Patents

Literature

52 results about "Wide bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

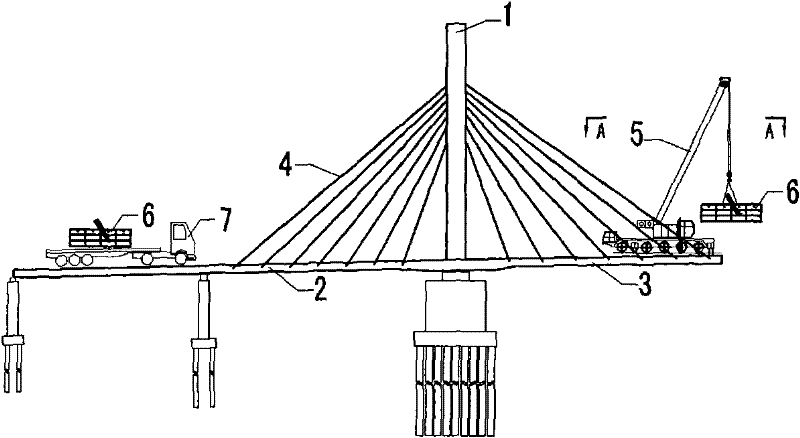

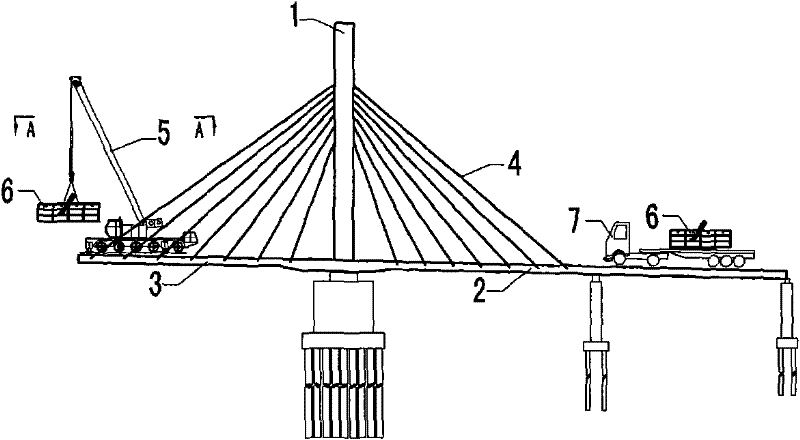

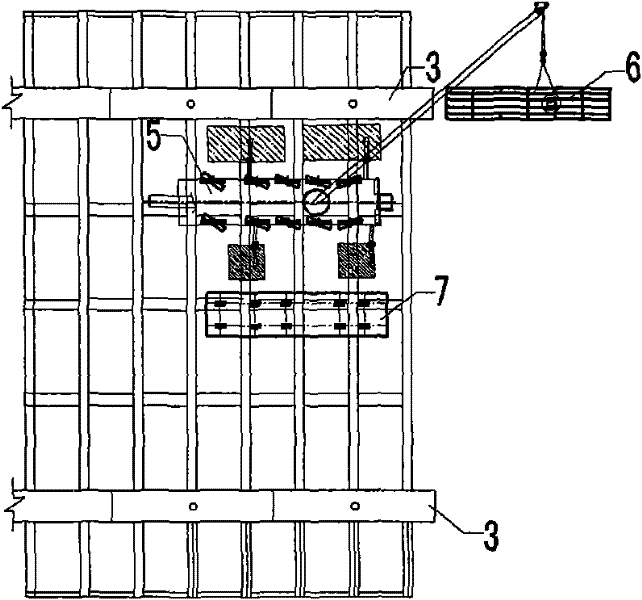

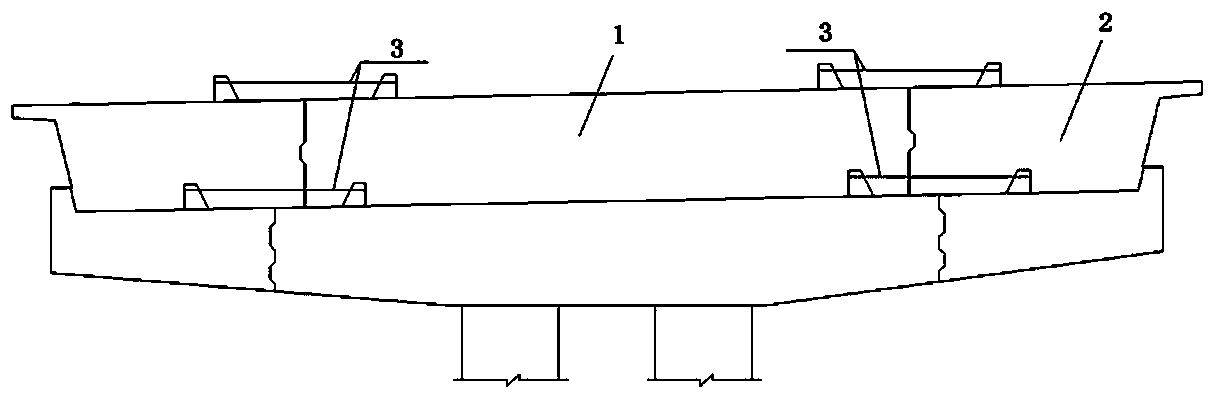

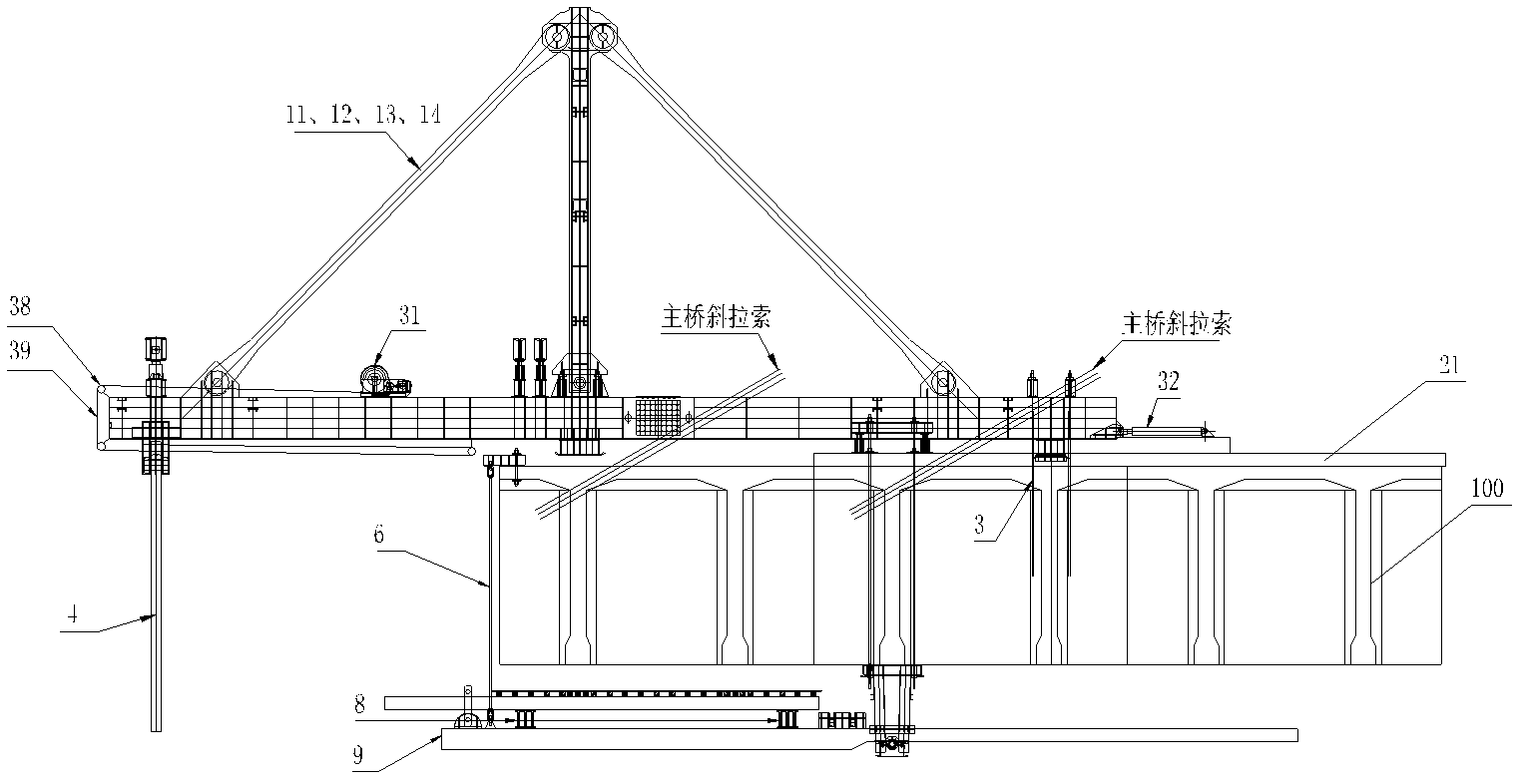

A new construction method of hybrid combined beam cable-stayed bridge

InactiveCN102286935AEliminate assemblyEliminate the hassle of disassemblyBridge erection/assemblyCable stayedBridge deck

The invention relates to a brand-new construction method of a mixed combined girder cable-stayed bridge. After the construction of the main tower, auxiliary piers, side piers, main bridge side span concrete beams and approach bridges, the mid-span steel girder members and prefabricated concrete decks of the cable-stayed bridges are transported from the ground via the approach bridges and main bridge side spans to Midspan. The truck crane also moves from the ground through the approach bridge and the side span of the main bridge to the front end of the completed combined beam in the mid-span, and lifts the components on the girder truck for cantilever construction. The bridge is hung with stay cables and tensioned for the first time. Construct the wet joints of the bridge deck, form the mid-span combined beam of this section, and repeat the construction until the main structure of the cable-stayed bridge is completed, and the bridge deck and the auxiliary structure of the main tower are constructed. The invention adopts the automobile crane, which can adapt to the construction of the wide bridge, and is convenient and flexible in use, and saves labor;

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

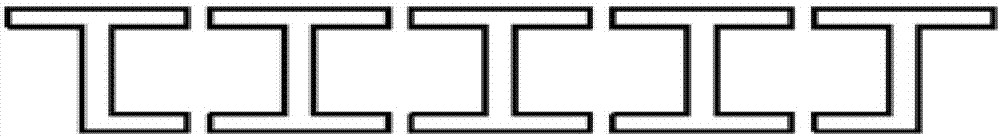

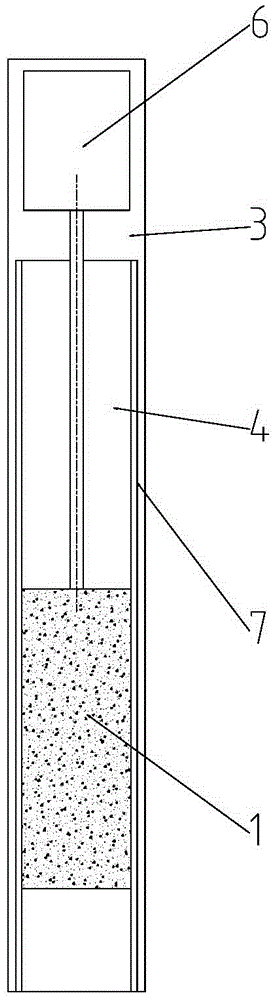

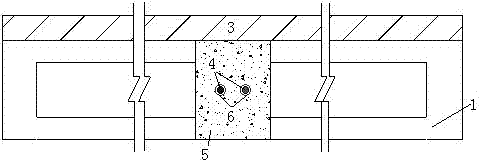

Segmental cantilever assembly pier capping beam and assembling method thereof

PendingCN108774948AReduce weightReduce the impactBridge structural detailsBridge erection/assemblyMiniaturizationCantilever

The invention discloses a cantilever segment assembly pier capping beam suitable for rapid safety site construction. The cantilever segment assembly pier capping beam suitable for rapid safety site construction is characterized in that the capping beam is spliced by using a plurality of precast capping beam segments along the length of the capping beam; joints between the adjacent precast cappingbeam segments are in the forms of bracket type vertical splicing joints; shear keys are arranged on the end surfaces of the capping beam segments on the two sides of the joints; epoxy adhesives are coated on the end surfaces of the precast capping beam segments; and the adjacent precast capping beam segments are bonded by using the epoxy adhesives. The cantilever segment assembly pier capping beamusing the assembling method is beneficial for promoting miniaturization and light weight of precast assembly members; the transporting and hoisting difficulty is reduced; under an equivalent transporting and hoisting condition, more wide bridge capping beams can be constructed in a precast assembly manner so that the construction cost is reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

