Processing device for rail systems in urban areas

A technology for treatment devices and urban areas, applied in the direction of fixed grinding wheel devices, rails, rail maintenance, etc., can solve the problems of high total weight, increase noise pollution and exhaust gas pollution, movable treatment devices cannot be used, etc., to achieve high friction coefficient, the effect of avoiding conversion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

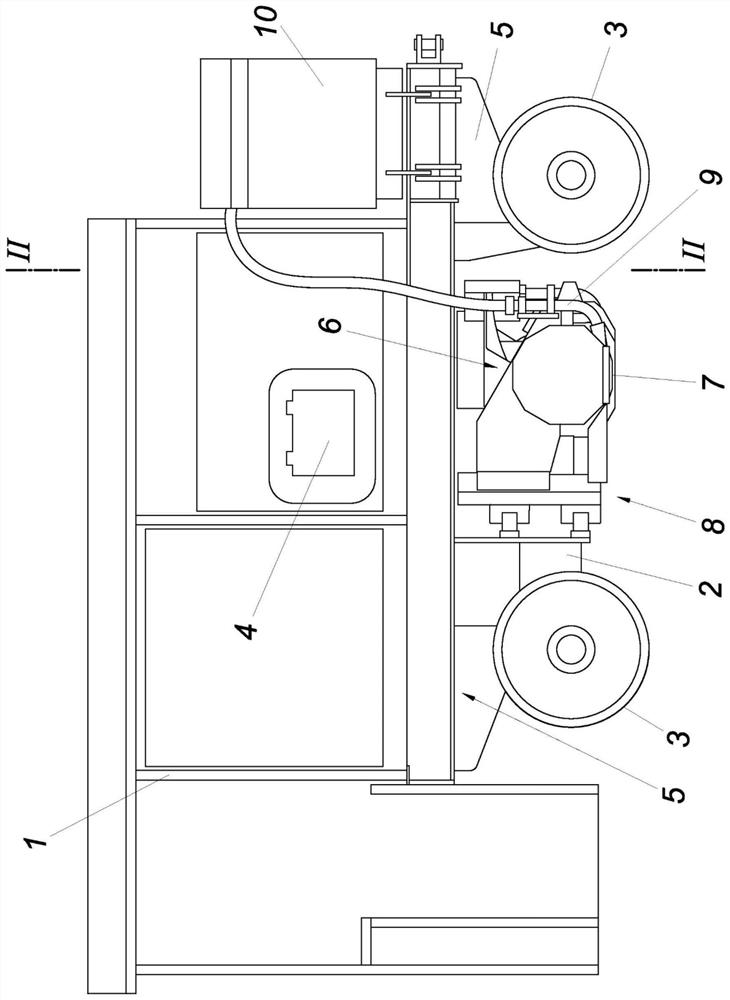

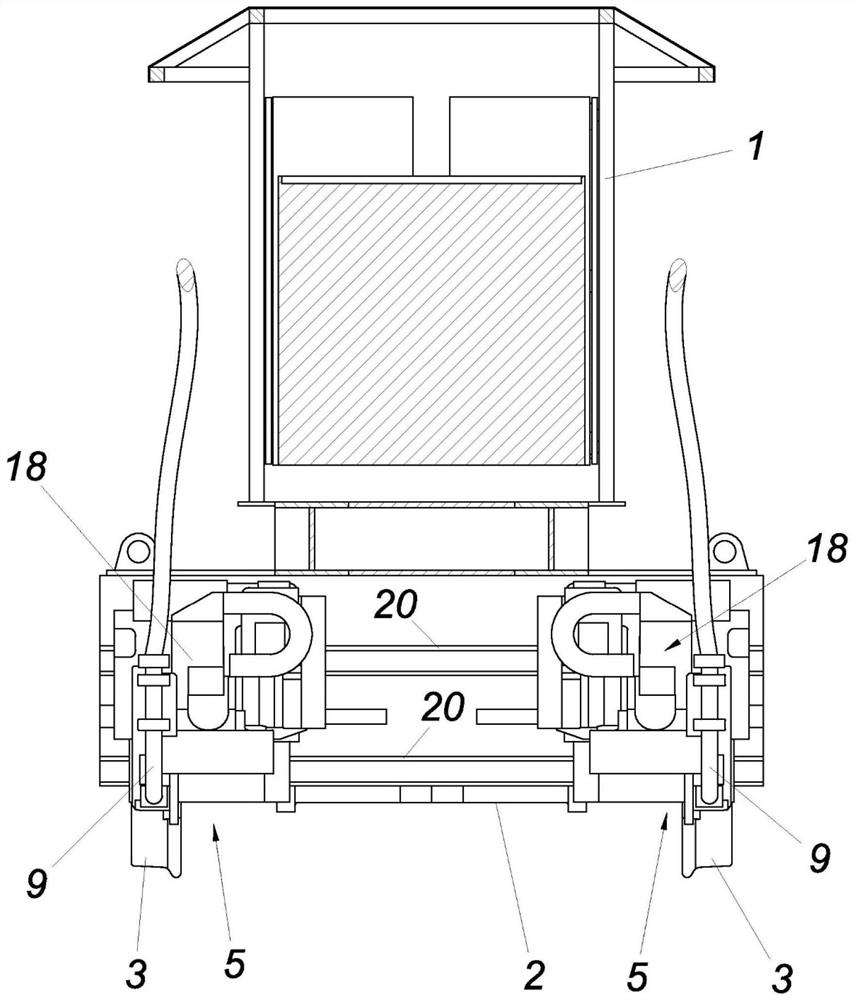

[0015] An embodiment of the treatment device according to the invention can have a vehicle frame 1, a chassis 2 with wheels 3, an electrical energy store 4, an energy distribution system, a travel drive 5, a treatment drive 6, a treatment tool 7, a feed drive 8 and Suction device 9 with chip collection container 10 .

