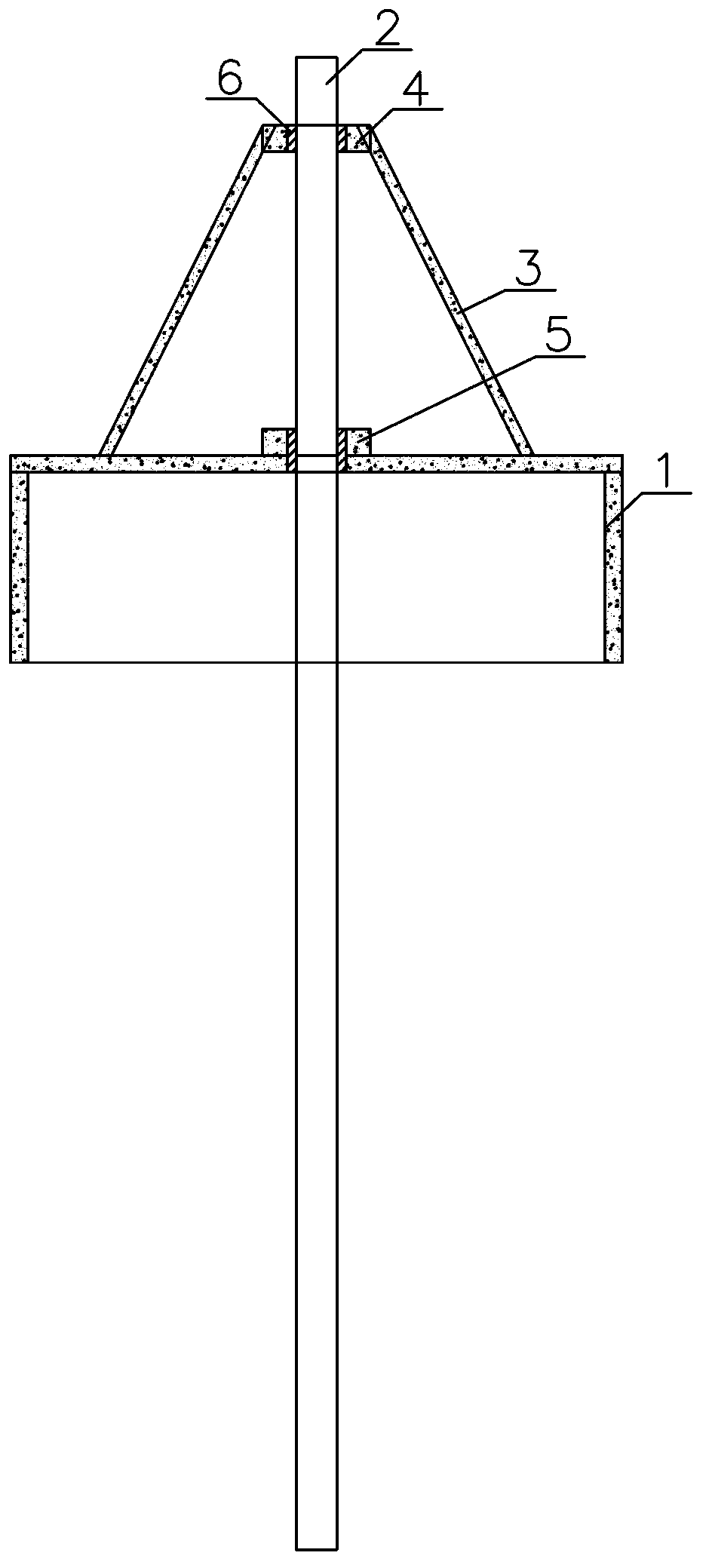

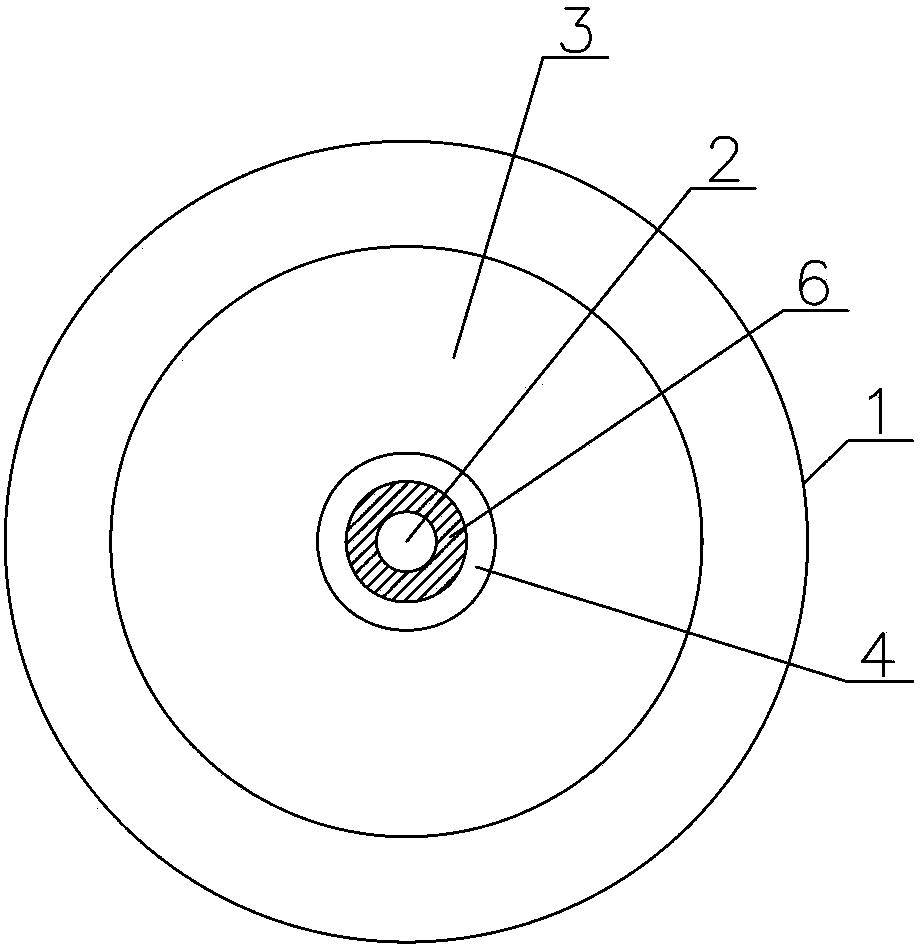

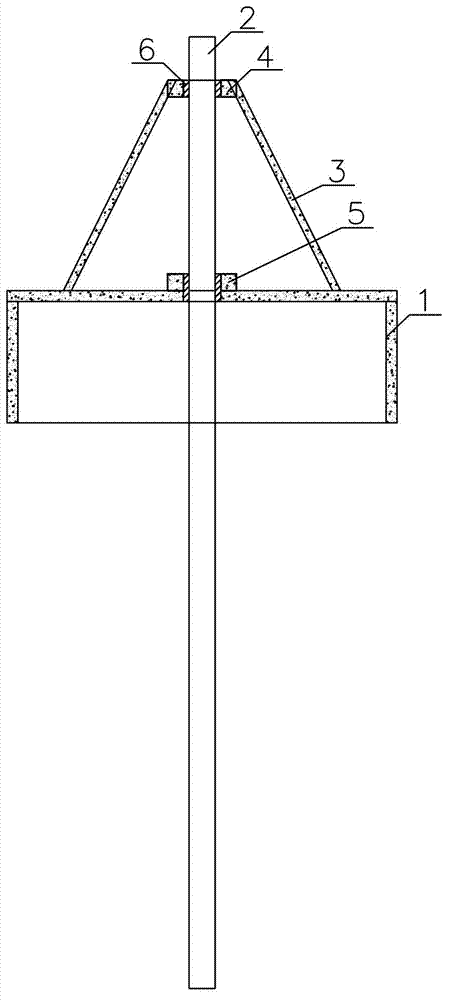

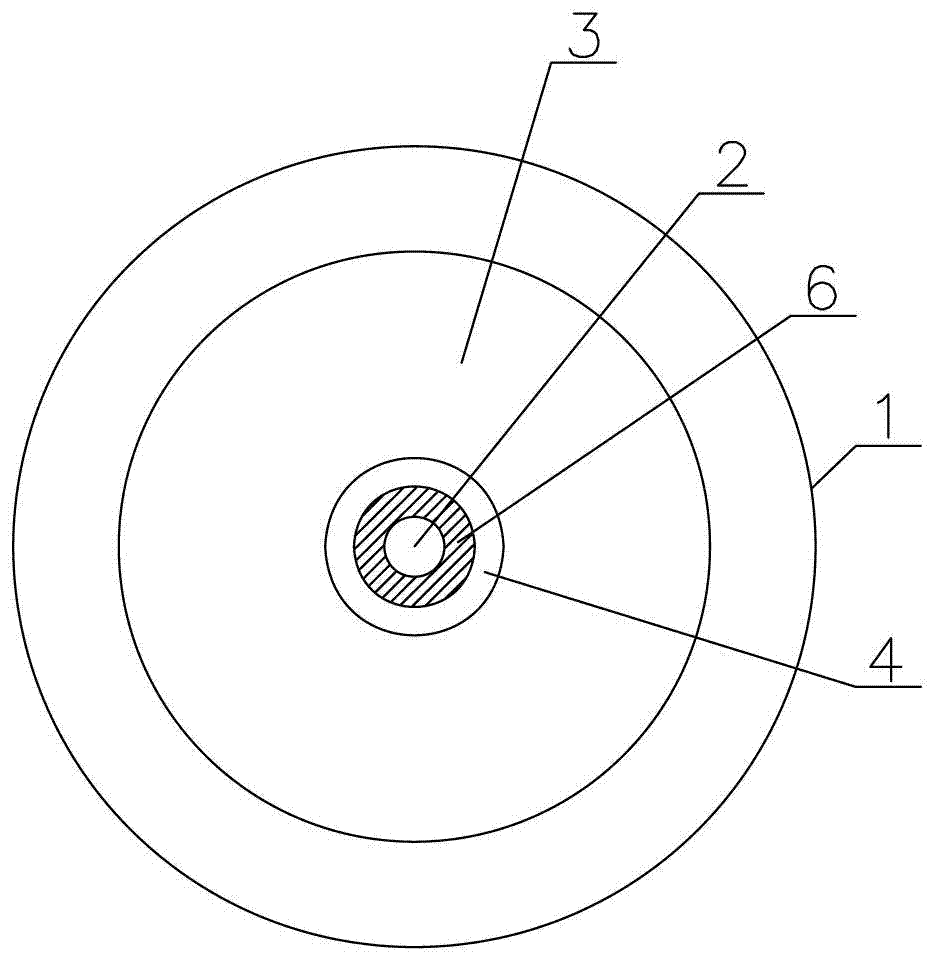

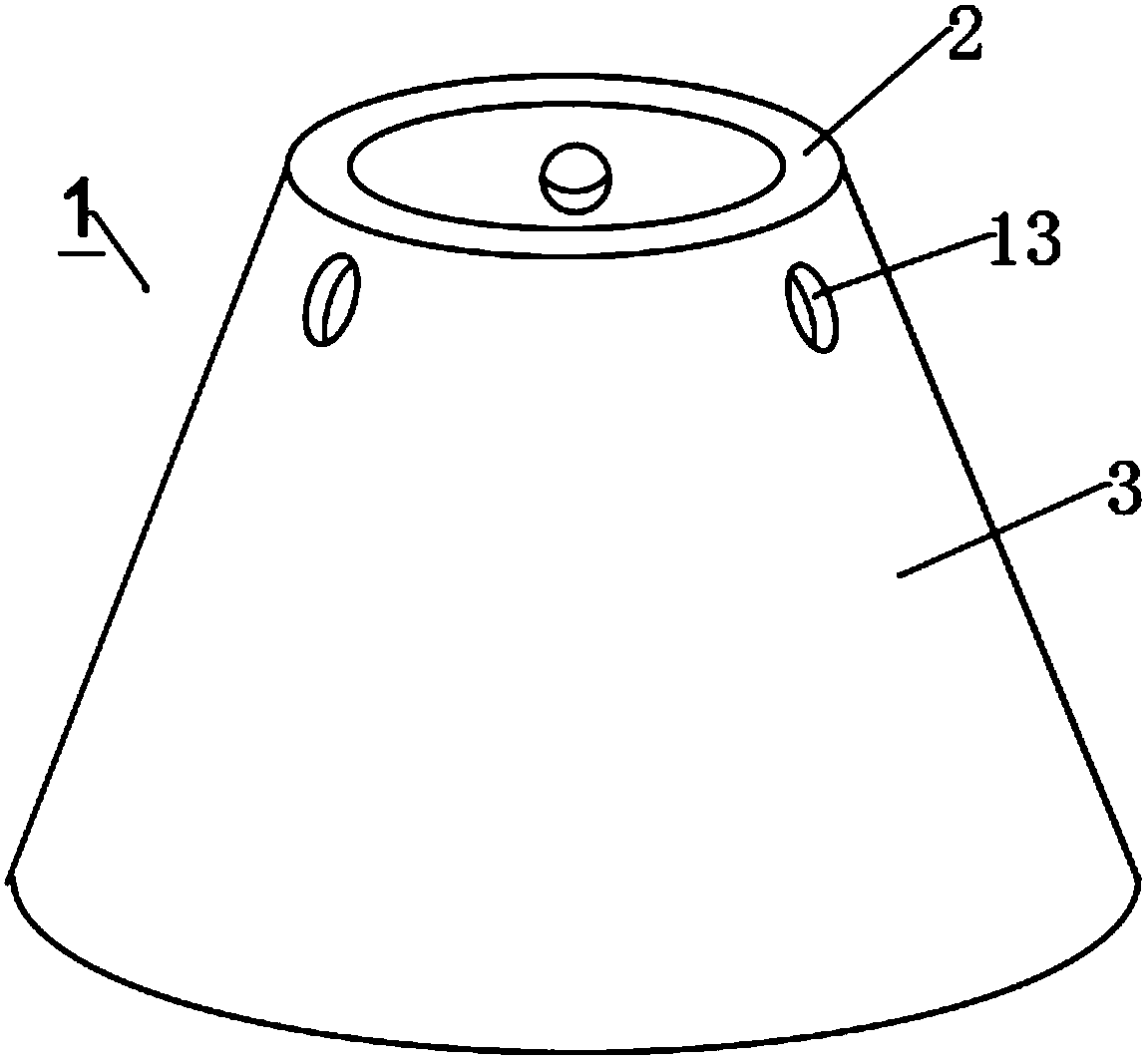

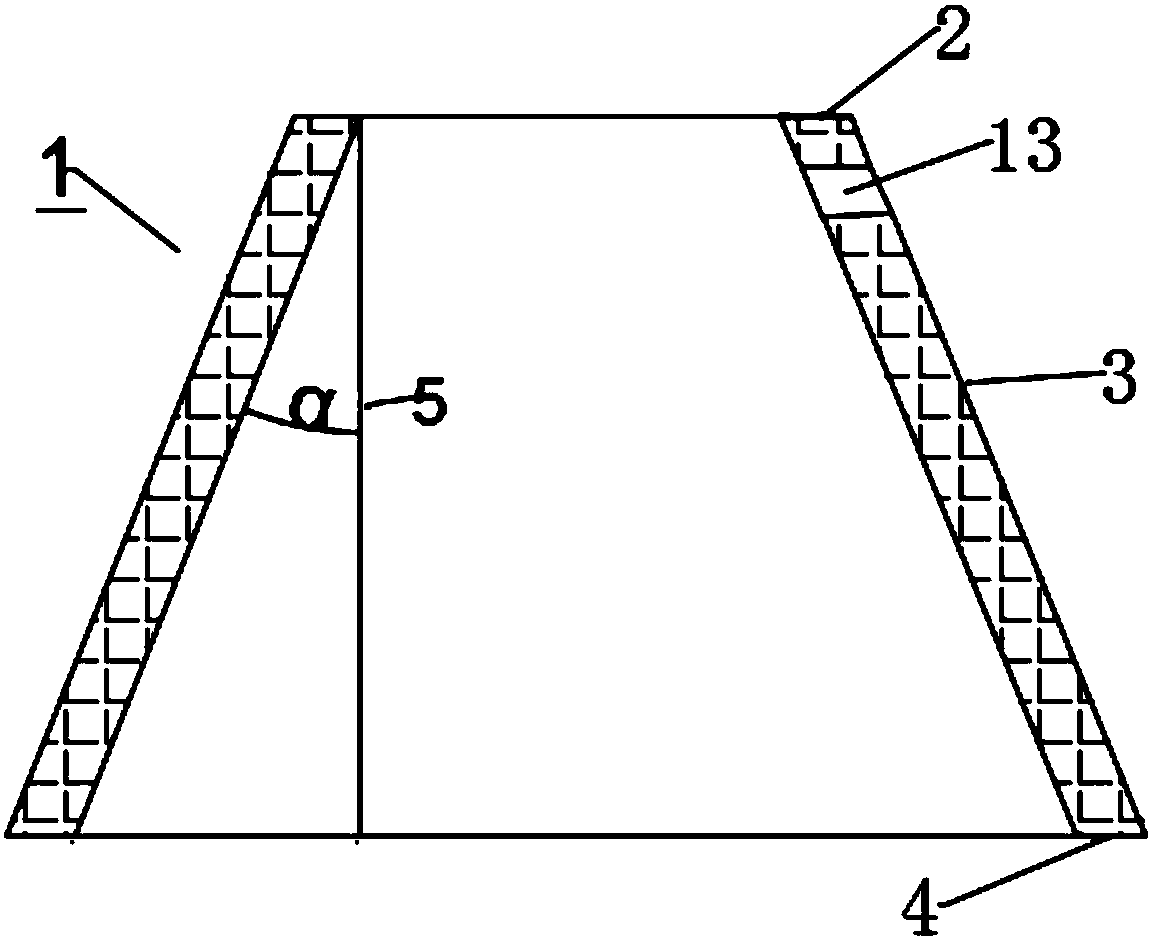

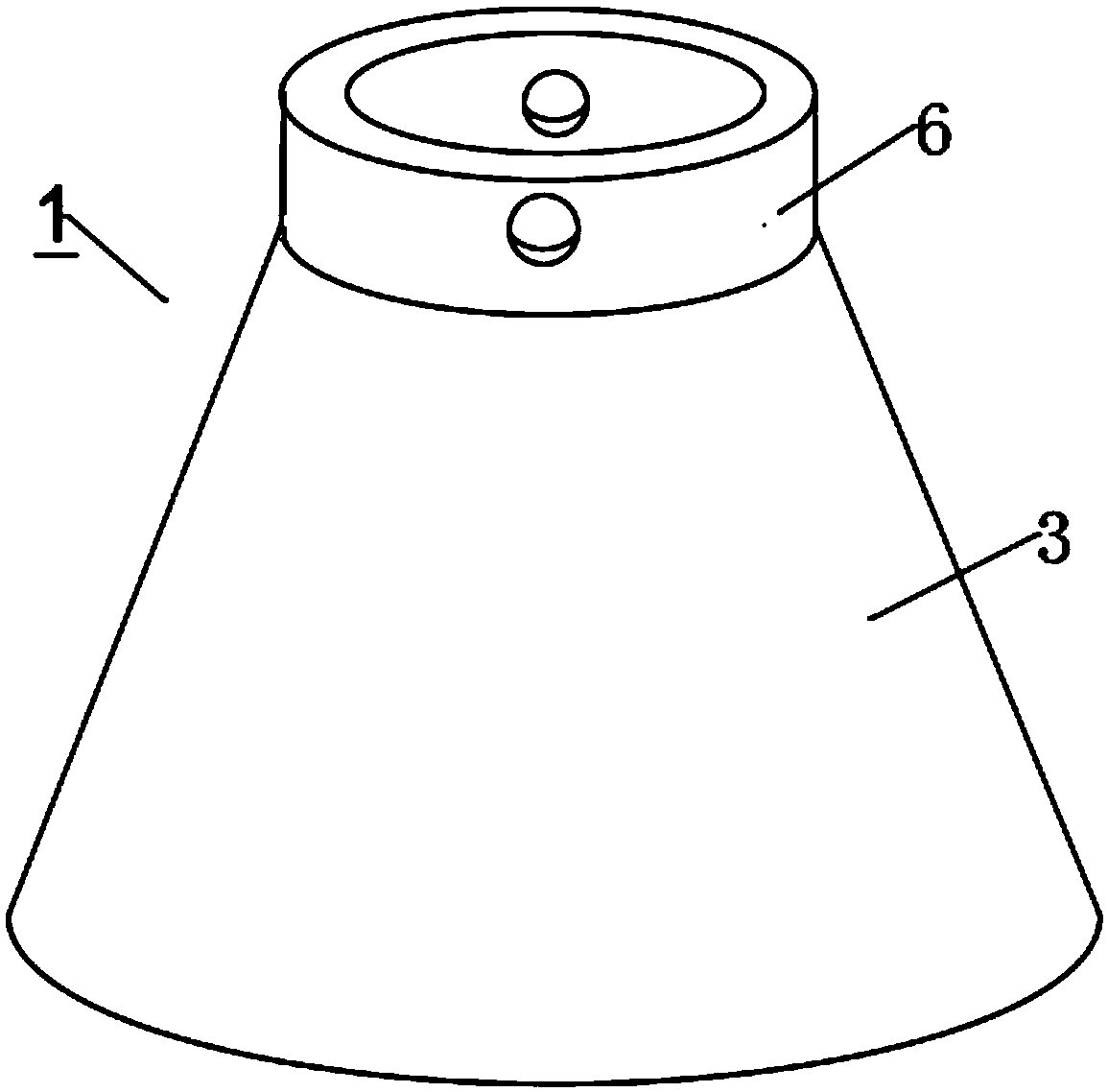

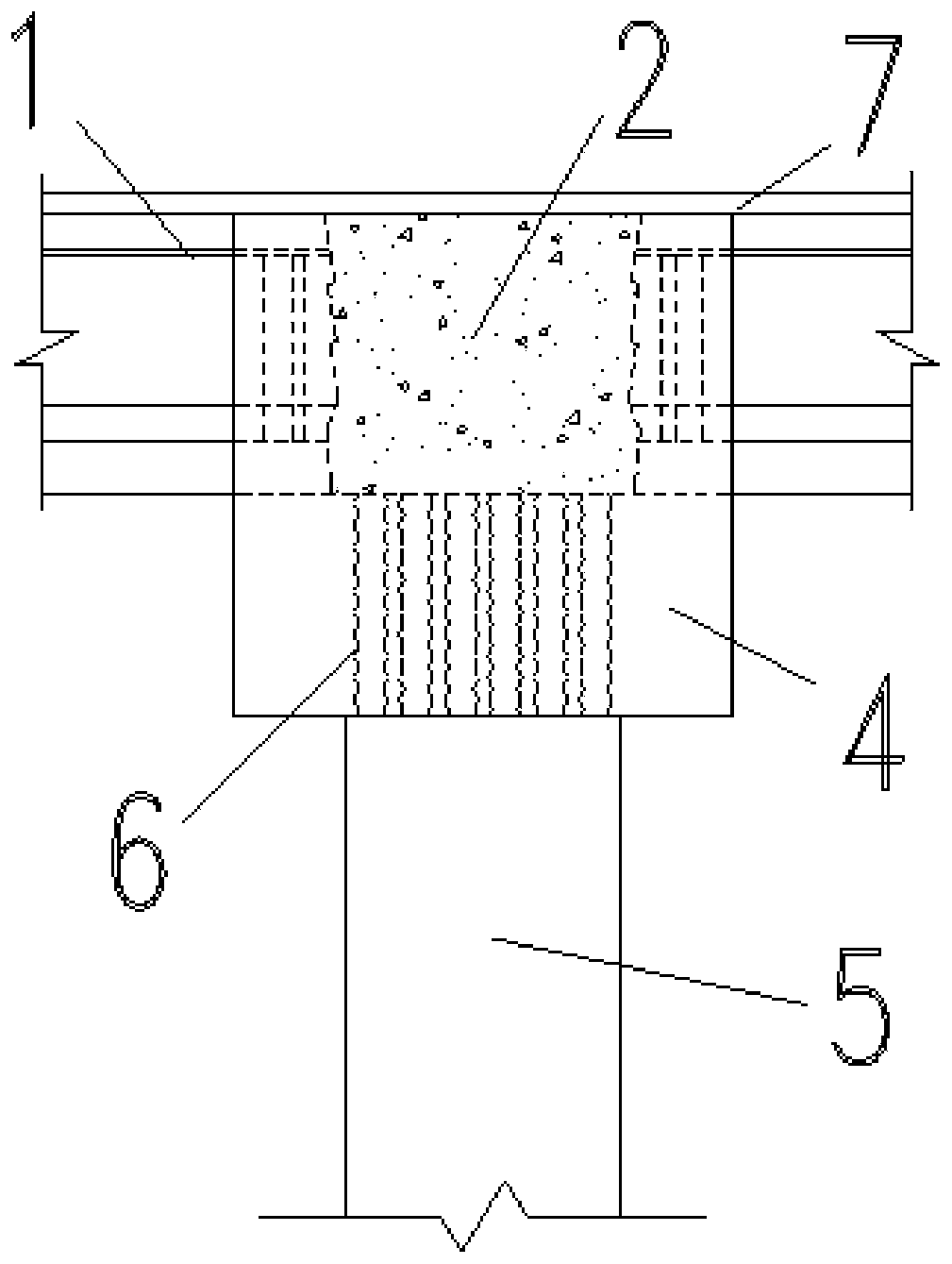

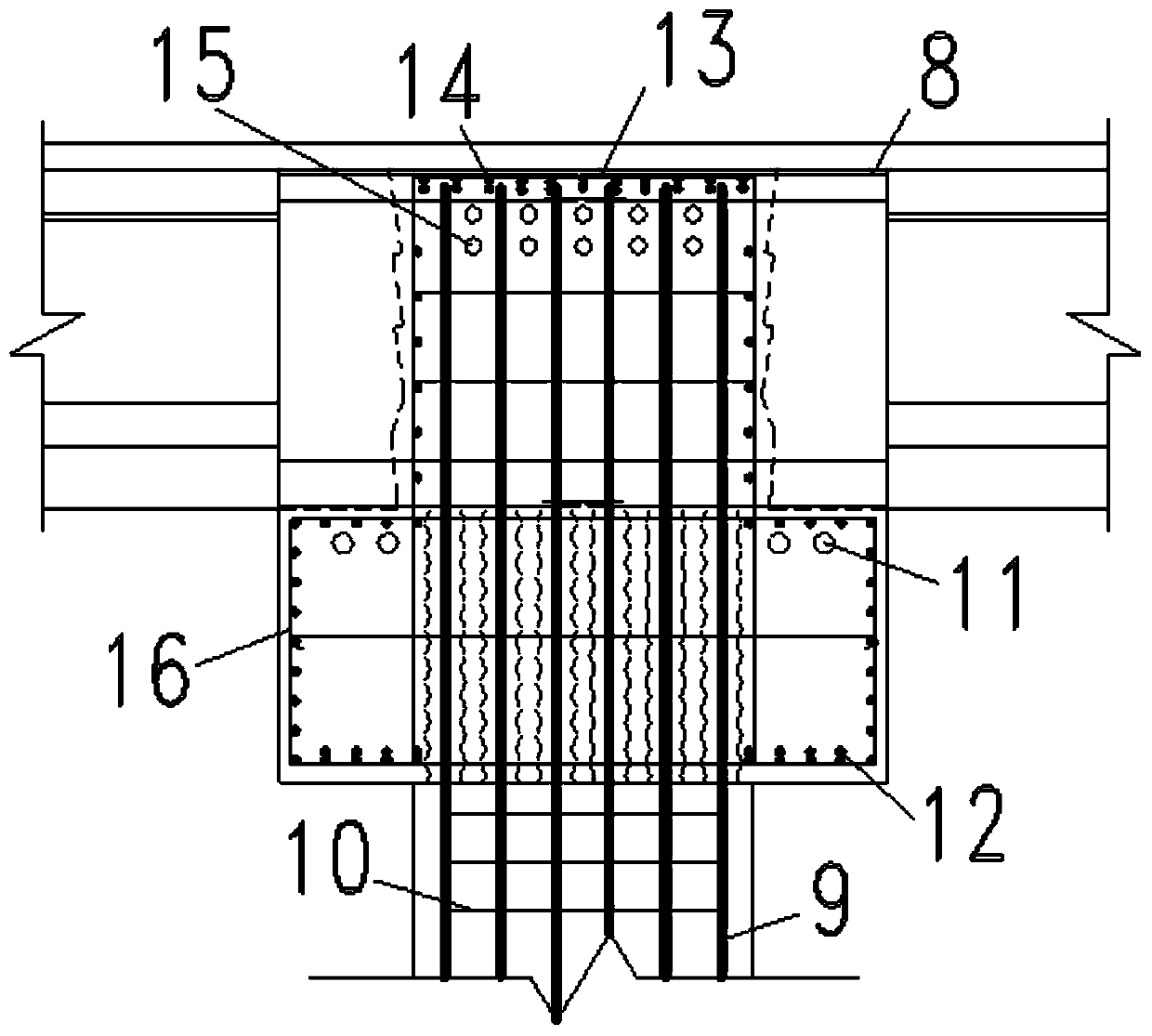

Combined pile foundation structure

ActiveCN102808419BIncrease stiffnessIncreased resistance to horizontal loadsFoundation engineeringElectricityCarrying capacity

The invention discloses a combined pile foundation structure. A hollow cone structure coaxial to a barrel-shaped foundation is arranged on the top of the barrel-shaped foundation; the centre of the top surface of the hollow cone structure is provided with a first connecting section ring girder structure; the centre of the top cover of the barrel-shaped foundation is provided with a second connecting section ring girder structure; a single-pile foundation is inserted in the first connecting section ring girder structure at the upper part and the second connecting section ring girder structure at the lower part; and the single-pile foundation is respectively fixedly connected with the first connecting section ring girder structure and the second connecting section ring girder structure. According to the combined pile foundation structure, the advantages of clear stress, strong applicability to soil layers, convenience in construction and good horizontal carrying capacity of the barrel-shaped foundation of the single-pile foundation are sufficiently utilized; the integral rigidness, horizontal load resistance, vertical load resistance and bending moment capacity are greatly improved, the bending moment load of a blower load to the foundation is effectively reduced and the horizontal displacement of a wind power structure is reduced, so that the pile length, pile diameter, wall thickness and penetrating depth of the pile foundation are reduced, the cost of materials is greatly reduced and the construction process is simpler.