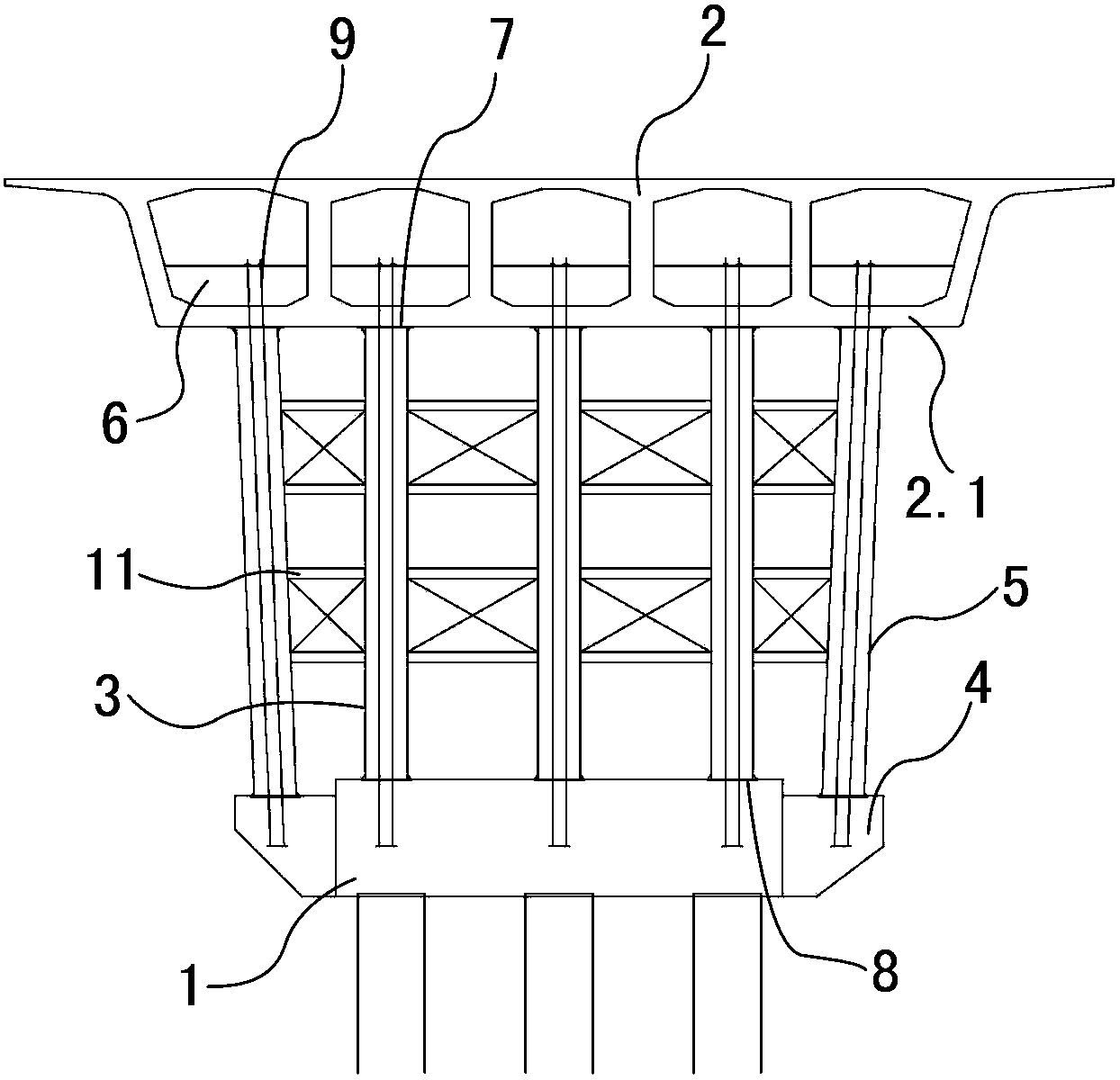

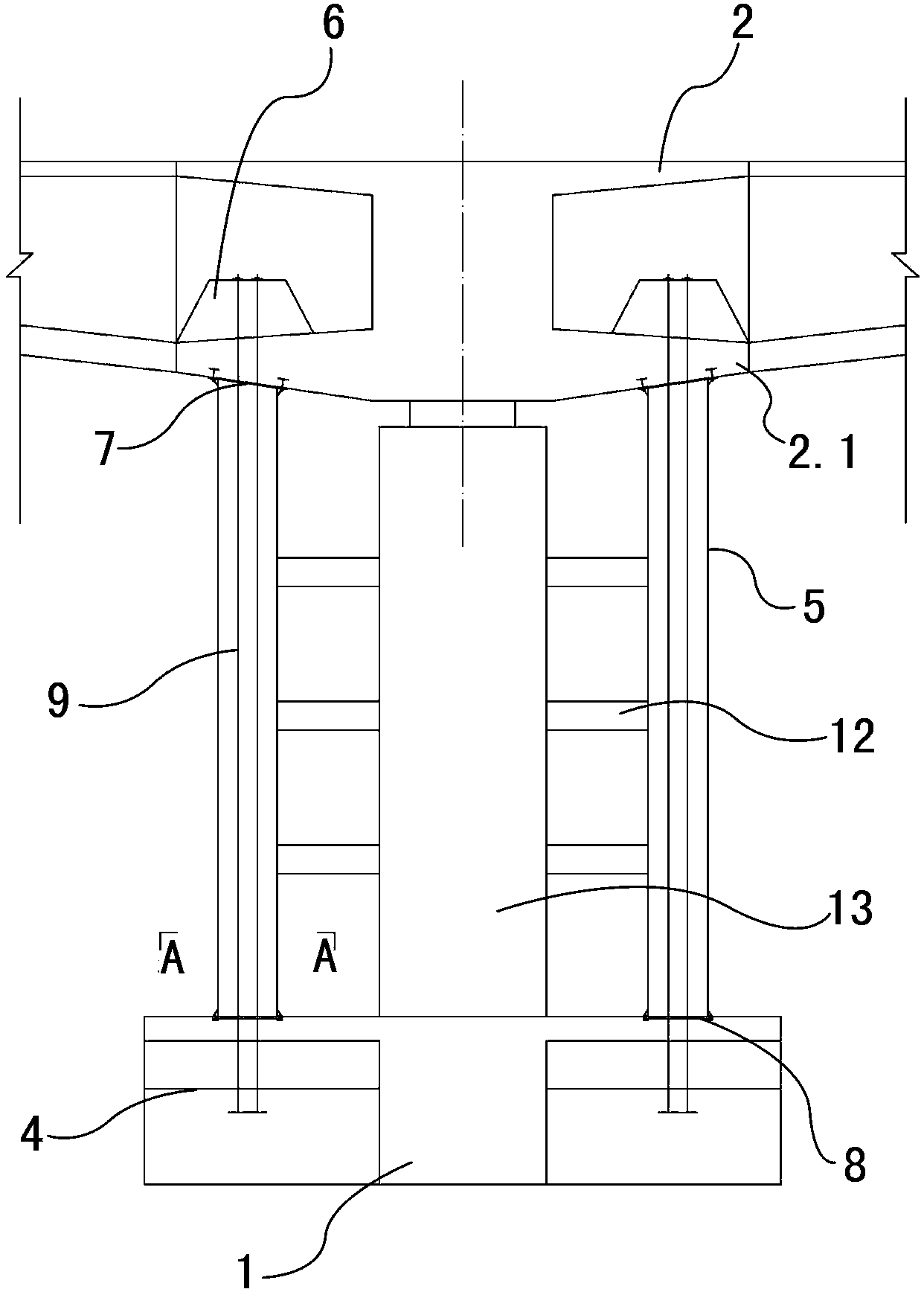

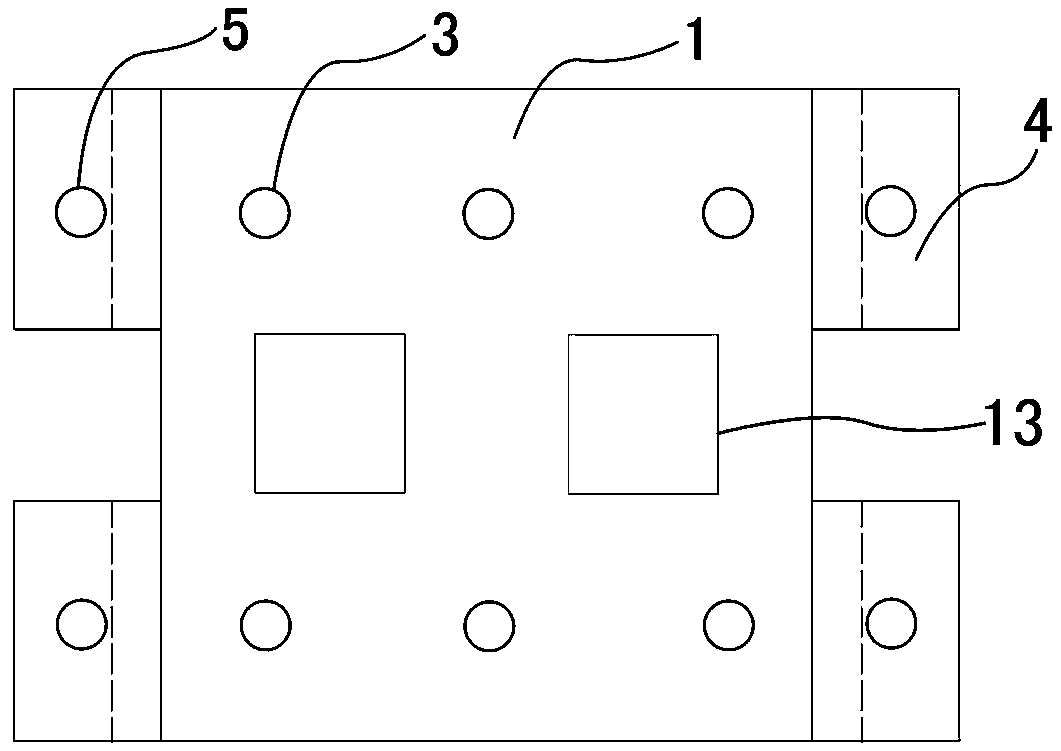

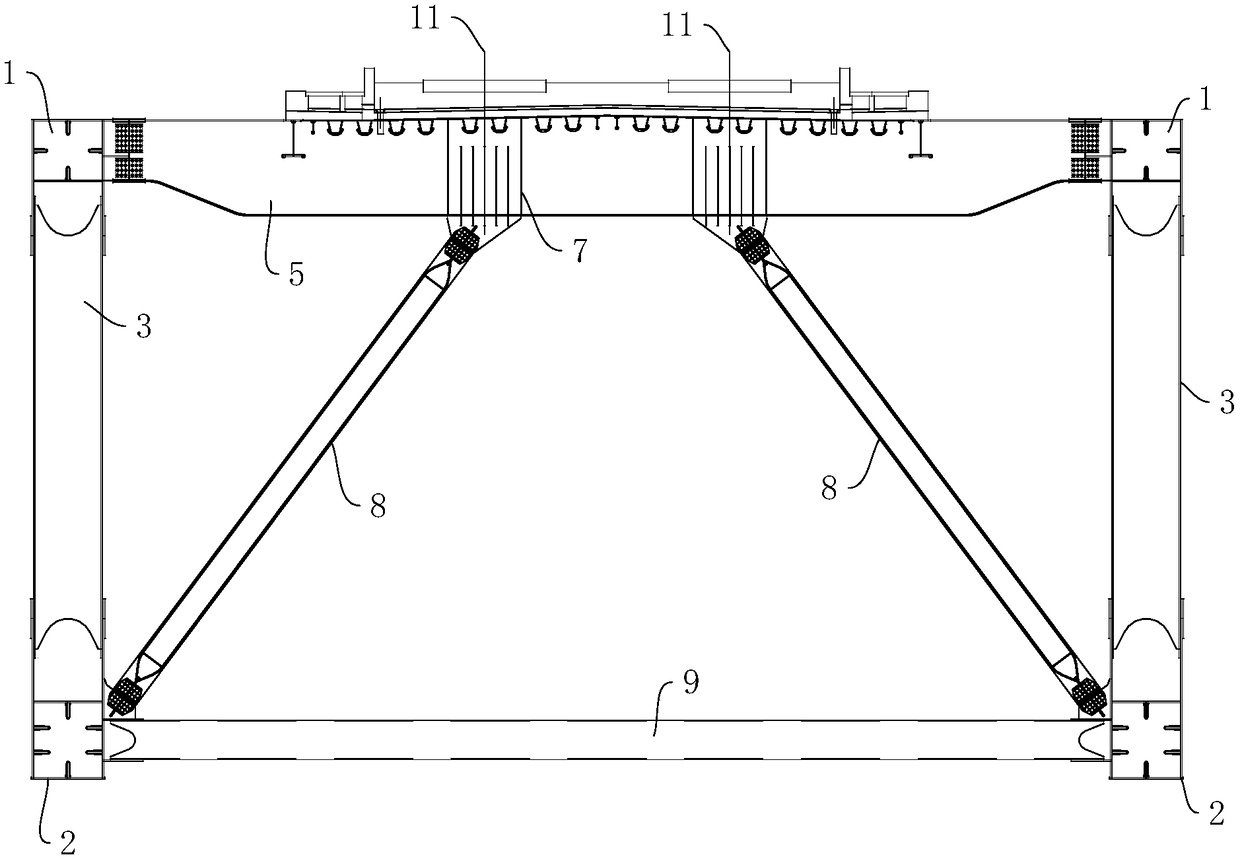

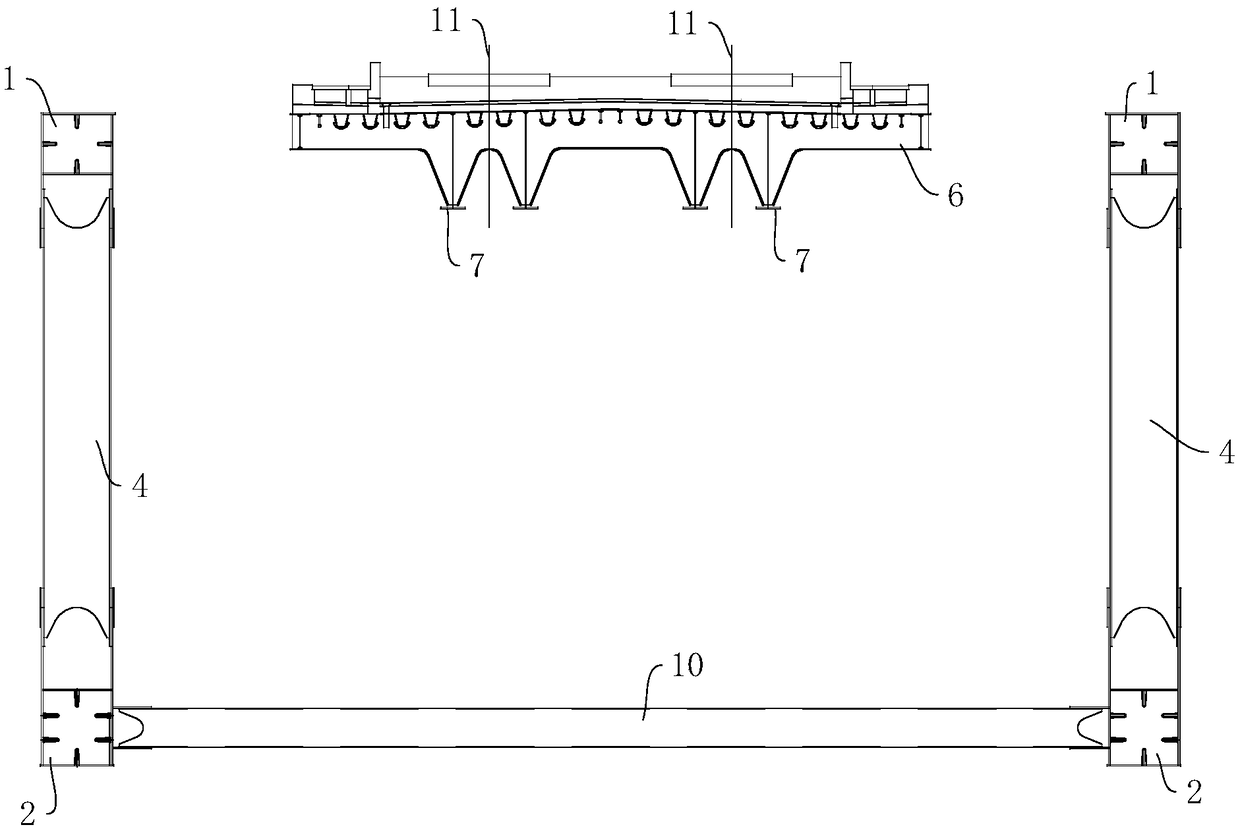

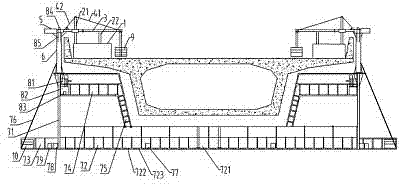

H-shaped double column pier wide-bridge-surface cantilever temporary consolidation structure and construction method thereof

InactiveCN103410102AReduce processingLow costBridge erection/assemblyPre stressStructure of the Earth

Provided are an H-shaped double column pier wide-bridge-surface cantilever temporary consolidation structure and a construction method thereof. The H-shaped double column pier wide-bridge-surface cantilever temporary consolidation structure comprises a concrete bearing platform, a box-shaped continuous beam located above the concrete bearing platform and a plurality of supporting columns connected with the concrete bearing platform and the box-shaped continuous beam. The supporting columns are symmetrically arranged on the front side and the rear side of the a pier column in two rows, four corbels poured into a whole with the concrete bearing platform are respectively symmetrically arranged at four corners of the concrete bearing platform along the left side and the right side of the transverse direction of a bridge, four inclined supporting columns symmetrically distributed along the longitudinal direction of the bridge are connected between the corbels and the box-shaped continuous beam, the supporting columns and the inclined supporting columns are steel pipe columns, a cast-in-place supporting beam is arranged on a base plate of the box-shaped continuous beam, and the supporting beam is in opposite-pull connection through prestress precision rolling threaded steel bars evenly distributed in the steel pipe columns. According to the H-shaped double column pier wide-bridge-surface cantilever temporary consolidation structure, the technical problems that temporary supporting points of a traditional temporary consolidation structure cannot be arranged, the fabricating cost is high, construction efficiency is low, and adverse effect is caused to the environment due to high energy consumption are solved.

Owner:浙江交工宏途交通建设有限公司

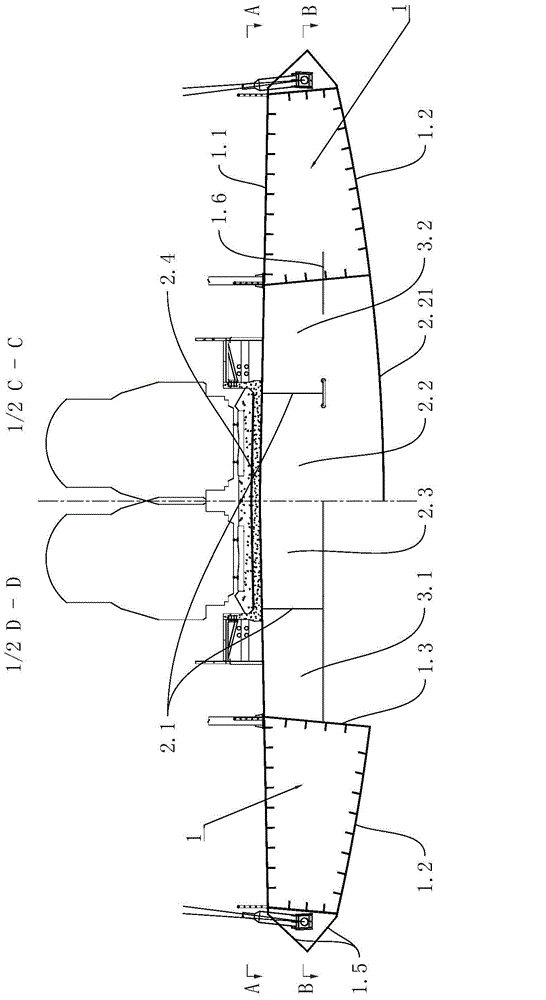

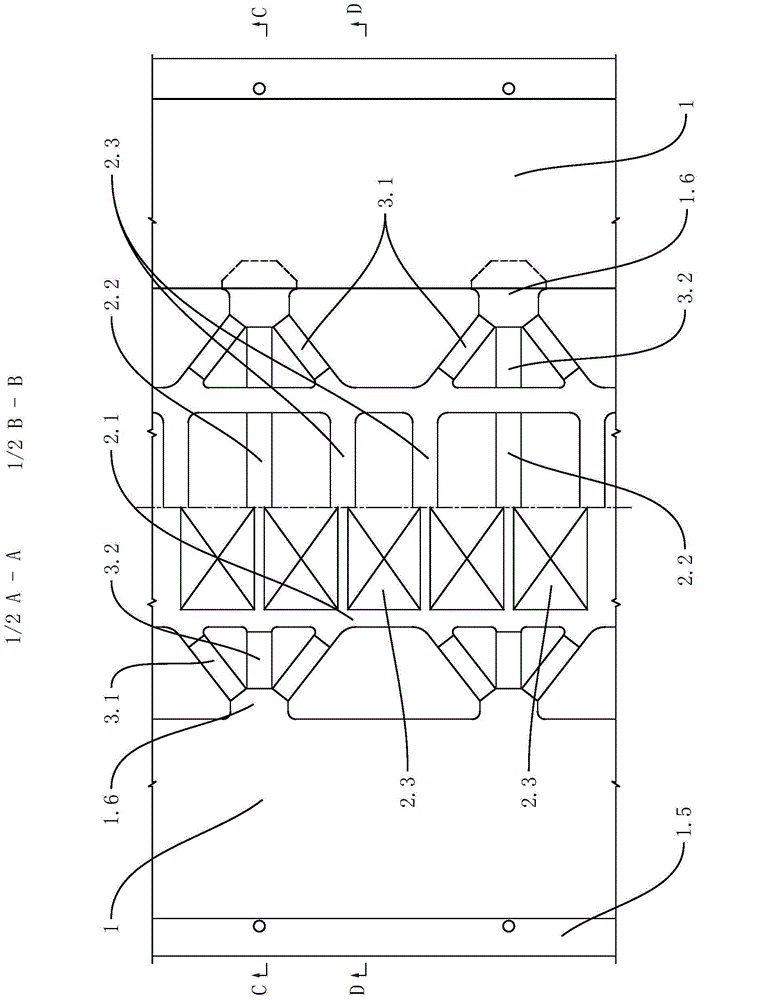

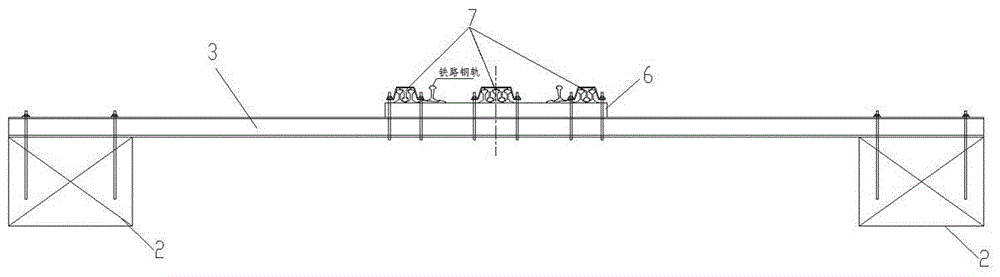

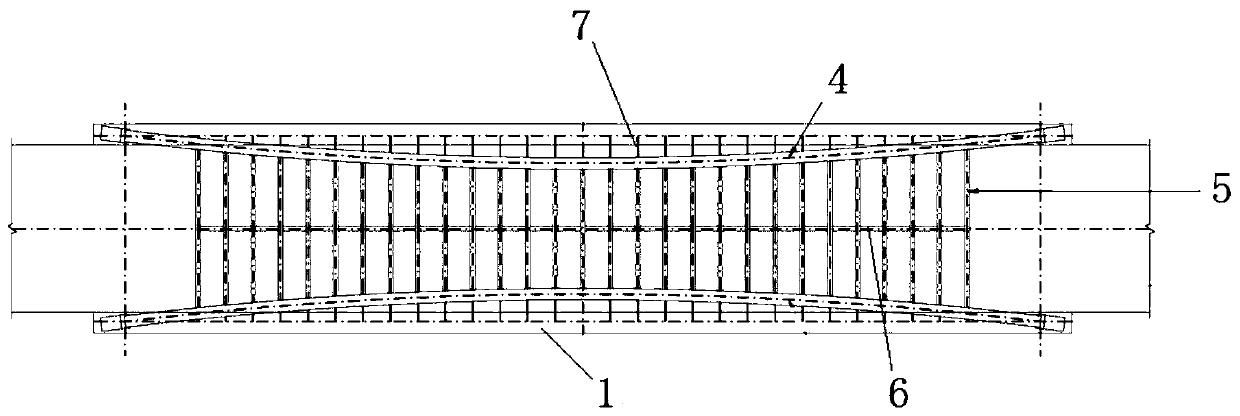

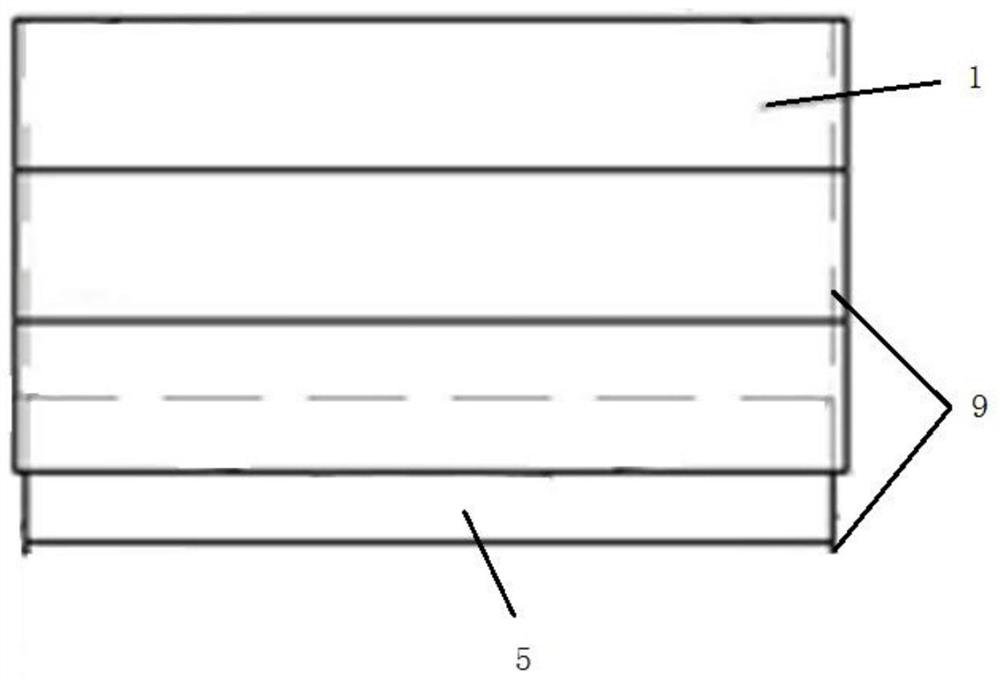

Main girder structure of cable-stayed bridge of large-span railway

ActiveCN103556566ASolve the technical problem of low lateral stiffnessImprove wind resistanceCable-stayed bridgeBridge structural detailsCross connectionCable stayed

The invention discloses a main girder structure of a cable-stayed bridge of a large-span railway. The main girder structure comprises steel box boundary beams, a longitudinal and cross beam bridge decking, and horizontal K-shaped supports, wherein the steel box boundary beams are positioned on two sides of a cross section; the longitudinal and cross beam bridge decking is positioned in the middle of the cross section, and comprises longitudinal beams and cross beams; the longitudinal beams and the cross beams are connected in a crossed manner; cross ribs which are connected with the longitudinal beams in the crossed manner are arranged between the cross beams; a concrete bridge deck is arranged at the top of the longitudinal and cross beam bridge decking; the longitudinal and cross beam bridge decking is connected with the side parts of the steel box boundary beams through the K-shaped supports. According to the invention, the main girder of the cable-stayed bridge is divided into three parts of the steel box boundary beams, the longitudinal and cross beam bridge decking, and the horizontal K-shaped supports; compared with a traditional steel box beam, the main girder structure can provide a relatively wide bridge deck width; meanwhile, the steel box boundary beams are distributed on the two sides of the cross section so as to greatly improve the transverse stiffness of the bridge, so that the technical problem of small transverse stiffness of the cable-stayed bridge is solved; compared with a traditional steel truss girder, the main girder structure has the advantages that the wind-resistant performance of the main girder and a train operation wind speed threshold value are improved, and the steel consumption is lowered.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

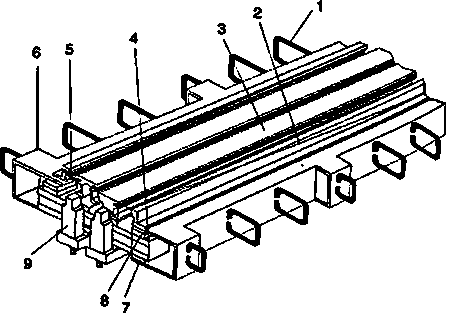

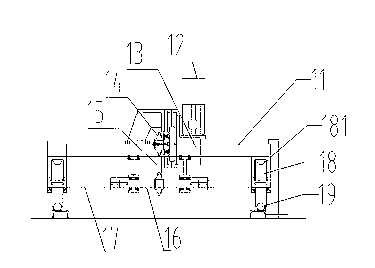

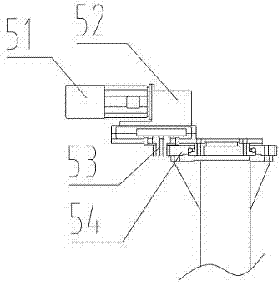

Modular intelligent bridge expansion joint

InactiveCN104233953AReduce in quantityForce safe and reliableBridge structural detailsControl systemEngineering

The invention relates to a modular intelligent bridge expansion joint, which comprises anchoring bars, side beams, middle beams, cross beams, rubber sealing strips and a displacement control box, wherein the anchoring bars are welded on the side beams, the upper parts of the side beams are in rigid connection with a bridge, the lower parts of the side beams are provided with the cross beams, lower part main bodies of the cross beams are provided with supporting hanging frames, the lower edges of the cross beams are glidingly arranged in the displacement control box, the middle beams are supported by the cross beams arranged at the lower parts of the middle beams, and the rubber sealing strips are embedded into the grooves of the side beams. When the technical scheme of the modular intelligent bridge expansion joint is adopted, a load bearing structure and a displacement control system are separated, the load bearing structure and the displacement control system do not interfere each other during stressing, the safety during the stressing is ensured, the number of the cross beams is reduced, the size of the displacement control box is reduced to the minimum range, steel materials are saved, and the adaptability to bent bridges, slope bridges, inclined bridges and wide bridges is high.

