Method for reinforcing railway through piling girders combined with I-steel cross girders

A technology of I-beams and beams, which is applied in the direction of roads, laying tracks, tracks, etc., can solve problems such as slope instability and collapse, endangering driving safety, and difficult control of the scope of railway subgrade collapse, so as to enhance integrity and improve construction efficiency , Reduce the effect of structural technical risk and construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

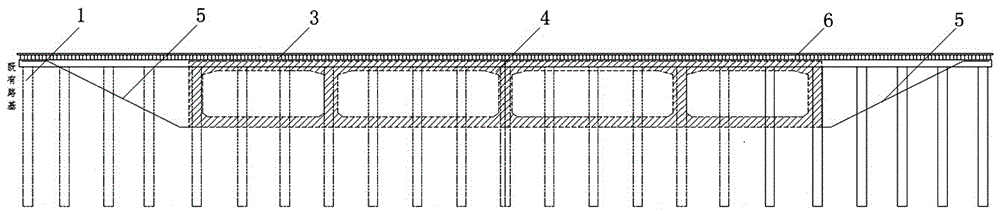

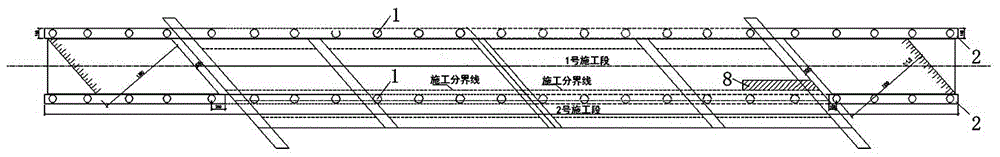

[0022] The method for reinforcing the railway with row pile beams combined with I-beam beams, the steps are:

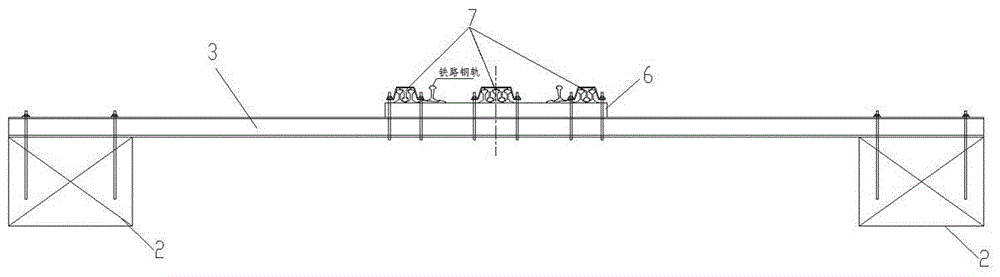

[0023] 1) Reinforcement of the structural foundation: On both sides of the construction entrance line, a row of bored piles 1 are used as the reinforcement foundation, and at the top of each row of bored piles 1, a pile top crown beam 2 is arranged along the direction of the arrangement of the bored piles 1 , the bolts connected with the I-beam beam 3 are reserved on the pile top crown beam 2, and the g grid structure size is determined by the specific structural conditions during construction.

[0024] 2) Lay buckle rail beams: carry out conventional stress relief and long rail relaxation on the line during the train skylight time, replace the sleepers 6, replace the concrete sleepers with wooden sleepers, and lay the buckle rail beams 7 on the sleepers 6, as described The buckle rail beam 7 is specifically a 3-5-3 buckle rail beam composed of 43kg / m rails.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com