Owner:TIANJIN UNIV

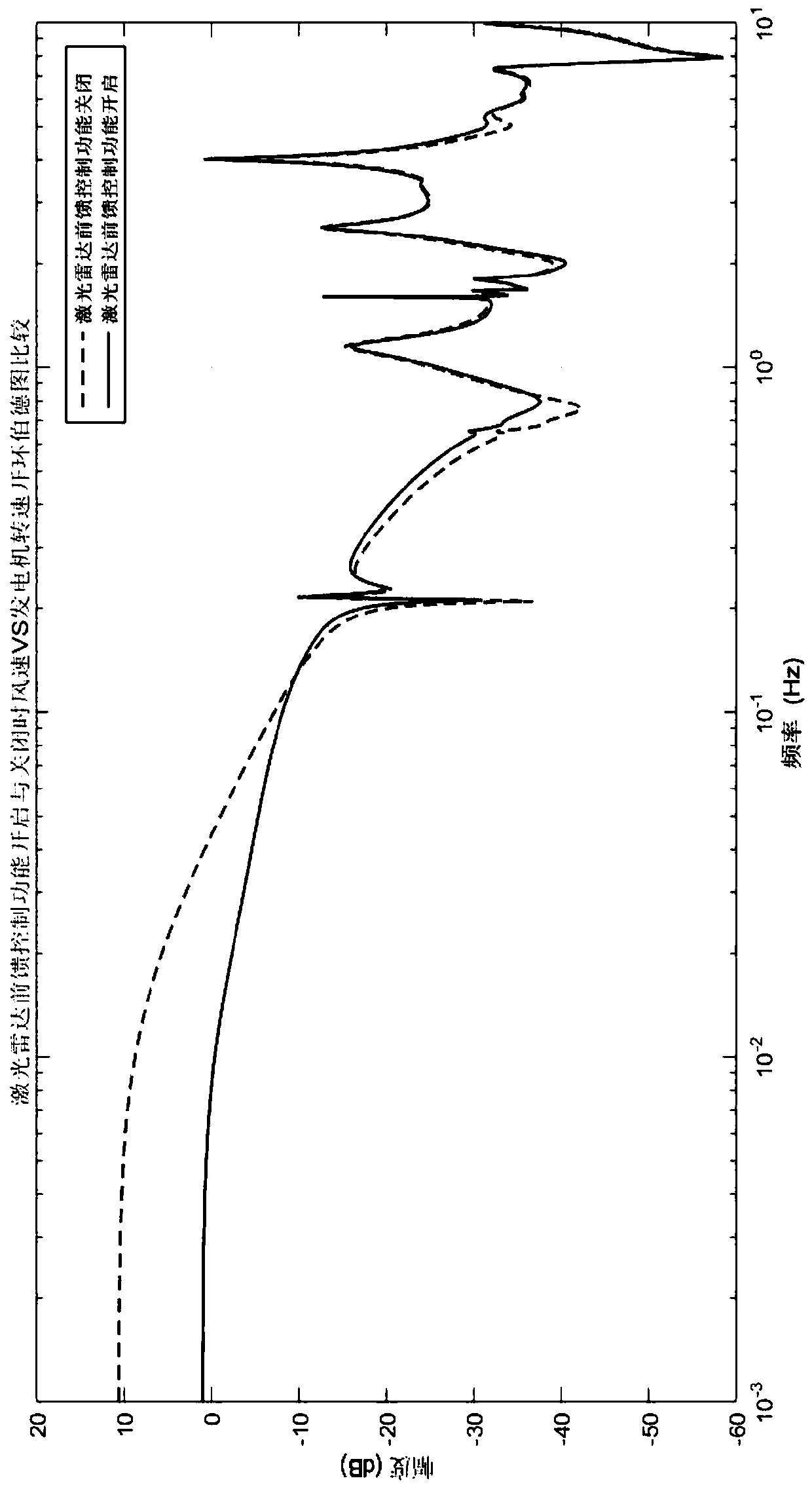

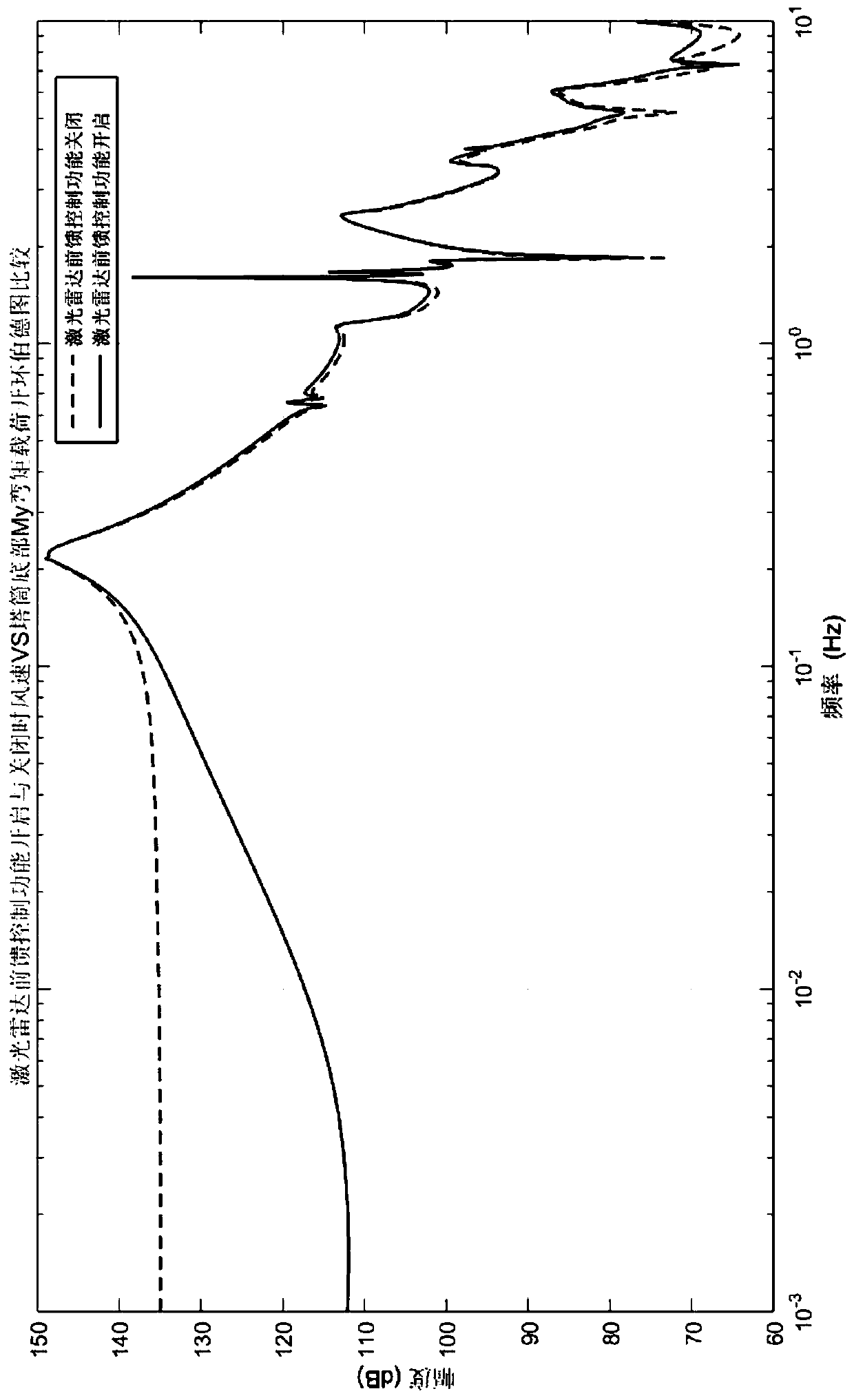

Feed-forward control method of wind generating set multi-laser beam multi-speed measurement section radar

ActiveCN110552838AReduce the fluctuation amplitude of the speed signalAvoid soft speed overspeed faultsWind motor controlMachines/enginesPhysicsSpeed measurement

The invention discloses a feed-forward control method of a wind generating set multi-laser beam multi-speed measurement section radar. According to the feed-forward control method, a pulse laser radaris adopted to provide a plurality of laser beams, the distance between the installation position of the laser radar and a speed measurement section in the axial direction of an impeller of a wind generating set is within 50-200 meters, and at most 10 wind speed measurement distances are set at will; and the number of the speed measurement distances and the corresponding speed measurement positions are determined, and thus, a multi-laser beam multi-speed measurement section radar feed-forward control wind speed measurement framework is formed, and then the multi-laser beam multi-speed measurement section radar feed-forward control wind speed measurement framework is controlled to achieve multi-laser beam multi-speed measurement section radar feed-forward control. By means of the feed-forward control method, the action of a variable-pitch actuating mechanism can be effectively reduced, the running reliability of the wind generating set is improved, the fluctuation range of the rotatingspeed of a generator is greatly reduced, and the My bending moment load at the bottom of a tower barrel is reduced.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