Owner:陈逵

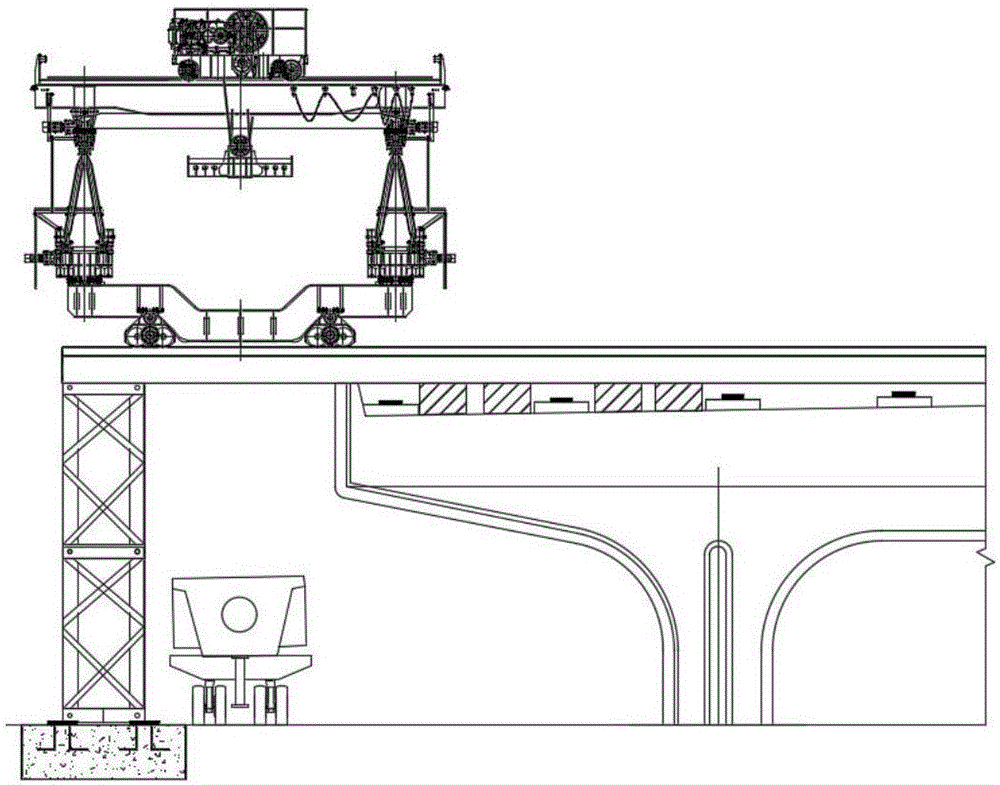

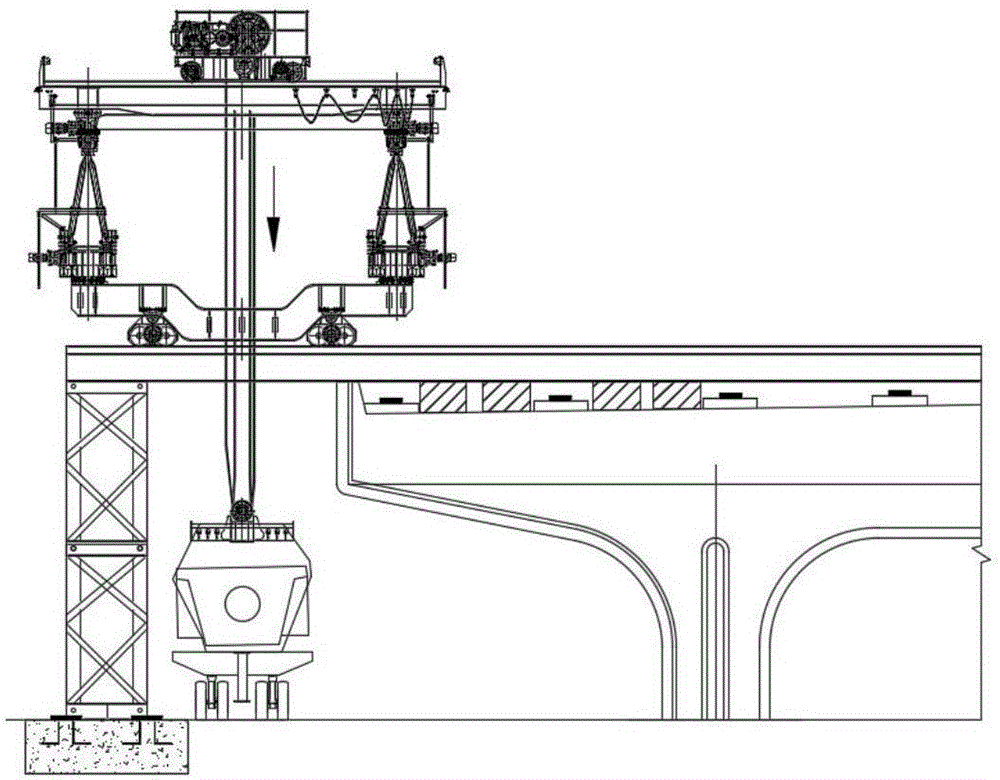

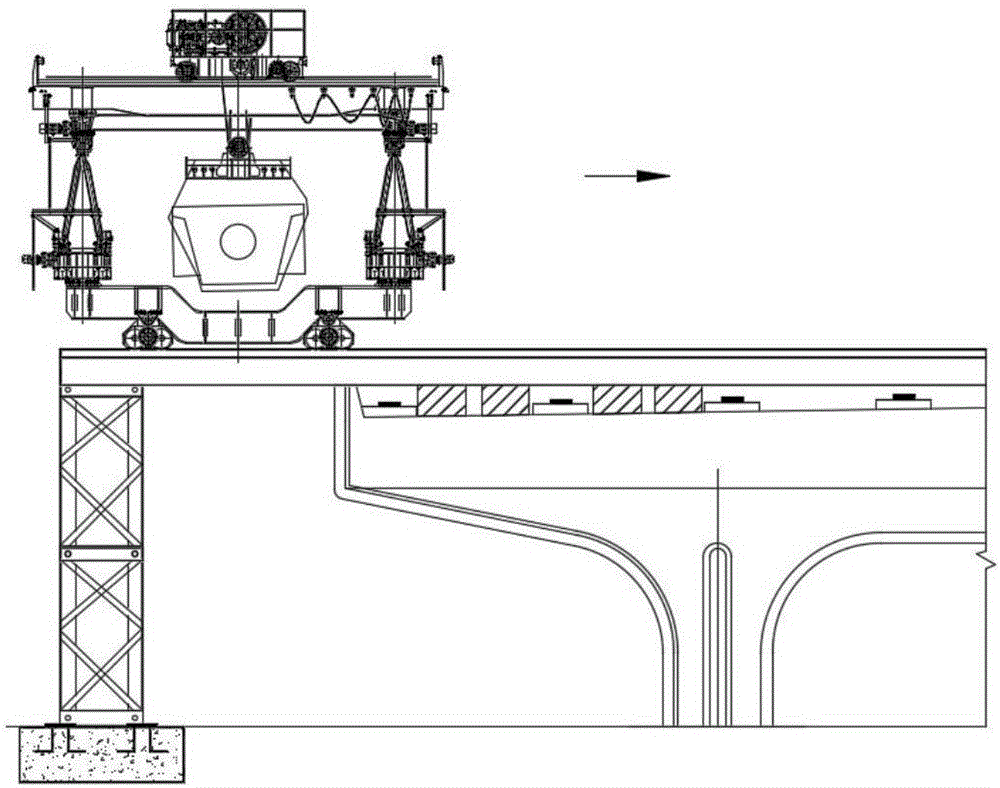

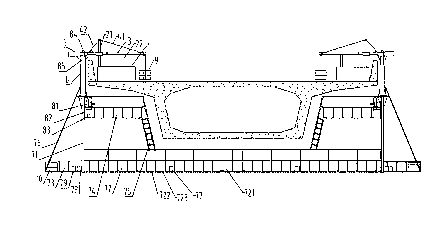

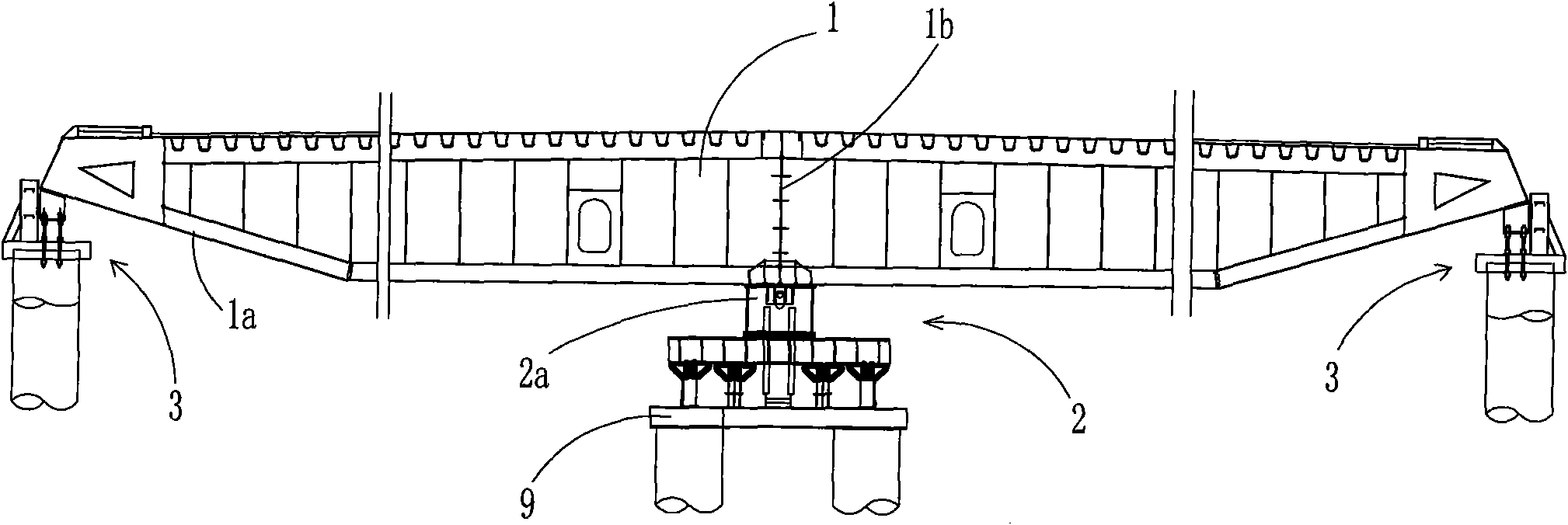

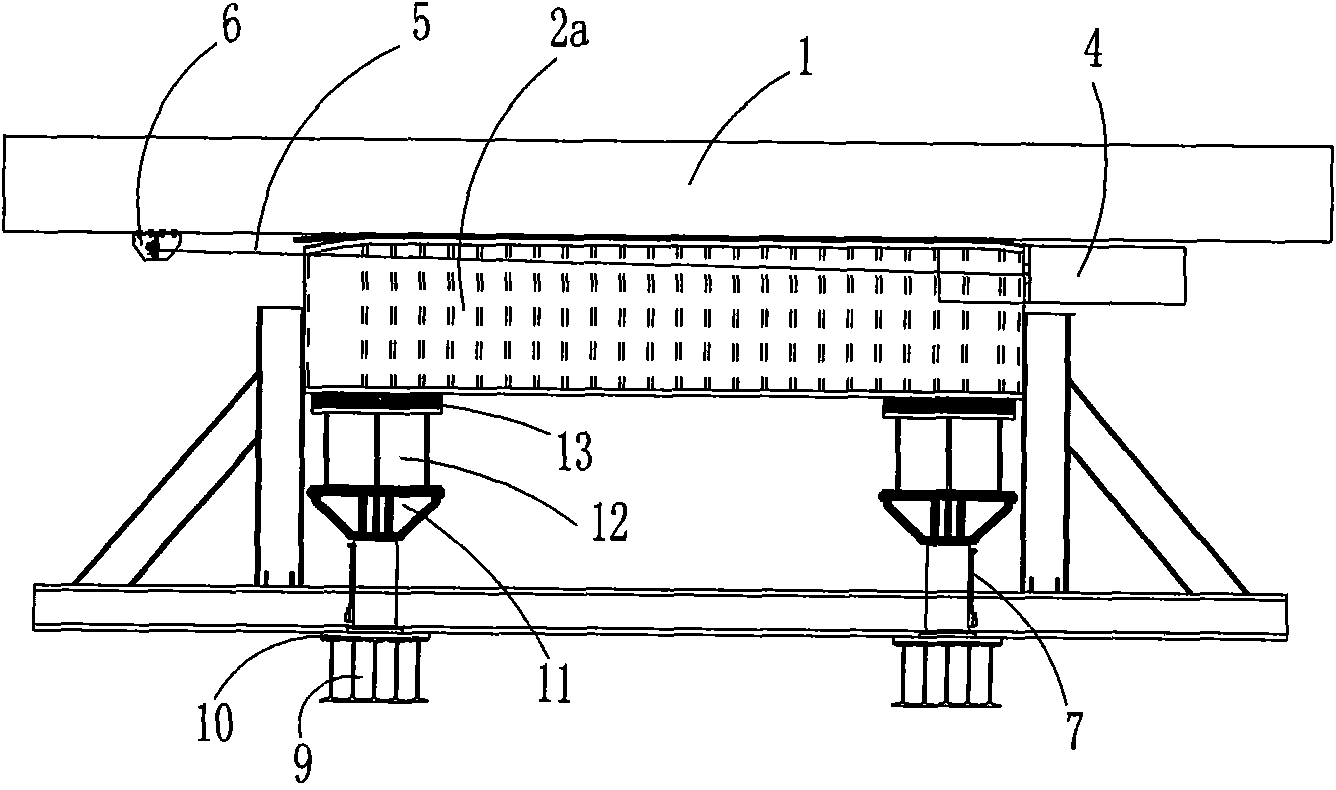

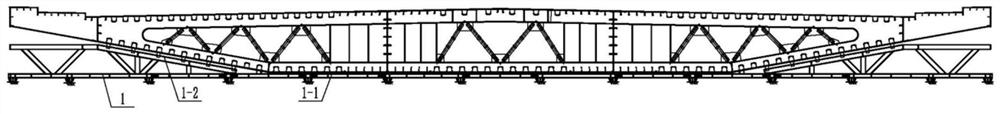

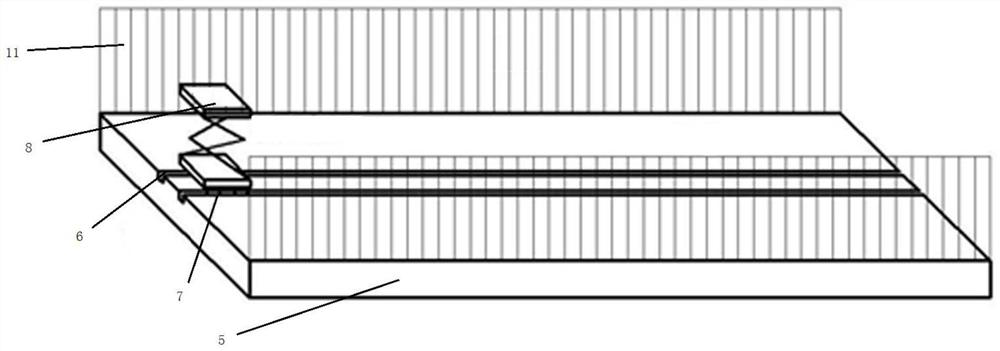

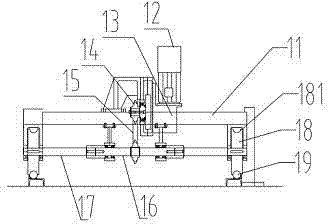

Method for erecting precast beam of super-wide bridge deck at narrow space by using high-low leg gantry crane

InactiveCN106567342AImprove installation speedSpeed up pre-installationBridge erection/assemblyTerrainEngineering

The present invention relates to a method for erecting a precast beam of a super-wide bridge deck at a narrow space by using a high-low leg gantry crane. The method comprises the concrete steps of installing a traversing type bridge-erecting machine and the high-low leg gantry crane at a beam hoisting area, erecting the precast beam at the beam hoisting area through the traversing of the bridge-erecting machine, completing the erection of the precast beam at the beam hoisting area, and erecting the precast beam in a beam-on-beam conveyance way. By applying the method, the problems of conveyance and erection of precast beams at narrow spaces can be well solved, the safety in the conveyance and erection processes of precast beams is guaranteed, and the working efficiency is greatly improved. The method in which the high-low leg gantry crane and the traversing type bridge-erecting machine are matched for construction is applied to complex terrains and narrow spaces for the first time, and the successful experience can guide the engineering construction under the type conditions.

Owner:SHANGHAI FOUND ENG GRP

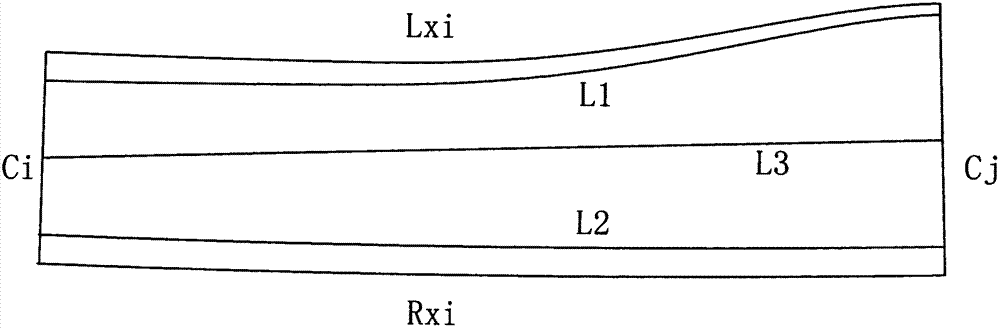

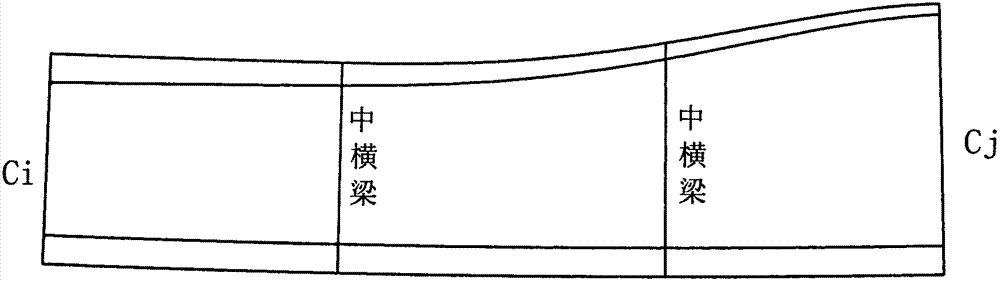

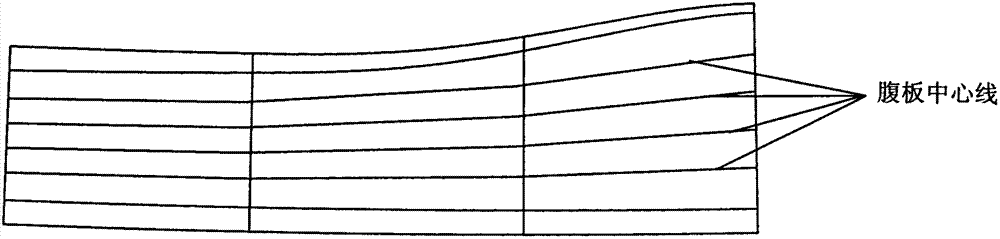

Automatic design method of concrete broadening girder bridge

The invention discloses an automatic design method of a concrete broadening girder bridge. The method comprises the steps of confirming a cantilever line, confirming the position of a middle beam, confirming the number of chambers, confirming the position of a central line of a web plate, forming a structural map of a top plate, and the like. By adoption of the method, the automatic design of the concrete broadening girder bridge can be realized. A design scheme can be formed as long as a designer inputs conventional parameters. Workload of the designer can be effectively reduced, working efficiency is improved, and design cost of a design unit can be effectively reduced.