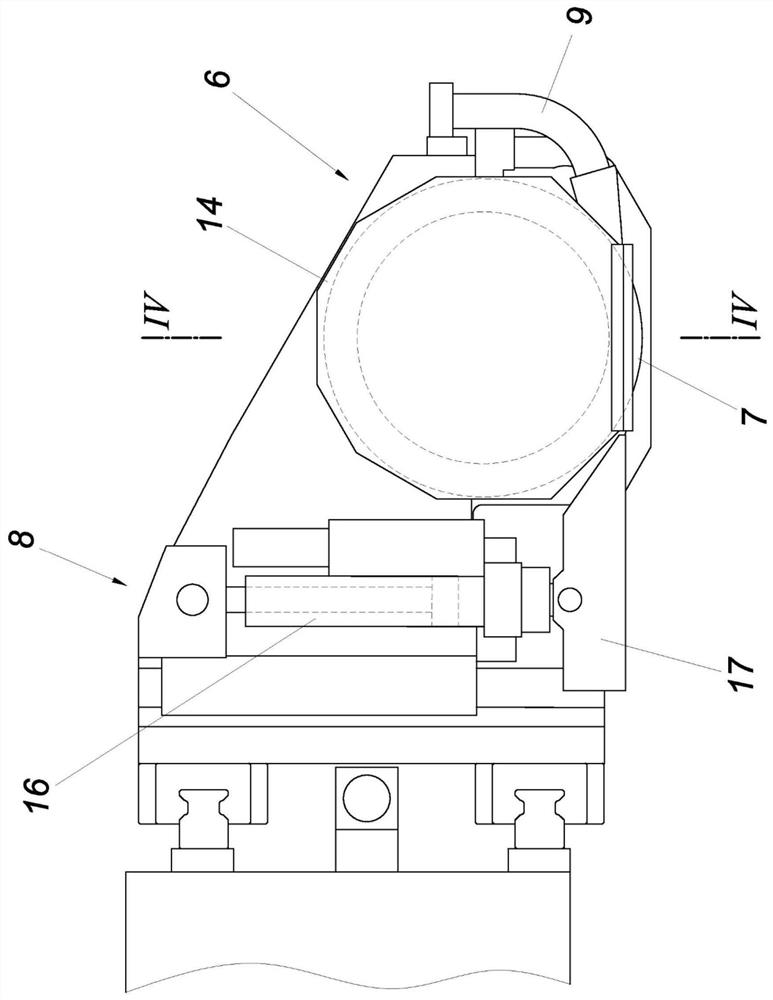

[0016] Figure 4 A processing tool 7 , which can be designed, for example, as a pot-shaped milling head or also as a grinding wheel, is shown mounted on the shaft 10 by means of bolts and supported in a floating manner on the shaft 10 . Furthermore, the shaft 10 can be arranged in a housing 11 and partially surrounded circumferentially by the pot-shaped treatment tool 7 so that an imaginary shaft extending normal to the longitudinal axis of the shaft and passing through the closer-located bearing 12 can be arranged. The plane intersects the processing tool 7 . For protection, the processing tool 7 can be surrounded by a cover or cover 14 which is open downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com