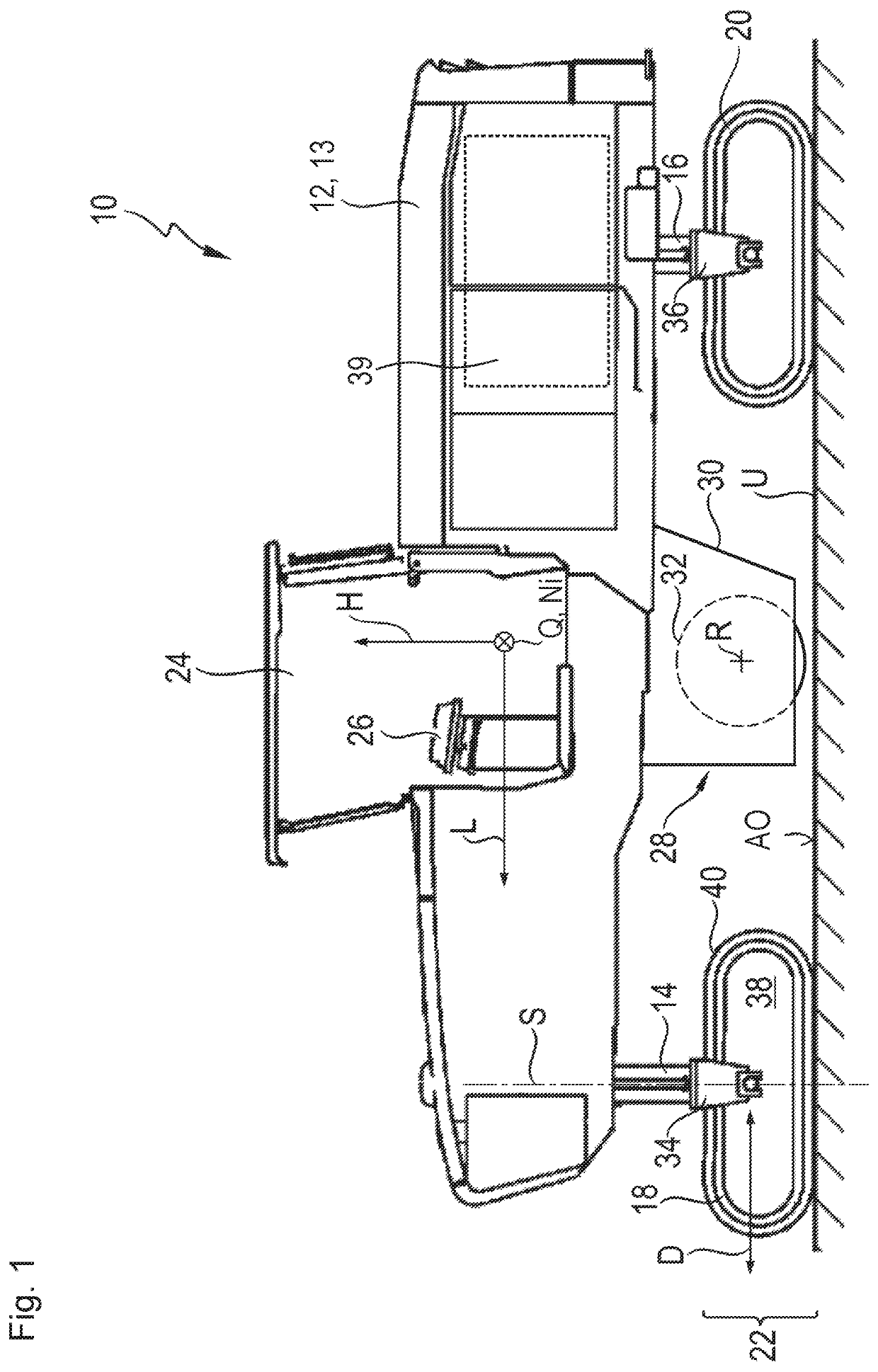

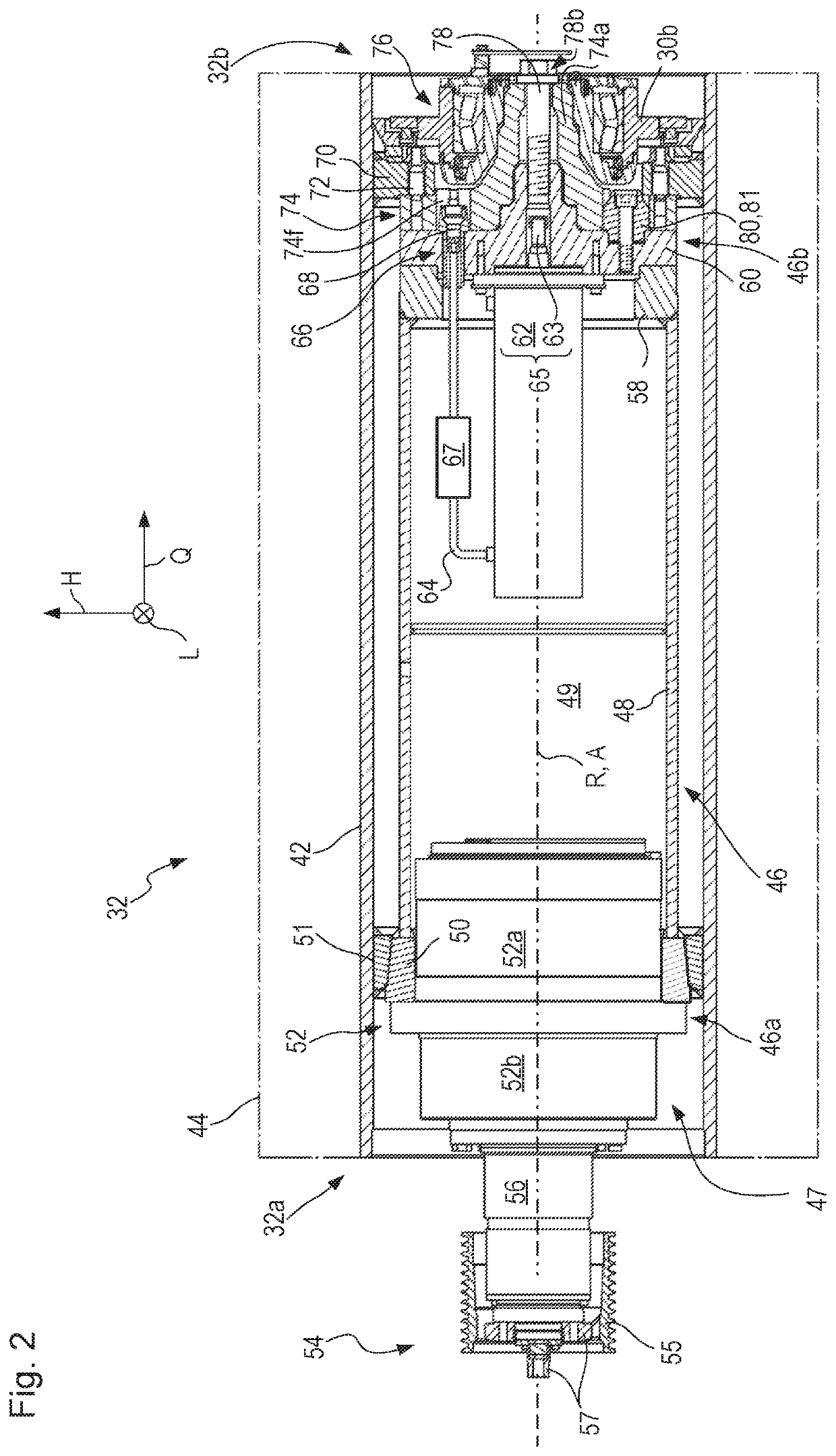

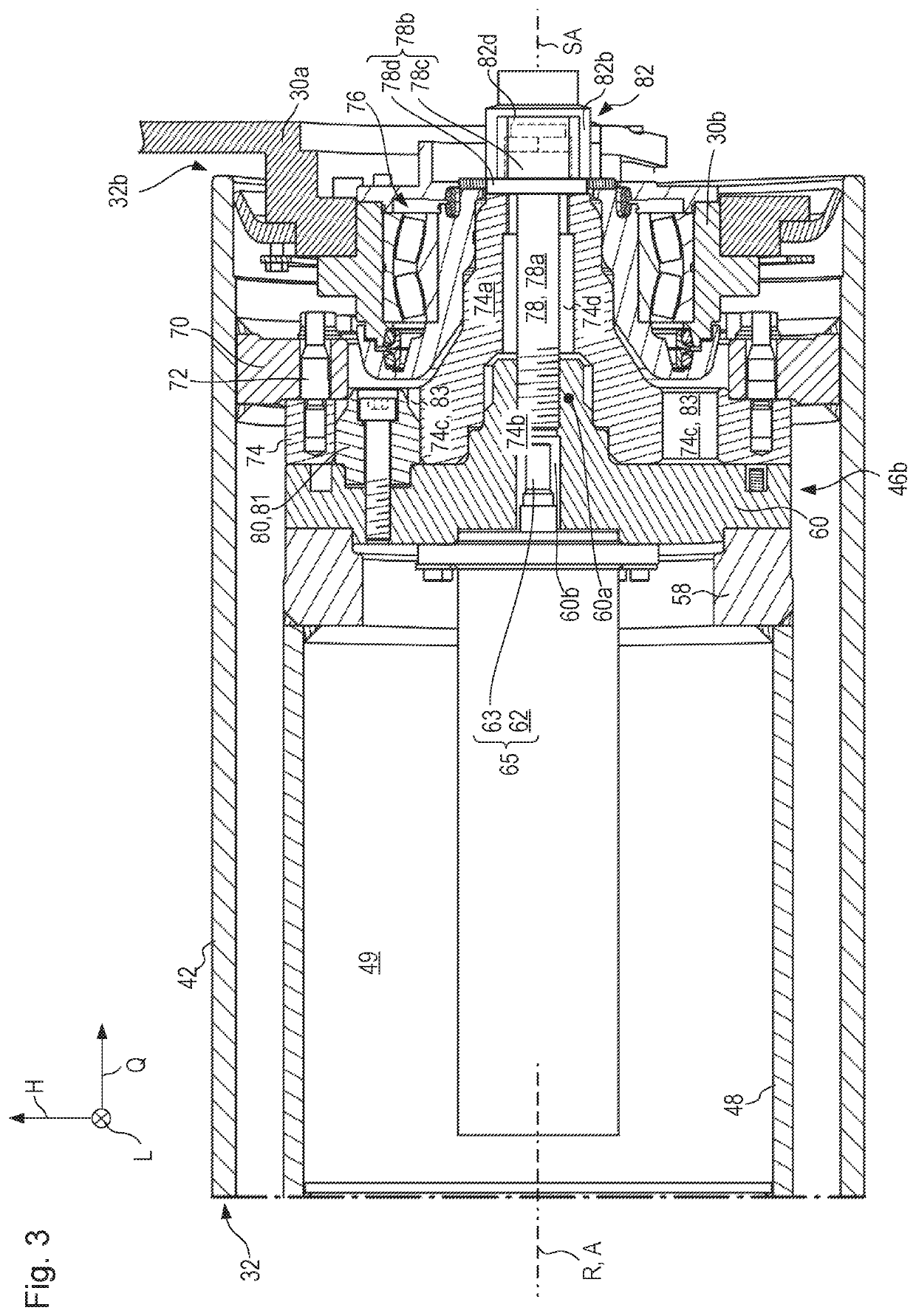

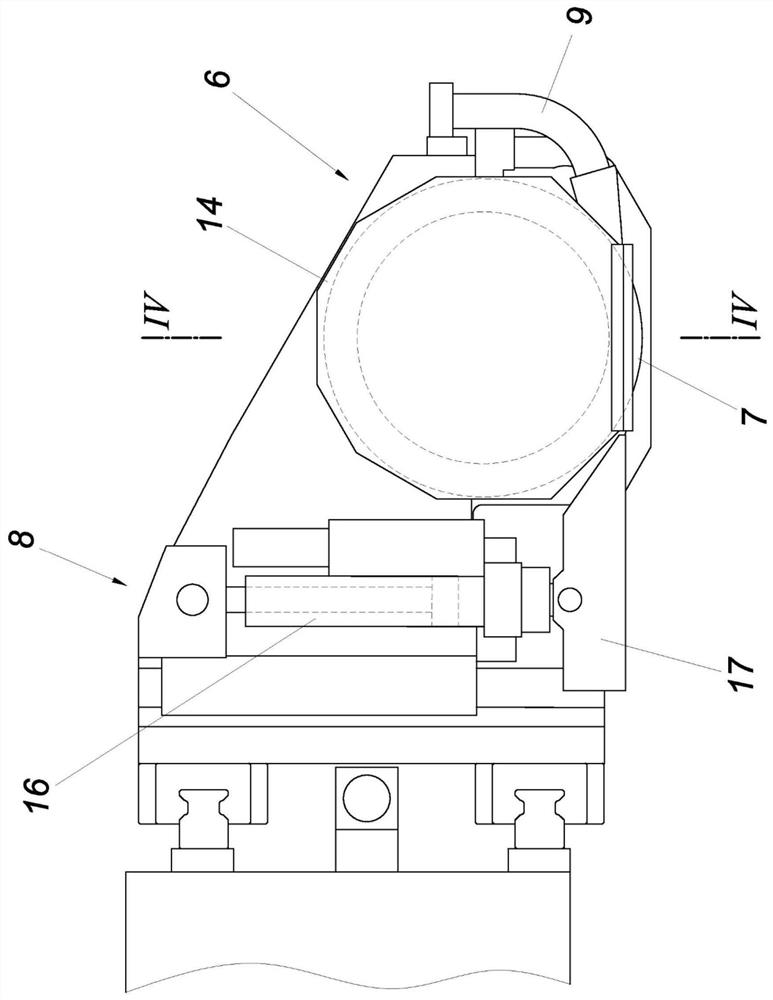

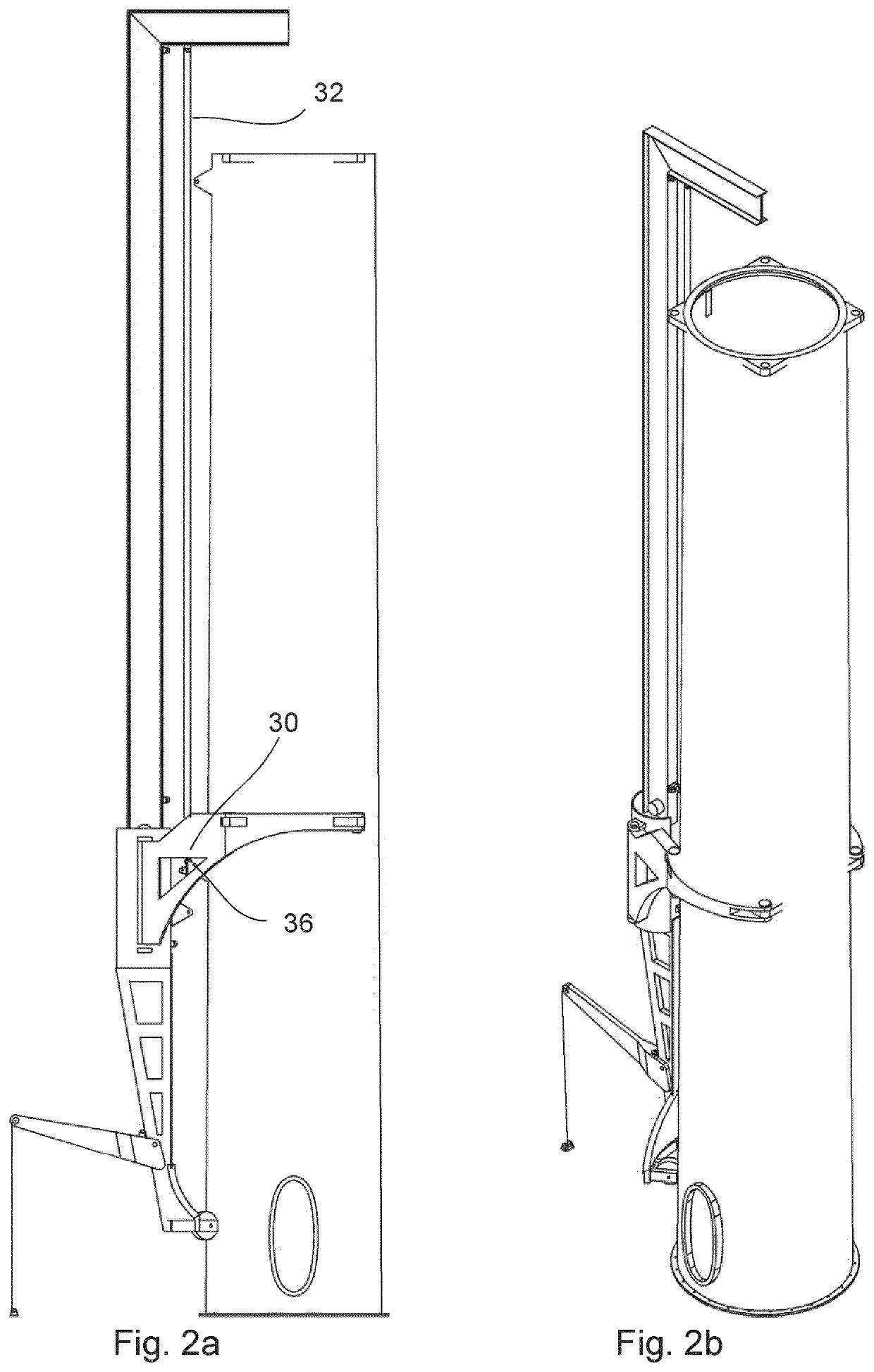

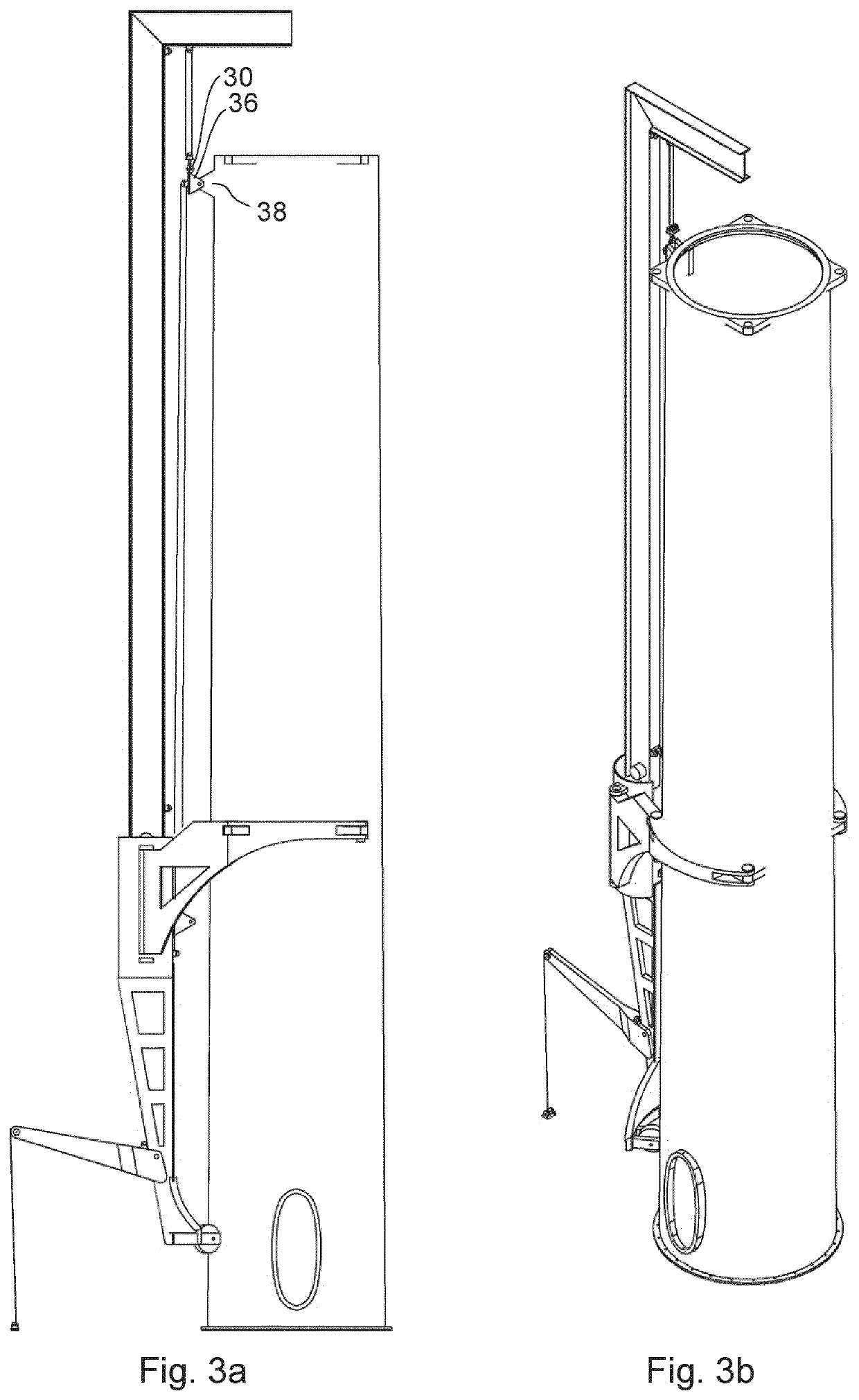

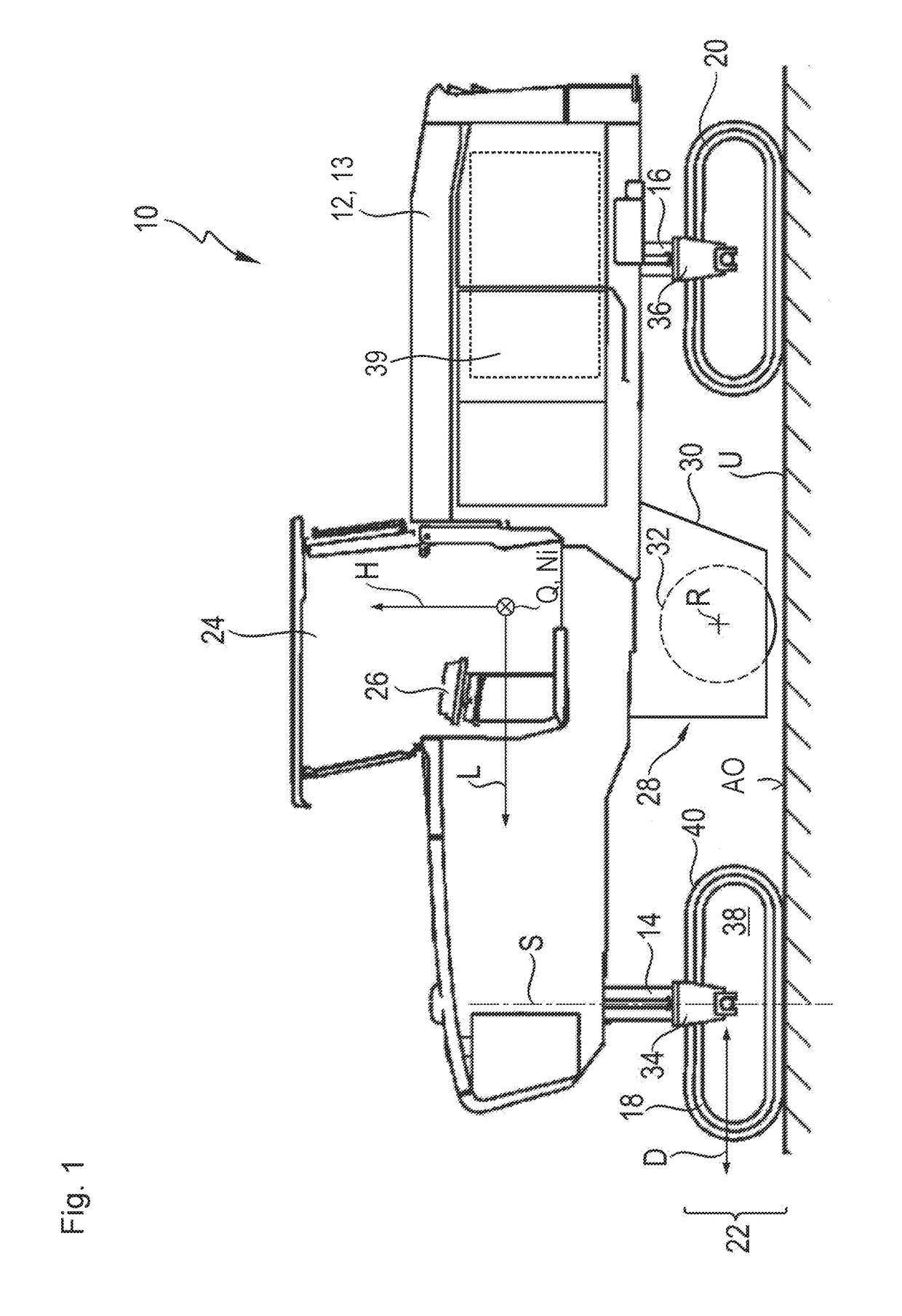

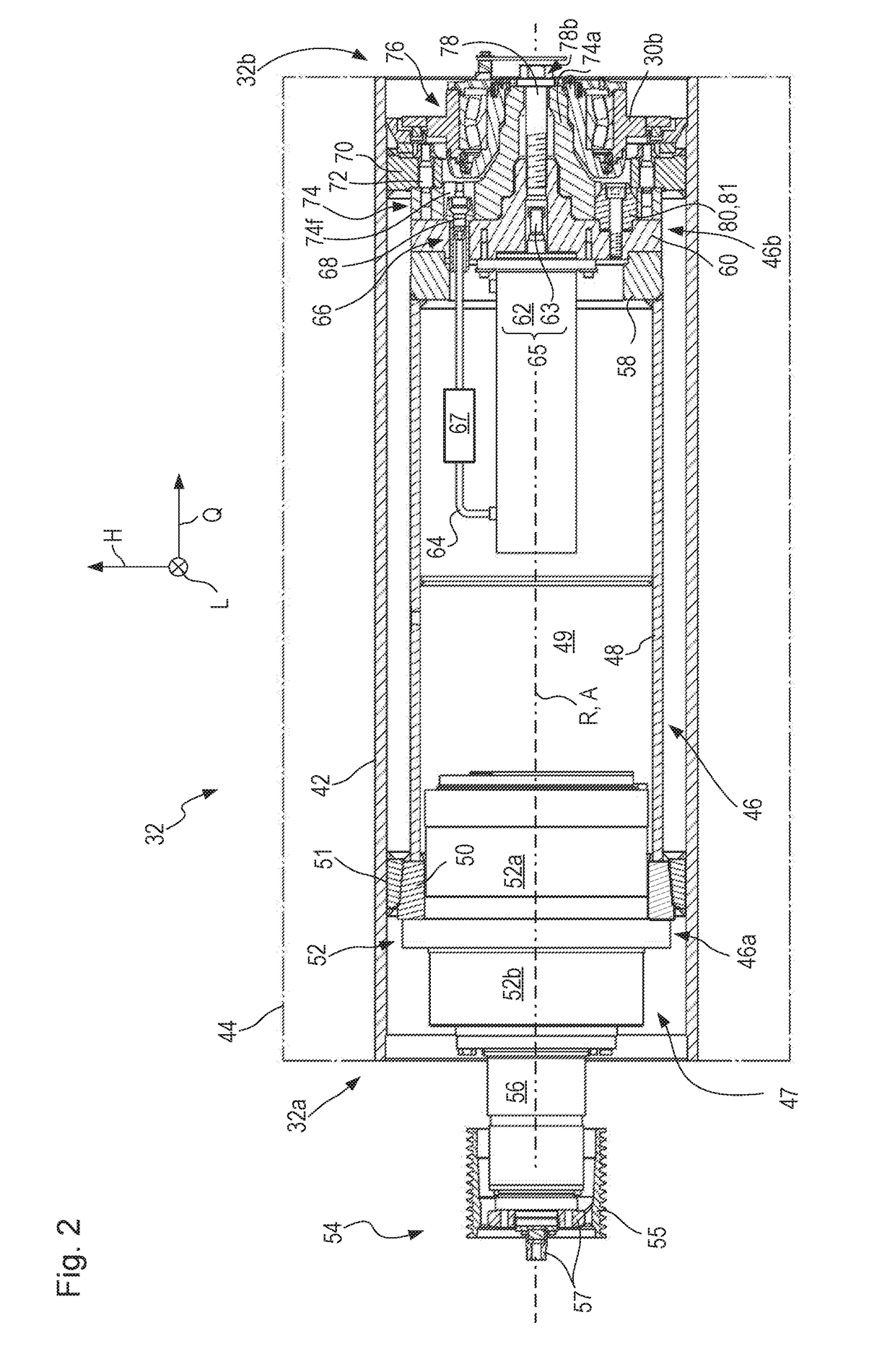

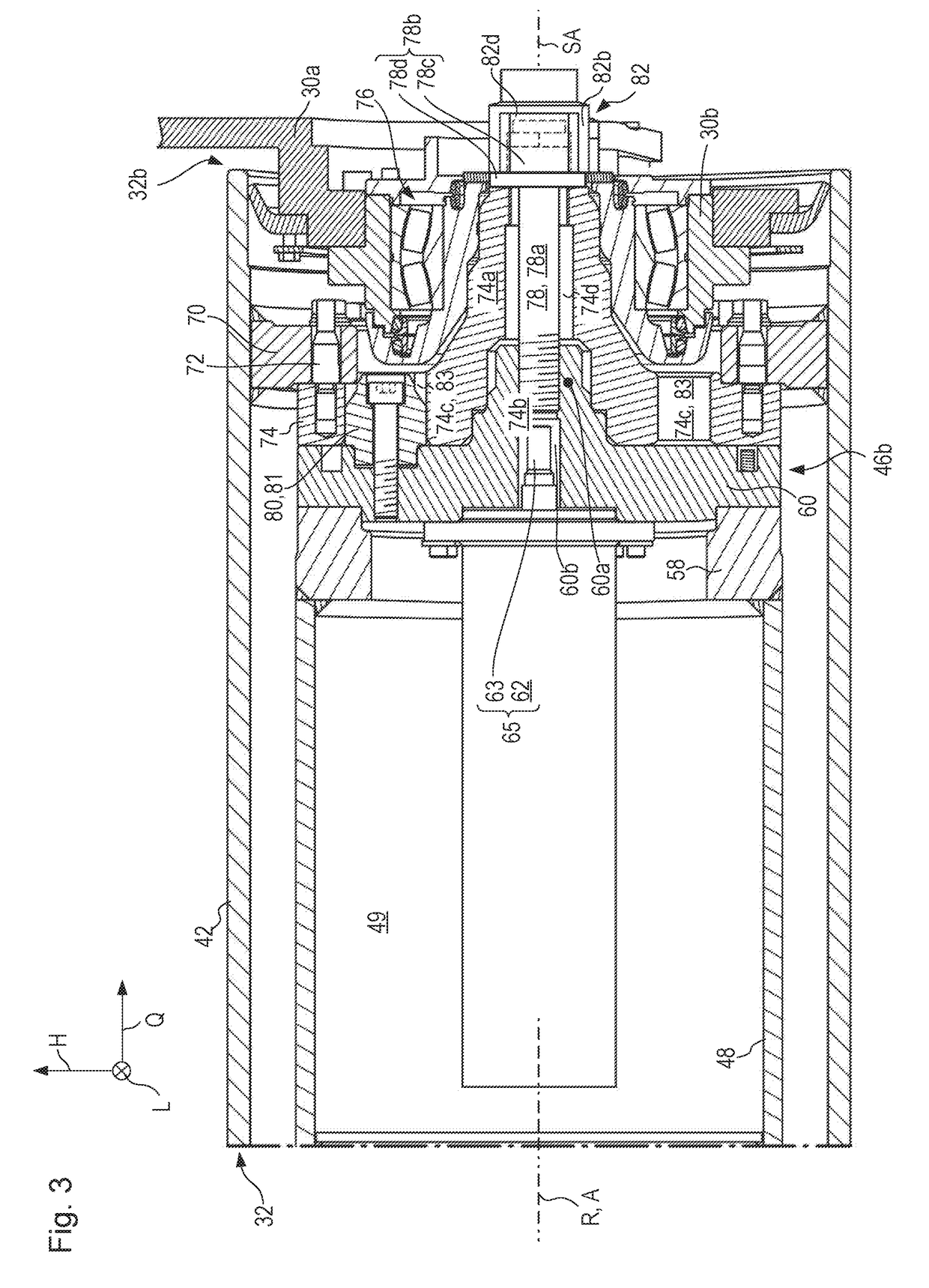

Earth working machine whose working apparatus is displaceable out of its operating position using an onboard actuator

ActiveUS10724187B2Avoiding orReduced moment loadMilling machinesLarge fixed membersClassical mechanicsTorque transmission

An earth working machine (10) includes a machine body (13) having a machine frame (12) and a drive configuration (46), rotationally drivable relative to the machine frame (12), and to which configuration a working apparatus (32) embodied for earth working is releasably connected in torque-transferring fashion, in an operating position, for rotation together around a drive axis (A), such that when the connection is released, the working apparatus (32) is removable from the operating position in an axial direction relative to the drive configuration (46) for deinstallation from the drive configuration (46) and, for installation on the drive configuration (46), is conveyable into the operating position in an axial direction relative to the drive configuration (46), an actuator (65) being provided which is embodied to move the working apparatus (32) out of the operating position when the connection is released.

Owner:WIRTGEN GMBH

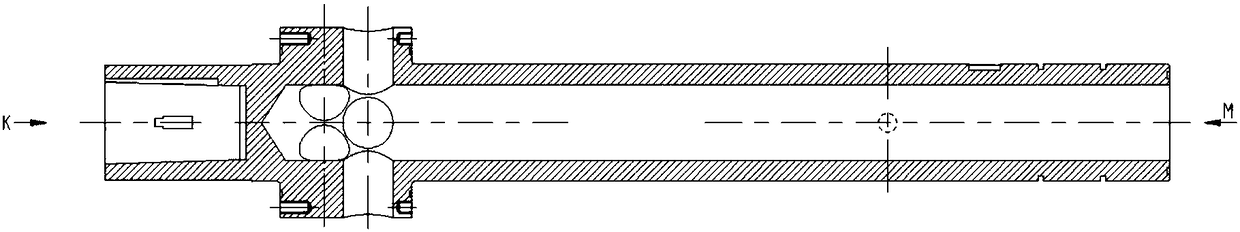

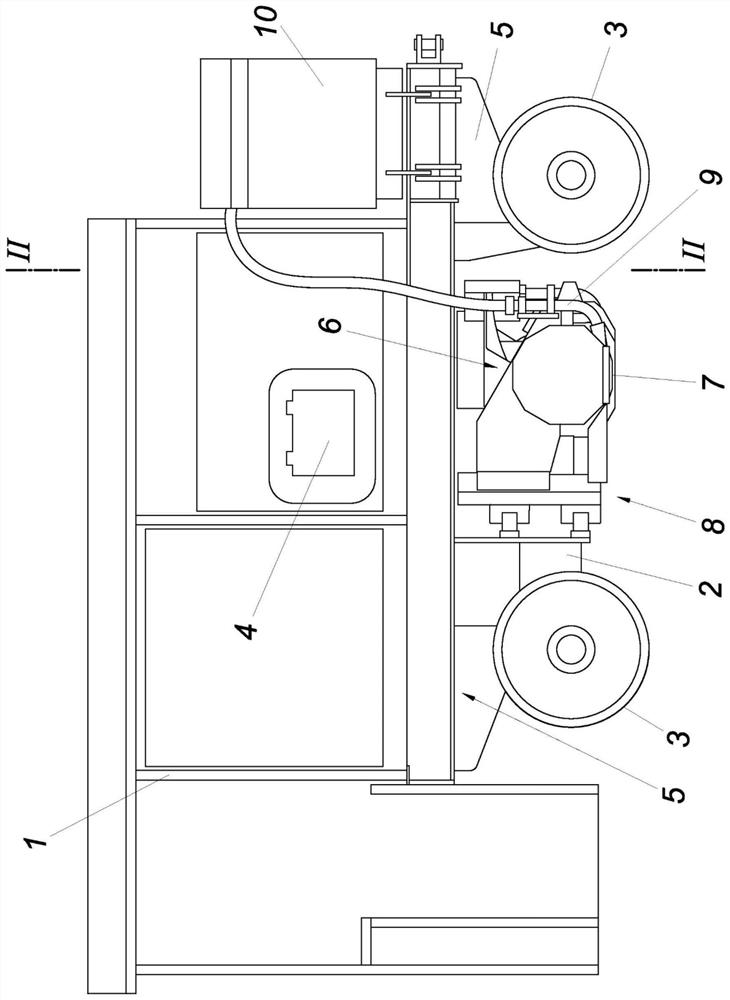

Force measuring system for spray pipe

ActiveCN108443029AReduced moment loadDesign Load CoordinationRocket engine plantsAir bridgeEngineering

The invention provides a force measuring system for a spray pipe. A front air bridge (5) is detachably connected with the air outlet end of a ventilating supporting rod (8), and balance mounting taperholes are formed in the front air bridge (5) and the ventilating supporting rod (8); the two ends of a balance (7) are correspondingly positioned in the balance mounting taper holes of the front airbridge (5) and the ventilating supporting rod (8), and the front air bridge (5) is connected with a seal head (3); the balance (7) is sealed in a sealed space formed by the seal head (3), the front air bridge (5) and the ventilating supporting rod (8), and a shell (6) is positioned outside the air outlet ends of the front air bridge (5) and the ventilating supporting rod (8); and the front air bridge (5) is detachably connected with one end of the shell (6), and the ventilating supporting rod (8) is connected with the other end of the shell (6) through a rear air bridge (9). The measuring accuracy of the force measuring system increases from 2% to 0.8%.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Combined pile foundation structure

ActiveCN102808419AIncrease stiffnessIncreased resistance to horizontal loadsFoundation engineeringElectricityCarrying capacity