Owner:苏州桥友信息科技有限公司

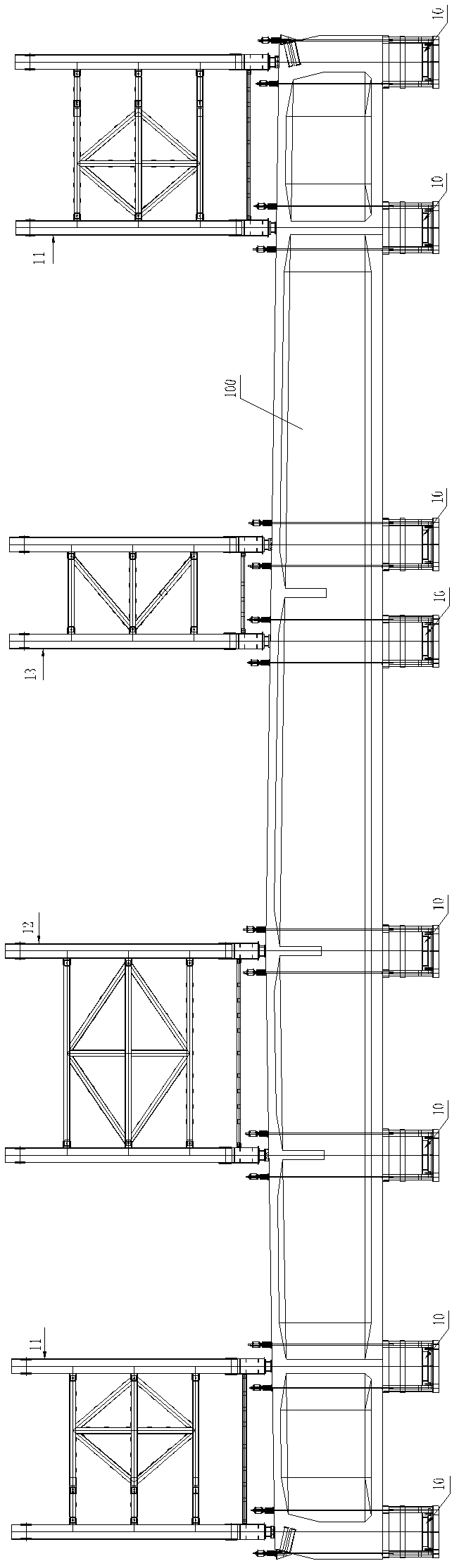

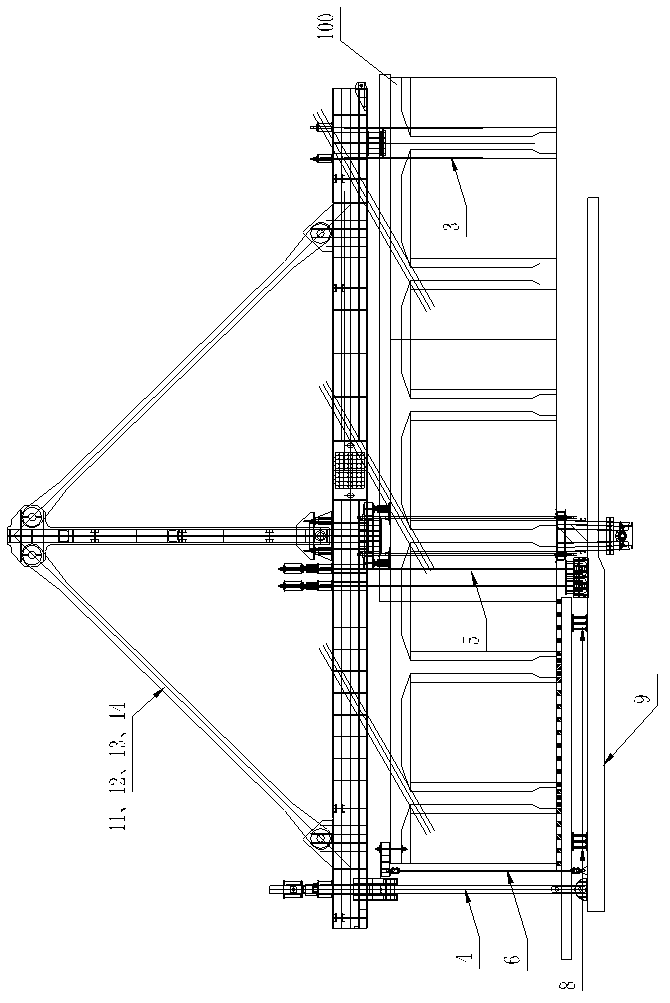

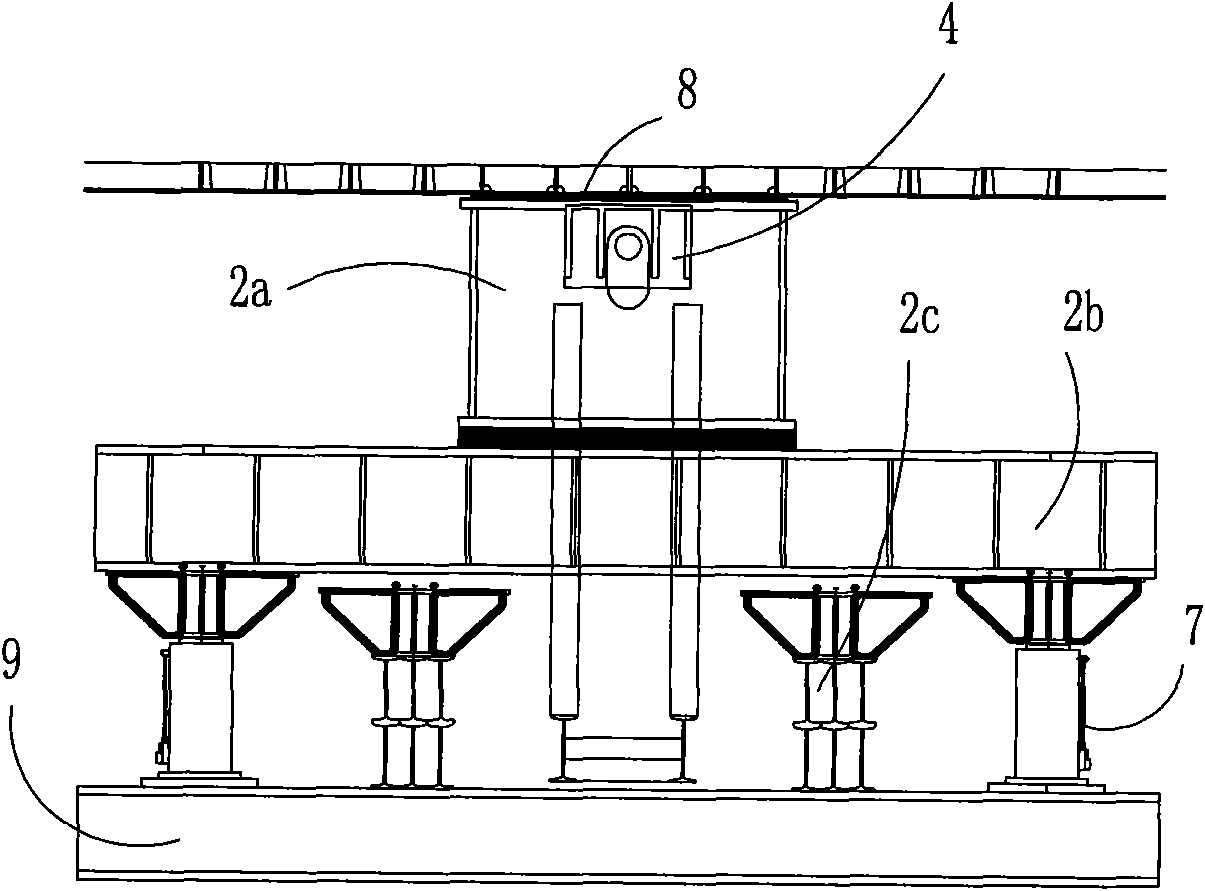

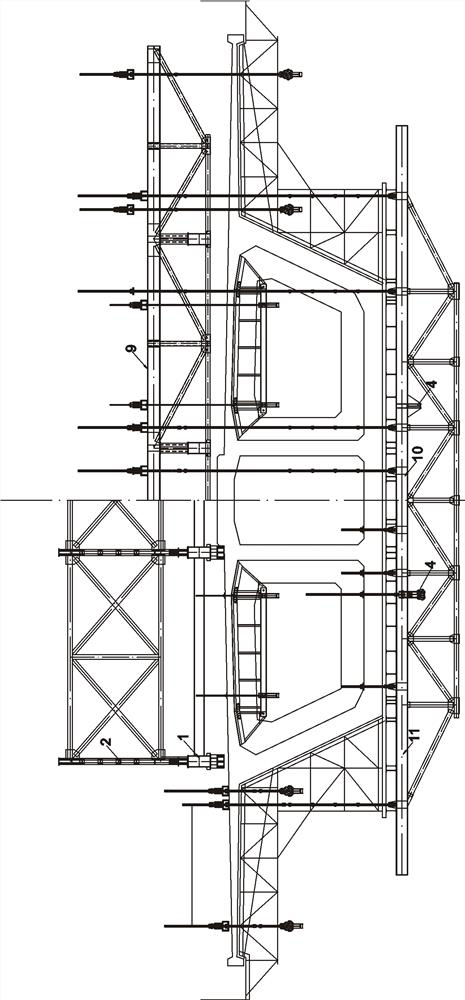

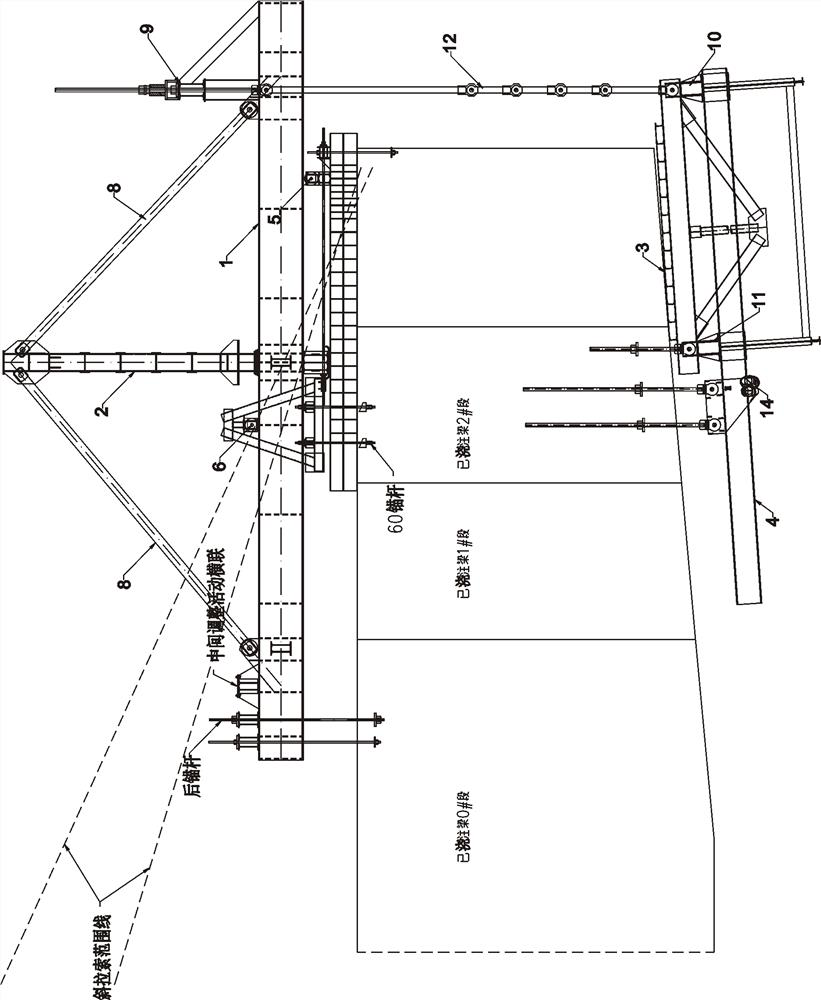

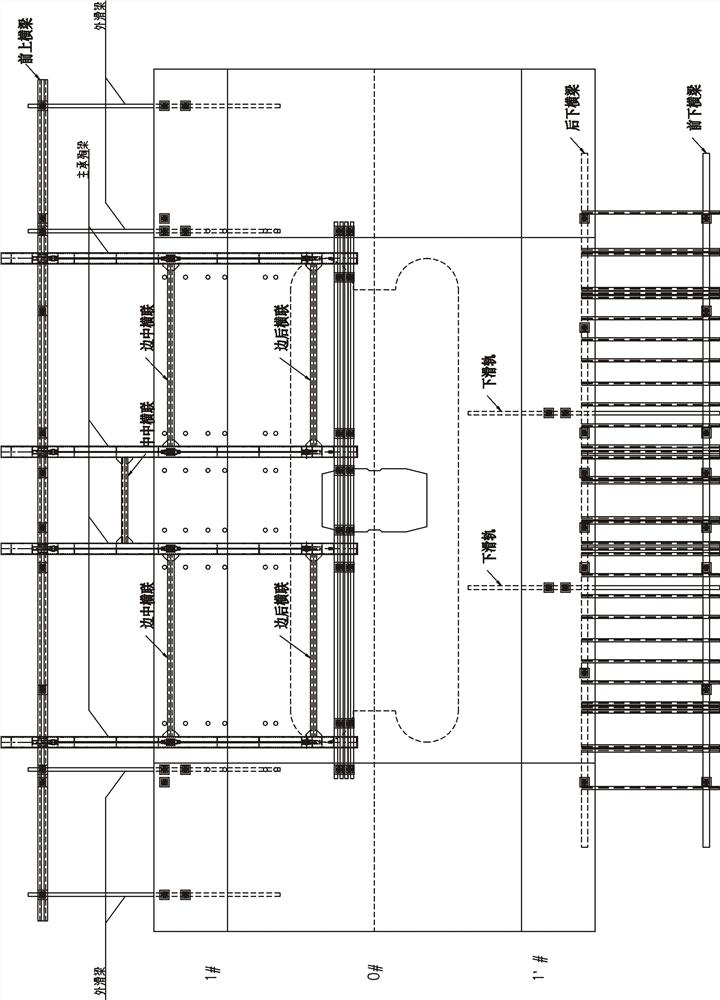

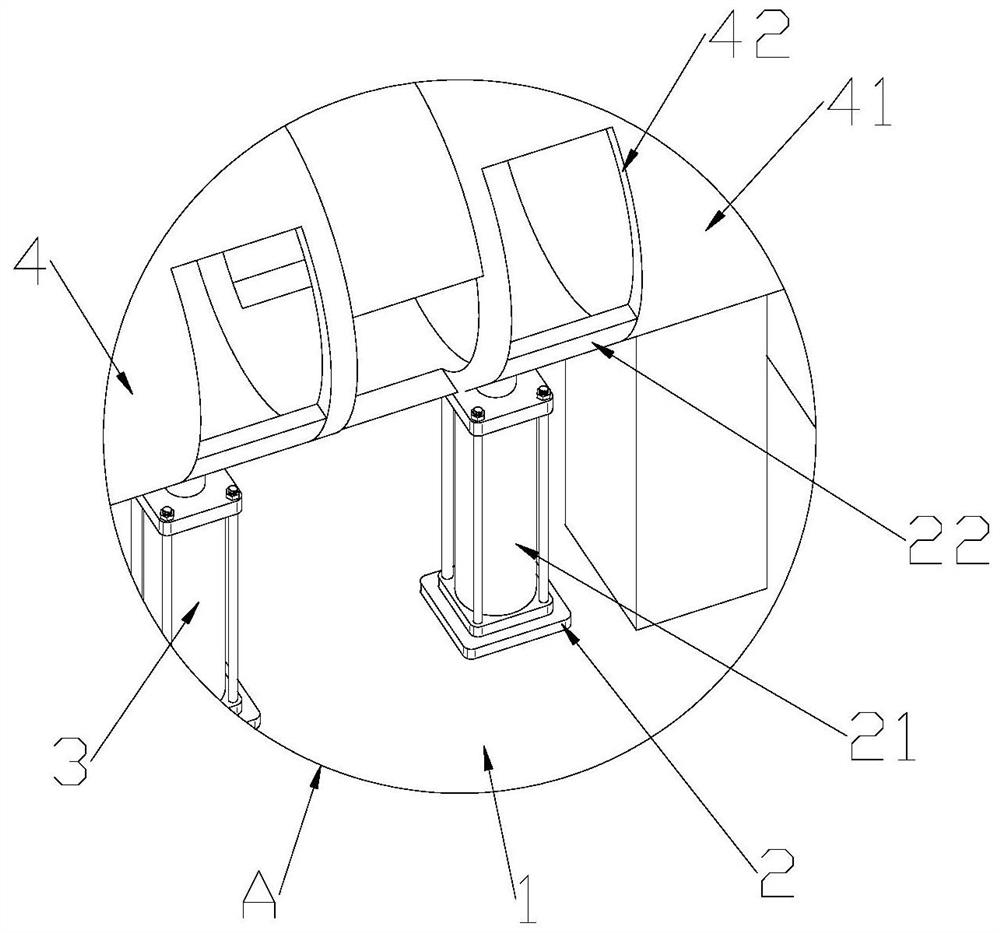

System and method for cradle cantilever construction

ActiveCN102587292ARealize hanging basket cantilevered constructionBridge erection/assemblyEngineeringCantilever

The invention discloses a system and a method for cradle cantilever construction. The system comprises a cradle device and a travelling device, the cradle device comprises a plurality of primary trusses and a plurality of bottom die supporting devices, each bottom die supporting device comprises a sliding beam and a transverse beam, the travelling device comprises a primary truss travelling device and a bottom die supporting device travelling device, the primary truss travelling device comprises a plurality of sliding ways and primary truss pushing jacks in one-to-one correspondence to the primary trusses, the bottom die supporting device travelling device comprises hoists and bottom die longitudinally-moving jacks, the hoists are fixed onto the corresponding primary trusses and are connected with front hangers through steel wire ropes, an anchor beam is fixed to the front end of a concrete girder or a cross wall, a longitudinally travelling reaction seat is arranged at the top of the rear end of each sliding beam, and the bottom die longitudinally-moving jacks are fixed onto the anchor beam and connected with the longitudinally travelling reaction seats through stretch-draw traction steel strands. By the aid of the primary trusses and the corresponding bottom die supporting devices, cradle cantilever construction of a wide bridge deck and girder structure can be realized.

Owner:中铁大桥局第九工程有限公司

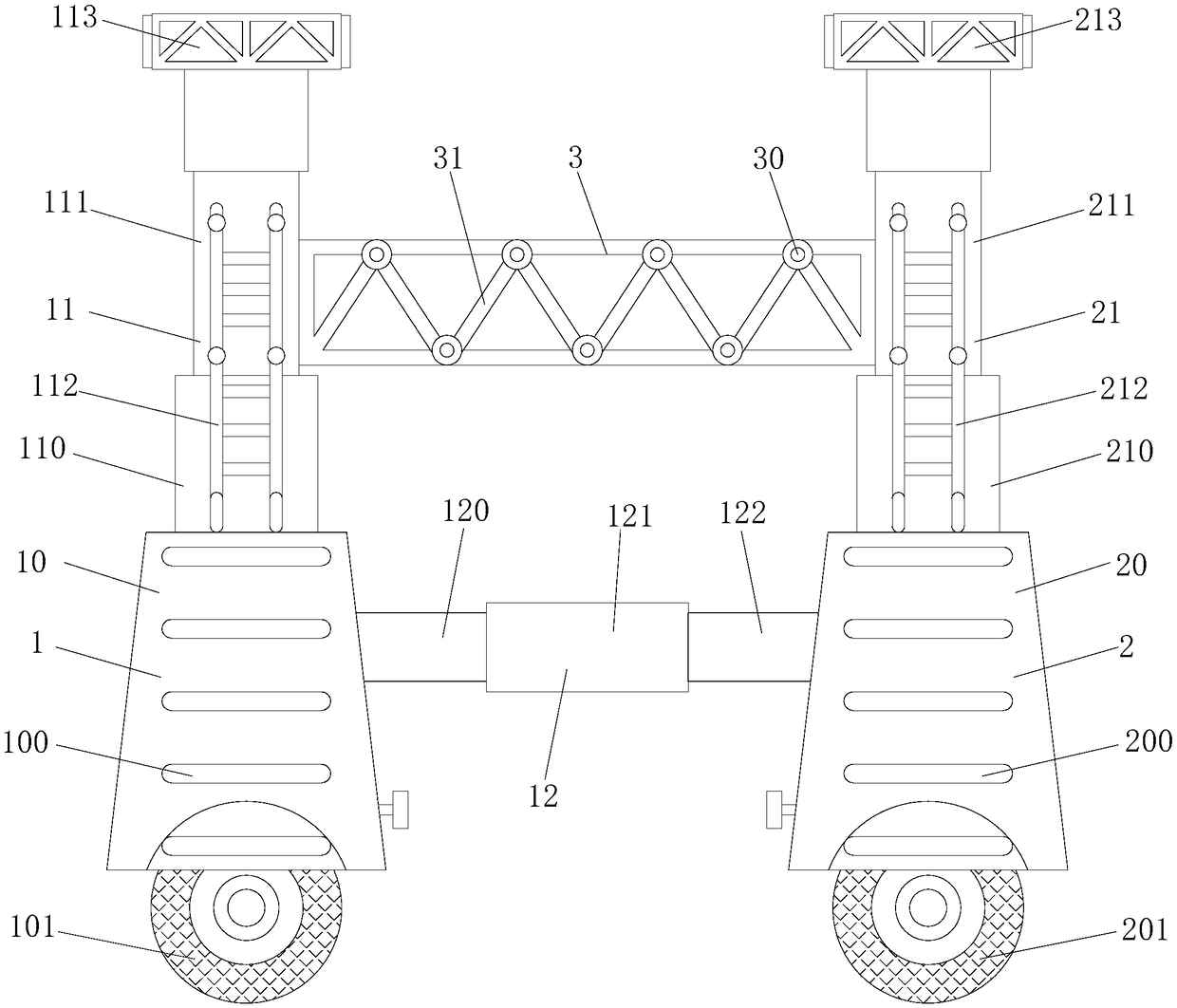

Bottom width overhaul hanging basket of bridge

InactiveCN103306218AImprove construction efficiencyImprove maintenance efficiencyBridge erection/assemblyBridge strengtheningConstruction engineeringBridge deck

The invention discloses a bottom width overhaul hanging basket of a bridge, which solves the problems that a bridge overhaul car and a vessel are not applicable to the large or oversize bridge with a wider deck and greater height in the prior art. The overhaul hanging basket comprises a travelling mechanism and a working platform, wherein the travelling mechanism comprises a first travelling mechanism and a second travelling mechanism capable of travelling along the two sides of the deck; the working platform comprises a first working platform and a second working platform; the first working platform is detachably arranged below the first travelling mechanism; the second working platform is detachably arranged below the second travelling mechanism; the first working platform and the second working platform are located below the bridge during working; and the end part of the first working platform is detachably connected with the end part of the second working platform. The overhaul hanging basket is applicable to the wider bridge, can improve the construction or overhaul efficiency of the bridge, and is free from the limitation of the height of the bridge.

Owner:CHONGQING YUNAN ELECTROMECHANICAL MFG

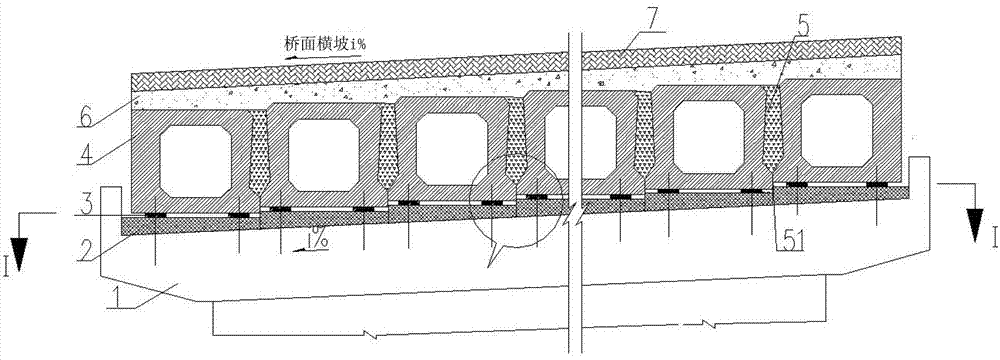

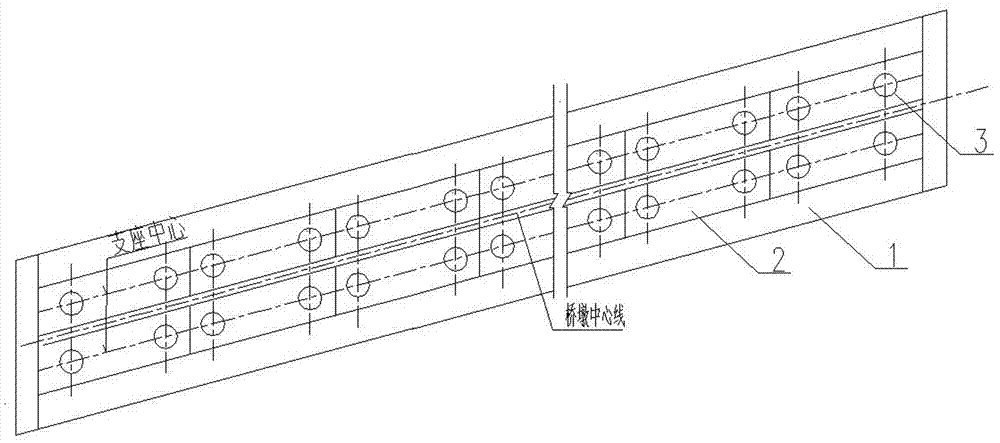

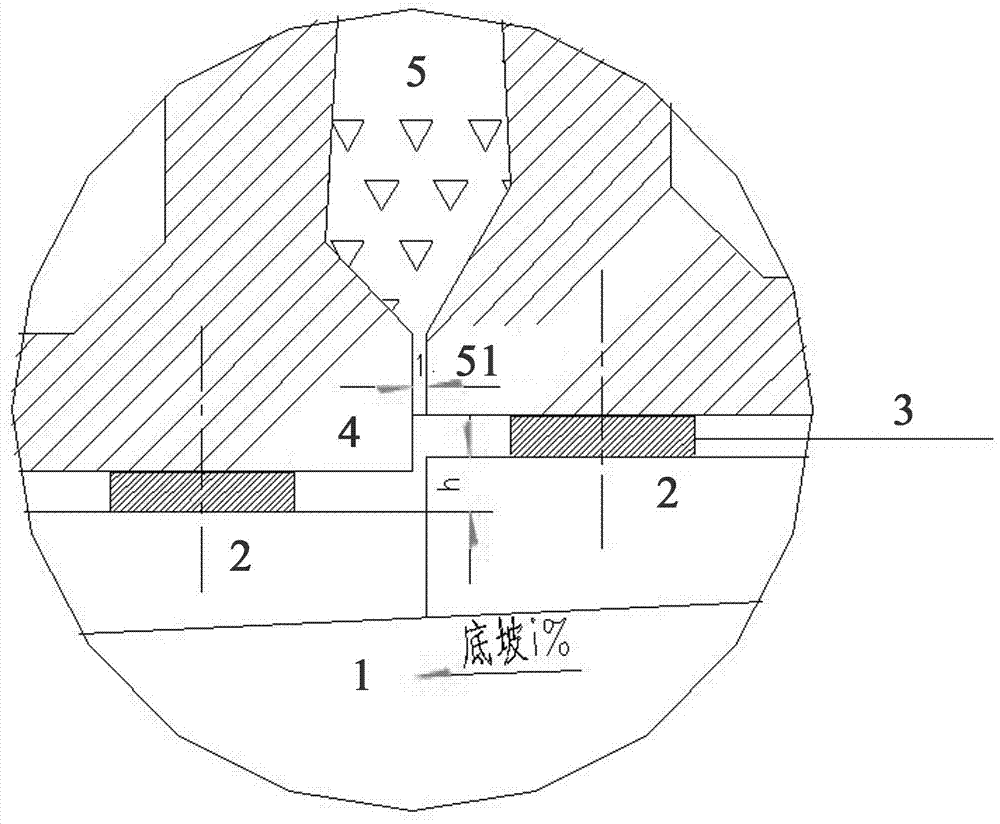

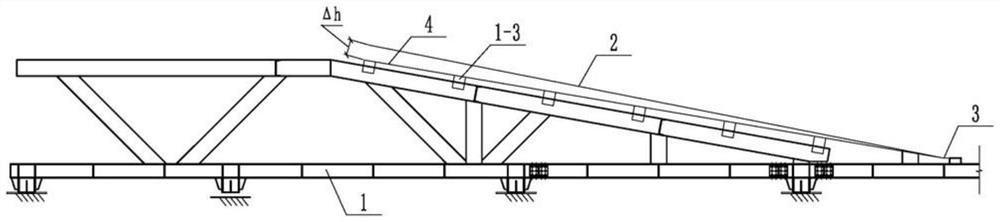

Bridge deck transverse slope regulating structure and paving method

InactiveCN106894325AWith wide bridgeWith characteristicsBridge structural detailsBridge erection/assemblyConstant loadReinforced concrete

The invention relates to a bridge deck cross-slope adjustment structure and laying method. The bridge deck cross-slope is realized by a series of slope-adjusting components including a cover beam with a cross-slope, a stepped pad stone layer, a prefabricated beam of equal height, and a slope-adjusting bridge deck pavement layer. The setting; this structure is suitable for bridges with prefabricated construction, bridges with wide bridges or super high transverse slope characteristics. The top surface of each level of pad stone is horizontal to ensure that the support and beam slab are placed horizontally; the steps on the top surface of each beam slab are staggered to form a slope; The top surface of the loading layer is a transverse slope; the structure method of the invention is reasonable and ingenious, and the dead load on the top surface of each prefabricated beam slab is the same, which is beneficial to the standardized construction of the prefabricated beam slab and is convenient for construction; it not only ensures the designed transverse slope of the bridge deck, but also reduces the prefabricated The self-weight load of the cast-in-place concrete layer on the top surface of the beam slab.

