Prefabricated assembly pier and beam fixing structure and construction method thereof

A prefabricated assembly and prefabricated structure technology, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problem of large bending moment at the bottom of the pier, the bending resistance of the top of the pier is not used, and the dead weight of the cover beam exceeds the local transportation and lifting capacity, etc. problems, to achieve the effect of reducing weight and reducing the amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

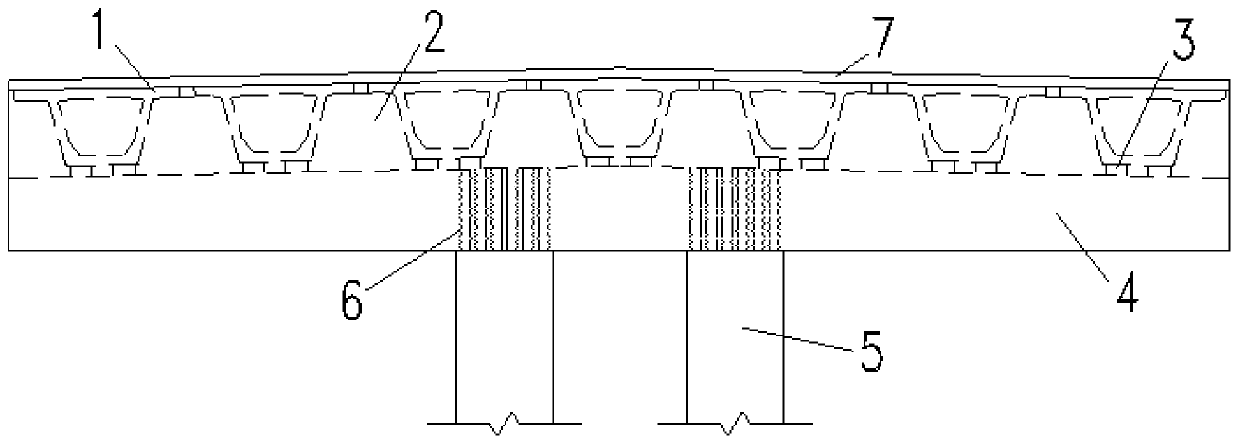

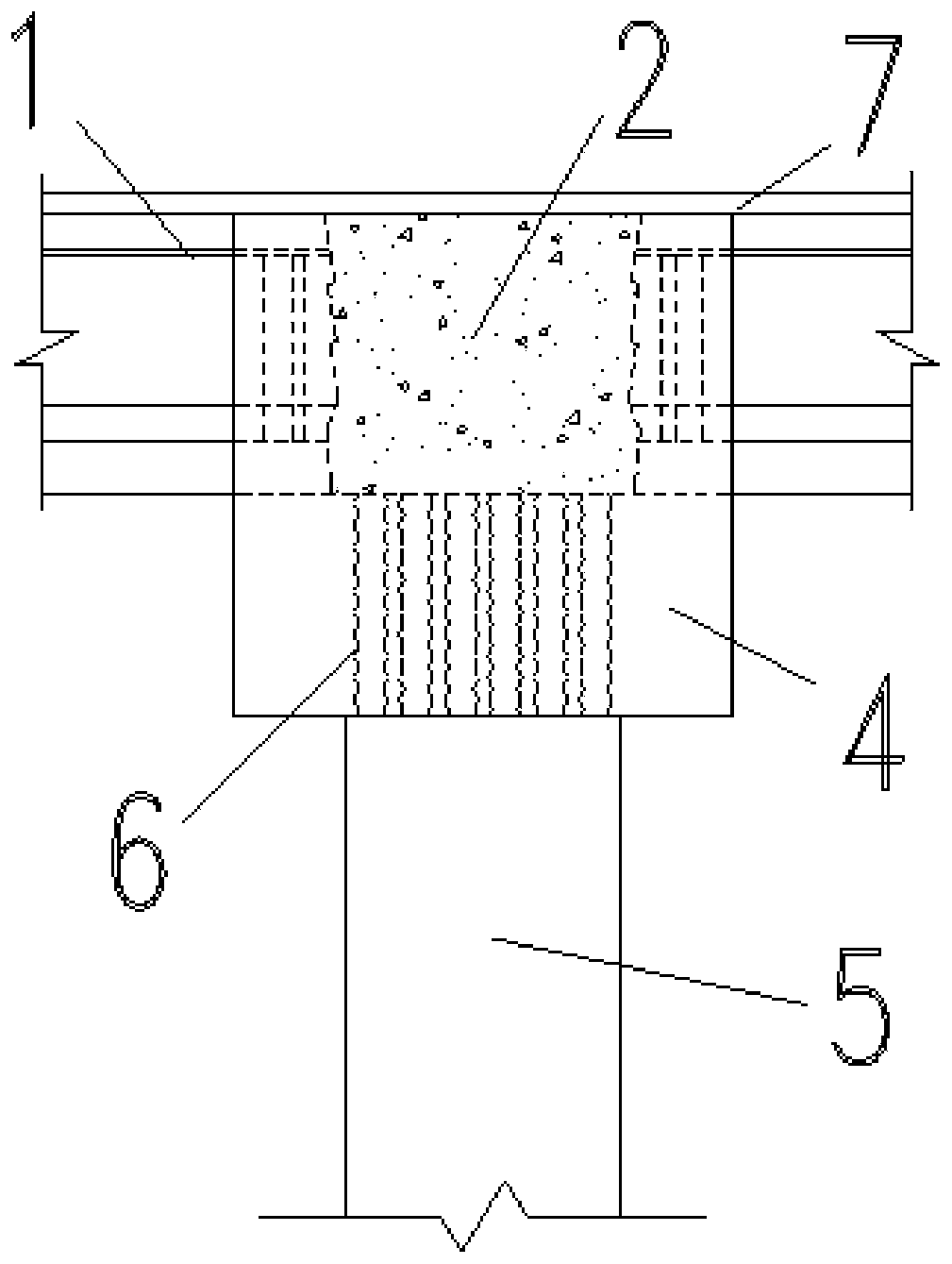

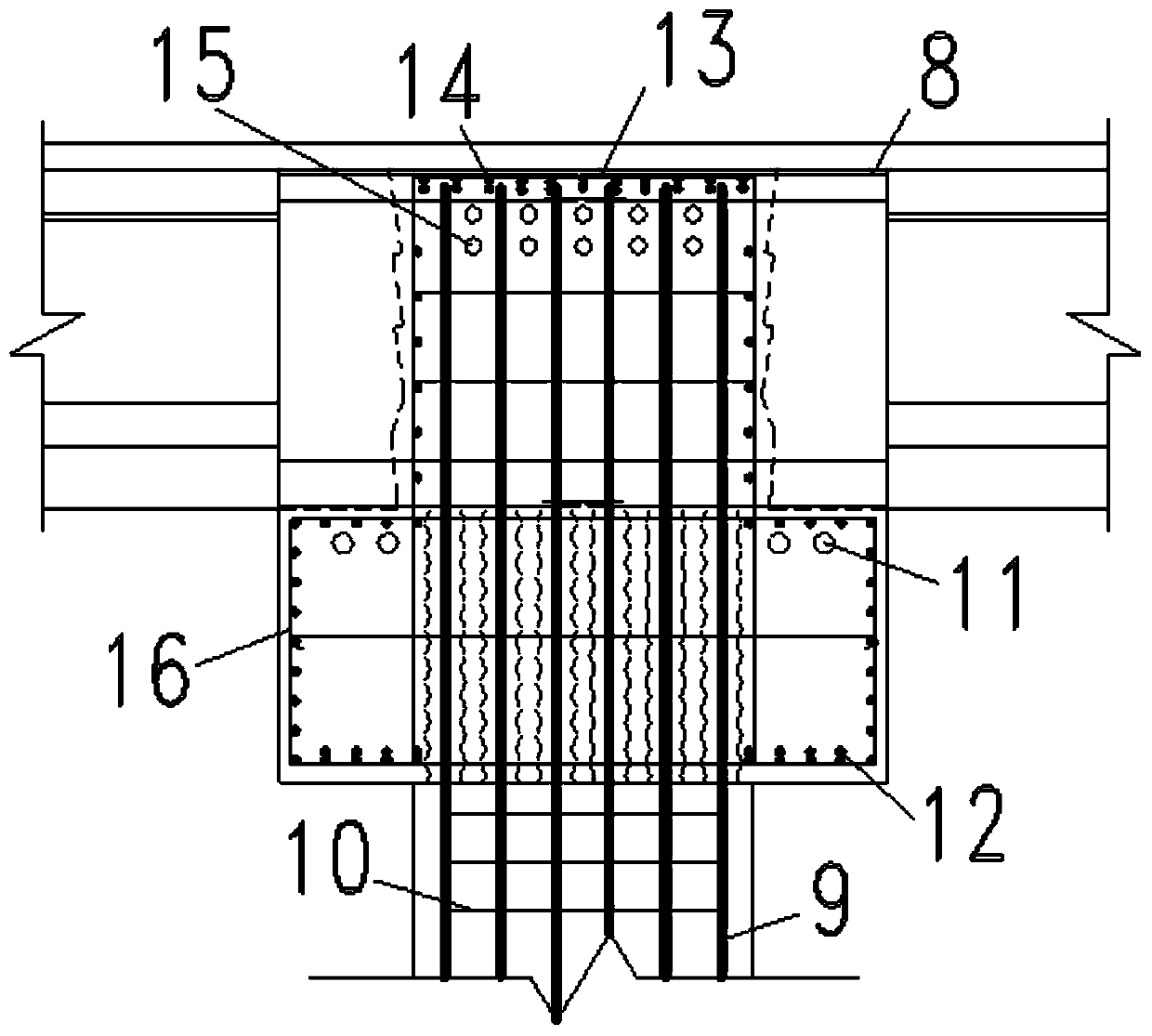

[0037] Such as Figure 1 to Figure 3 As shown, the prefabricated assembled pier beam consolidation structure includes a main beam 1 and a prefabricated pier column 5, and a cover beam is provided between the main beam 1 and the prefabricated pier column 5.

[0038] Among them, the cover beam includes the upper cast-in-place structure 2 and the lower prefabricated structure 4;

[0039] The upper cast-in-place structure 2 is provided with several welded steel bars 13 along the length direction;

[0040] The two ends of several welded steel bars 13 are respectively connected with the corresponding main beam longitudinal main bars 8 of the two main beams 1 located on both sides of the cover beam;

[0041] The lower prefabricated structure 4 is provided with a plurality of metal bellows 6 parallel to each other and arranged vertically corresponding to the positions connected to each prefabricated pier column 5;

[0042] Each prefabricated pier column 5 includes several pier colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com