The invention discloses a combined pile foundation structure. A hollow cone structure coaxial to a barrel-shaped foundation is arranged on the top of the barrel-shaped foundation; the centre of the top surface of the hollow cone structure is provided with a first connecting section ring girder structure; the centre of the top cover of the barrel-shaped foundation is provided with a second connecting section ring girder structure; a single-pile foundation is inserted in the first connecting section ring girder structure at the upper part and the second connecting section ring girder structure at the lower part; and the single-pile foundation is respectively fixedly connected with the first connecting section ring girder structure and the second connecting section ring girder structure. According to the combined pile foundation structure, the advantages of clear stress, strong applicability to soil layers, convenience in construction and good horizontal carrying capacity of the barrel-shaped foundation of the single-pile foundation are sufficiently utilized; the integral rigidness, horizontal load resistance, vertical load resistance and bending moment capacity are greatly improved, the bending moment load of a blower load to the foundation is effectively reduced and the horizontal displacement of a wind power structure is reduced, so that the pile length, pile diameter, wall thickness and penetrating depth of the pile foundation are reduced, the cost of materials is greatly reduced and the construction process is simpler.

Owner:TIANJIN UNIV

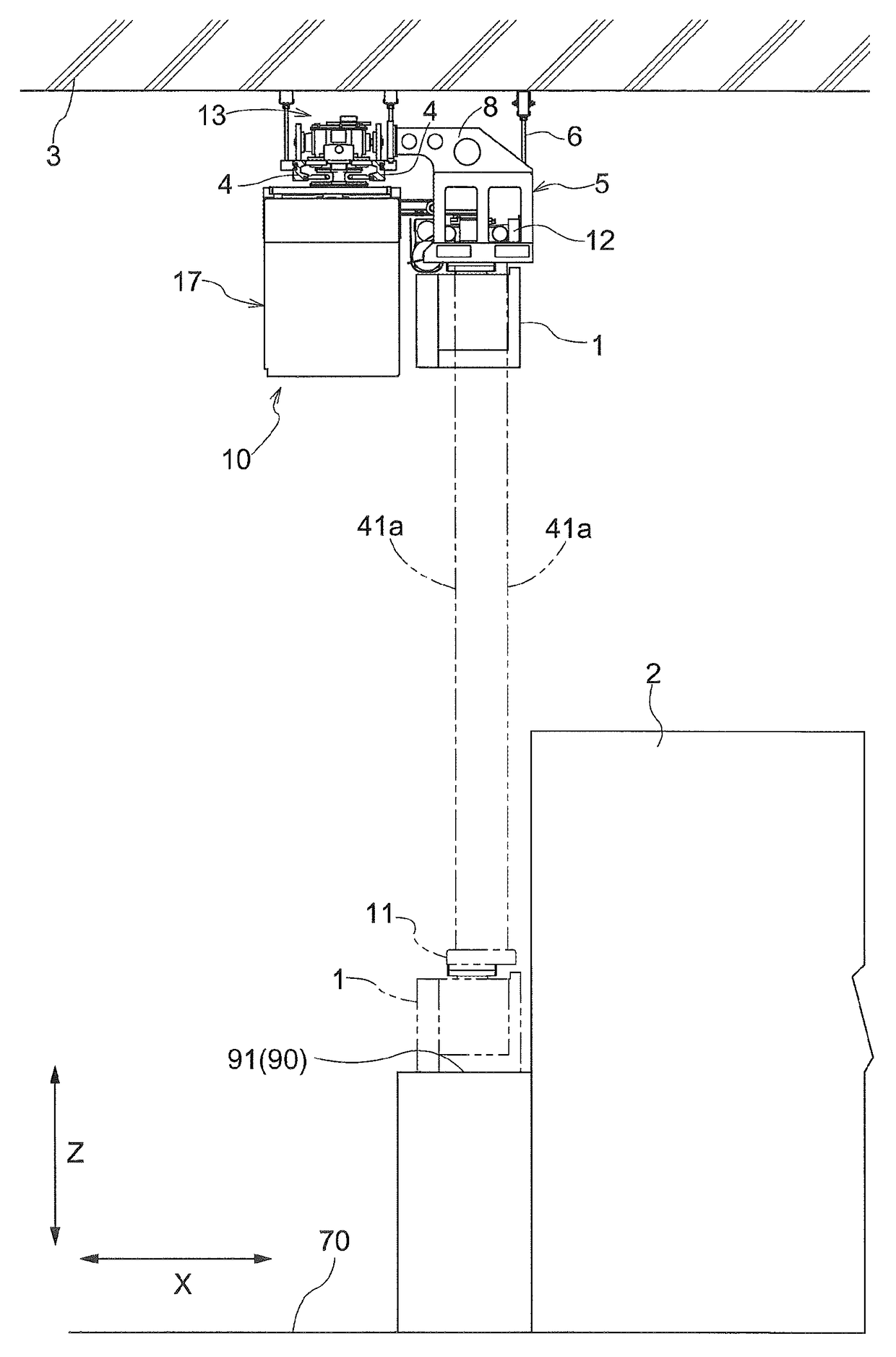

Workpiece transport device

InactiveCN105270863AAchieve compactnessReduce moment loadCharge manipulationConveyor partsJoint axisEngineering

The invention aims to shorten the moment of the vertical dimension of a swing arm relative to an arm root and provides a workpiece transport device. The workpiece transport device comprises a support base, a support arm in rotatable connection with a main rotation axis relative to the support base, a hand retaining arm in rotatable connection with an elbow joint axis relative to the support arm, a hand in rotatable connection with the elbow joint axis relative to the hand retaining arm, a support arm motor used for driving the support arm to rotate around the support base and arranged in the support base, a hand retaining arm motor used for driving the hand retaining arm to rotate around the support arm, a hand motor used for driving the hand to rotate around the hand retaining arm and arranged in the support arm, a joint axis coaxially arranged together with the elbow joint axis and used for driving the hand retaining arm to rotate relative to the support arm, a transmission shaft used for transmitting the power for driving the hand to rotate, a first reduction mechanism arranged in the support base and used for reducing the output of the support arm motor, and a second reduction mechanism arranged in the support arm and used for reducing the output of the hand retaining arm motor.