Owner:LUOYANG INST OF SCI & TECH

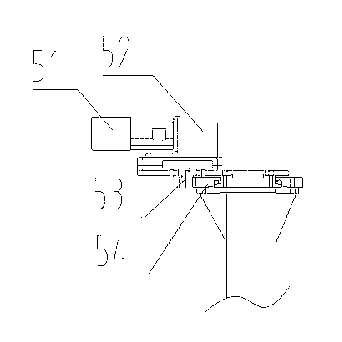

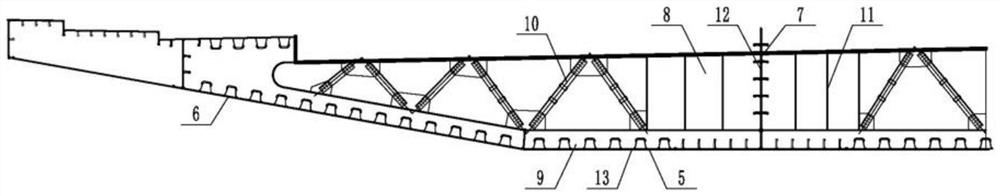

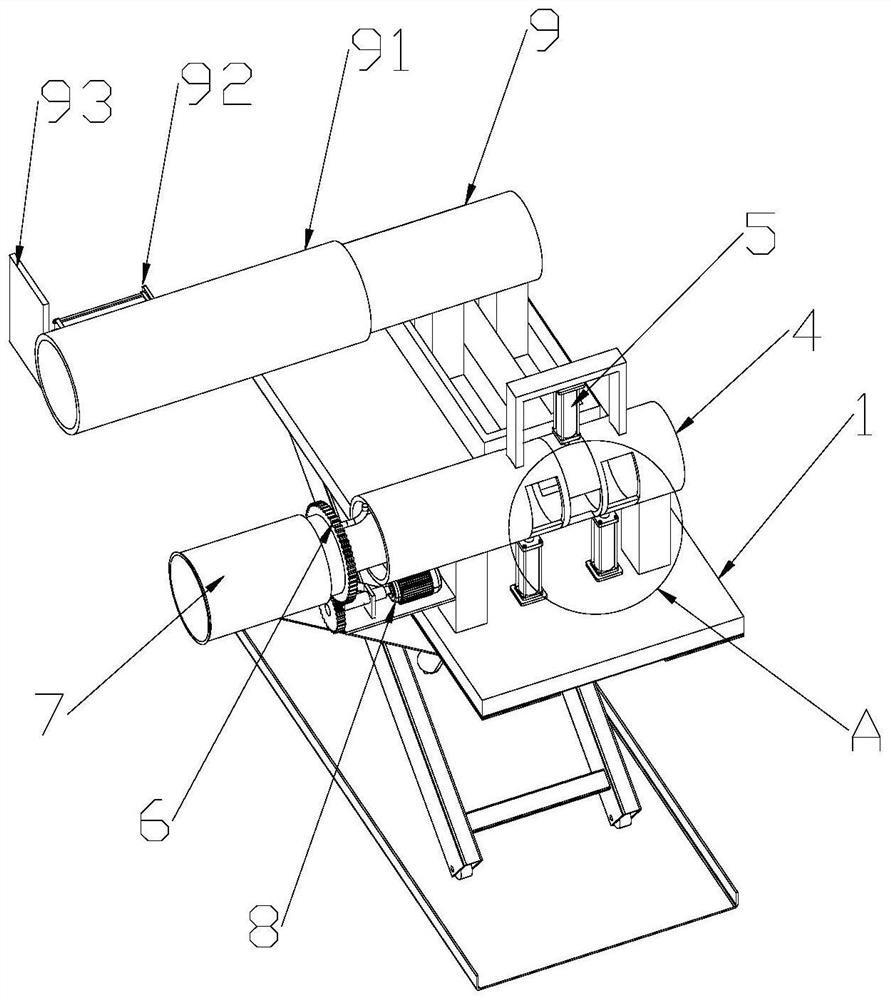

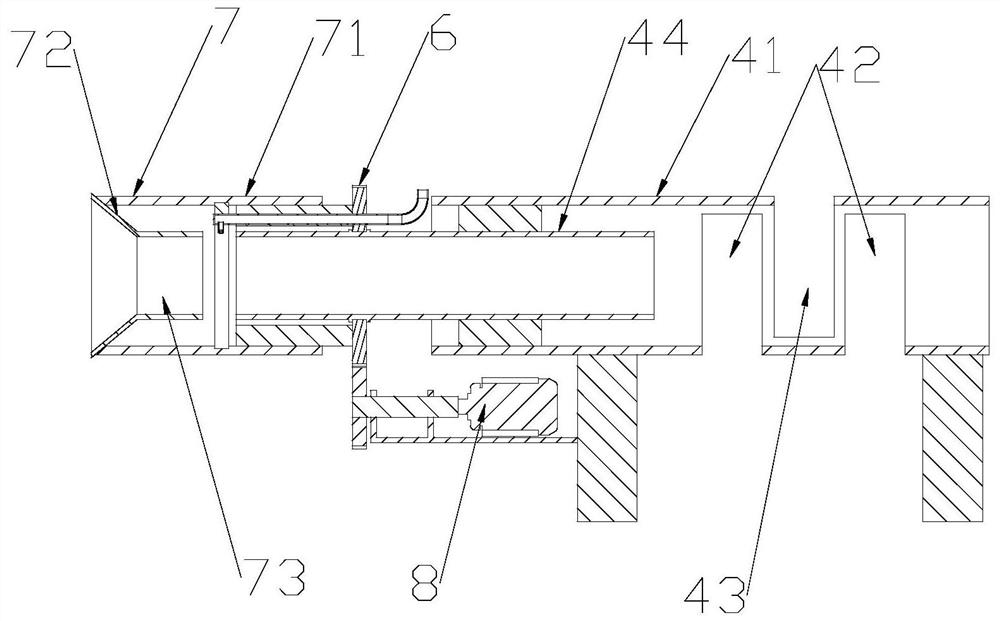

Top pushing mechanism of steel box girder of single longitudinal clapboard on wide bridge deck and top pushing method

The invention discloses a top pushing mechanism of a steel box girder of a single longitudinal clapboard on a wide bridge deck and a top pushing method, which is characterized in that the top pushing mechanism comprises a main top pushing mechanism and two auxiliary traction mechanisms, wherein the two auxiliary traction mechanisms are respectively arranged in the lower bevel board ends of steel box girders at two sides; the main top pushing mechanism is provided with a longitudinal main slideway which is supported on a central buttress platform; a top pushing jack is fixedly arranged on the central buttress platform; one end of a main traction rope is connected to the top pushing jack and the other end thereof is connected to the tail end of each sectional steel box girder by an anchor-pulling device; the bottom of the central buttress platform is provided with a top lifting jack and a steel buttress which can be additionally provided with an adjusting cushion block and is used for adjusting the supporting height of the central buttress platform; and the auxiliary traction mechanisms are characterized in that two buttress platforms at the two sides are respectively provided with a lateral limit palate and a bottom auxiliary slideway corresponding to the lower bevel boards of the steel box girders at the two sides, and the end parts of the lower bevel boards at the two sides of the steel box girder are provided with the auxiliary traction ropes. The steel box girder of the invention has definite stress and can ensure top pushing quality of the steel box girder and cable shape of a bridge.

Owner:THE FIRST CIVIL ENG CO LTD OF CREC SHANGHAI GRP

Method for reinforcing railway through piling girders combined with I-steel cross girders

InactiveCN105735056AImprove integrityLow costRailway track constructionSocial benefitsEconomic benefits

The invention creatively provides a method for reinforcing a railway through piling girders combined with I-steel cross girders, namely line reinforcement is performed in the form of a combined structure of the piling girders combined with I-steel cross girders, besides, longitudinal connection of the I-steel cross girders is performed through rail girders, the completeness of the I-steel cross girders is strengthened, and the line reinforcing form enables railway load within a range of line roadbed earthfall to be effectively transmitted to a piling girder structure through the I-steel cross girders. Lines are reinforced by the method disclosed by the invention, construction can be performed through a conventional cast-in-situ construction technology below the lines, so that the construction cost is reduced, the construction efficiency is improved, the structural technique risk and the construction risk are reduced, and economic benefits and social benefits are good; a series of problems that the earthfall range of railway roadbeds is not liable to control, the exposure time of the lines within the earthfall range is too long, destabilization and collapse of slopes are easy to cause, and driving safety is endangered, which are generated when high-roadbed skew-intersection wide bridge structures are reinforced by a conventional longitudinal and horizontal girder lifting method, are solved.

Owner:SHENYANG RAILWAY SURVEY DESIGN CONSULTING CO LTD

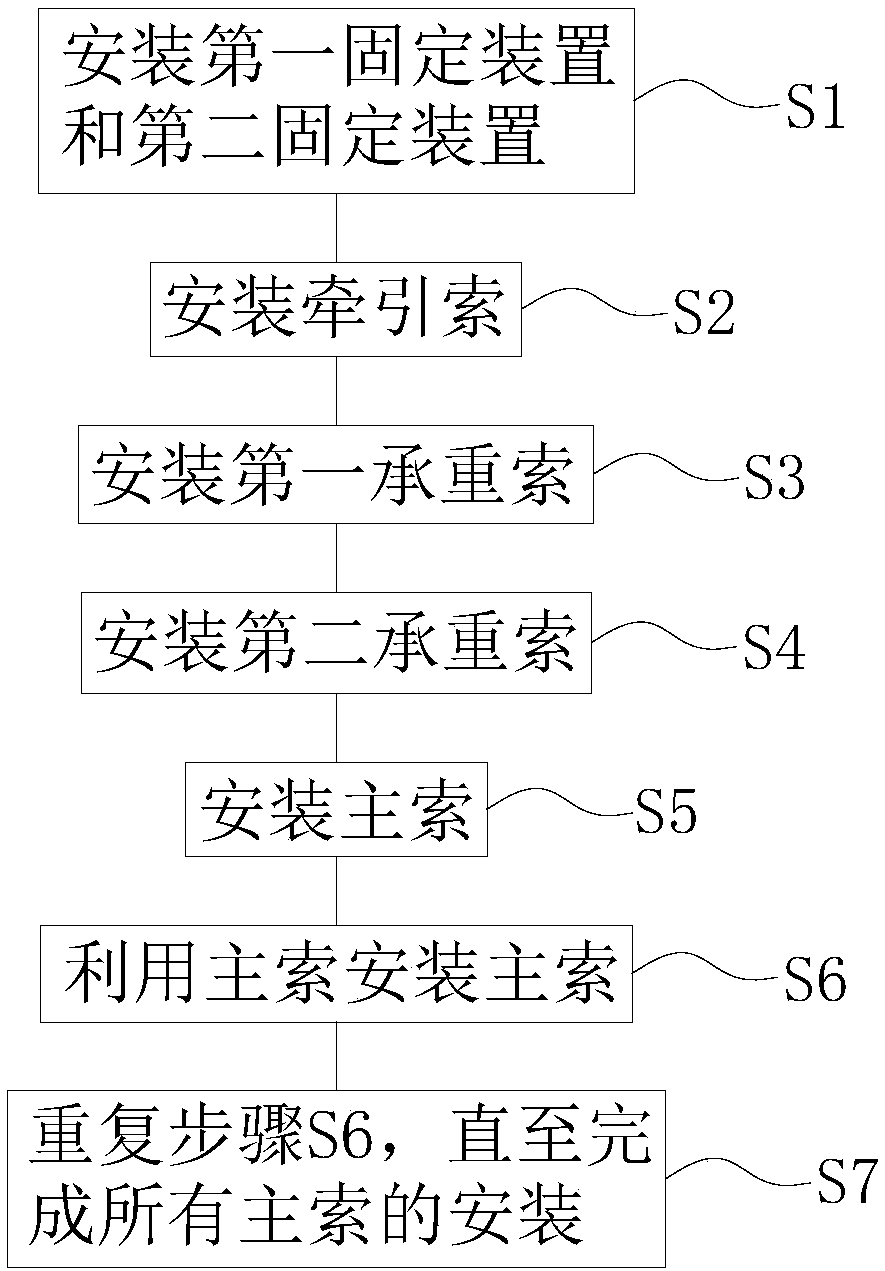

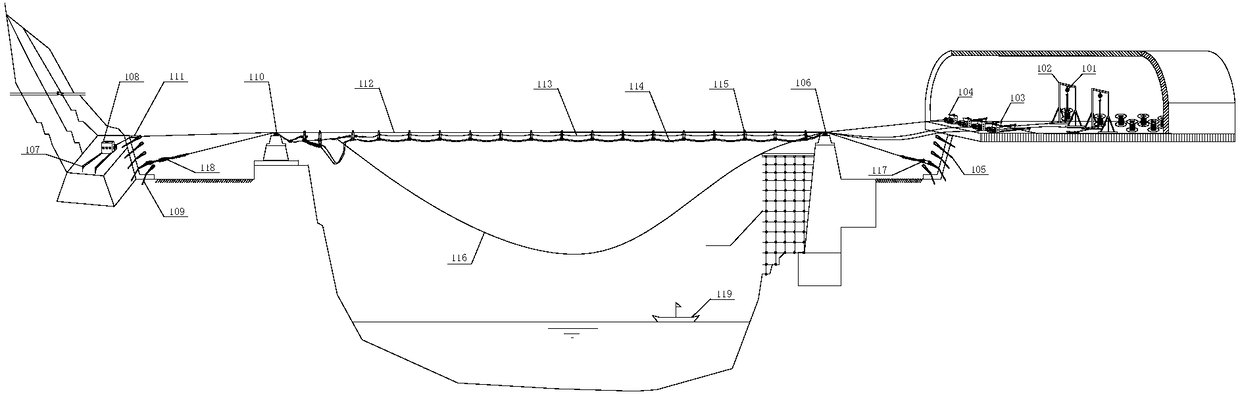

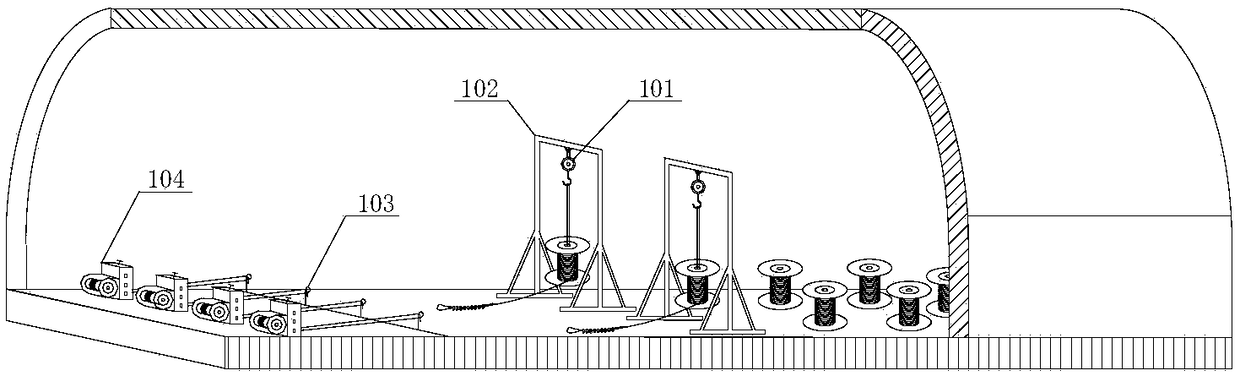

Quick main cable erecting and mounting method

The invention provides a quick main cable erecting and mounting method and belongs to the field of construction of canyon cable ways. The method comprises the steps of installing a traction cable, installing a first bearing cable through the traction cable and installing a second bearing cable through the first bearing cable; and finally installing a main cable thorough the second bearing cable, wherein transportation equipment is only required for installation of the traction cable in the installation process. Through the quick main cable erecting and mounting method provided by the invention, the pre-construction cycle is short, the material recovery and utilization rate is high, and the construction cost is low; transportation is conducted mechanically, the required number of personnelis less, and the safety risk of the personnel in the erecting and installing process is low; the process controllable degree of a transportation system is high, and the transportation system can conduct large-span and wide-bridge-deck transportation; the mechanized utilization degree is high, the transportation speed is increased, and the erecting and installing efficiency is high. Mechanical control is adopted in the erecting and installing process, the automation degree is high, and the labor intensity of workers is greatly relieved.

