Workpiece transport device

A technology for conveying devices and workpieces, applied in the directions of conveyor objects, transportation and packaging, furnace components, etc., can solve the problems of increasing the upper and lower height of the conveying chamber, increasing the mechanical strength, and changing the upper and lower positions, and achieves compactness, restraint The effect of increasing the size and reducing the moment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the drawings.

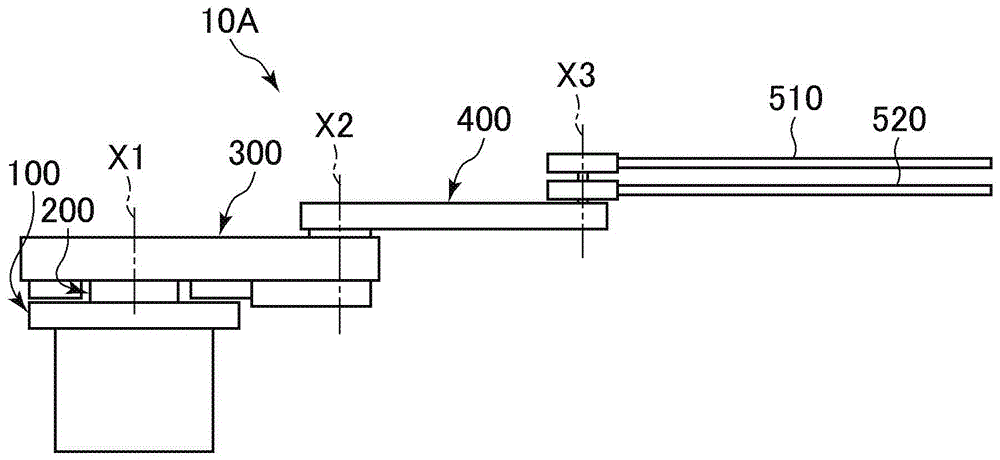

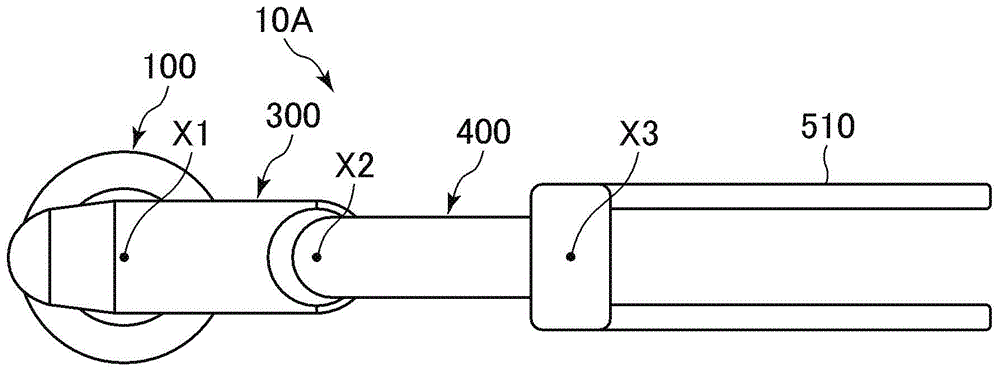

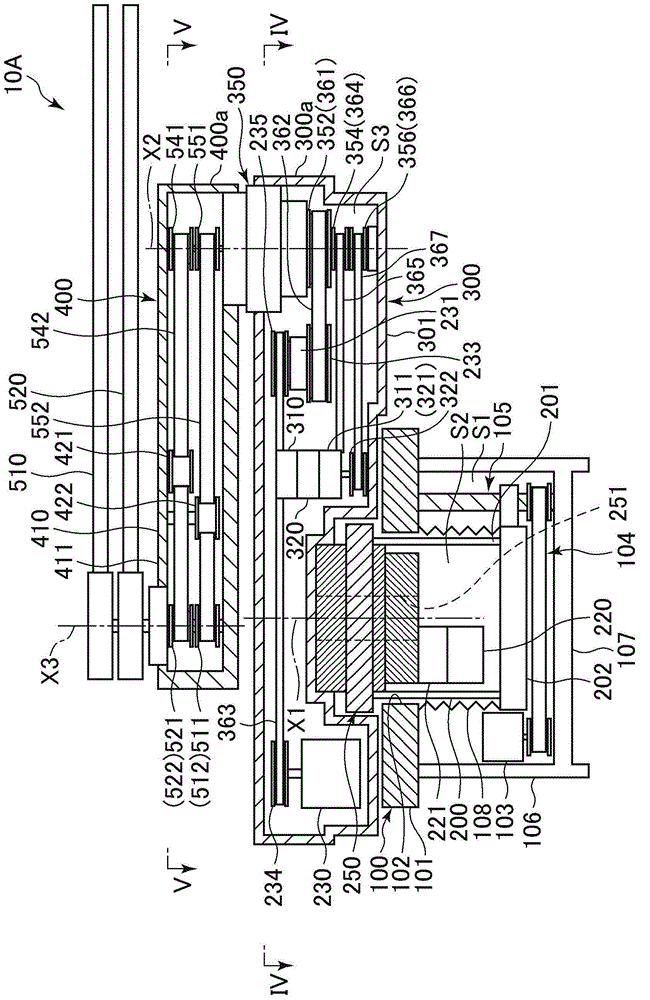

[0043] Figure 1 to Figure 6 10A of workpiece|work conveyance apparatuses which concerns on 1st Embodiment of this invention are shown. This workpiece conveyance device 10A includes a fixed base 100 , a support base 200 , a support arm 300 , a hand holding arm 400 , and two hands 510 , 520 . This workpiece conveyance device 10A is installed, for example, in a transfer chamber in a processing system performed in a vacuum environment.

[0044] Such as image 3 As shown in , the fixed base 100 accommodates and holds the support base 200 in a liftable manner. The support base 200 has its upper portion protruding from the opening 102 provided in the top plate 101 of the fixed base 100, and is supported so as to be movable up and down by vertical guides (not shown). Further, the support base 200 is raised and lowered by a ball screw mechanism 105 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com