Owner:DAIHEN CORP

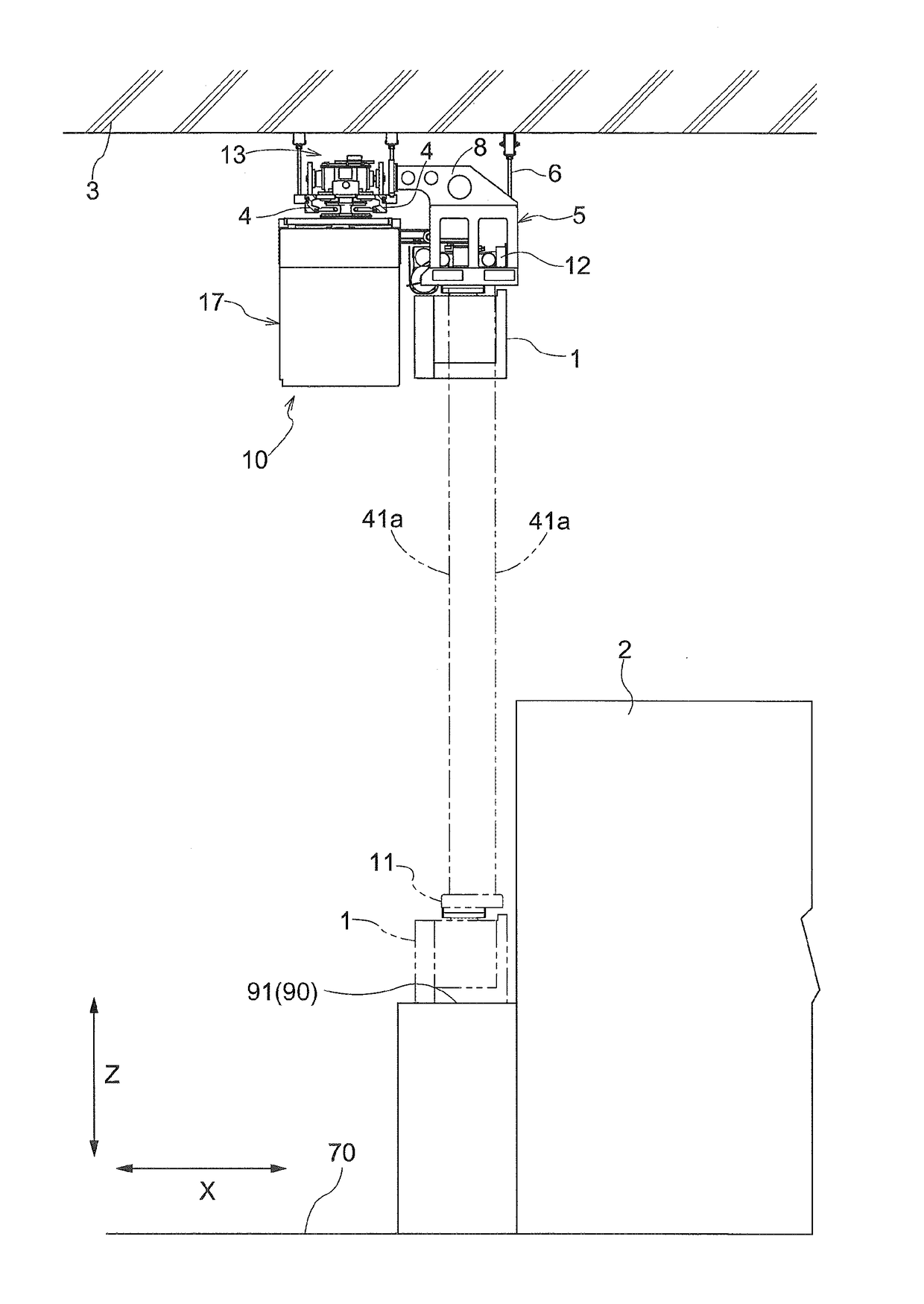

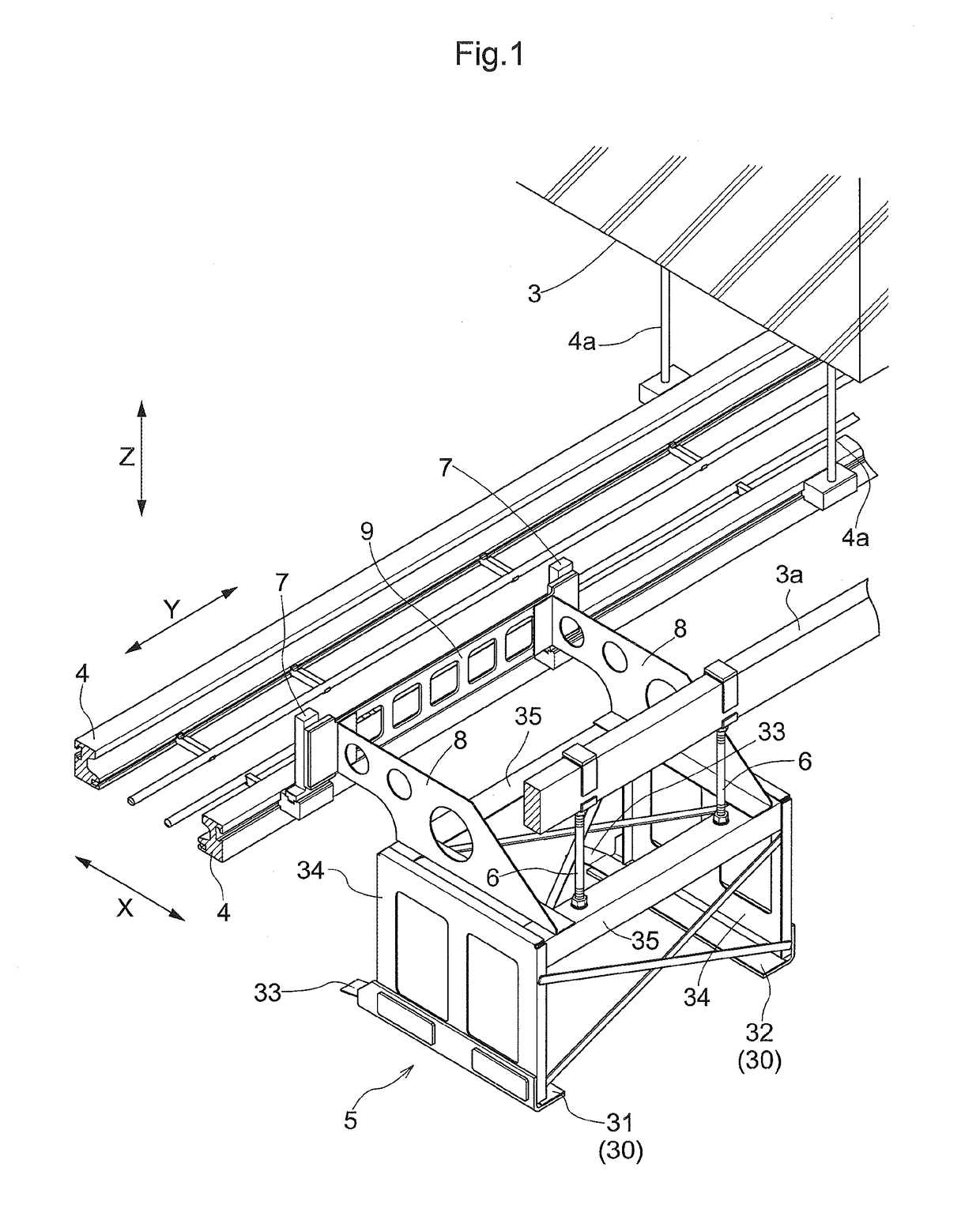

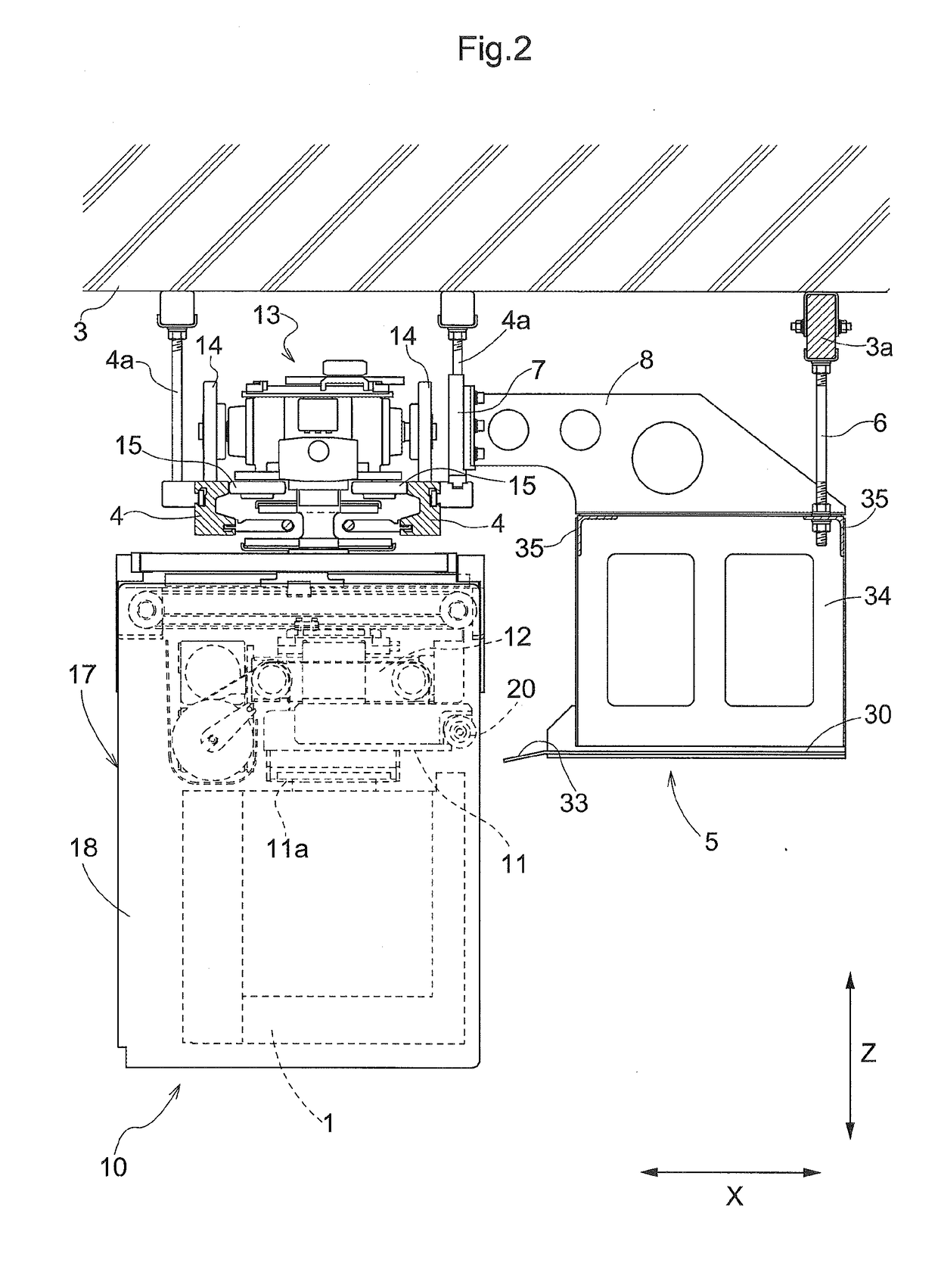

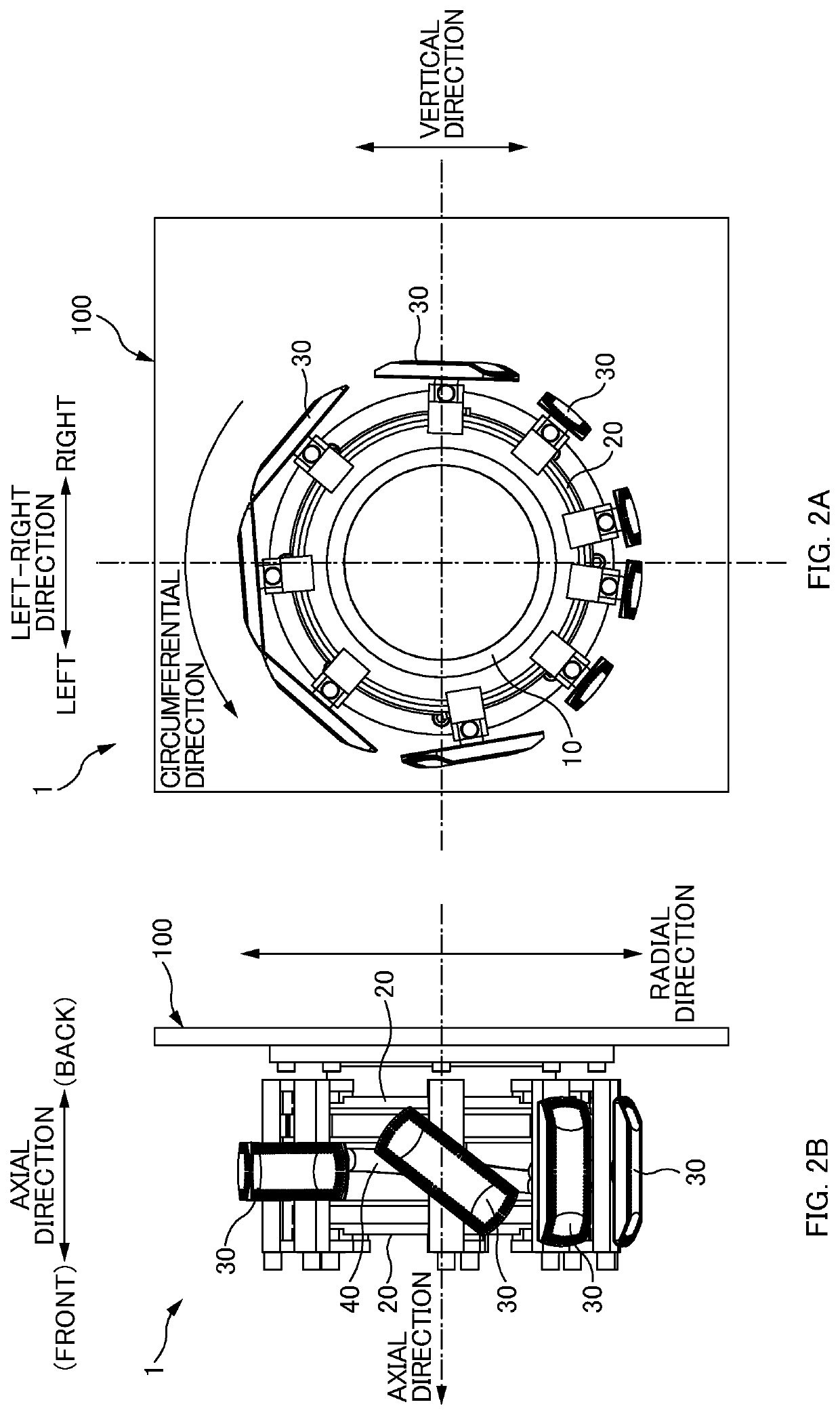

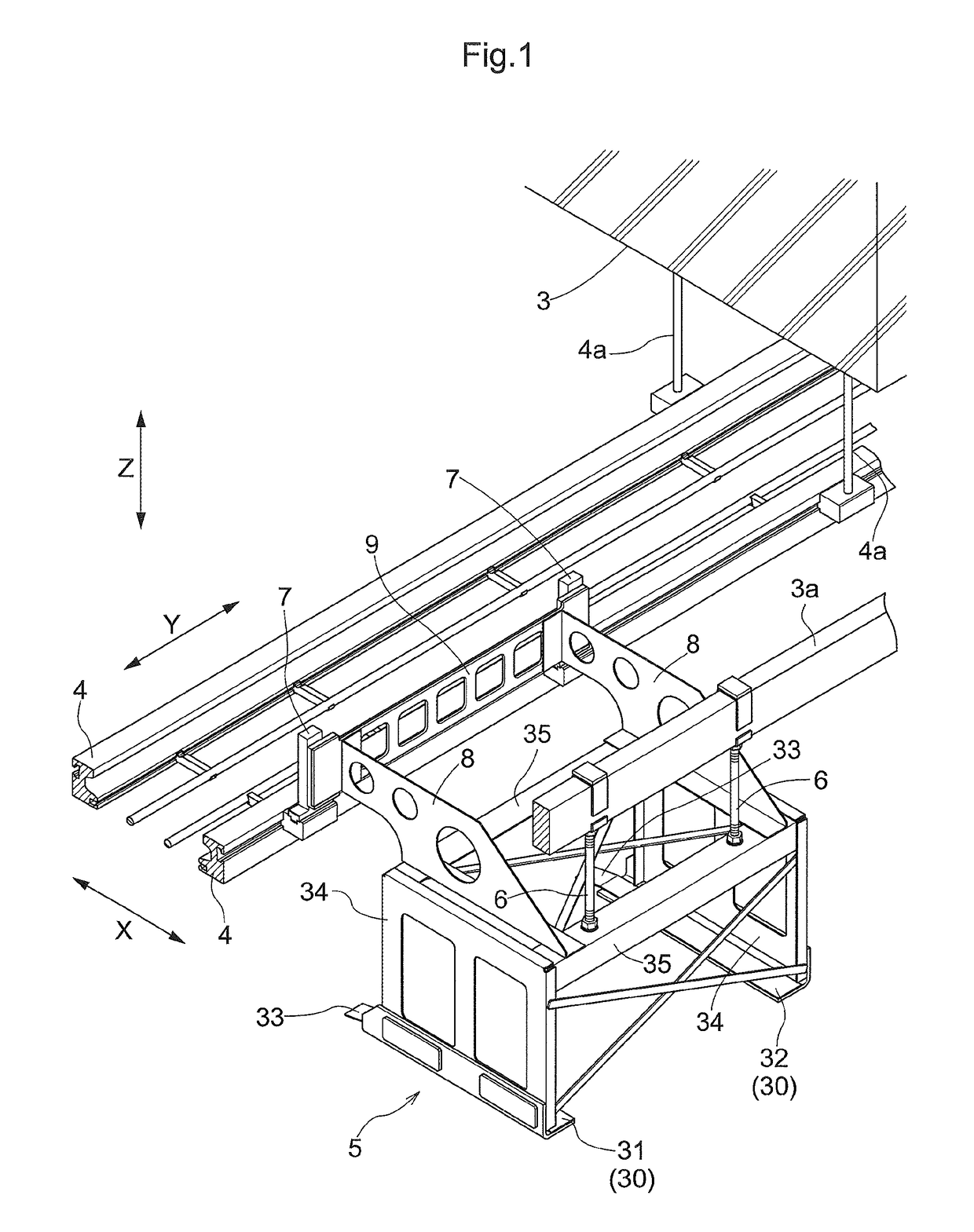

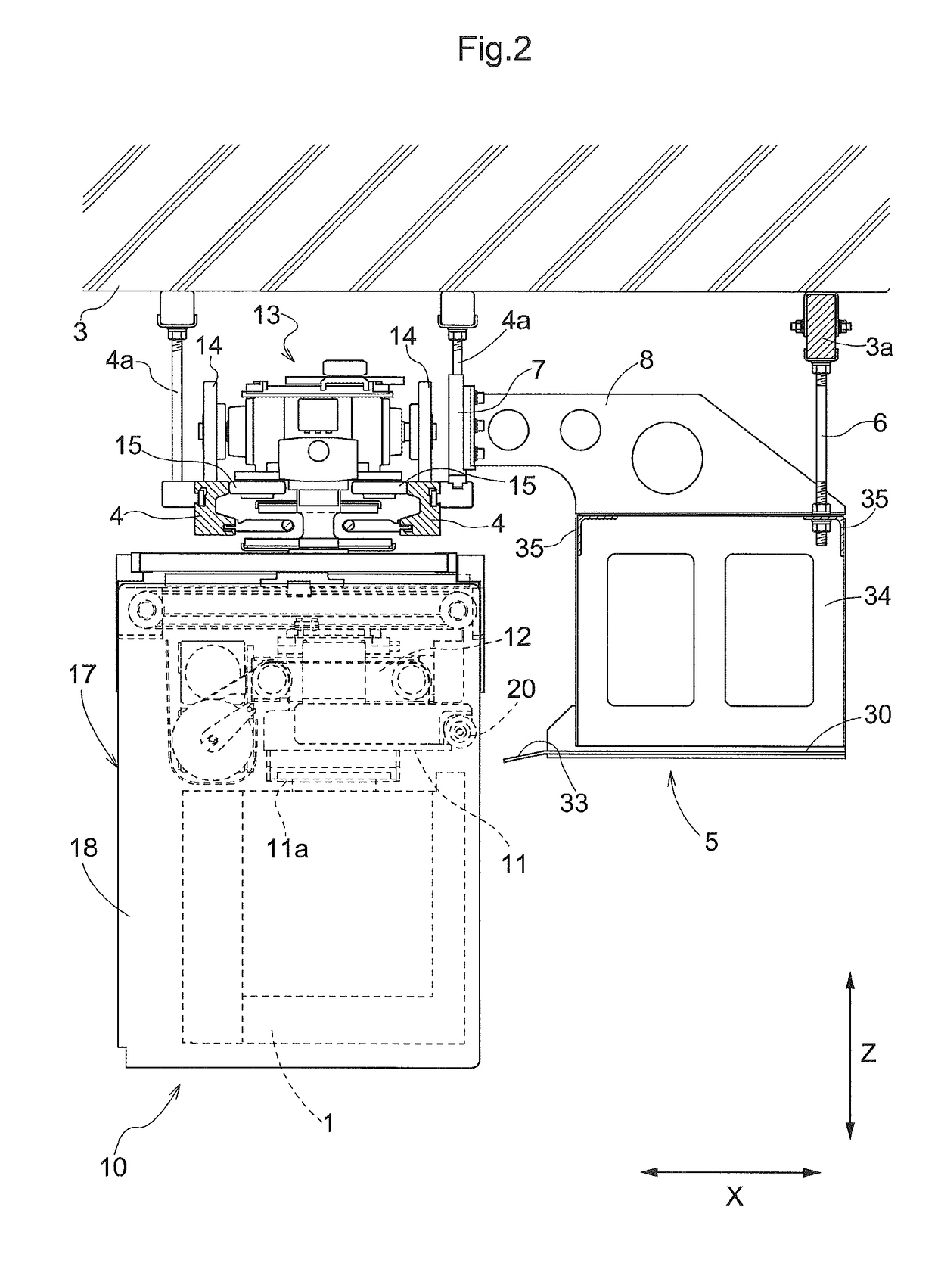

Article Transport Facility

ActiveUS20170137240A1Tilt is limitedReduced moment loadSemiconductor/solid-state device manufacturingLoading/unloadingEngineeringTransport facility

An article transport facility includes a support member capable of supporting a second support component from below while allowing a vertical movement of a first support component with respect to the second support component, in a projected state in which the second support component is located in a projected position. The support member is supported directly or indirectly by a ceiling.

Owner:DAIFUKU CO LTD

Structure for constructing underwater foundation and mounting method thereof

InactiveCN107724416AEasy constructionReduce erosionBulkheads/pilesRenewable energy source integrationElectricityRound table

The invention discloses an underwater building foundation structure which is a hollow round-table-shaped structure. The structure is characterized in that the advantages, such as clear force-bearing state, high soil applicability, convenient construction and high horizontal bearing capacity of the round table structure, of a single-pile foundation, are fully utilized; the overall rigidity, the horizontal load resistance, the vertical load resistance and the anti-bending capacity of the structure are greatly improved; the bending load caused by wind turbine load to the foundation can be effectively reduced; the horizontal displacement of a wind-powered generations structure is reduced; the sedimentation value is decreased. Therefore, the pile length, the pile diameter, the wall thickness and the extending depth of the pile foundation can be reduced; the material cost is greatly decreased; the construction technology is simple. The structure also has the characteristics of being resistant to corrosion, and long service life in water. The invention also discloses a method for mounting the underwater building foundation structure. The underwater building foundation structure can be mounted in an area with complex underwater condition through the method.

Owner:CHINA METALLURGICAL CONSTR HIGH TECH ENG TECH CO LTD

Processing device for rail systems in urban areas

InactiveCN111684133AReliable deliveryIncrease coefficient of frictionGrinding wheel securing apparatusGrinding machinesAbove groundFeed drive

The invention describes a processing device for rail systems in urban areas, having a travel drive (5), a processing drive (6) and a contour-defining, rotationally driven processing tool (7) mounted in a floating manner on a shaft (10) arranged in a housing (11), wherein the processing tool (7), the housing (11) and the shaft (10) are arranged on a chassis (2) having wheels (3) and can be placed by a feed drive (8) against a rail head (13) to be processed. In order to configure a device of the type described at the outset in such a way that it has a compact design such that it can be used forprocessing rail systems in urban areas both above ground and below ground, it is proposed that the processing tool (7) is of pot-shaped design and attached end-side by its base to the shaft (10), wherein the circumferential surface of the cutting edge-bearing flank of the processing tool (7) at least partially circumferentially encloses the shaft (10) and the closer-situated shaft bearing (12).

Owner:林辛格工程有限责任公司

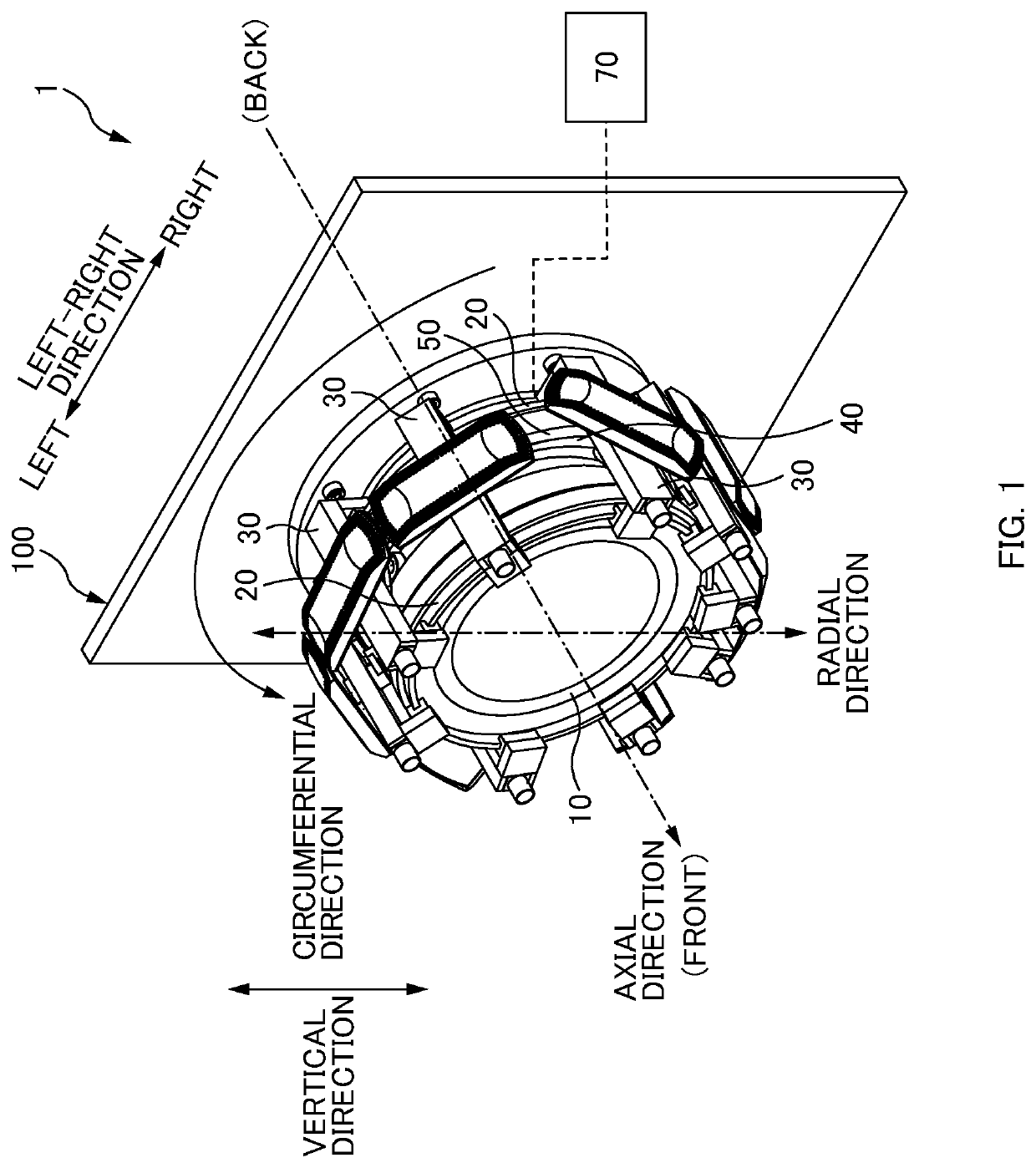

Linear-motor type transport device for transporting material for absorbent article and method for manufacturing absorbent article

ActiveUS20210104944A1Reduced moment loadLinear motor controlAbsorbent padsRotational axisEngineering

A linear-motor type transport device for transporting material for an absorbent article includes: a shaft portion that has an axial direction, a radial direction, and a circumferential direction; a pair of guide portions that is disposed on the shaft portion with a predetermined axial-direction space between the guide portions and that forms an orbital transport path that extends along the circumferential direction; a mobile unit that moves on the transport path along the guide portions while supporting a transport head rotatably about a rotation axis; a cam mechanism that rotates the transport head about the rotation axis through a predetermined angle when the mobile unit is moved on the transport path; and a controller that moves the mobile unit by supplying currents to conductors and generating a propulsive force between one of the conductors and a magnet that is disposed on the mobile unit.