Owner:CHINA FIRST HIGHWAY ENG +1

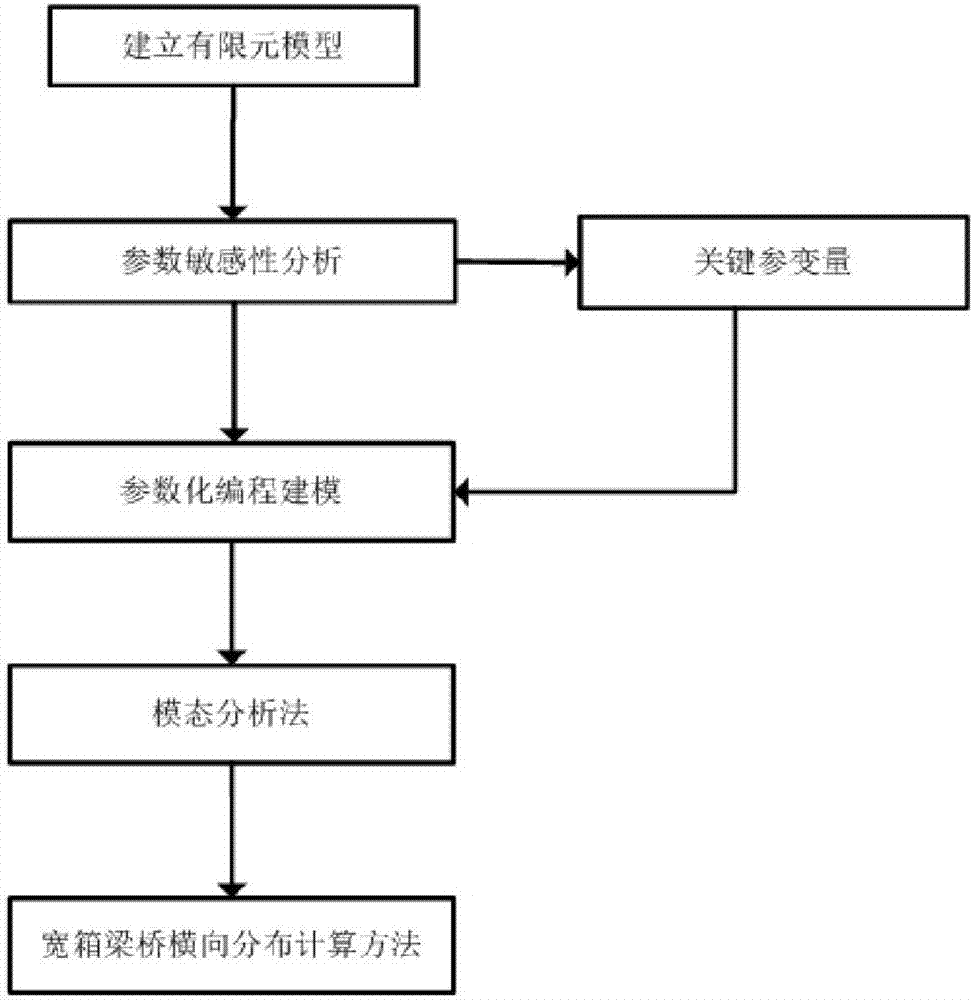

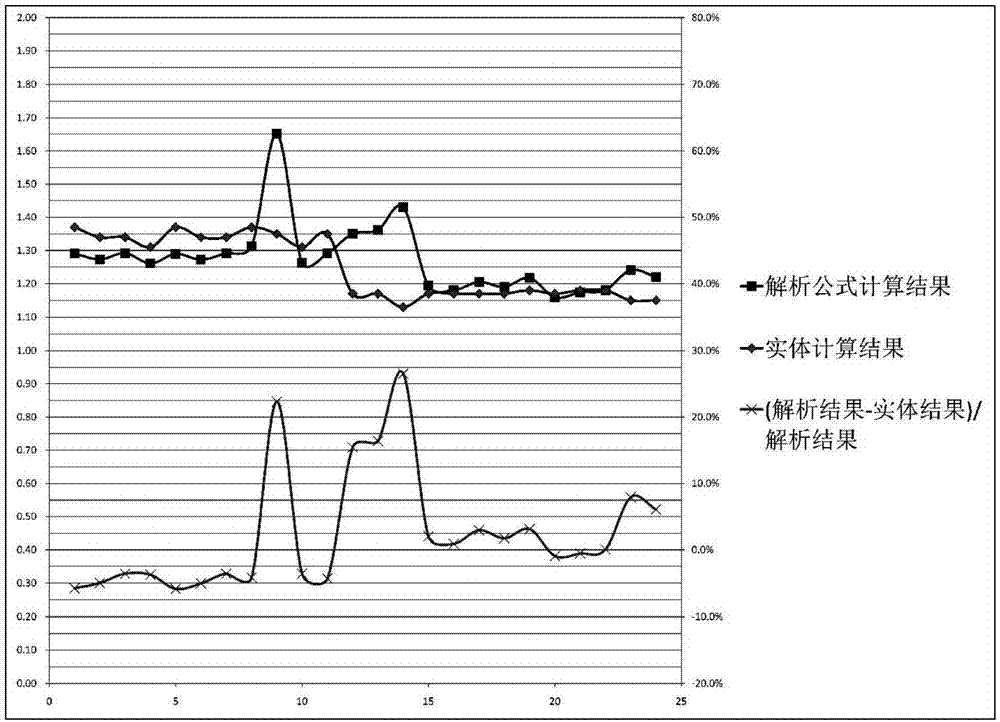

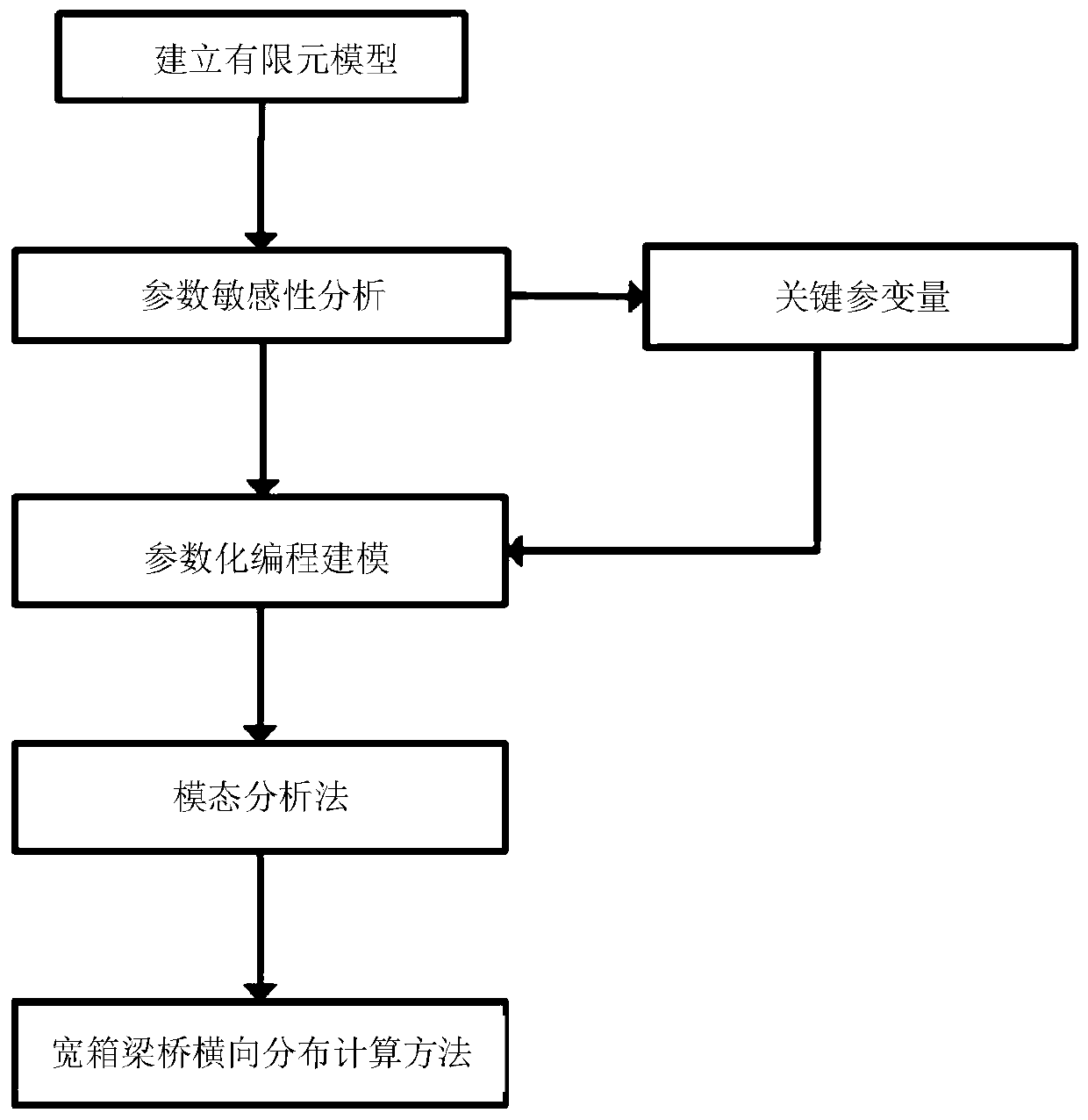

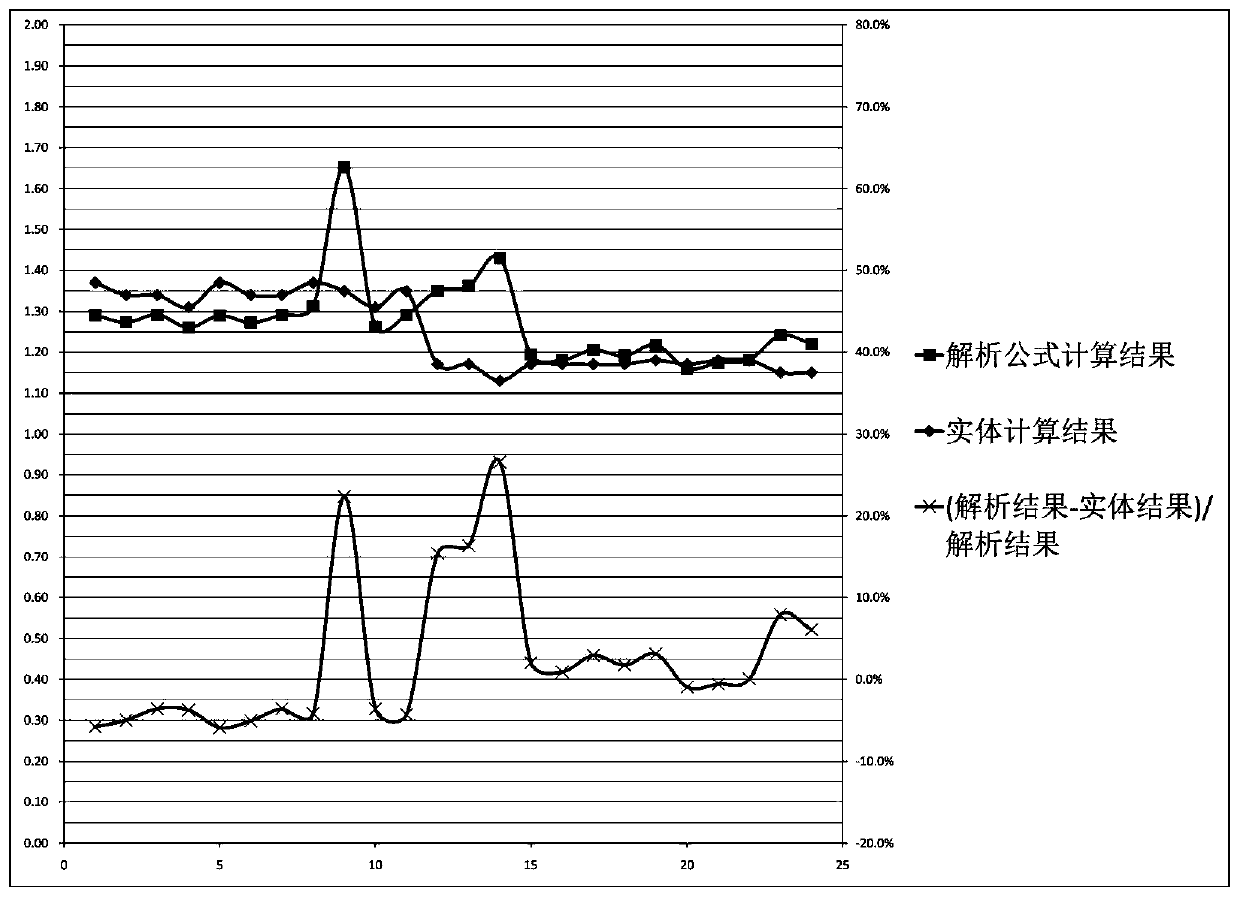

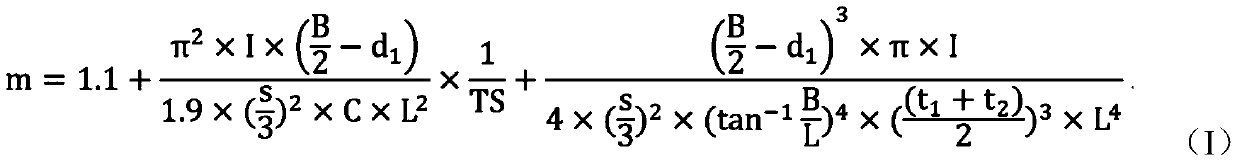

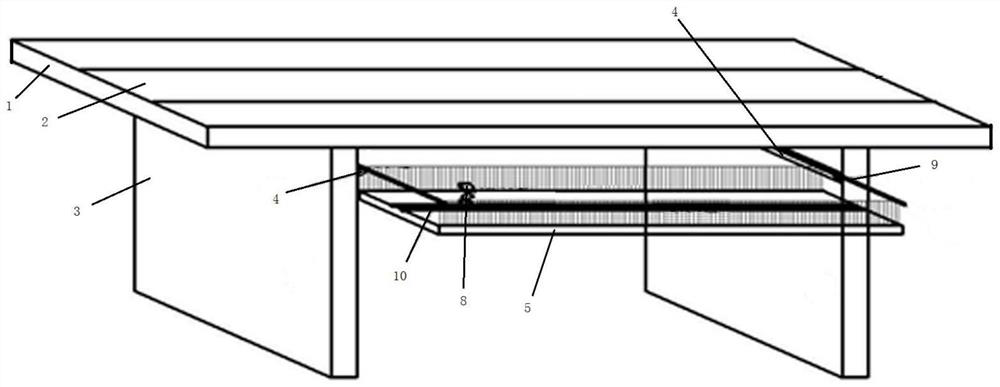

Calculation method of transverse distribution coefficient of single-box and multiple-chamber wide girder bridge

ActiveCN107025330AReduce processing complexityIncreased durabilityGeometric CADSpecial data processing applicationsEngineeringField tests

The invention provides a calculation method, based on a modal analysis method, of the transverse distribution coefficient of a single-box and multiple-chamber wide girder bridge. The sensitivity factor and the sensitivity level of the transverse distribution coefficient of the wide bridge are determined by universal limit element software. Heavy numerical simulation is performed through parameterized programming for analysis, a simplified calculation method applicable to the transverse distribution coefficient of the wide bridge is obtained through solid model comparison, model tests, field tests and other contrasts, convenience is brought to design of the wide bridge, the project design quality can be improved, and the calculation method plays active roles in raising the refined design level of the wide box girder bridge, guaranteeing the structural durability of the bridge, reducing bridge diseases and reasonably controlling the project cost.

Owner:SHANXI TRAFFIC PLANNING PROSPECTING & DESIGN INST +1

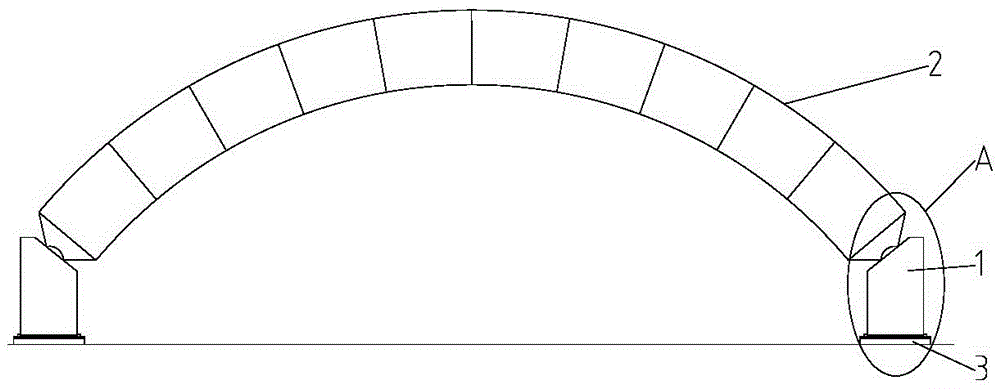

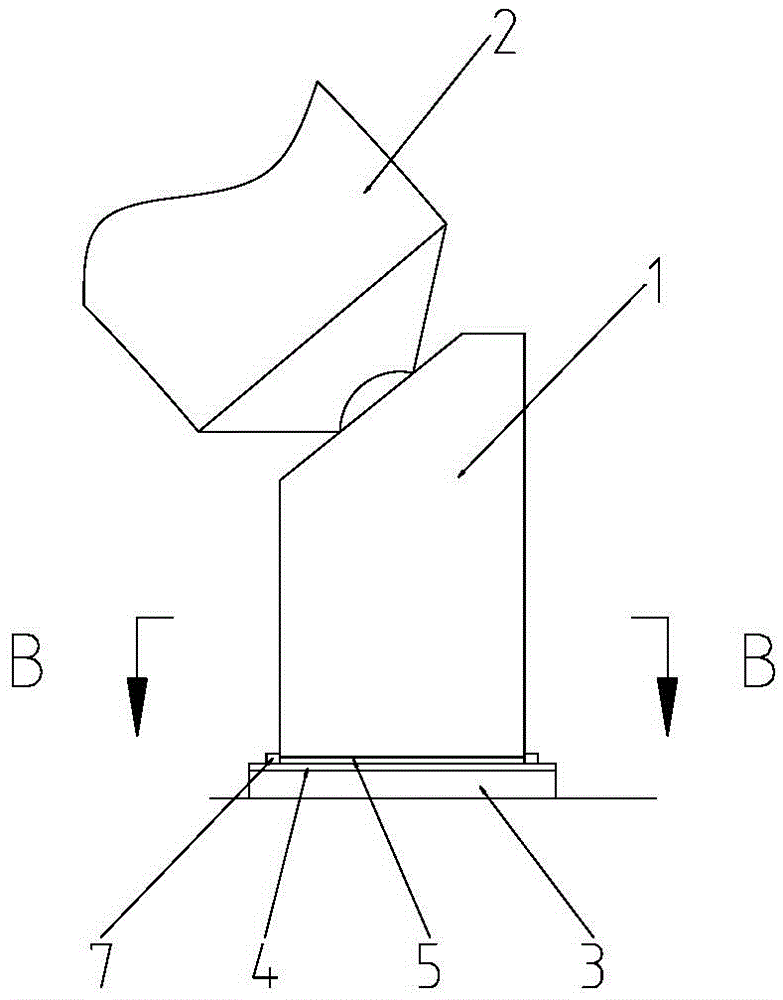

Translational bridge arch frame

InactiveCN106812064ASave human effortShorten the construction period of the projectBridge erection/assemblyLocking mechanismArchitectural engineering

The invention discloses a translational bridge arch frame, comprising skewbacks on two ends and an arch frame body between the two skewbacks, and a support base under the skewbacks. The top surface of the support base is provided with a straight sliding rail. The bottom surface of the skewback is provided with a sliding plate cooperated with the straight sliding rail. The support base is fixedly provided with a traction device used to drive the skewback to move along the straight sliding rail, and a position locking mechanism used to lock the positions of the skewback is also arranged between the support base and the skewback. Through arranging the support base under the skewback, and arranging the straight sliding rail and the sliding plate between the support base and the skewback, the skewbacks of the translational bridge arch frame can be driven to move horizontally by the traction device. Thus, the arch frame can be driven to move horizontally along the straight sliding rails, and just one arch frame is needed, and construction requirements of relatively wide bridge can be realized, and the arch frame is just built once, thereby effectively saving manpower and shortening engineering construction period.

Owner:CHONGQING BIAOWANG INTEGRATED HOUSING TECH DEV CO LTD

Multi-truss ultra-wide bridge construction hanging basket

InactiveCN108999095AAdjustable spacingHeight adjustableBridge erection/assemblyArchitectural engineeringHanging basket

The invention discloses a multi-truss ultra-wide bridge construction hanging basket, the structure comprises a hanging blue support frame for the construction of the first bridge, A support frame forhang blue for that construction of the second bridge, A foldable construction hanging basket device A first basket base internal drive chassis A second hanging basket base internal drive chassis, A third basket base internal drive chassis, A third hydraulic support column triggering and starting device is arranged in an internal transmission chassis of the third hanging basket base, A third hydraulic support column controls the transmission, A third support base internal drive motor arrangement A third material transfer control transmission, When the equipment is in use, the spacing of the hanging basket can be adjusted at will, the height of the hanging basket can be adjusted through simple operation, the use flexibility can be improved, and the feeding problem of the high-altitude operation can be solved through automatic feeding at the same time of construction. The invention is light and flexible, and the spacing can be adjusted, and is safe and stable.

Owner:广东博昊实业集团有限公司

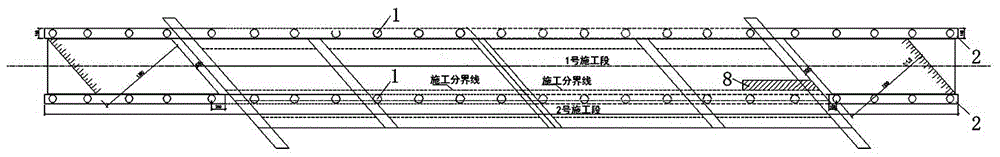

Ultra-wide steel box girder total splicing cross slope control method

ActiveCN114178736AAvoid influenceReduce the impactWelding/cutting auxillary devicesAuxillary welding devicesButt weldingUpper tooth

The invention discloses a cross slope control method for ultra-wide steel box girder assembly. The cross slope control method comprises the steps that an assembly jig frame is manufactured; a tooth plate is arranged on the tread; the elevation value of the inclined tread upper tooth plate is corrected according to the design reversible deformation of the steel box girder inclined bottom plate; a flat bottom plate of the steel box girder is placed on the tooth plates on the horizontal tread according to the designed elevation, inclined bottom plates on the two sides of the steel box girder are placed on the corrected tooth plates, and the flat bottom plate and the inclined bottom plates on the two sides are assembled, positioned, welded and fixed; then, the web and the partition plate are assembled, positioned, welded and fixed, vertical butt weld joints of the partition plate are welded firstly, then vertical butt weld joints of the partition plate and the web are welded, and finally transverse structure weld joints of the partition plate and the bottom plate are welded; and finally, the top plate units are assembled, positioned, welded and fixed, butt welding seams of the top plate units are welded firstly, then butt welding seams of the transverse connecting plates on the top plate units are welded, and finally transverse structure welding seams of the transverse connecting plates and the partition plates are welded. According to the method, the structural size precision control level in steel box girder manufacturing is improved, and the cross slope precision of the ultra-wide bridge floor is guaranteed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

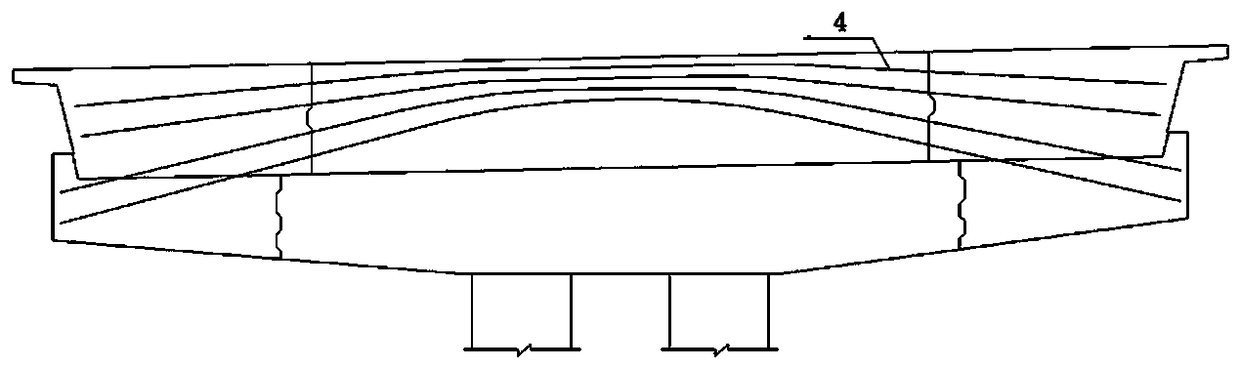

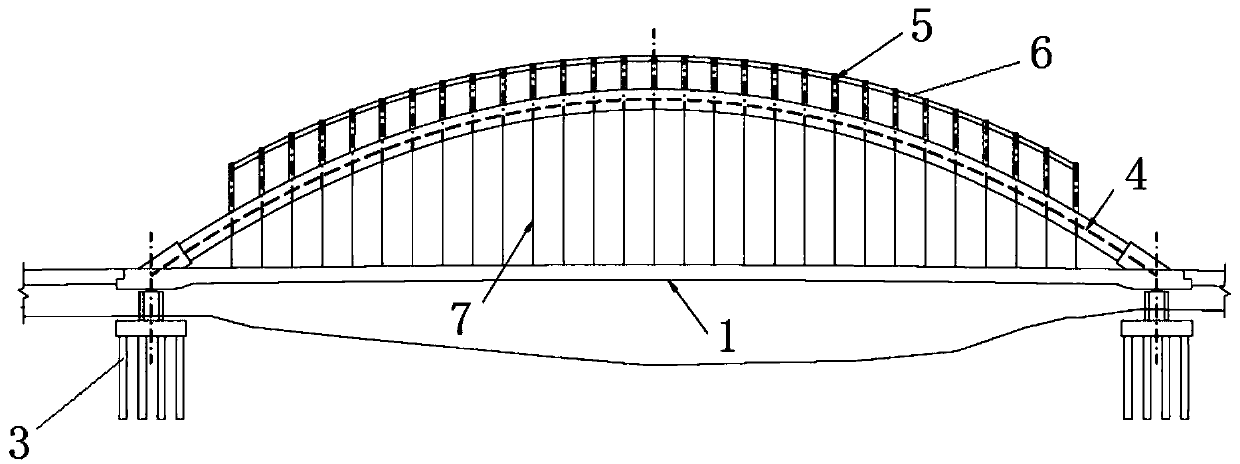

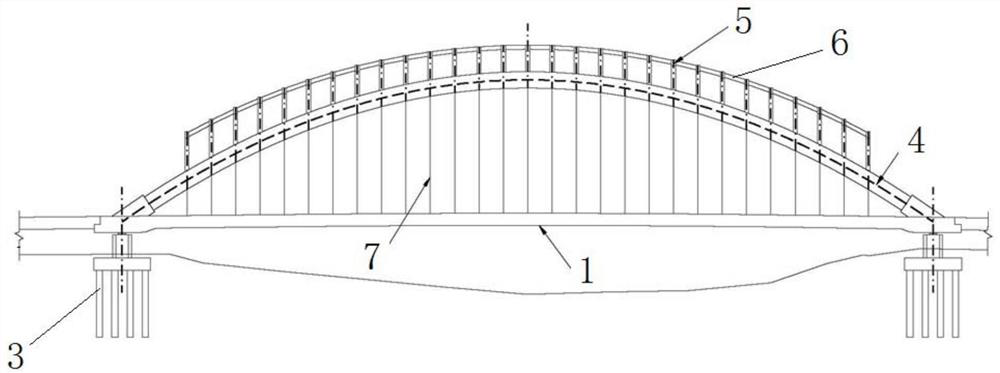

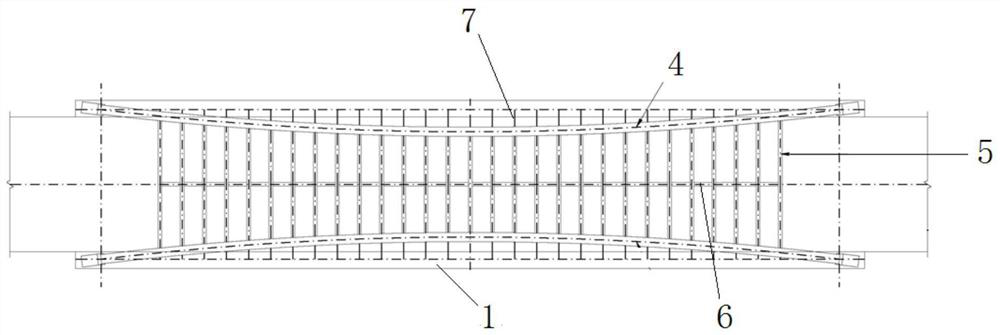

Novel two-way curved arch bridge

ActiveCN109763416AThe stress is reasonableOptimize the vertical forceArch-type bridgeStructural engineeringWide bridge

The invention relates to a novel two-way curved arch bridge. The novel two-way curved arch bridge comprises a main beam, main arch ribs, auxiliary arch ribs, a side hanging rods and middle hanging rods, wherein one parabolic main arch rib is arranged on each of the two sides of the main beam; a plurality of parabolic auxiliary arch ribs are arranged between the two main arch ribs; the two ends (namely arch feet) of the main arch ribs are positioned above middle piers respectively; the two ends of the auxiliary arch ribs are fixed to the two main arch ribs respectively. Compared with the priorart, the novel two-way curved arch bridge provided by the invention has the advantages as follows: due to the actions of the hanging rods and the auxiliary arch ribs which are added between the parabolic main arch ribs, stress on a cross beam is reduced for a wide bridge, so that reduction on the beam height of the cross beam and control of the height of a wide bridge structure are facilitated.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

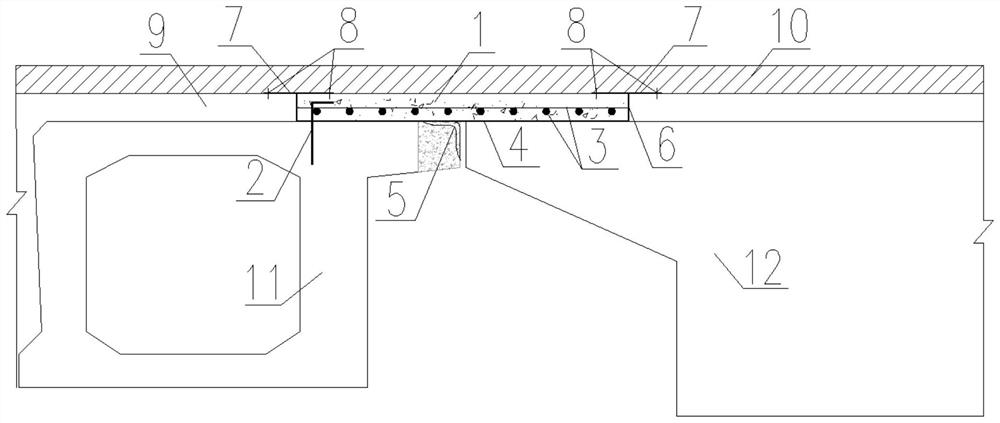

Anti-settling plate device for widening bridge joint

ActiveCN111648233AFast constructionWith vertical and horizontal extension performanceBridge structural detailsReinforced concreteArchitectural engineering

The invention discloses an anti-settling plate device for a widening bridge joint. The device comprises an ultrahigh-toughness reinforced concrete anti-settling plate and tensile anchoring steel bars,the ultrahigh-toughness reinforced concrete anti-settling plate is arranged above a joint of the newly-built bridge and the old bridge; one end of the high-toughness reinforced concrete anti-settlingplate is hinged to the old bridge through the tensile anchoring steel bars, the other end of the high-toughness reinforced concrete anti-settling plate is placed on the newly-built bridge, bridge floor cast-in-place layers are laid on the old bridge and the newly-built bridge, and the two ends of the ultrahigh-toughness reinforced concrete anti-settling plate are connected with the bridge floor cast-in-place layers on the two sides respectively. According to the method, longitudinal cracks, caused by settlement deformation of the newly-built bridge, of the asphalt pavement layer can be effectively avoided, the durability of joints of the spliced wide bridge can be improved, and the driving comfort of the spliced wide bridge is greatly improved.

