Pouring device for cast-in-place box girder of spliced wide bridge

A cast-in-place and box girder technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high labor intensity, time-consuming and laborious, etc., and achieve the effects of reducing labor intensity, ensuring stability, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

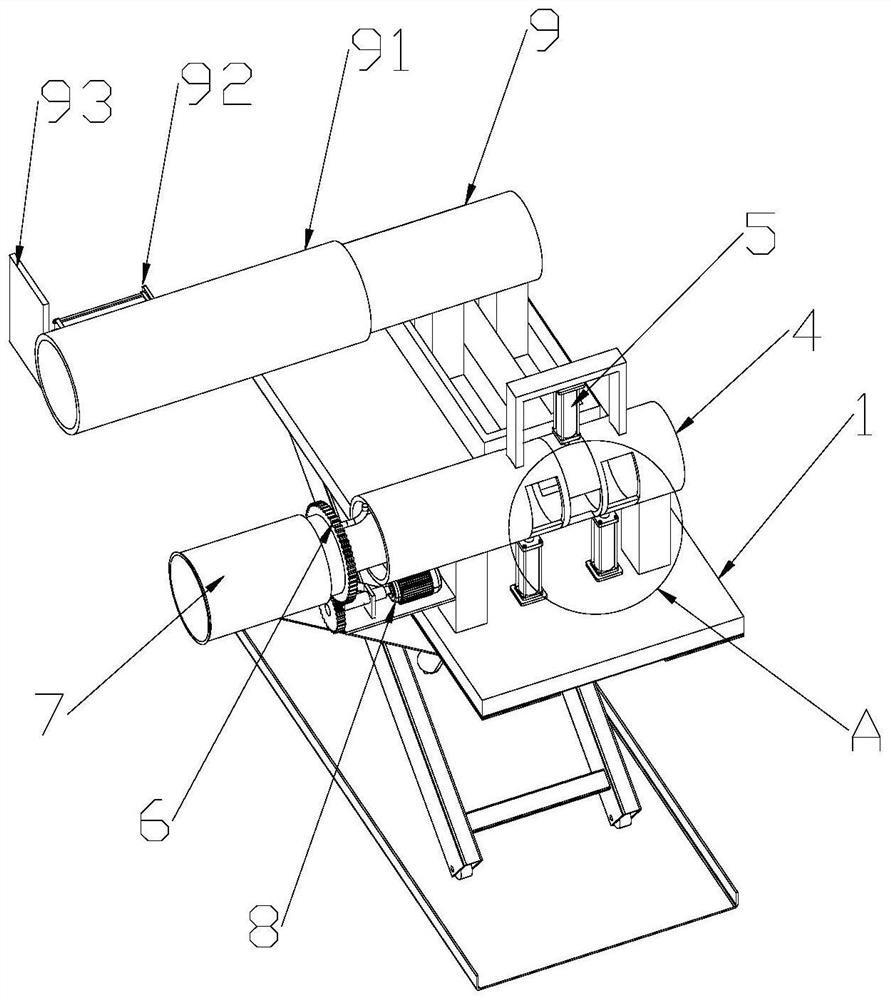

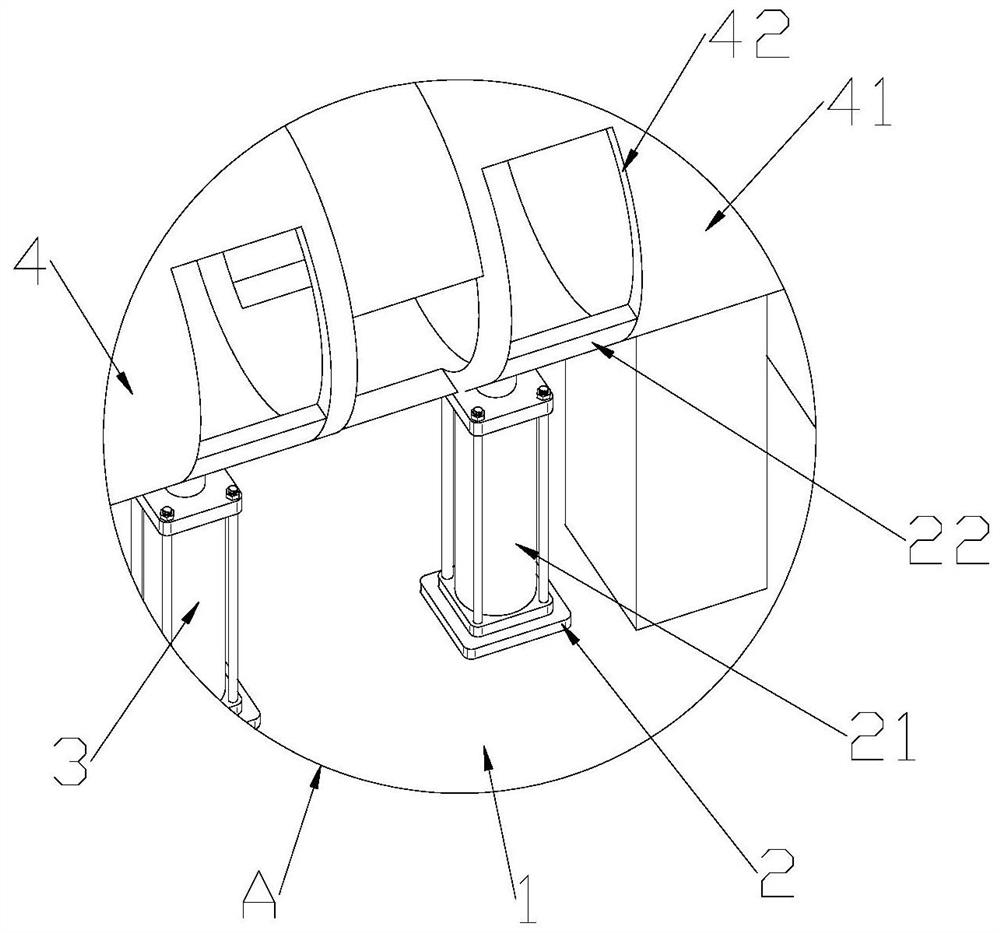

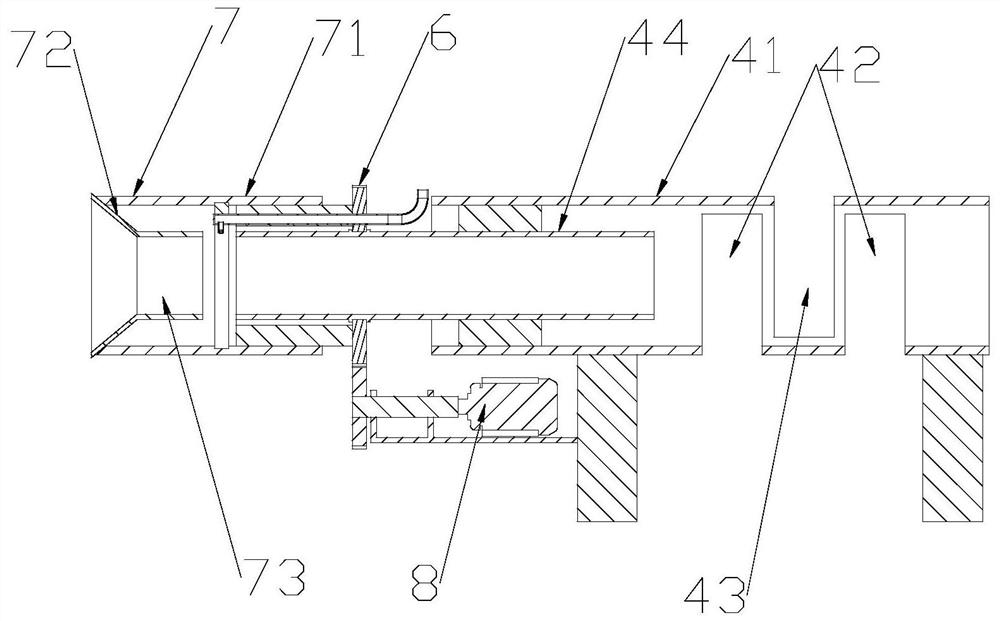

[0026] A pouring device for cast-in-place box girders of Pinkuan Bridge, the pouring device includes a lifting platform 1, such as figure 1 , figure 2 As shown, universal wheels are provided under the lifting platform 1, a first clamping part 2 is provided on the lifting platform 1, a second clamping part 3 is provided on the lifting platform 1, and a fixing part 4 is provided on the lifting platform 1. The fixing part 4 is provided with a third clamping part 5, and the fixing part 4 is provided with a cutting part 6 for rotation, and the cutting part 6 is provided with a material guide part 7, and the material guide part 7 is connected with the cutting part 6 in rotation, and the guide material The part 7 can also be firmly connected with the cutting part 6, and the driving part 8 is arranged on the lifting table 1.

[0027] The first clamping member 2 includes a hydraulic cylinder 21, such as figure 2 As shown, the output shaft of the hydraulic cylinder 21 is tightly con...

Embodiment 2

[0033] Embodiment 2 further includes a grouting part 9 on the basis of Embodiment 1.

[0034] Grouting part 9 comprises telescoping tube 91, as figure 1 As shown, the telescopic tube 91 is slidingly connected with the lifting platform 1, the telescopic tube 91 is provided with a telescopic cylinder 92, the output shaft of the telescopic cylinder 92 is fastened to a scraper 93, and the telescopic tube 91 is connected with the grouting machine.

[0035] When in use, move the lifting platform 1 so that the trumpet tube 72 is aligned with the concave hole at the end of the box girder, and push the transfer so that the concave hole steel bar is inserted into the horn hole 72 and the guide tube 44, and the outer tube is inserted into the end hole of the box beam. The hydraulic cylinders on the holding part 2, the second holding part 3 and the third holding part 5 push the splint 22 to clamp the steel bar group, start the motor 81 and the gas cutting machine, and the cutting part 6 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com