Owner:UNI CHARM CORP

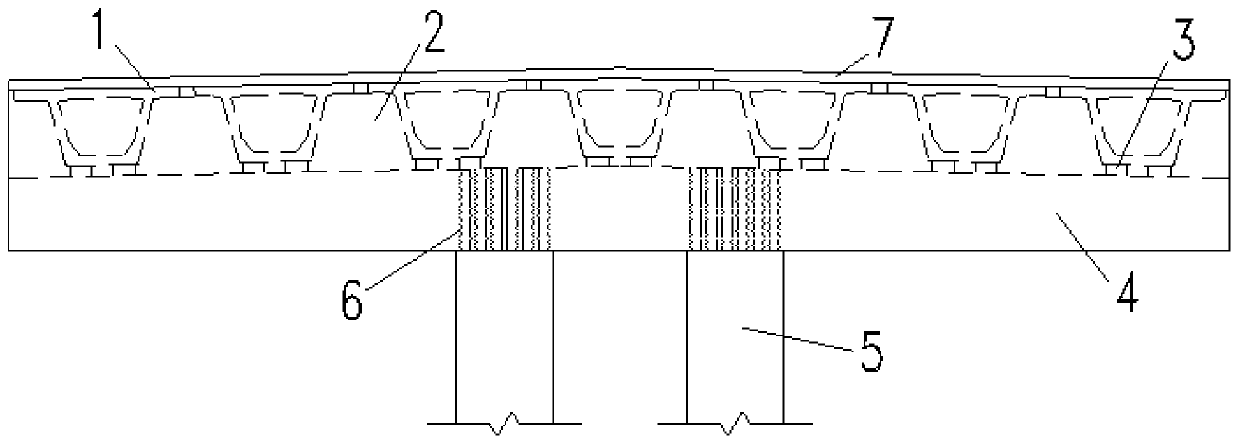

Prefabricated assembly pier and beam fixing structure and construction method thereof

PendingCN109868753AReduce weightSmall amount of workBridge structural detailsBridge erection/assemblyRebarBending moment

The invention discloses a prefabricated assembly pier and beam fixing structure and a construction method thereof. The prefabricated assembly pier and beam fixing structure comprises girders, prefabricated pier columns and a bent cap. The bent cap comprises an upper layer cast-in-place structure and a lower layer prefabricated structure. Multiple welding reinforcing steel bars arranged on the upper layer cast-in-place structure are connected with corresponding girder longitudinal main ribs of the two girders located on the two sides of the bent cap. The position, correspondingly connected witheach prefabricated pier column, of the lower layer prefabricated structure is provided with multiple parallel vertically-arranged metal corrugated pipes. Each prefabricated pier column comprises multiple vertically-arranged pier column main ribs. The upper ends of the multiple pier column main ribs extend upwards out of the upper faces of the corresponding prefabricated pier column. The extend-out portions of the multiple pier column main ribs are matched with the multiple metal corrugated pipes. In the installation process, each pier column main rib penetrates through the corresponding metalcorrugated pipe. The bending moment load of each pier bottom in the bridge axis direction is reduced, the weight of the prefabricated bent cap is greatly reduced, and the requirements for local transportation and elevating capacity can be easily met.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

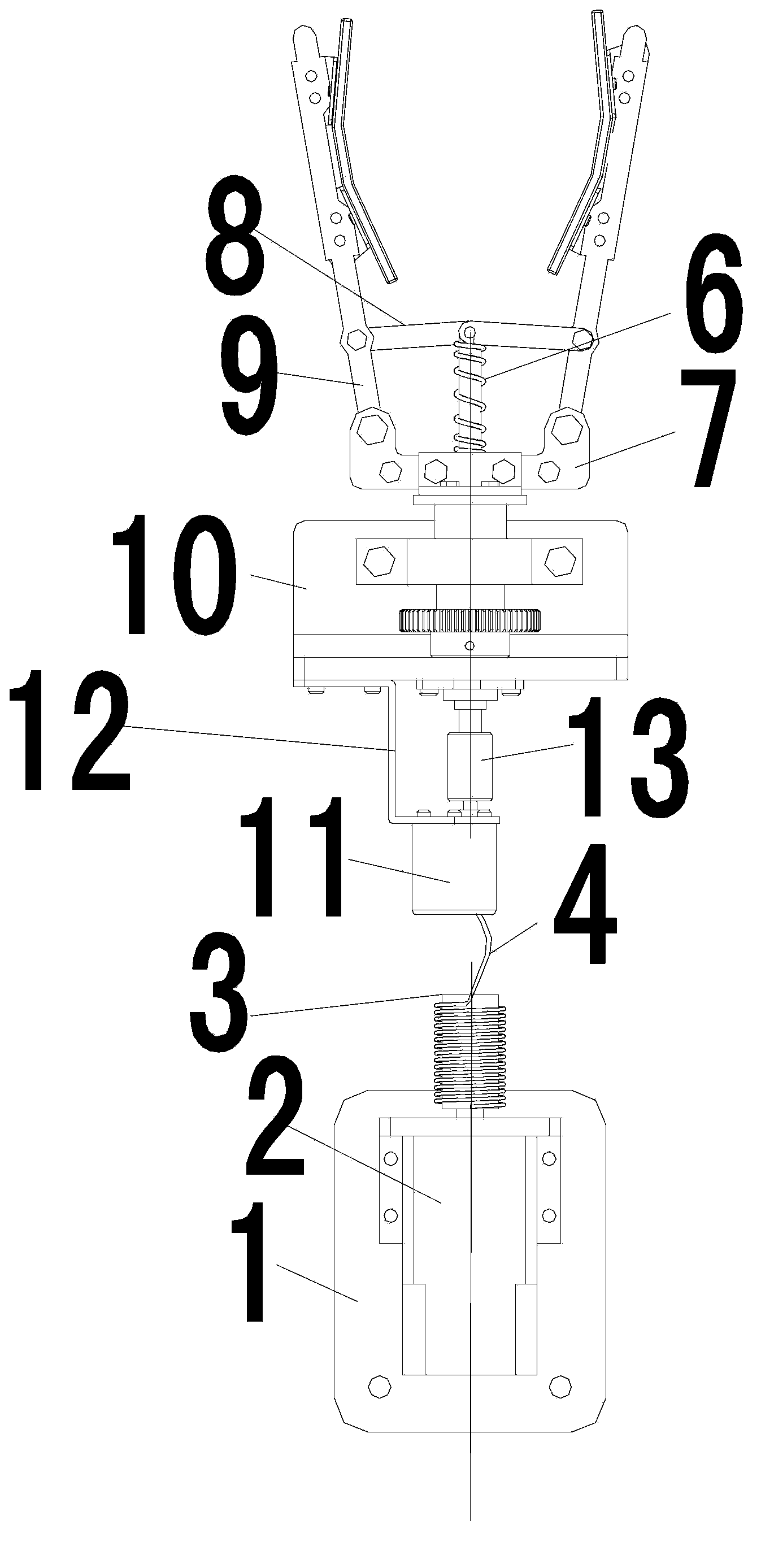

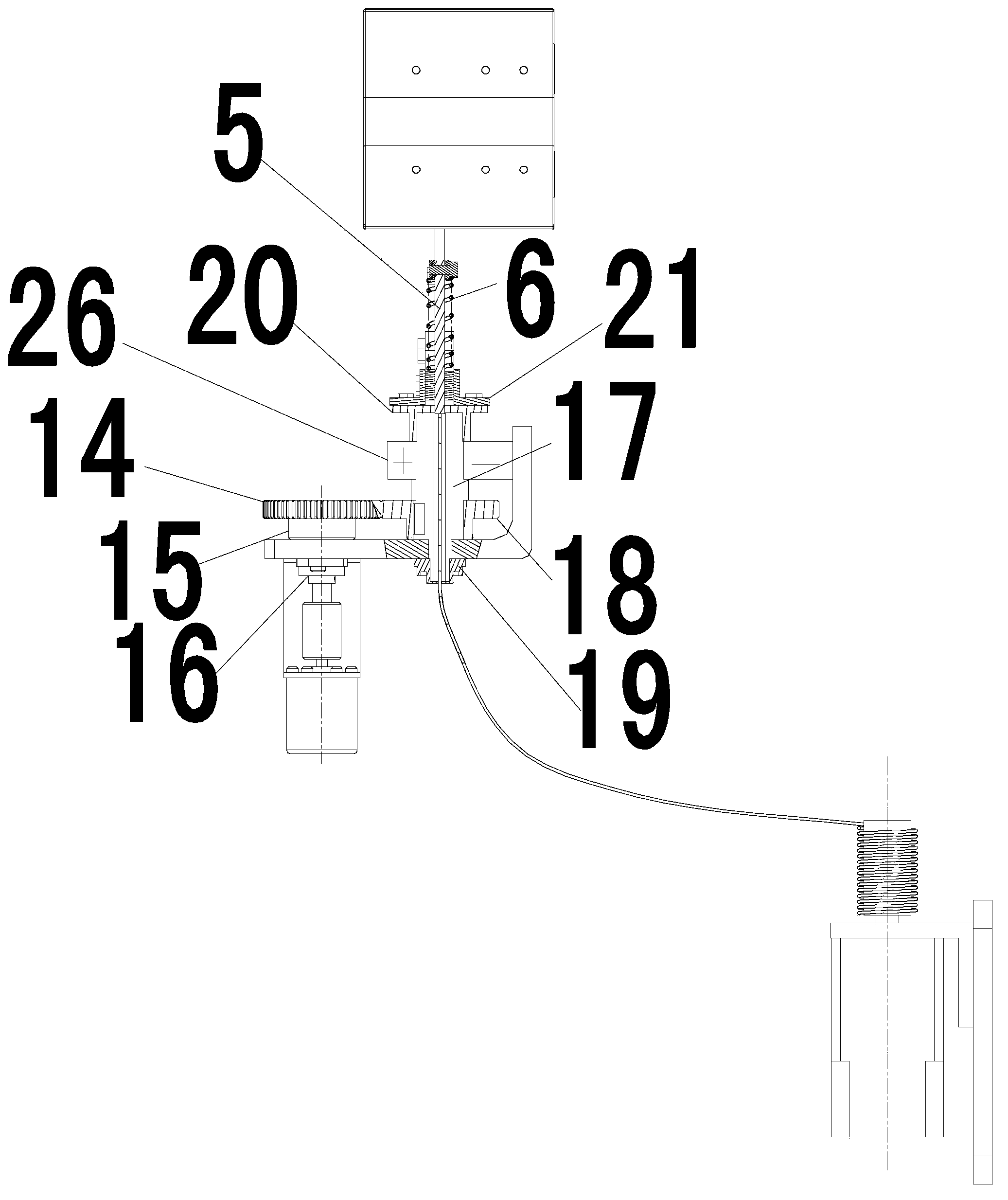

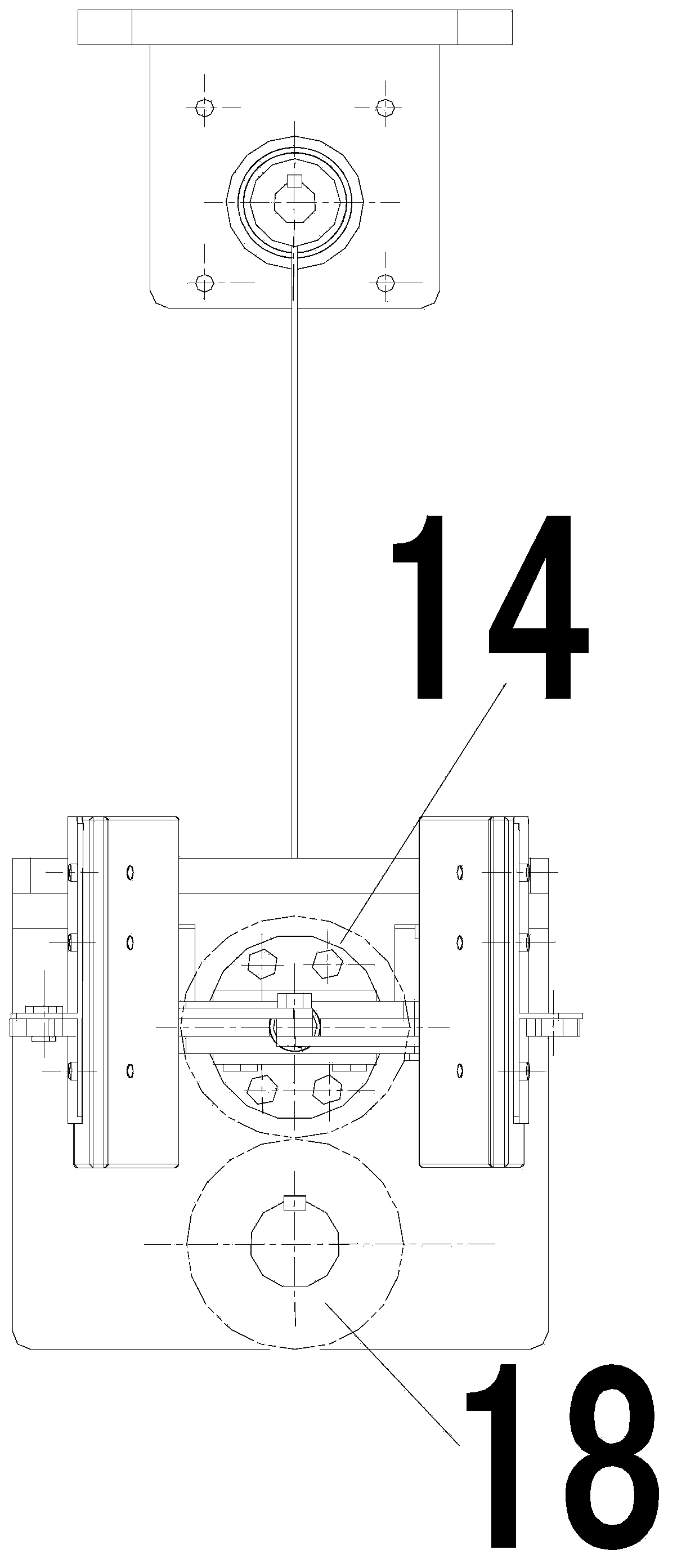

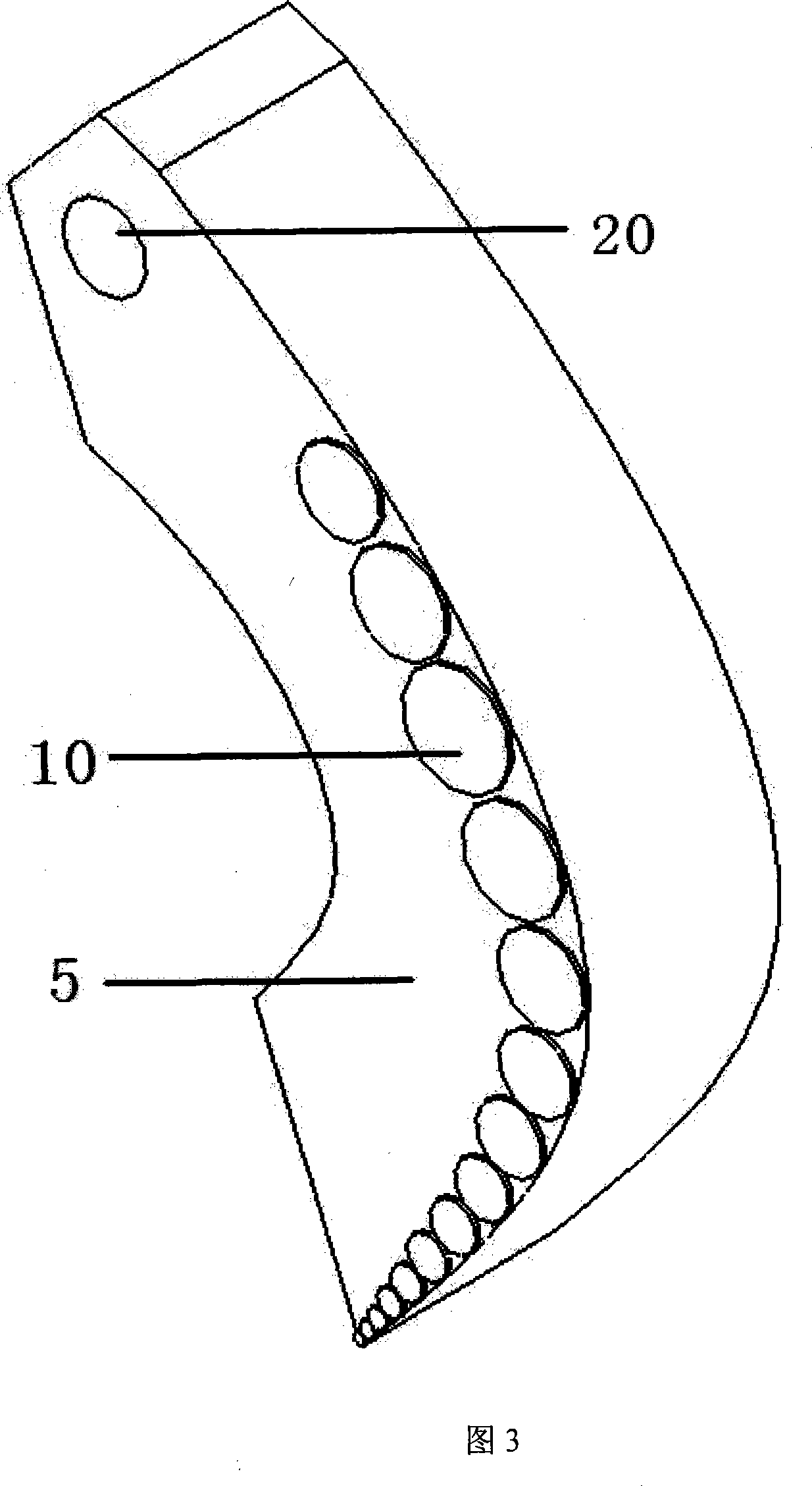

Picking actuating mechanism used at tail end of pineapple picking mechanical arm

ActiveCN102907213BTorsional Separation AchievedRealize the clamping effectHarvestersEngineeringUltimate tensile strength