Owner:中冶南方城市建设工程技术有限公司 +1

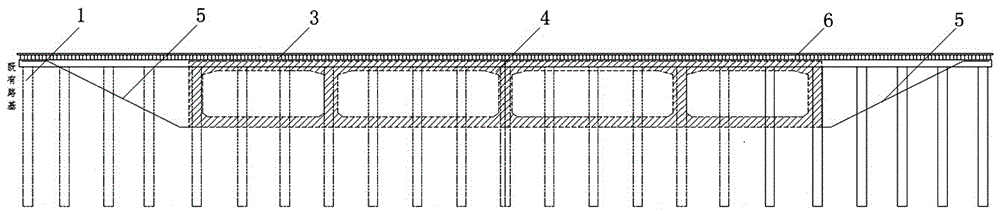

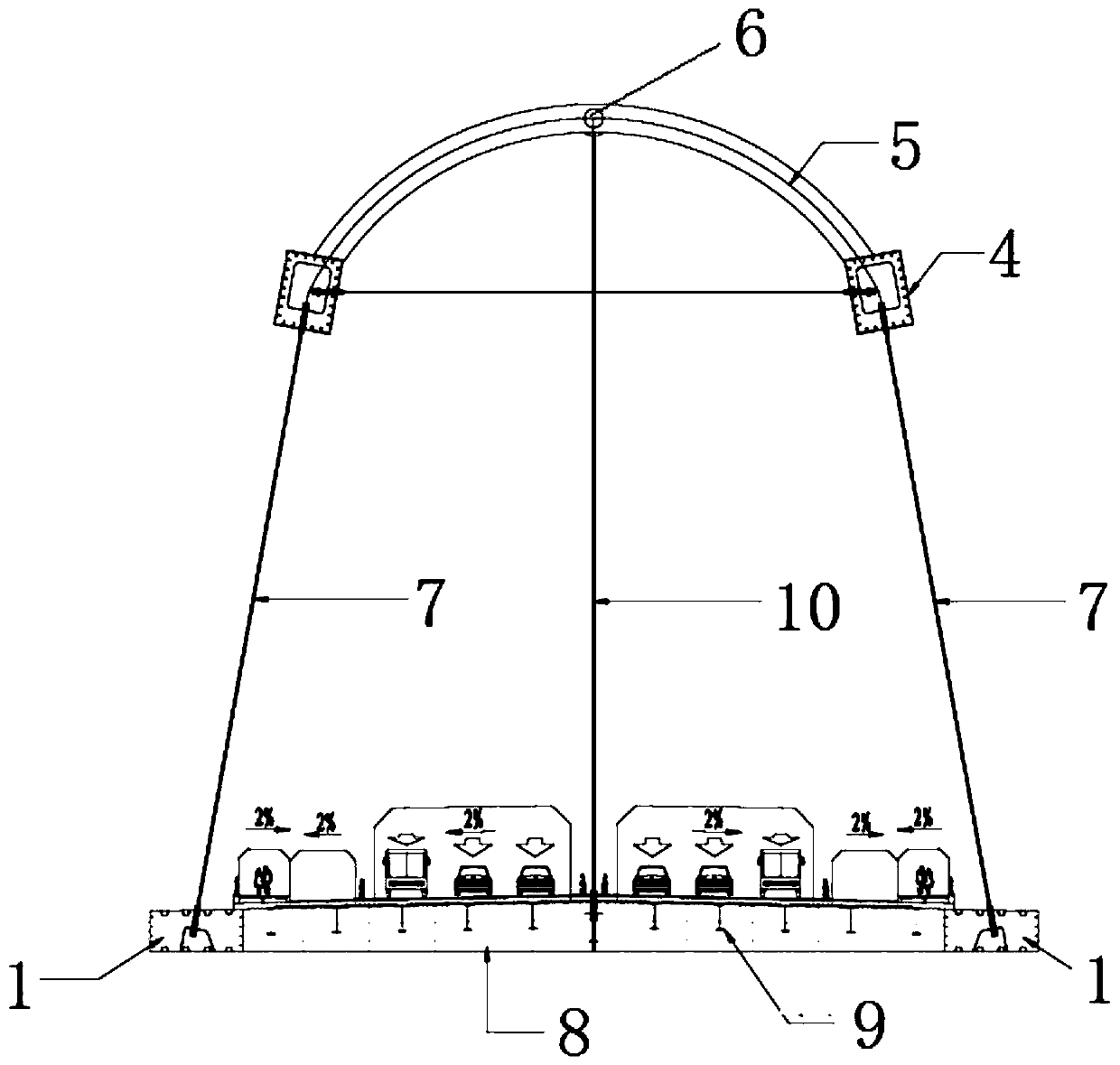

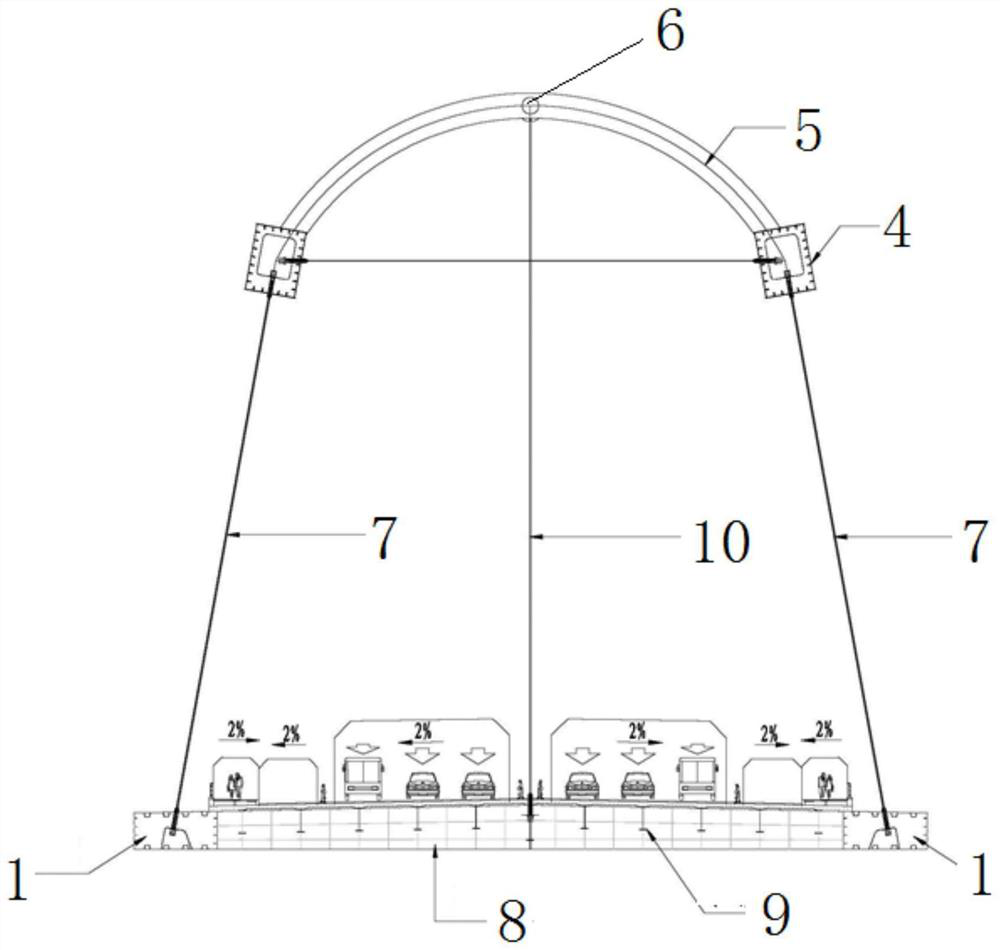

An ultra-wide cross-sectional structure suitable for a through steel truss girder of a double-track railway

PendingCN109056494AReduce vertical deflectionLower the altitudeBridge structural detailsVertical deflectionWide bridge

The invention relates to a railway bridge, in particular to an ultra-wide cross-sectional structure suitable for a through steel truss girder of a double-track railway. Comprises a steel truss beam, across beam for supporting the line and a transverse inclined bar, wherein the cross beam is located at the top of the steel truss beam, the transverse inclined bar is located below the cross beam, one end of the transverse inclined bar is connected with the middle of the cross beam, the other end of the transverse inclined bar is connected with the steel truss beam, and the transverse inclined bar is inclined arranged on the cross section of the line. As that transverse incline bar vertically supports the cross beam, the vertical deflection of the cross beam unde the action of dead load and live load is greatly reduced, and the height of the cross beam of the ultra-wide truss-wide bridge deck system is effectively reduced, thereby realizing the effect of saving material and reducing self-weight.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Bridge and tunnel intelligent detection vehicle mechanical arm system

InactiveCN111775851ALarge torqueImprove rigidityBridge structural detailsVehicle componentsStructural engineeringControl theory

The invention discloses a bridge and tunnel intelligent detection vehicle mechanical arm system. A first mechanical arm, a second mechanical arm and a third mechanical arm are driven or controlled bylead screw pairs, the moment of force is large, the rigidity is high, the stability is good, the mechanical arms can be lengthened according to needs without limitation, and wide bridges and large tunnels can be measured only through cameras or other detection devices installed at the tail ends of the mechanical arms.

