Top pushing mechanism of steel box girder of single longitudinal clapboard on wide bridge deck and top pushing method

A technology of steel box girders and medial diaphragms, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem that it is difficult to ensure that the steel box girders are well stressed and the alignment of the bridge can not meet the requirements of the bridge design, and affect the force of the steel box girders and other issues, to achieve the effect of simplifying construction, saving costs, and clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

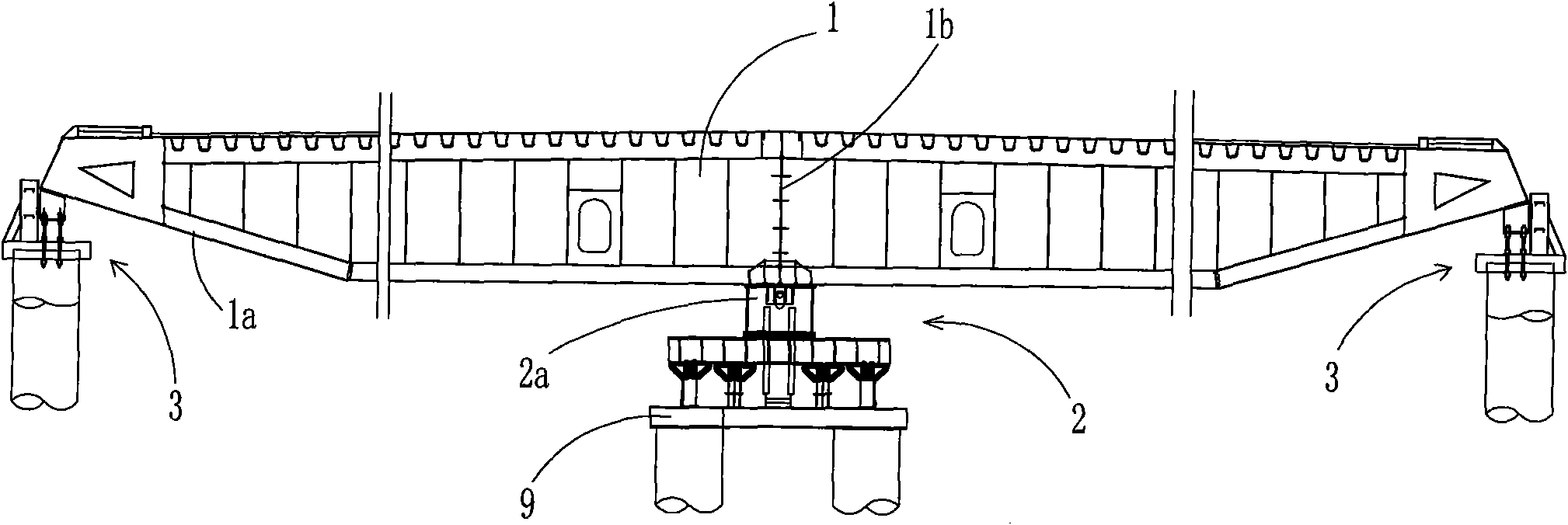

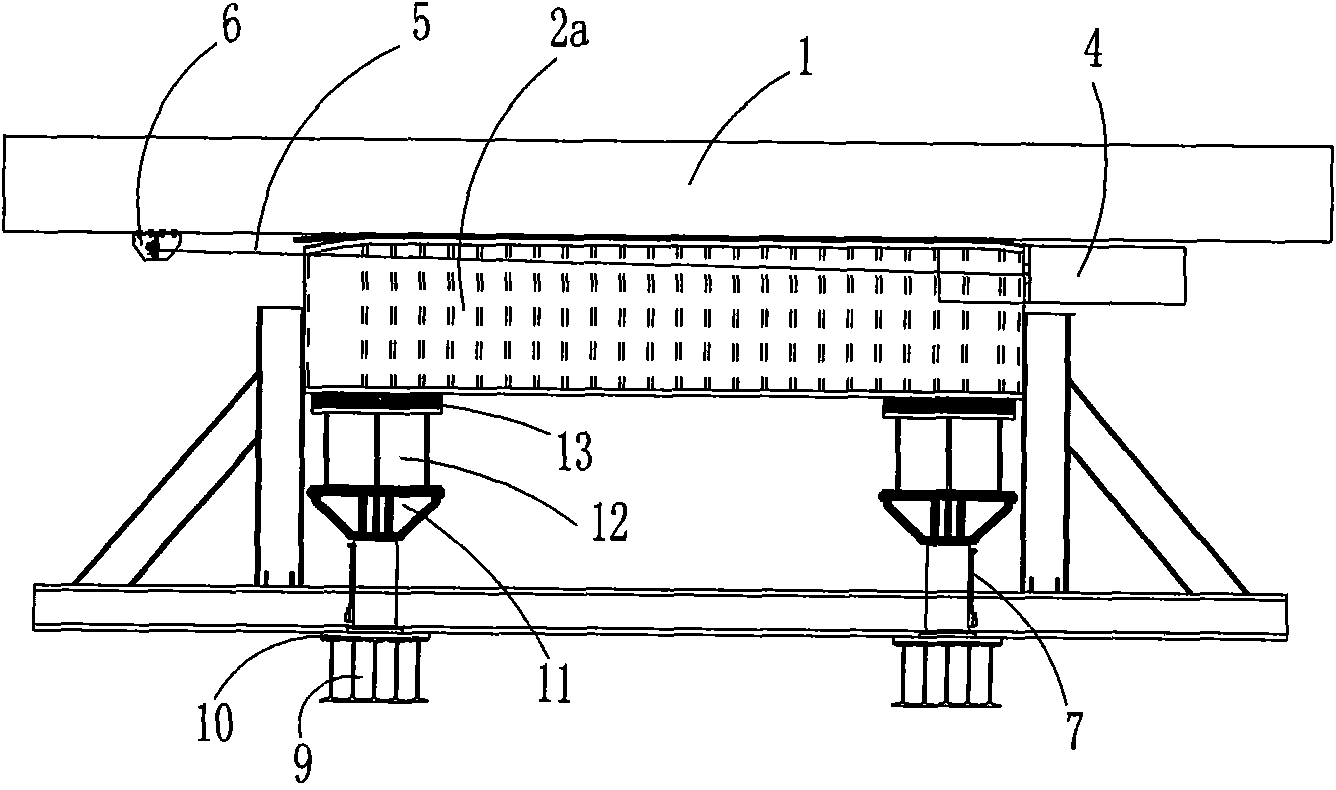

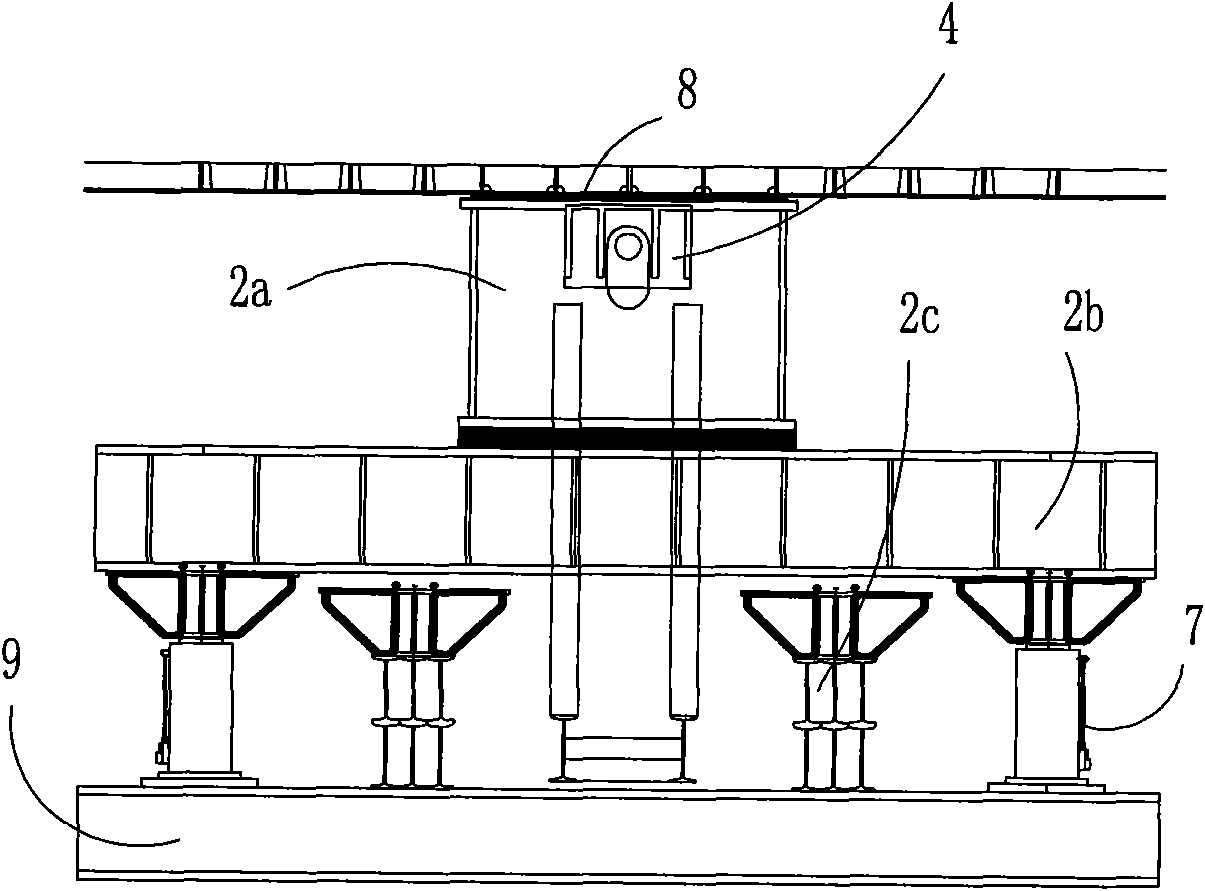

[0026] see figure 1 , figure 2 with image 3 , the pushing mechanism in this embodiment is composed of a main pushing mechanism 2 located in the center of the bottom of the steel box girder 1 and an auxiliary traction mechanism 3 respectively located at the ends of the lower inclined plates 1a of the steel box girder on both sides;

[0027] The main pushing mechanism 2 has a longitudinal main slideway 2a, which is located at the corresponding position of the central longitudinal diaphragm 1b of the steel box girder. The longitudinal main slideway 2a is supported on the central pier platform 2b, and the jacking jack 4 fixedly arranged on the central pier platform 2b, one end of the main traction cable 5 is connected to the jack 4, and the other end is connected to the tail of the steel box girder 1 of each segment through the anchor puller 6; on the central pier platform 2b The bottom is provided with a jacking jack 7 and a steel pier 2c that can be equipped with an adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com