Owner:SOUTH CHINA AGRI UNIV

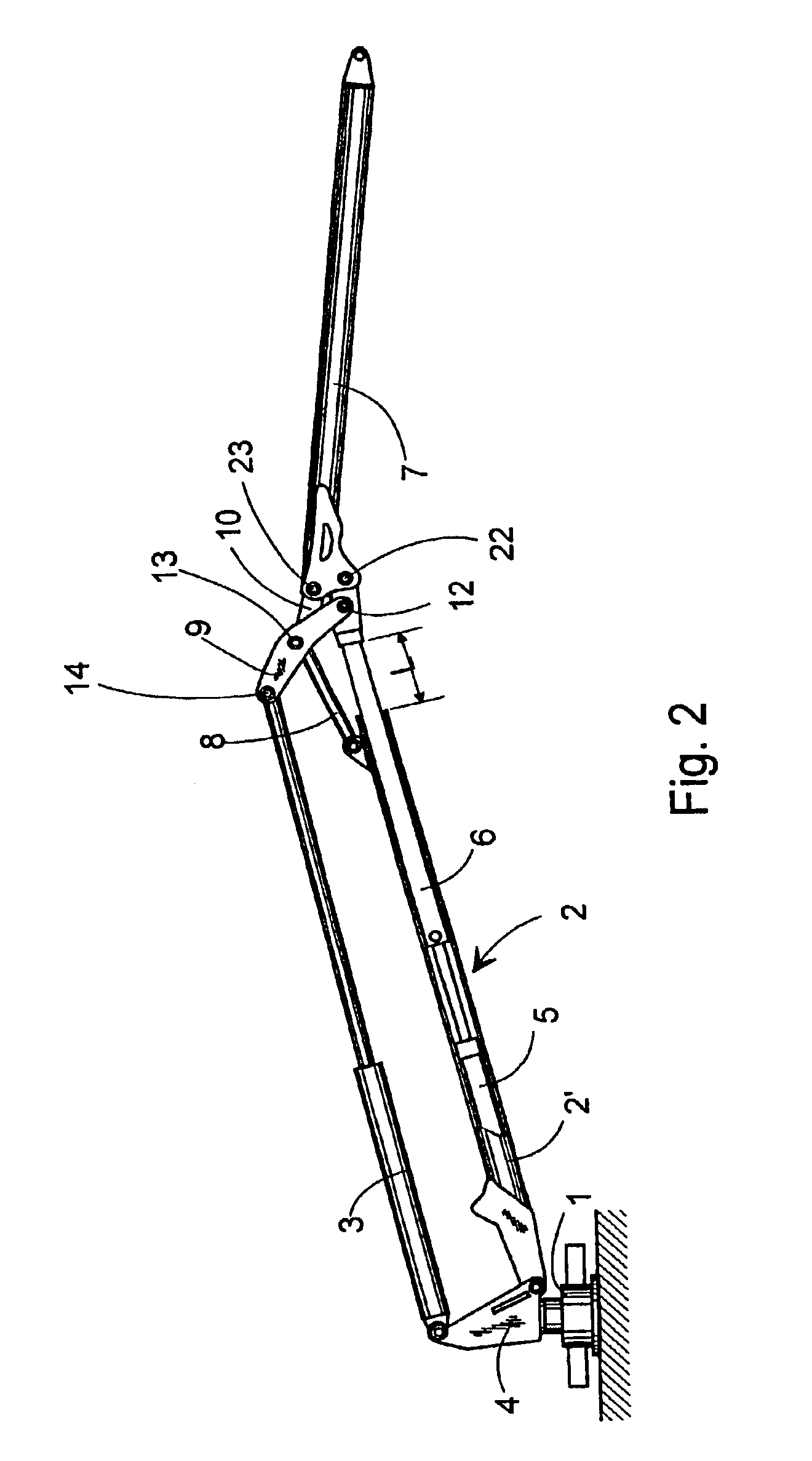

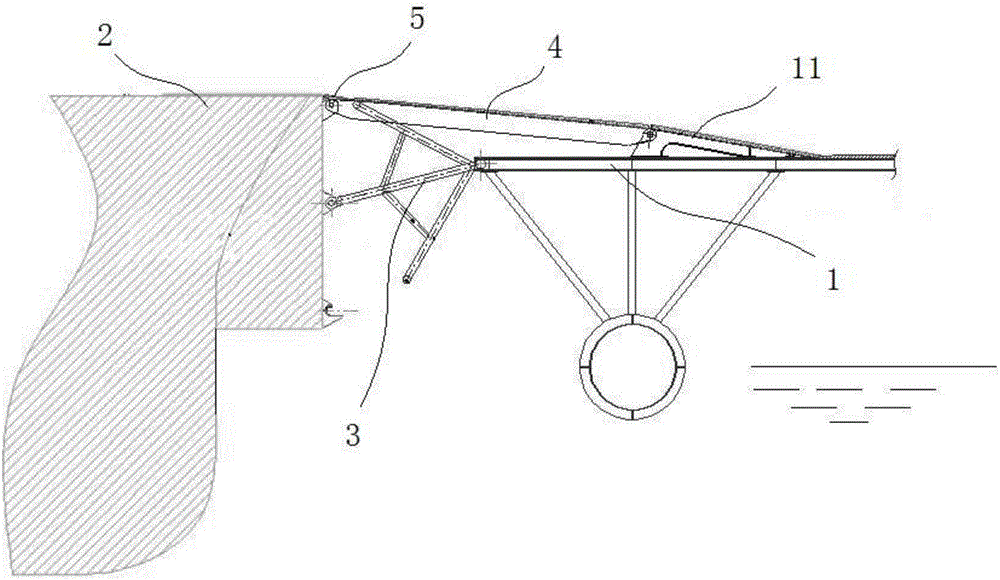

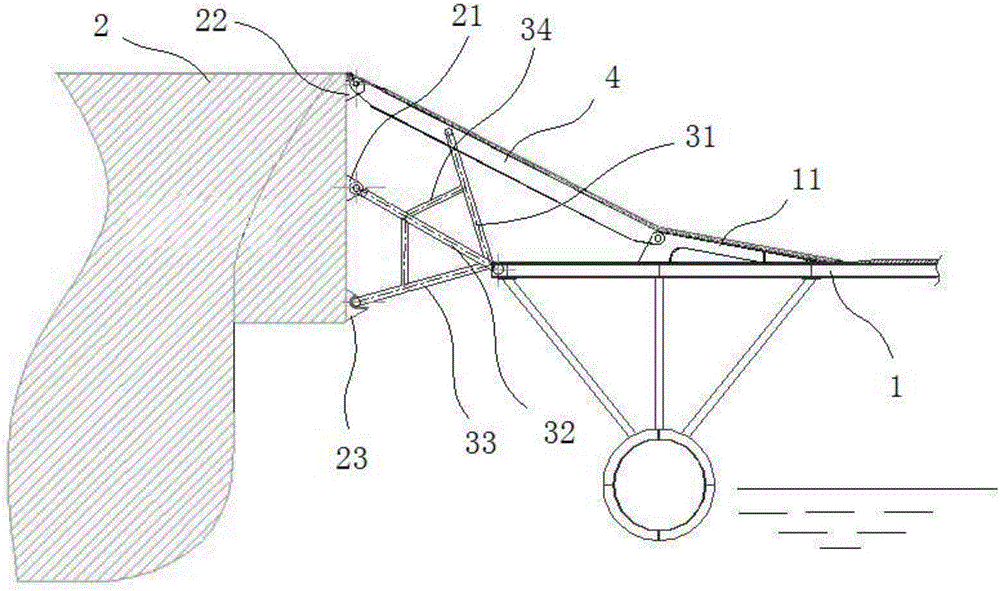

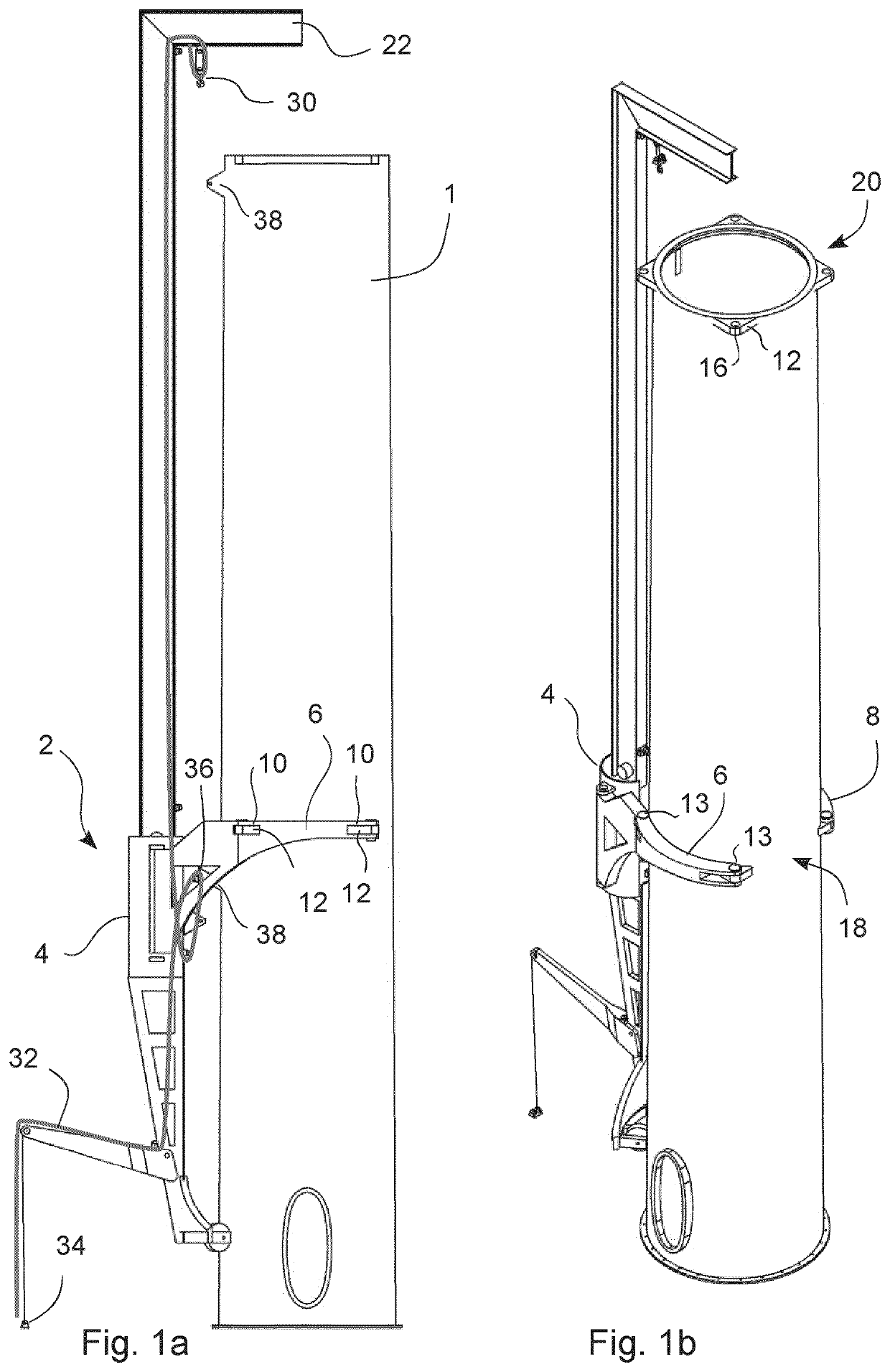

Wind turbine tower with crane connection elements and a crane with tower flange connection elements

PendingUS20220235739A1Simple wayGuarantee support safetyEngine manufactureWind motor assemblyClassical mechanicsEngineering

A crane (2) comprising a base portion (4), two arms (6, 8) displaceably connected to the base portion and a lifting boom (22) displaceably connected to the base portion, said lifting boom being provided with a lifting wire (32) and a lifting member (30), for example a lifting hook, for lifting a load, wherein the two arms and the base portion in combination comprise at least three tower flange connection element (10) is arranged to be detachably connectable to cooperating crane connection elements on a flange of a wind turbine tower section, wherein each arm comprises one of the tower flange connection elements, and wherein the vertical distance between any two tower flange connection elements in the normal operating position of the crane is less than 1 m, less than 50 cm or less than 25 cm. In this way a crane is provided which can be attached to a flange located at the upper portion of a tower section.

Owner:ELEVATORRA IP APS

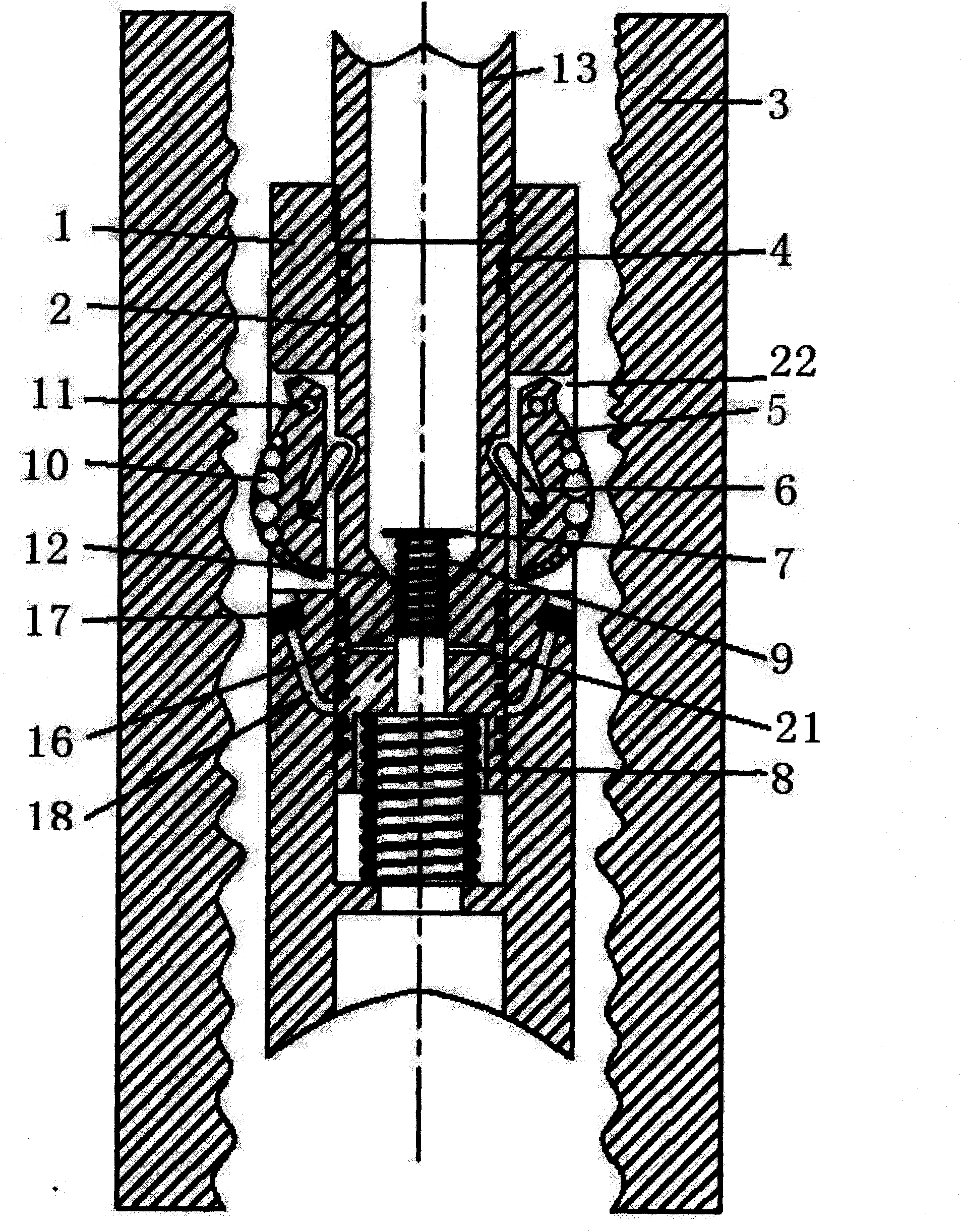

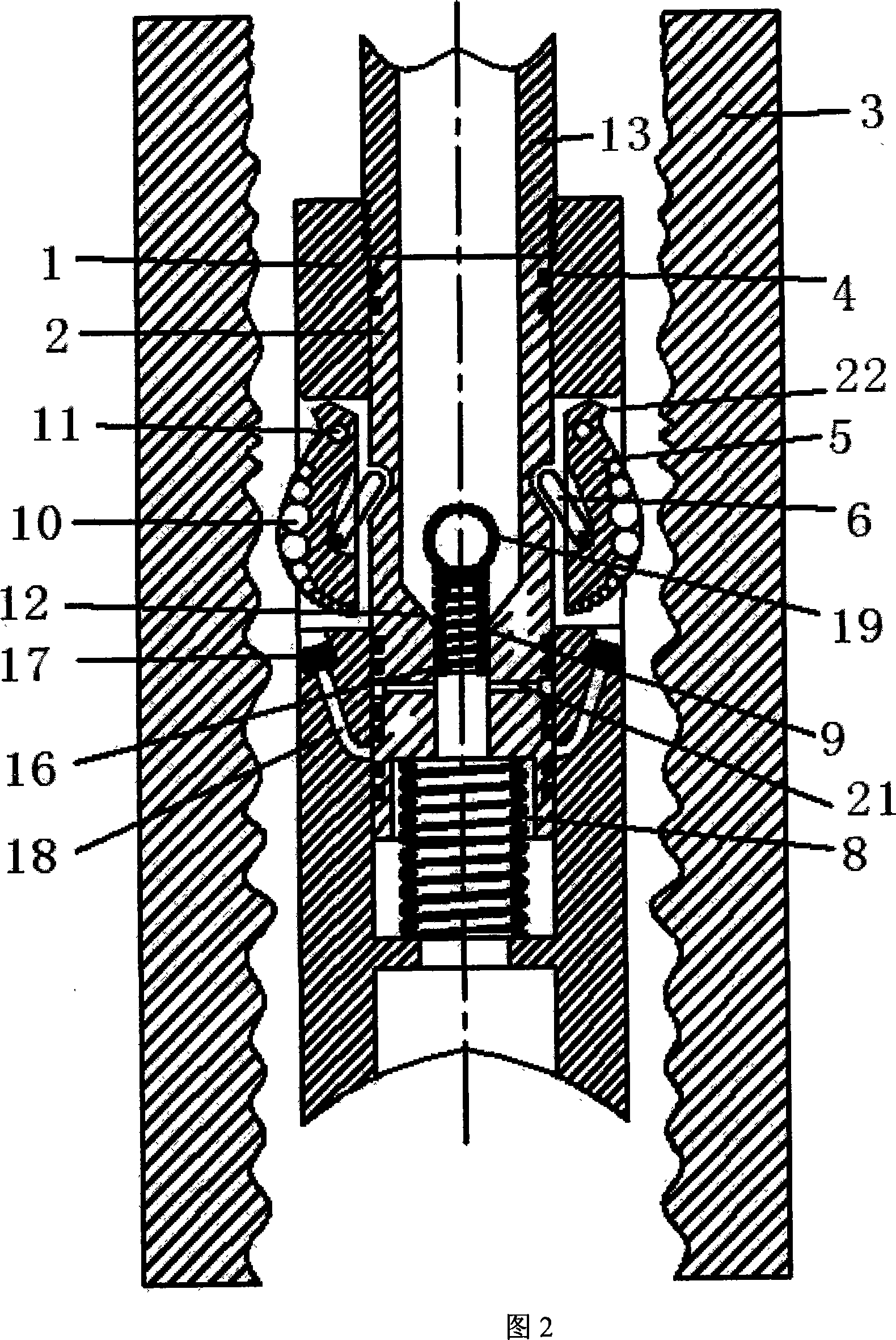

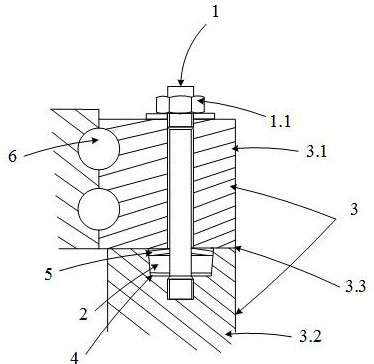

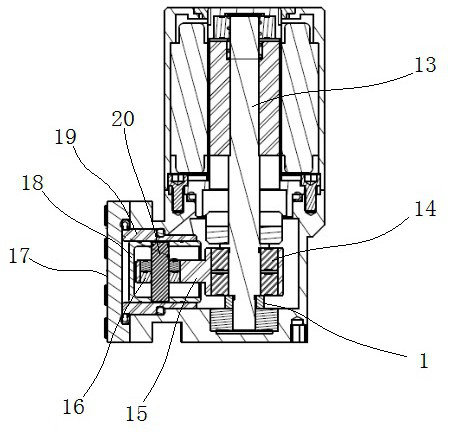

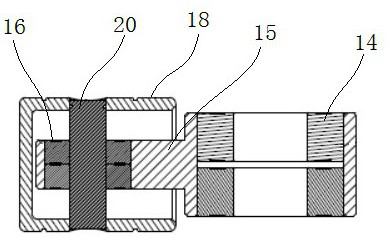

Hydraulic double-acting drilling reamer

The invention relates to a drilling hole reamer with hydraulic double effect used in well drilling of petroleum and natural gas, comprising a central tube, a body, a knife wing, a valve flake, a spring, a bend, a nozzle, a sealing ring, a crank and a cutting teeth. The body is connected with a drill stem by a thread connection. The technical proposal is that: the knife is embedded outside the body and is connected with the body by a pin roll connection; the central tube is arranged in the body; an overflow opening and the valve flake are arranged in the central tube and connected together by a spring. Under normal displacement work condition, overflowing area between the valve flake and the overflowing opening is large; the overflowing area is reduced when the displacement is enlarged andthe central tube is driven to downlink by differential pressure, and the knife wing is open to work by the crank arranged on the knife wing, at the moment the cutting tooth is cleaned by partial slurry passing through the bend; when the displacement is reduced, the central tube is driven to uplink by thrust of the bottom spring and then the knife wing is reset. The drilling hole reamer with hydraulic double effect used in well drilling of petroleum and natural gas has the advantages of simple structure, high functional reliability, less loss of pressure consumption, balance load of the knife wing, usage along with the drilling or the single and usage in well drilling construction of a bore hole wall with reducing diameter, collapsing block or blocking well condition.

Owner:SOUTHWEST PETROLEUM UNIV

Article transport facility

ActiveUS9896283B2Increase the amount of cuttingWeight increaseSemiconductor/solid-state device manufacturingLoading/unloadingEngineeringTransport facility

An article transport facility includes a support member capable of supporting a second support component from below while allowing a vertical movement of a first support component with respect to the second support component, in a projected state in which the second support component is located in a projected position. The support member is supported directly or indirectly by a ceiling.

Owner:DAIFUKU CO LTD

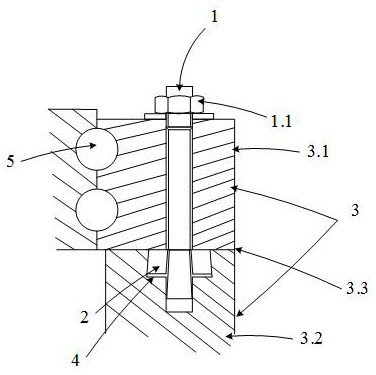

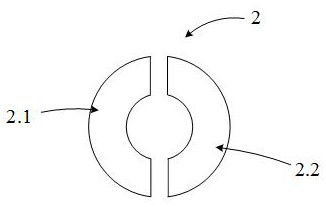

Anti-bending bolt connecting device for wind generating set and mounting method

ActiveCN114576244AImprove reliabilityReduced moment loadSheet joiningScrewsStress concentrationScrew thread

The invention discloses an anti-bending bolt connecting device for a wind generating set and a mounting method. The bolt connecting device is composed of a bolt, a tightening piece and a connected piece. The number of the connected pieces is at least two, and bolt holes are reserved in the connected pieces. The tightening piece is of a split structure and is composed of at least two parts. And the tightening piece can wrap part of a screw rod of the bolt. At least one connected piece is provided with a stepped hole, the stepped hole is composed of a large-diameter taper hole and a small-diameter hole, the small-diameter hole is a part of a bolt hole, and the tightening piece can be placed in the large-diameter taper hole. The tightening piece is arranged in the large-diameter taper hole, deformation of a part of a polished rod of the bolt after the polished rod is loaded is limited, then the action of a bending moment load borne by a protected thread is greatly reduced, and bolt connection becomes more reliable after stress concentration is eliminated.

