Vertical shaft tidal current generating set

A tidal power generation, vertical axis technology, applied in the direction of tidal flow/damless hydropower, hydropower, ocean energy power generation, etc. The vertical self-weight load and horizontal impact load of the main shaft are large, so as to improve the starting performance and power generation efficiency, reduce the bending moment load and friction resistance of the main shaft, and increase the maximum horizontal load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing example:

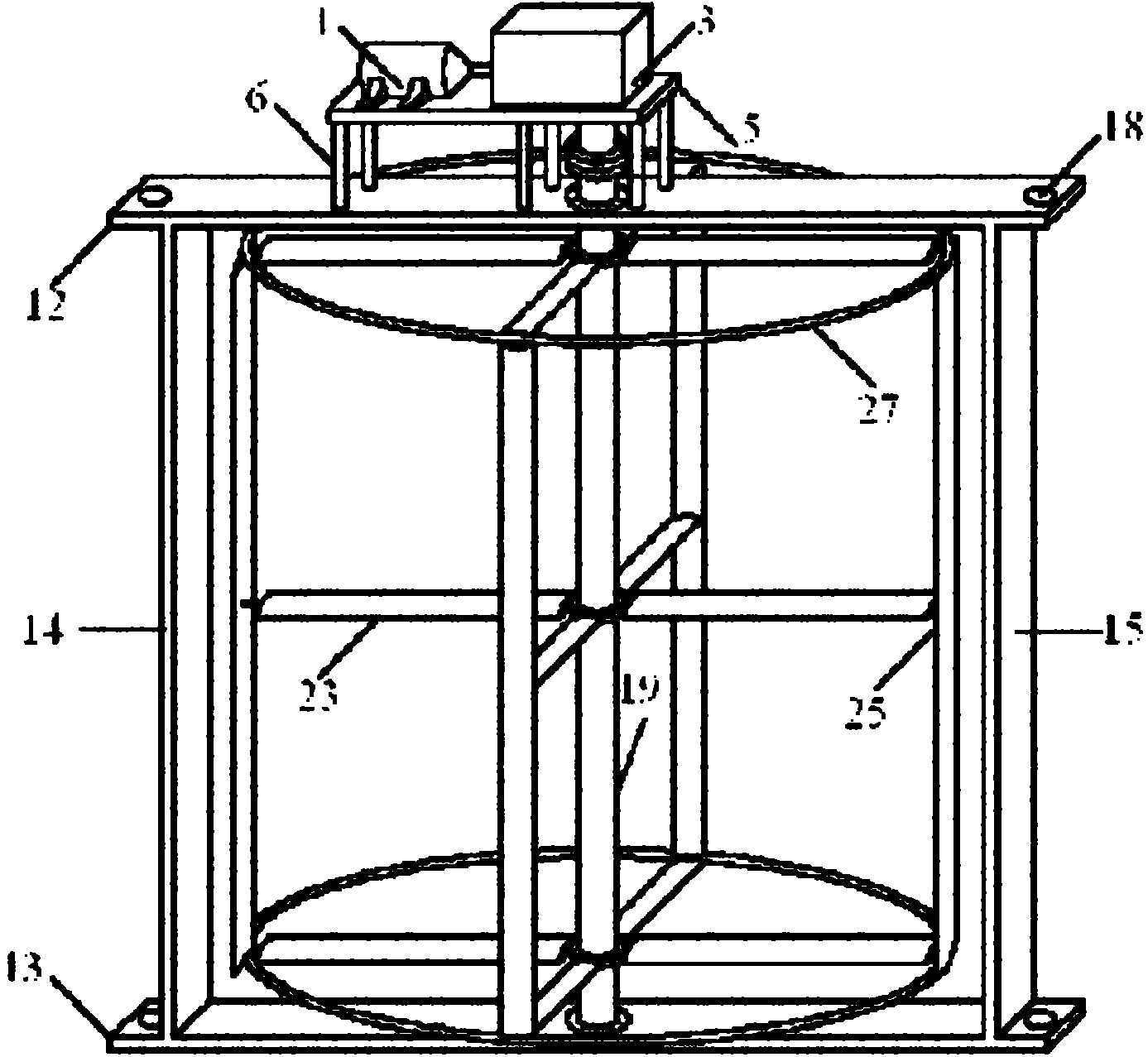

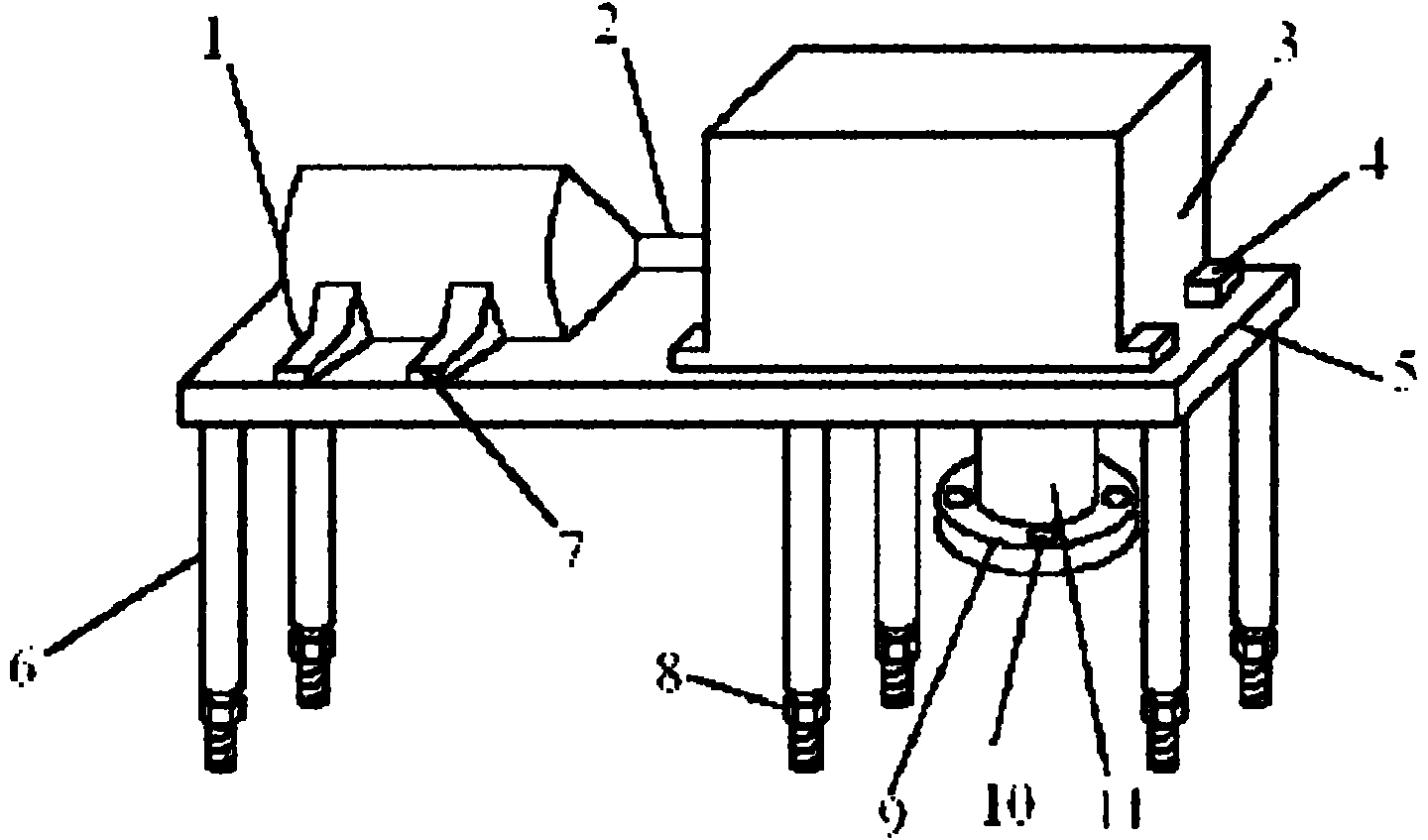

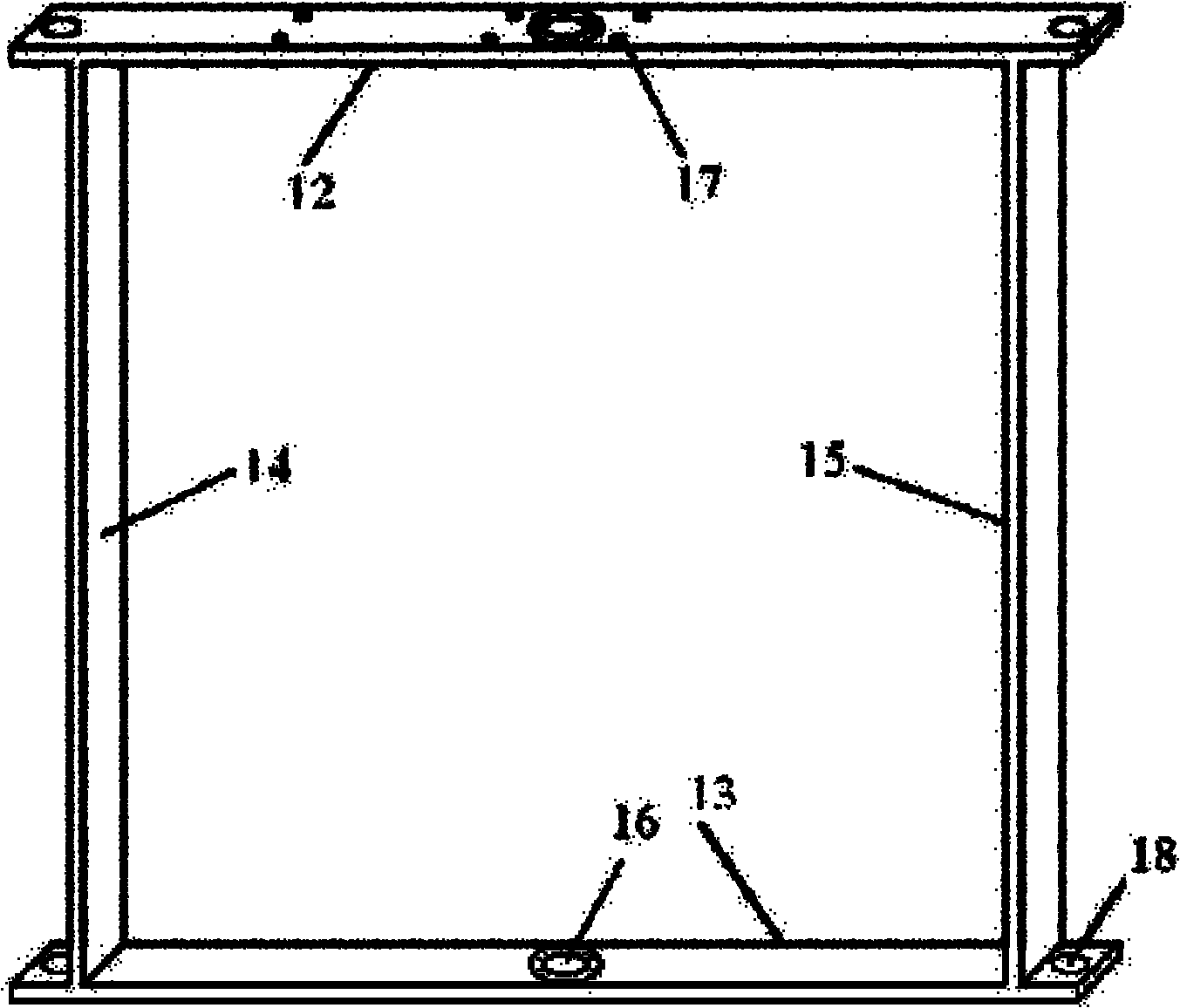

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the patent of the present invention includes three modules of the upper platform part, the support frame part and the impeller part.

[0025] The upper platform part includes a generator 1, a horizontal connecting shaft 2, a gearbox 3, a gearbox seat 4, a supporting platform 5, six pillars 6, a generator seat 7, six rotating bolts 8, a vertical Connecting shaft flange 9, and a vertical connecting shaft 11. The support platform 5 is supported by six pillars 6 and fixed on the upper frame plate 12 by six rotating bolts 8 . The left end of the support platform 5 is provided with a generator 1 and the right end is provided with a gear box 3 . The gearbox 3 and the generator 1 are connected through a horizontal connection shaft 2 . The generator 1 is provided with a generator base 7, the gear box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com