Owner:SHANDONG JIAOTONG UNIV +2

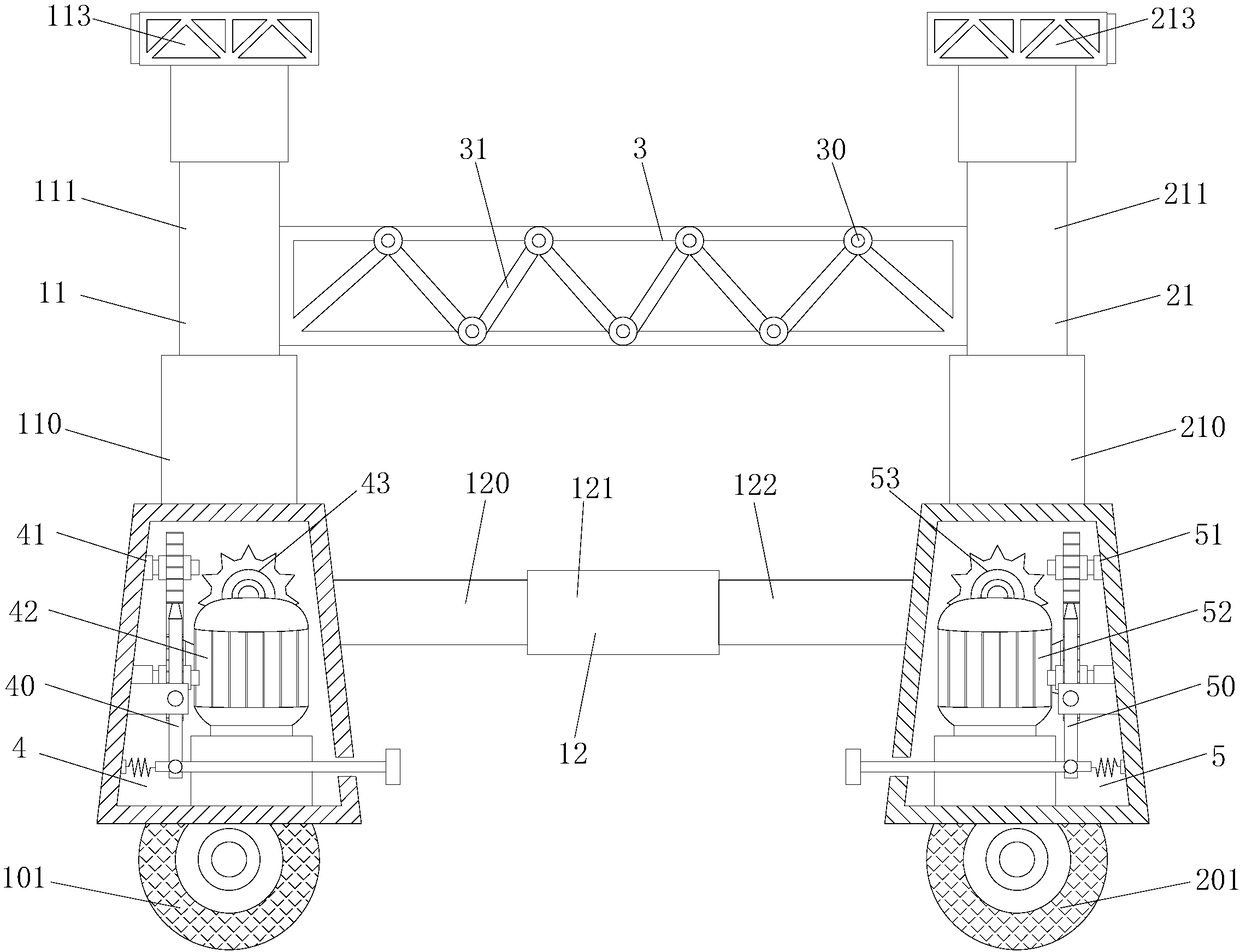

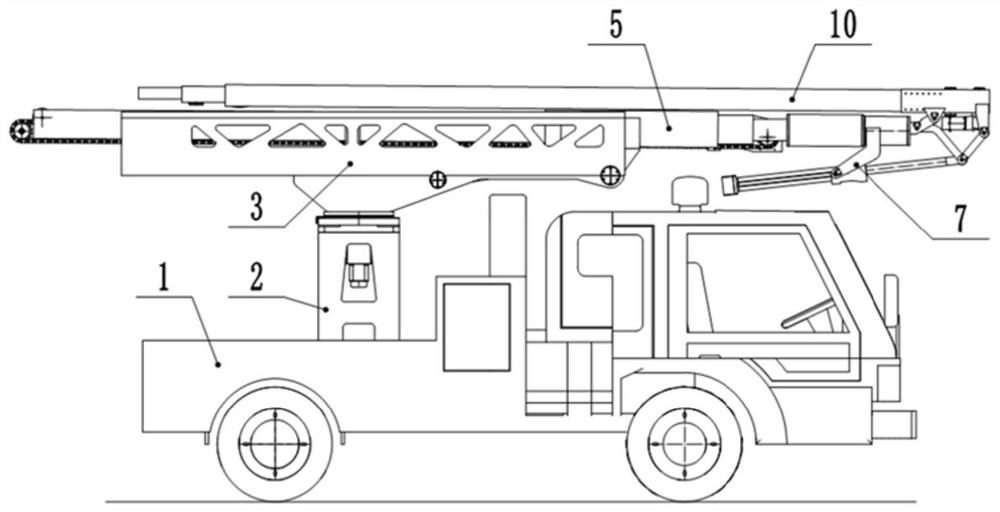

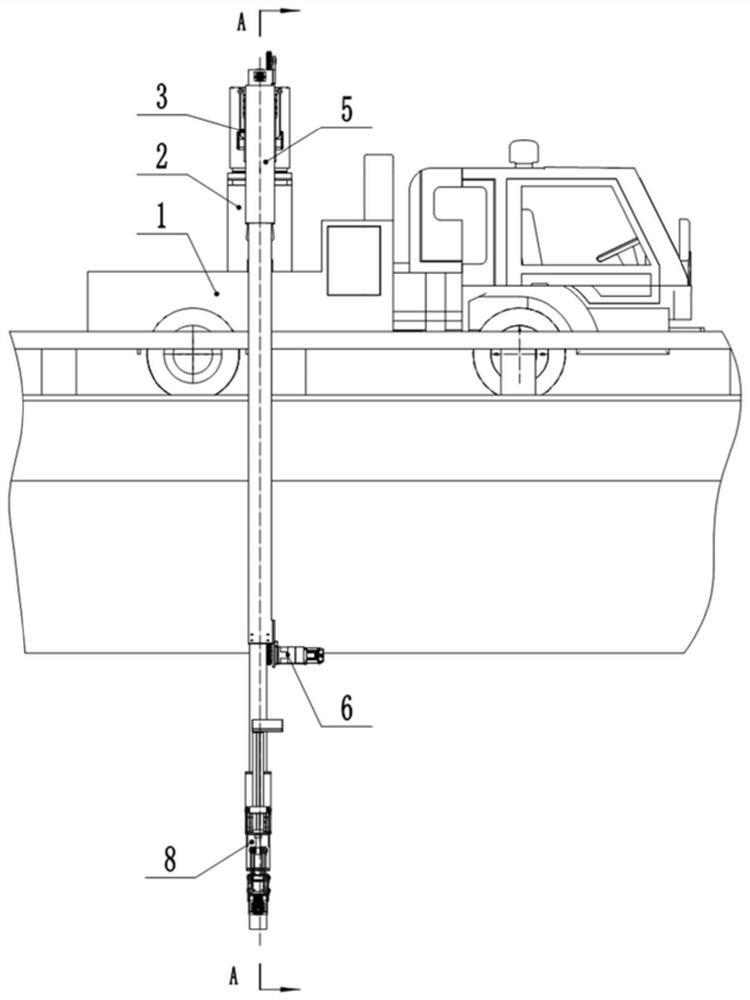

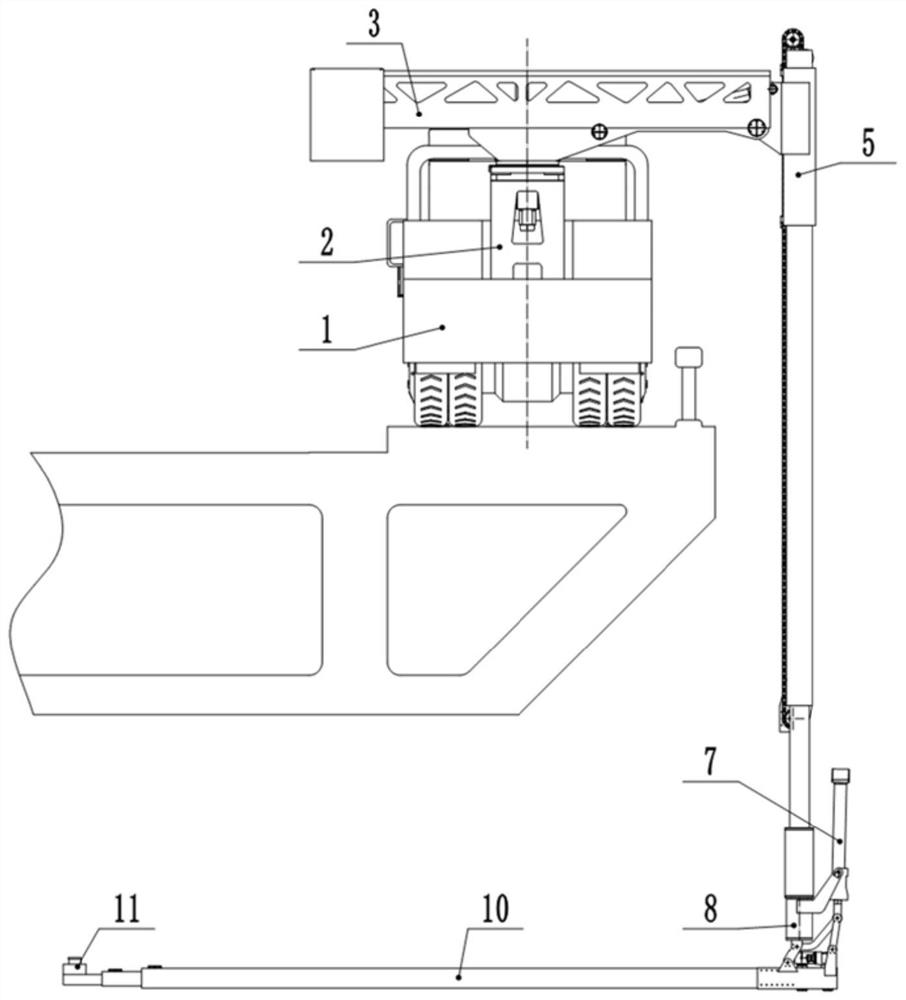

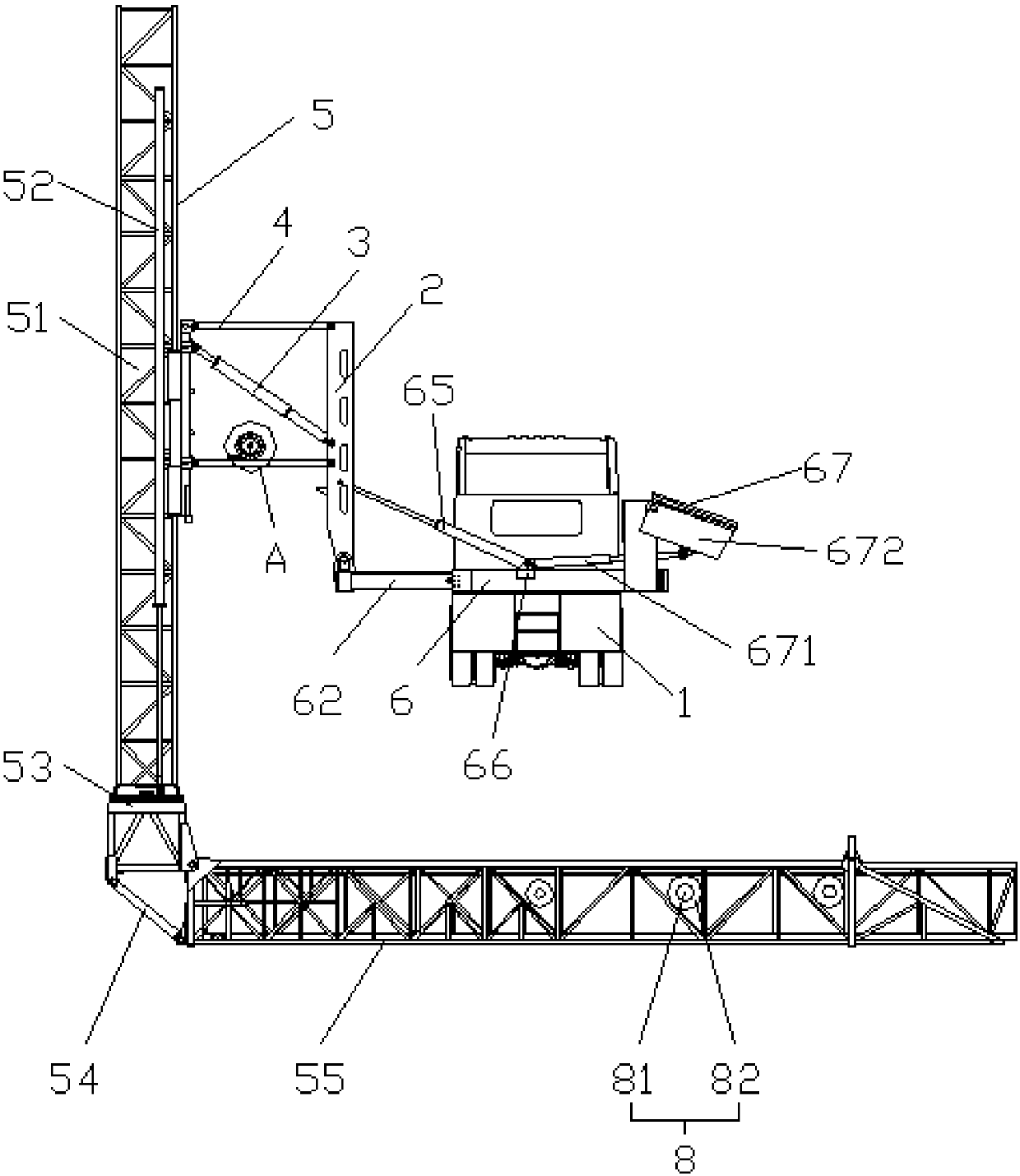

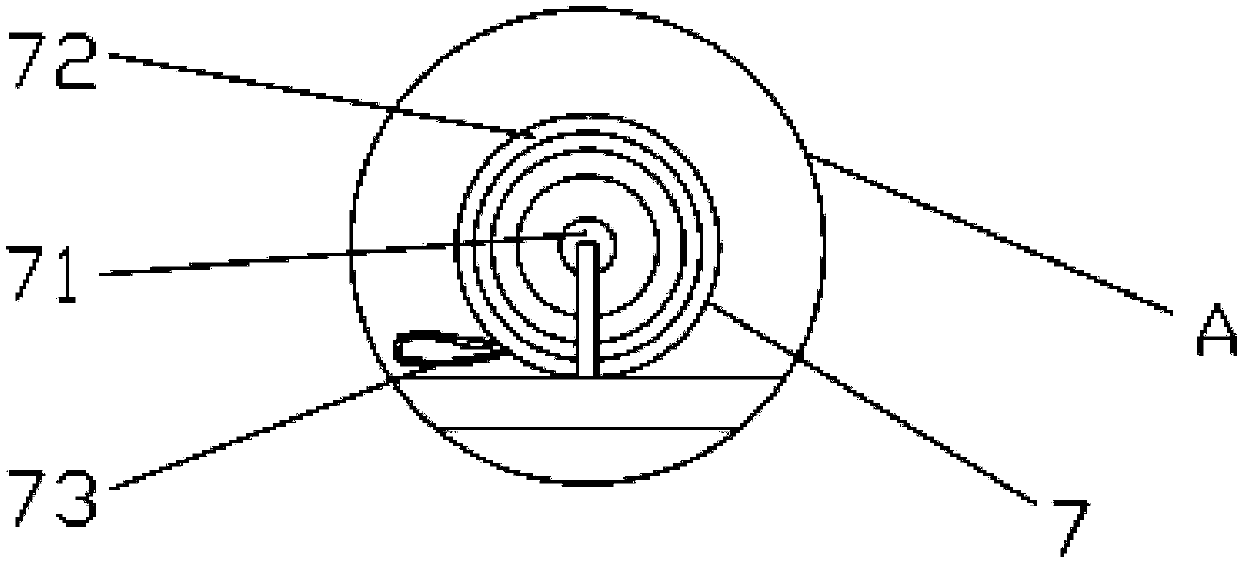

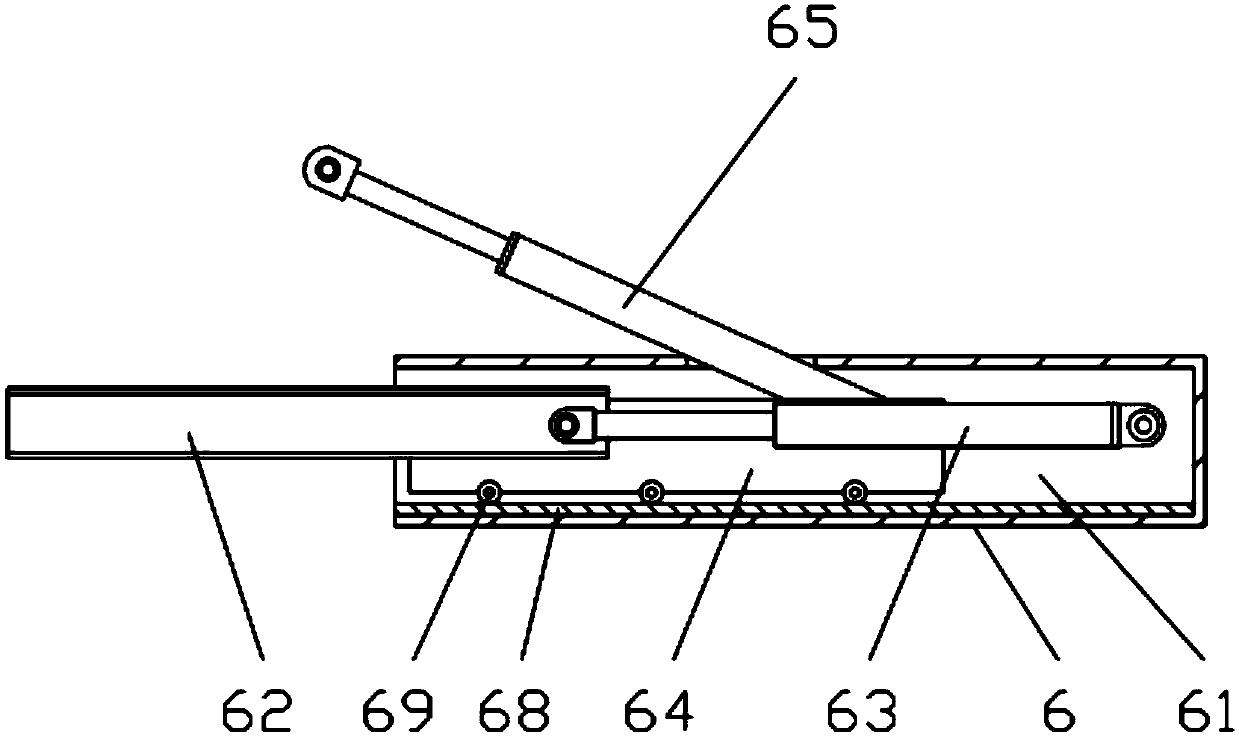

A horizontal telescopic ultra-wide bridge inspection vehicle

ActiveCN106049276BExpand span widthEasy to useBridge structural detailsOperational safetyWide bridge

The invention mainly discloses a horizontal telescopic ultra-span bridge inspection vehicle. Its technical proposal includes a vehicle body, a turning platen, a connecting rod oil cylinder, connecting rods and a truss as a whole. The vehicle body is provided with a large turntable. The inside of the large turntable is provided with a slideway, and the telescopic arm and the telescopic oil cylinder are arranged in the slideway, and the telescopic oil cylinder pushes the telescopic arm to move left and right in the slideway so as to push the turning table to move left and right. There is a bracket, and a counterweight is provided on the bracket, and the counterweight includes a counterweight oil cylinder and a counterweight, and a safety device is provided on the turning table, and the safety device includes a reel, wound on the reel safety rope and binder. The invention can realize the horizontal expansion and contraction of the whole truss, increase the spanning width, expand the use range of the bridge inspection vehicle, change the position of the counterweight center, improve the use performance of the inspection vehicle, and improve the operation safety of the bridge inspection vehicle.

Owner:HANGZHOU SPECIAL AUTOMOBILE

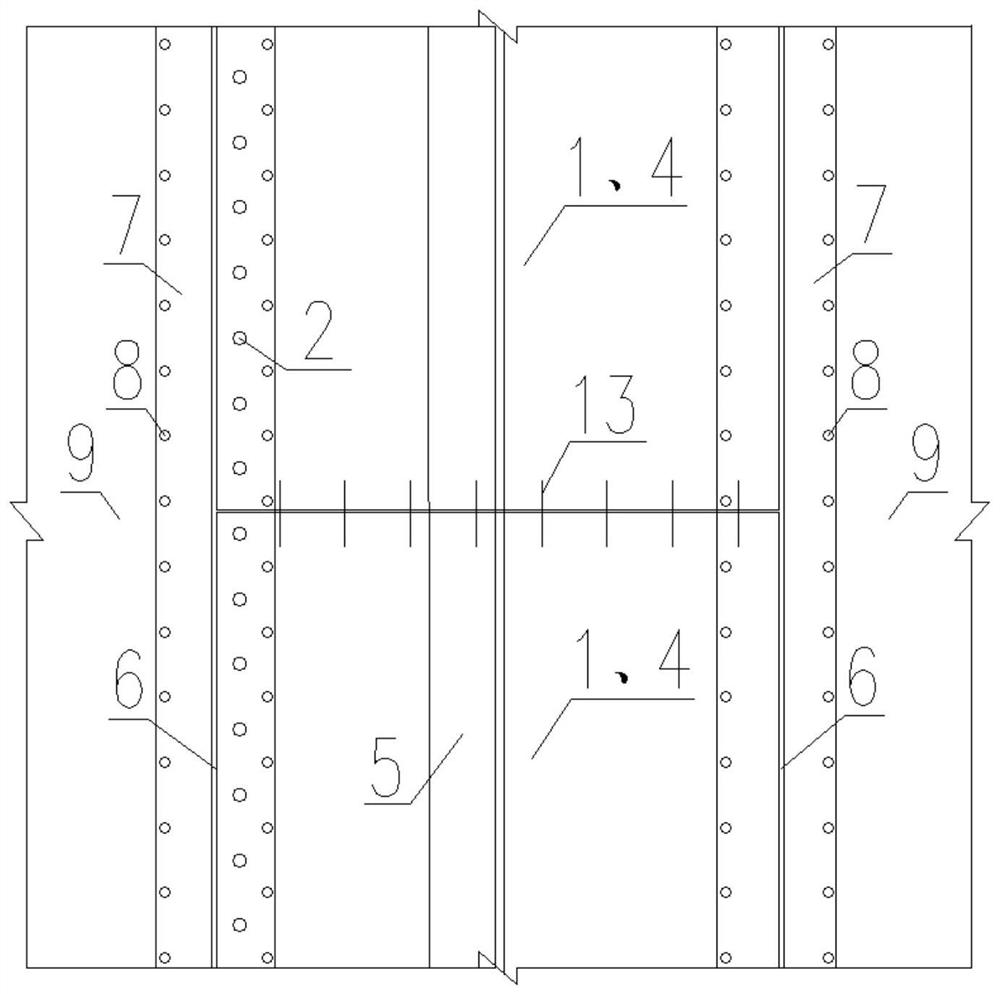

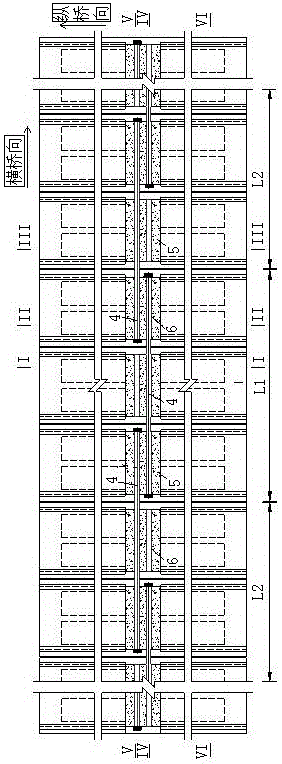

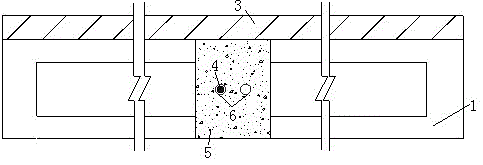

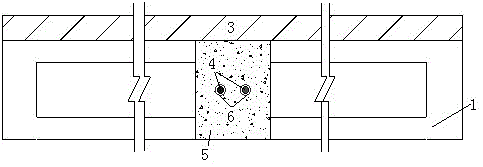

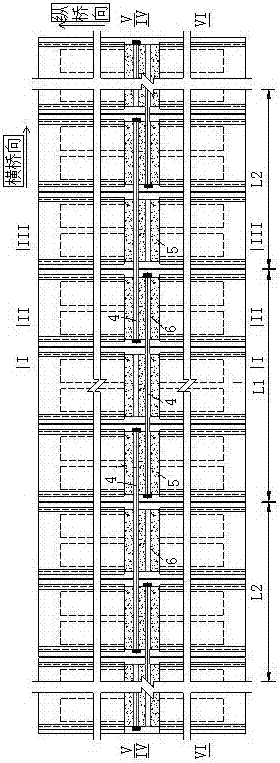

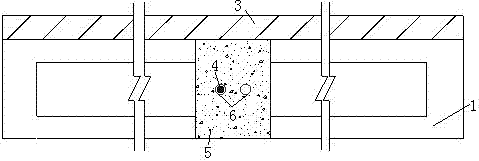

Hollow slab wide bridge structure for reinforcing hinge joints through batch transverse tensioning and construction method of hollow slab wide bridge structure

ActiveCN105672115ASimple structureTo overcome the shortage of transverse prestress tensionBridge structural detailsBridge erection/assemblyPre stressUltimate tensile strength

The invention relates to a hollow slab wide bridge structure for reinforcing hinge joints through batch transverse tensioning and a construction method of the hollow slab wide bridge structure.The hollow slab wide bridge structure comprises prefabricated hollow slabs which are arranged continuously in the transverse direction of a bridge side by side, each hinge joint is arranged between every two adjacent prefabricated hollow slabs, a bridge surface pavement layer is poured above the prefabricated hollow slabs and the hinge joints, and prestressed steel beams are tensioned transversely in batches inside the prefabricated hollow slabs.The construction method comprises the steps of prefabricating the hollow slabs; hoisting the first batch of prefabricated hollow slab sets, and making the first batch of prestressed steel beams penetrate through the first batch of prefabricated hollow slab sets; pouring hinge joint concrete among the first batch of prefabricated hollow slab sets, after design strength is achieved, tensioning the prestressed steel beams transversely, and conducting grouting and anchor sealing; hoisting the second batch of prefabricated hollow slab sets, and meanwhile making the second batch of prestressed steel beams penetrate; conducting the batch transverse tensioning construction procedure of remaining prefabricated hollow slab sets as mentioned till the prestressed steel beams are tensioned completely; pouring the bridge surface pavement layer, and forming the bridge after strength of the bridge surface pavement layer is achieved.The hollow slab bridge is simple in structure, and in addition, the transverse prestressed tensioning defects of an assembly type hollow slab wide bridge are effectively overcome.

Owner:福建省陆海工程科技有限公司

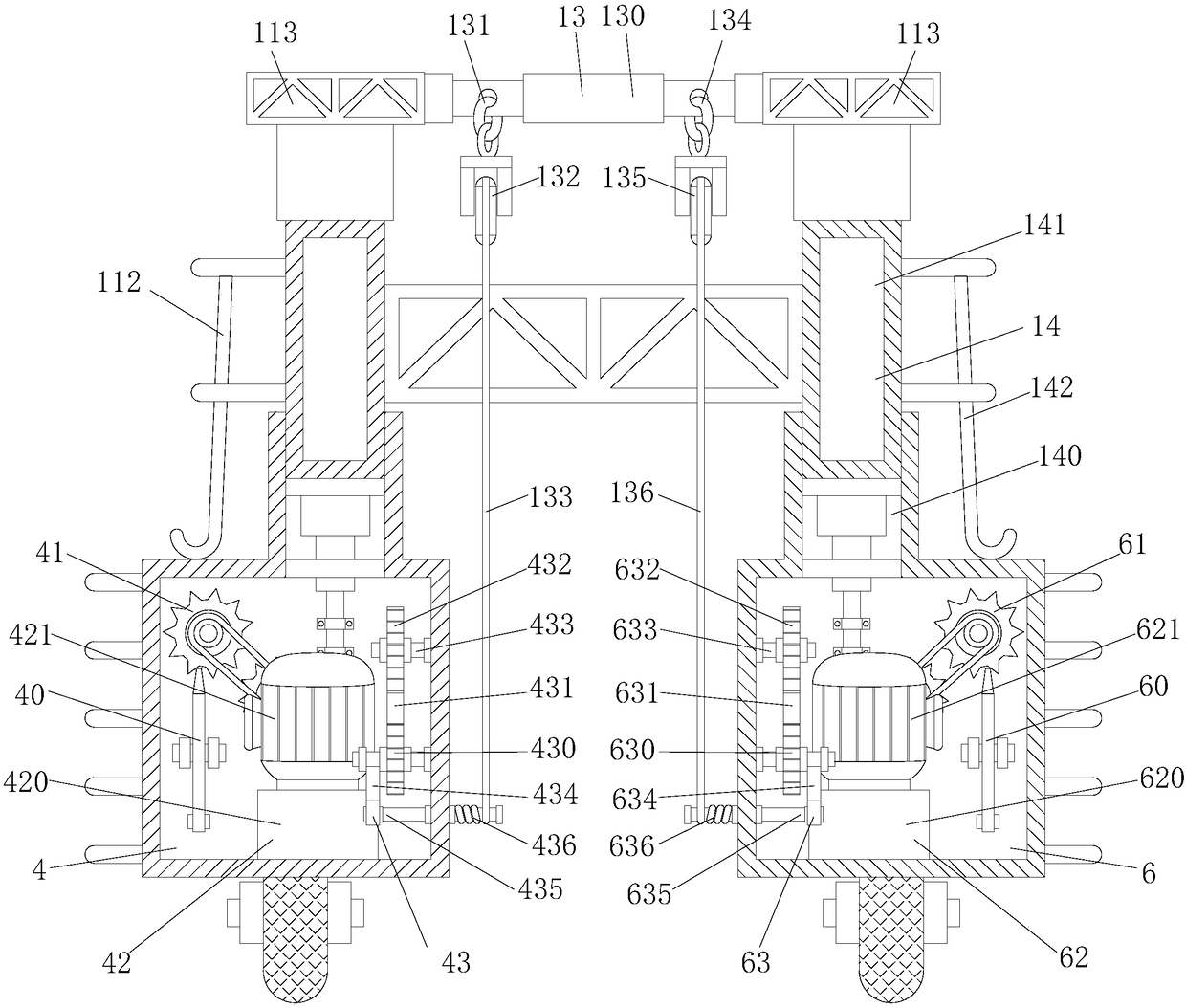

Ultra-wide bridge hanging basket structure and implementation method

PendingCN113026571AQuality assuranceEnsure safetyBridge erection/assemblyWide beamArchitectural engineering

The invention discloses an ultra-wide bridge hanging basket structure and an implementation method. The hanging basket structure is realized by adopting a plurality of groups of main bearing beams and stand columns, so that the bearing requirement of an ultra-wide beam is ensured; The hanging basket structure is further provided with a hanging basket bottom platform. The main bearing beams and the stand columns are connected through the inclined pull belts, the bearing lower sliding rails are designed below the bottom platform of the hanging basket, the transverse span of the bottom fence is reduced, and the gravity of an overweight structure during walking is shared. According to the ultra-wide bridge hanging basket structure, the construction problem of any ultra-wide suspended pouring segmental beam is solved; The method has the advantages that (1) the development of the ultra-wide section suspended pouring bridge is promoted; (2) graded construction at the current stage is changed into one-time segmental pouring, so that the construction quality, progress and cost are guaranteed; and (3) the safety degree of hanging basket construction is further improved through the structural design and invention of the hanging basket.

Owner:SICHUAN ROAD & BRIDGE GRP

Structure and Construction Method of Hollow Slab Wide Bridge with Batch Transverse Stretch Strengthening Hinge Joints

ActiveCN105672115BSimple structureTo overcome the shortage of transverse prestress tensionBridge structural detailsBridge erection/assemblyPre stressUltimate tensile strength

Owner:福建省陆海工程科技有限公司

A new double-curved arch bridge

ActiveCN109763416BThe stress is reasonableOptimize the vertical forceArch-type bridgeClassical mechanicsEngineering

The invention relates to a novel double-curved arch bridge. The arch bridge includes a main girder, a main arch rib, an auxiliary arch rib, a side suspender and a middle suspender. Both sides of the main girder are provided with a parabolic main arch rib. There are multiple parabolic auxiliary arch ribs between the two main arch ribs, the two ends of the main arch ribs (i.e. The main arch rib is fixed. Compared with the prior art, the present invention reduces the stress on the beam for wide bridges due to the addition of suspenders and auxiliary arch ribs between the parabolic main arch ribs, which is beneficial to reduce the height of the beam and control the width of the wide bridge. structure height.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

A Calculation Method of Lateral Distribution Coefficient of Single-box Multi-chamber Wide-Girder Bridge

ActiveCN107025330BReduce processing complexityIncreased durabilityGeometric CADSpecial data processing applicationsModel testControl theory

Owner:SHANXI TRAFFIC PLANNING PROSPECTING & DESIGN INST +1

Construction reinforcing platform for medium-and-small-span beam bridge

PendingCN113622325AEasy constructionEasy to transportBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention provides a construction reinforcing platform for medium-and-small-span beam bridge, which comprises a construction platform, wherein a rail is arranged on the top surface of the construction platform; the rail is parallel to the length direction of the construction platform; a pulley is installed on the rail in a rolling mode; a jacking machine is installed through the pulley in a sliding mode; fences are arranged on the two opposite sides of the top face of the construction platform; and the jacking machine is arranged between the fences on the two sides. The pulley devices are arranged on the two opposite sides of the construction platform, the two opposite sides are parallel to the width direction of the construction platform, the pulley devices are located on the outer sides of the fences, the construction platform is slidably installed on sliding rails through the pulley devices, the sliding rails are fixed to a beam bridge through bracket columns on beam bridge columns, and the sliding rails are arranged in the width direction of the beam bridge and each have one end extends out of the beam bridge. The construction reinforcing platform can guarantee construction safety, can reinforce a beam bridge with a wide bridge floor, can conveniently reinforce the bridge floor by using heavy materials such as externally bonded steel plates, saves time and labor, saves cost, is wide in application range, and does not influence traffic.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

Pouring device for cast-in-place box girder of spliced wide bridge

PendingCN113699886AShorten the lengthReduce labor intensityBridge erection/assemblyRebarMechanical engineering

The invention discloses a pouring device for a cast-in-place box girder of a spliced wide bridge , which comprises a lifting platform, a first clamping piece is arranged on the lifting platform, a second clamping piece is arranged on the lifting platform, a fixing piece is arranged on the lifting platform, a third clamping piece is arranged on the fixing piece, a cutting piece is rotationally arranged on the fixing piece, and a material guiding piece is arranged on the cutting piece. A driving part is arranged on the lifting table, and a grouting part is arranged on the lifting table in a sliding mode. According to the pouring device, the material guiding piece penetrates into the concave hole in the end of the box girder to be matched with the rotating cutting piece, a steel bar group in the concave hole is cut off through gas cutting, the cutting efficiency is high, the labor intensity of workers is reduced. Meanwhile, the length of the cut steel bar is smaller than the depth of the hole, later grouting and trowelling are facilitated, the steel bar is effectively clamped by the clamping piece during cutting. The cutting scatter is prevented, and the subsequent cutting cleaning is faciliated. The device is provided with the grouting piece, so that the holes are efficiently grouted and flattened, and the stability of the box girder structure is guaranteed.

Owner:CHINA FIRST HIGHWAY ENG +1

Bottom width overhaul hanging basket of bridge

InactiveCN103306218BImprove construction efficiencyImprove maintenance efficiencyBridge erection/assemblyBridge strengtheningEngineeringHanging basket

The invention discloses a bottom width overhaul hanging basket of a bridge, which solves the problems that a bridge overhaul car and a vessel are not applicable to the large or oversize bridge with a wider deck and greater height in the prior art. The overhaul hanging basket comprises a travelling mechanism and a working platform, wherein the travelling mechanism comprises a first travelling mechanism and a second travelling mechanism capable of travelling along the two sides of the deck; the working platform comprises a first working platform and a second working platform; the first working platform is detachably arranged below the first travelling mechanism; the second working platform is detachably arranged below the second travelling mechanism; the first working platform and the second working platform are located below the bridge during working; and the end part of the first working platform is detachably connected with the end part of the second working platform. The overhaul hanging basket is applicable to the wider bridge, can improve the construction or overhaul efficiency of the bridge, and is free from the limitation of the height of the bridge.

Owner:CHONGQING YUNAN ELECTROMECHANICAL MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com