Owner:BEIJING SANLI XINNENG SCI & TECH

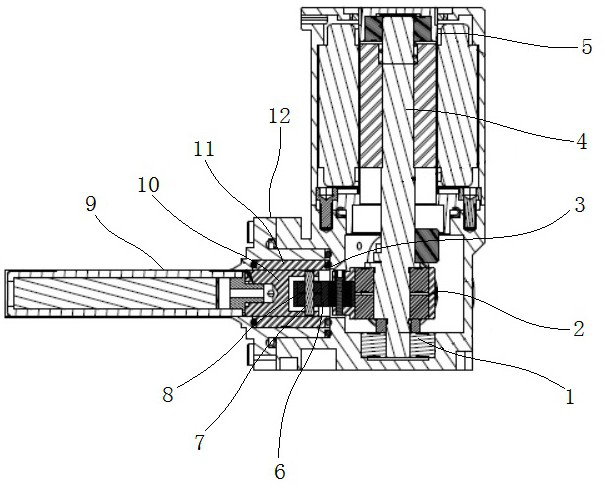

Ultra-miniature rotary integral Stirling cryocooler

PendingCN113390197AReduce axial heightReduce volumeCompression machinesGas cycle refrigeration machinesElectric machineEngineering

The invention provides an ultra-miniature rotary integral Stirling cryocooler. The ultra-miniature rotary integral Stirling cryocooler comprises a base, a compression assembly, a pushing assembly, a rotor assembly and a stator assembly, the rotor assembly comprises a motor rotor and an eccentric rotating shaft, and an eccentric part of the eccentric rotating shaft extends into the base; and the compression assembly is in transmission connection with the eccentric rotating shaft through a compression connecting rod, one end of the pushing assembly is connected with the side face of the compression connecting rod, and the movement axes of the compression assembly and the pushing assembly are located on the same horizontal plane. According to the ultra-miniature rotary integral Stirling cryocooler, the compression assembly and the pushing assembly are connected with the eccentric rotating shaft through the compression connecting rod, the movement axes of the compression assembly and the pushing assembly are located on the same horizontal plane, the axial height of the cryocooler is effectively reduced, therefore, the size of the cryocooleris reduced, the problems that an existing integral Stirling cryocooler is tedious in structure, large in size and heavy in mass are solved, the movement direction of the compression assembly and the movement direction of the pushing assembly are located on the same horizontal plane, the bending moment load of the rotating shaft is reduced, and the system reliability is improved.

Owner:WUHAN GAOXIN TECH

An ipc control method for reducing vibration and load in the left and right direction of wind power tower

ActiveCN110439747BReduced moment loadStable output powerWind motor controlWind motor supports/mountsImpellerActuator

The invention discloses an IPC control method for reducing side-side direction vibration and load of a wind power tower barrel. According to the method, a side-side direction acceleration signal of anunbiased engine room is compared with a target value of the side-side direction acceleration signal of the engine room after being filtered by a notch filter and a band-pass filter, the deviation ofthe side-side direction acceleration signal and the target value is processed by a PI controller to obtain a given value of a d-axis variable pitch speed in a dq rectangular coordinate system, and thegiven value of the q-axis variable pitch speed is set in advance; the given value of the d-axis variable pitch speed and the given value of the q-axis variable pitch speed are subjected to integral operation to obtain a given value of a d-axis variable pitch position and a given value of a q-axis variable pitch position respectively; the PI controller is used for acquiring a given value of a uniform pitch position in a power generation mode of a wind generating set, and an absolute value encoder is used for acquiring an azimuth angle of an impeller in the power generation mode of the wind generating set; and through the Park inverse transformation from the dq rectangular coordinate system to a rotating coordinate system, the given values of the variable pitch positions of three blades areobtained, and finally implemented by a variable pitch actuator. The method can effectively reduce the first-order natural frequency vibration and load of the tower barrel in the side-side direction.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Vertical shaft tidal current generating set

InactiveCN101988463BEasy to startImprove power generation effectFinal product manufactureMachines/enginesImpellerComputer module

The invention provides a vertical shaft tidal current generating set. The vertical shaft tidal current generating set comprises three modules, namely an upper layer platform part, a supporting frame part and an impeller part, wherein the upper layer platform part mainly comprises a generator, a gear box, a horizontal connecting shaft, a supporting platform, a supporting column and a vertical connecting shaft; the supporting frame part is formed by connecting an upper frame plate, a lower frame plate, a left frame plate and a right frame plate; and the impeller part comprises a main shaft, a spoke sleeve, a spoke, a spoke shaft, a blade, a blade shaft, a wheel disk and an adaptive attack angle control device. The invention provides the high-performance vertical shaft tidal current generating set, which has high starting and generating performances and high structural strength, can be developed towards large-scale direction, can be used below a floating platform and above a pile base and a tension leg, is convenient to produce, manufacture, install and debug, and is suitable for engineering application.

Owner:HARBIN ENG UNIV

Earth working machine whose working apparatus is displaceable out of its operating position using an onboard actuator

ActiveUS20180340300A1Avoiding orReduced moment loadMilling machinesLarge fixed membersOperating pointActuator

An earth working machine (10) encompasses a machine body (13) having a machine frame (12) and a drive configuration (46), rotationally drivable relative to the machine frame (12) around a drive axis (A) that defines an axial direction, that extends along the drive rotation axis (A) from an introduction longitudinal end (46a) at which the drive configuration (46) is embodied for introduction of a drive torque to a functional longitudinal end (46b) located axially oppositely from the introduction longitudinal end (46a), and to which configuration a working apparatus (32) embodied for earth working is releasably connected in torque-transferring fashion, in an operating position, for rotation together around the drive axis (A), such that when the connection is released, the working apparatus (32) is removable from the operating position in an axial direction relative to the drive configuration (46) for deinstallation from the drive configuration (46) and, for installation on the drive configuration (46), is conveyable into the operating position in an axial direction relative to the drive configuration (46), an actuator (65) being provided which is embodied to move the working apparatus (32) out of the operating position when the connection is released.According to the present invention, provision is made that an actuator housing (62) of the actuator (65) is provided on the drive configuration (46) for movement together therewith, at a position that is located closer to the functional longitudinal end (46b) than to the introduction longitudinal end (46a), an actuator member (63) of the actuator (65) being movable relative to the actuator housing (63).

Owner:WIRTGEN GMBH

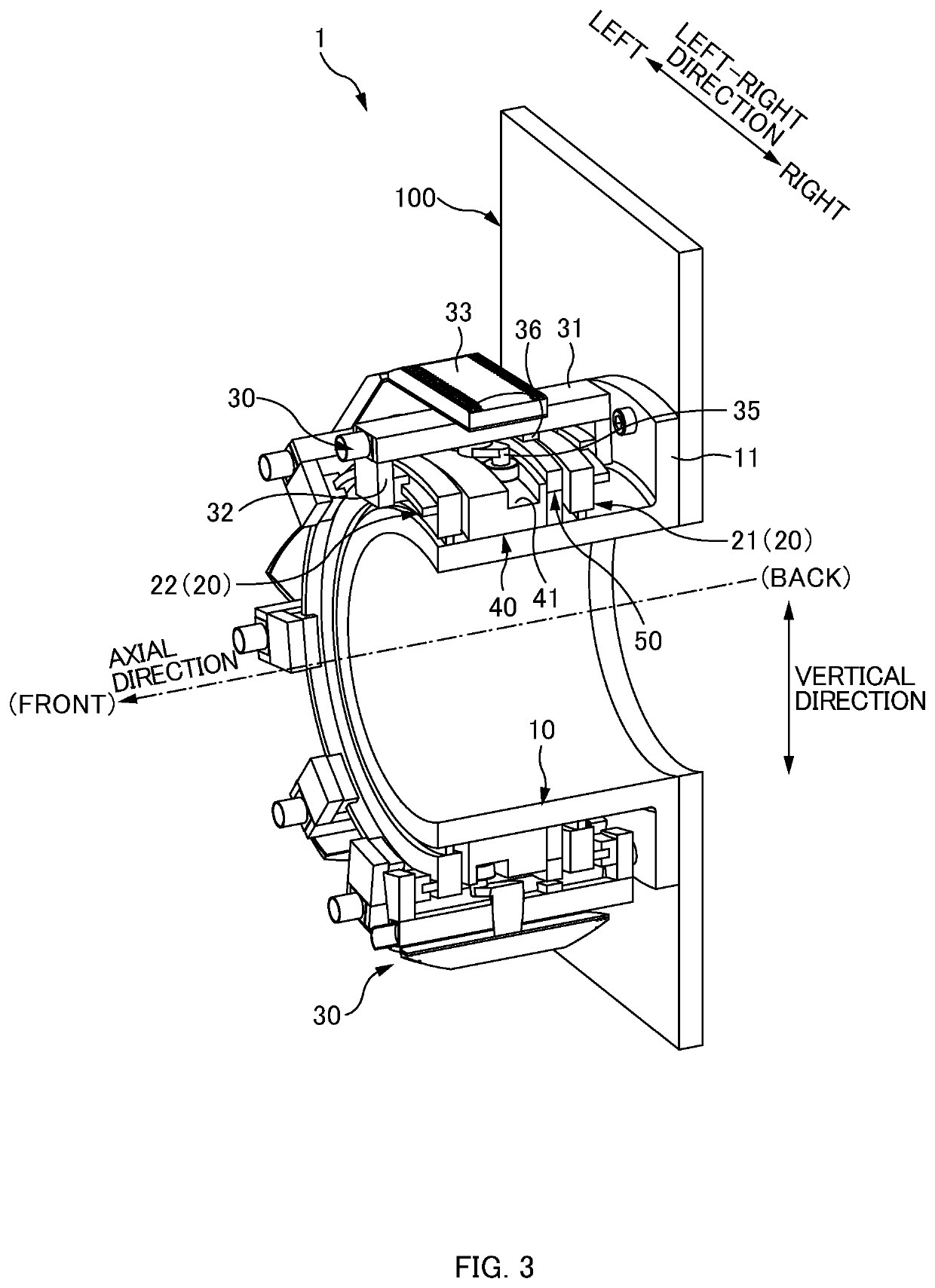

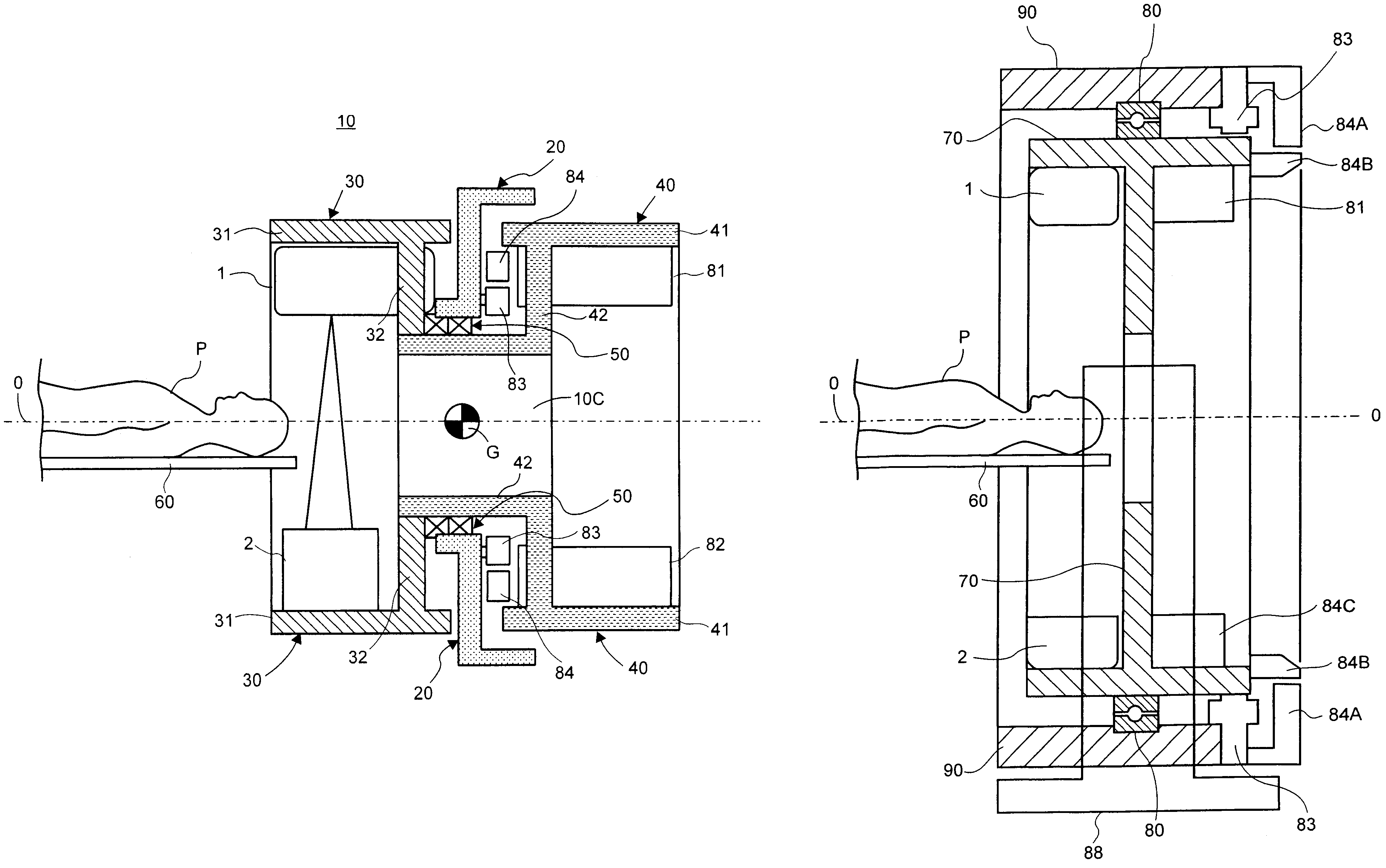

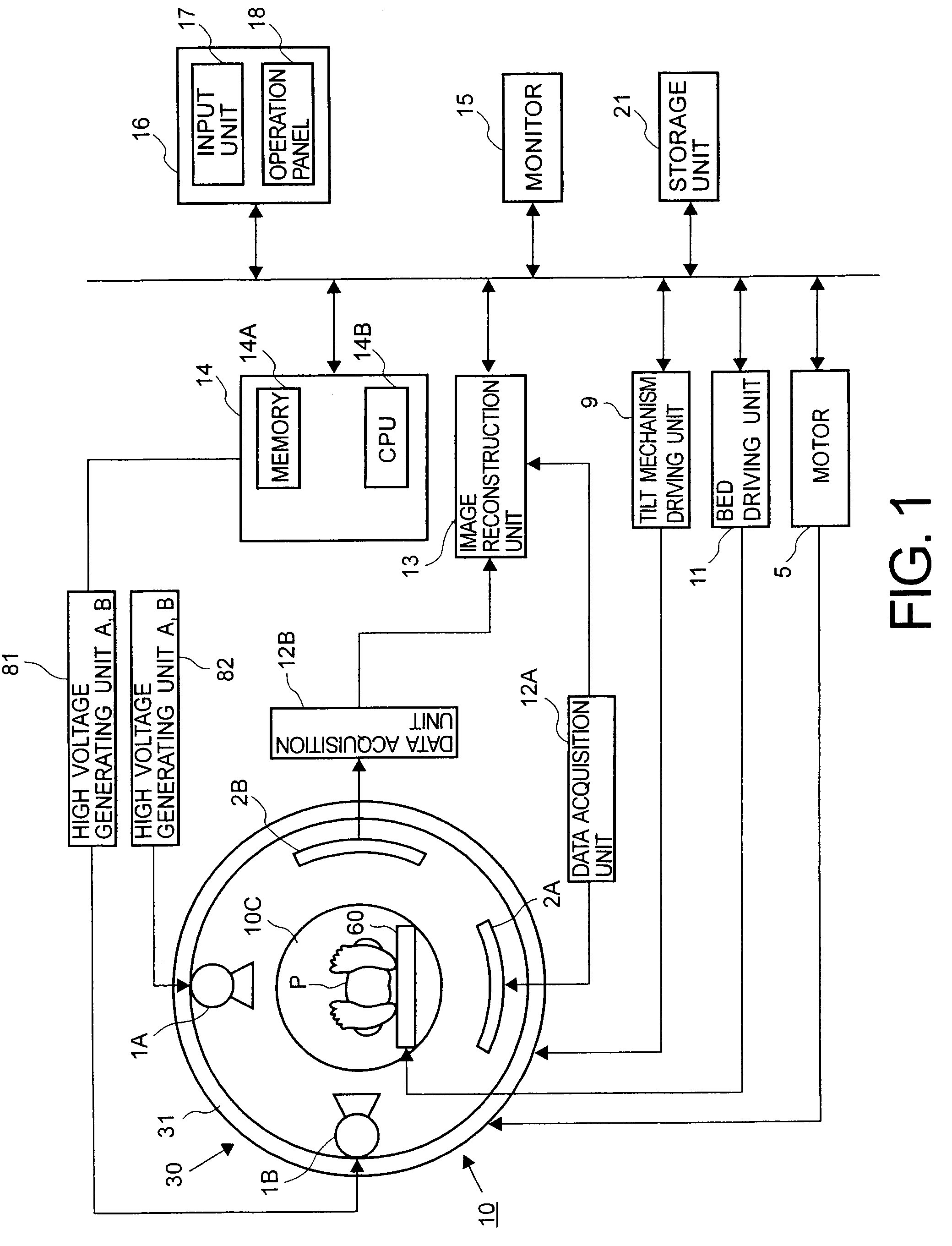

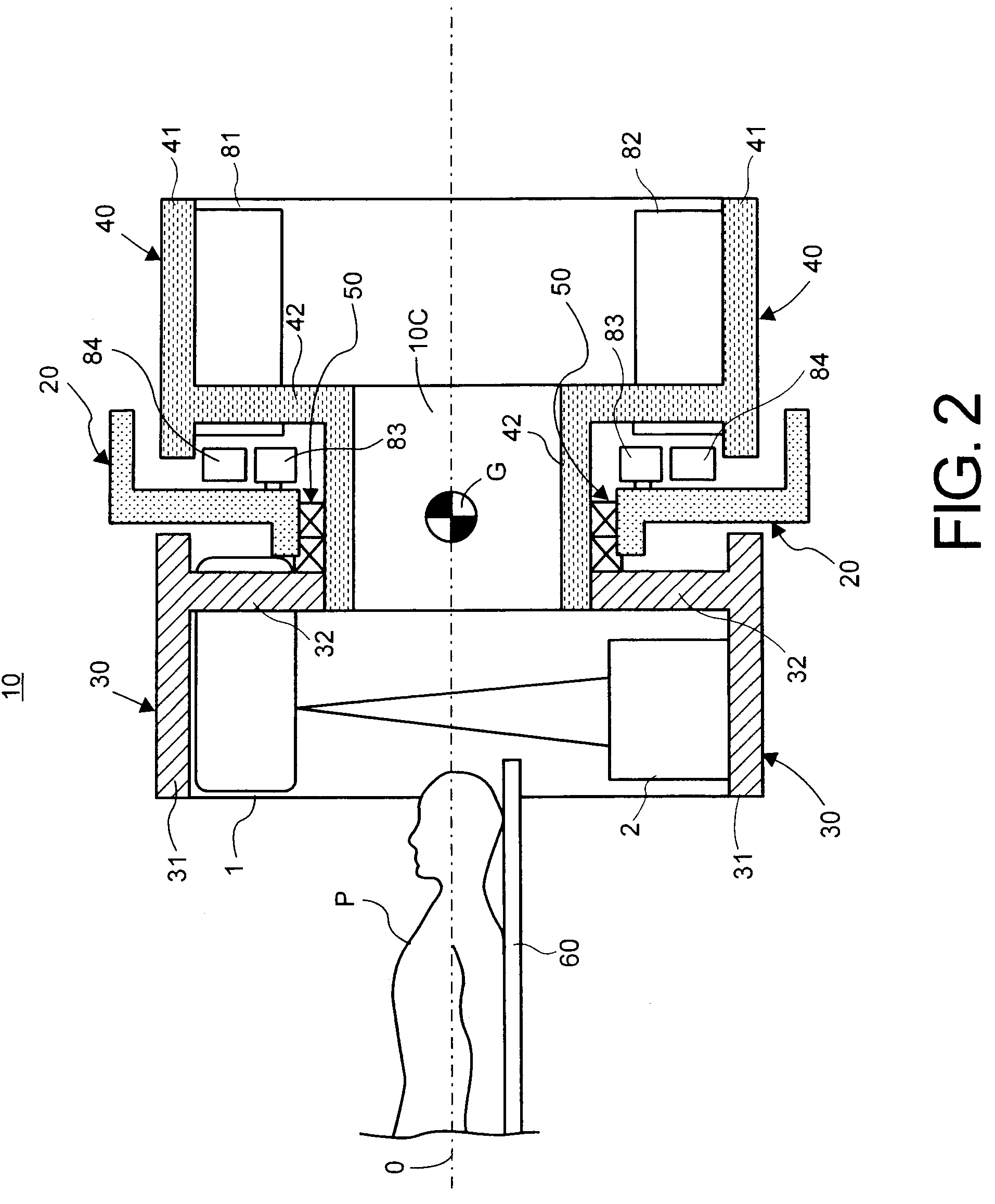

X-ray CT apparatus

InactiveUS7623619B2Reduced moment loadProlong lifeMaterial analysis using wave/particle radiationRadiation/particle handlingX-rayPhysics

An X-ray CT apparatus that achieves a higher quality of reconstructed CT images by preventing displacements of relative positions of the X-ray tube and the X-ray detector from occurring, including a front side rotation frame configured to mount at least one X-ray tube and at least one X-ray detector facing the X-ray tube, and a rear side rotation frame configured to mount rotation units other than the X-ray tube and the X-ray detector in order to access both sides of the gantry.

Owner:TOSHIBA MEDICAL SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com