Post-grouting construction method of bridge cast-in-place pile

A construction method, cast-in-situ pile technology, applied in sheet pile walls, foundation structure engineering, construction, etc., to achieve the effects of reducing pile length, saving costs, and improving pile bottom resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

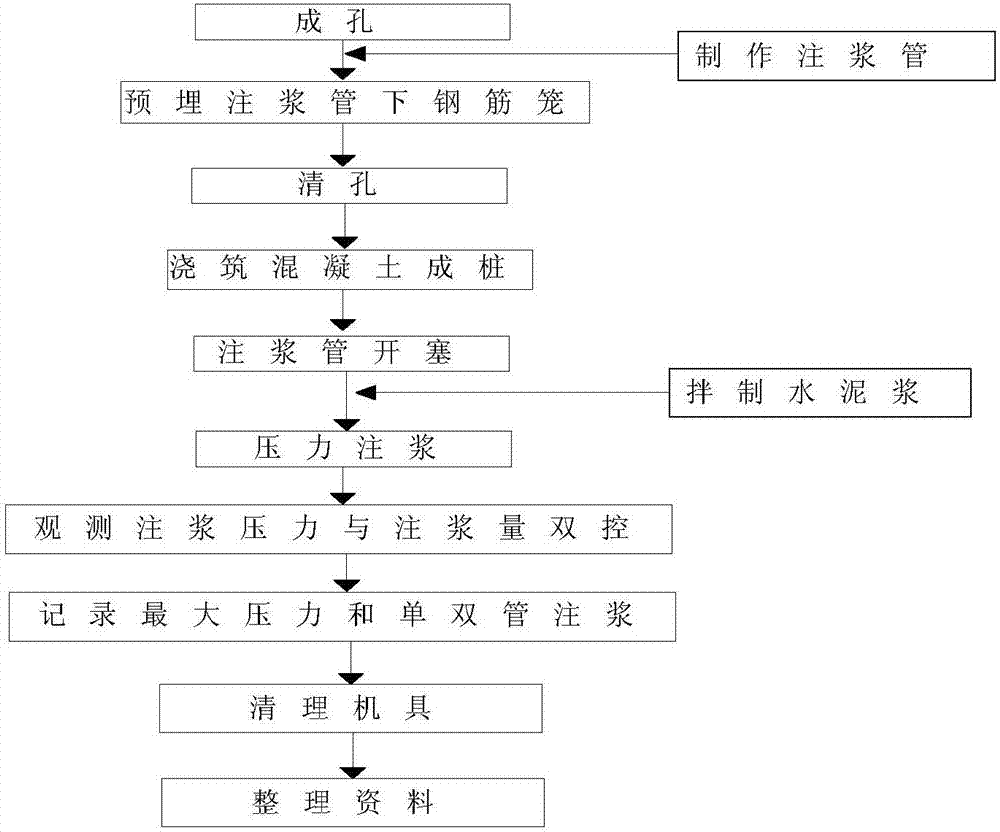

[0037] The method of the present invention, such as figure 1 shown, including the following steps:

[0038] Step 1 Fabrication of the grouting nozzle

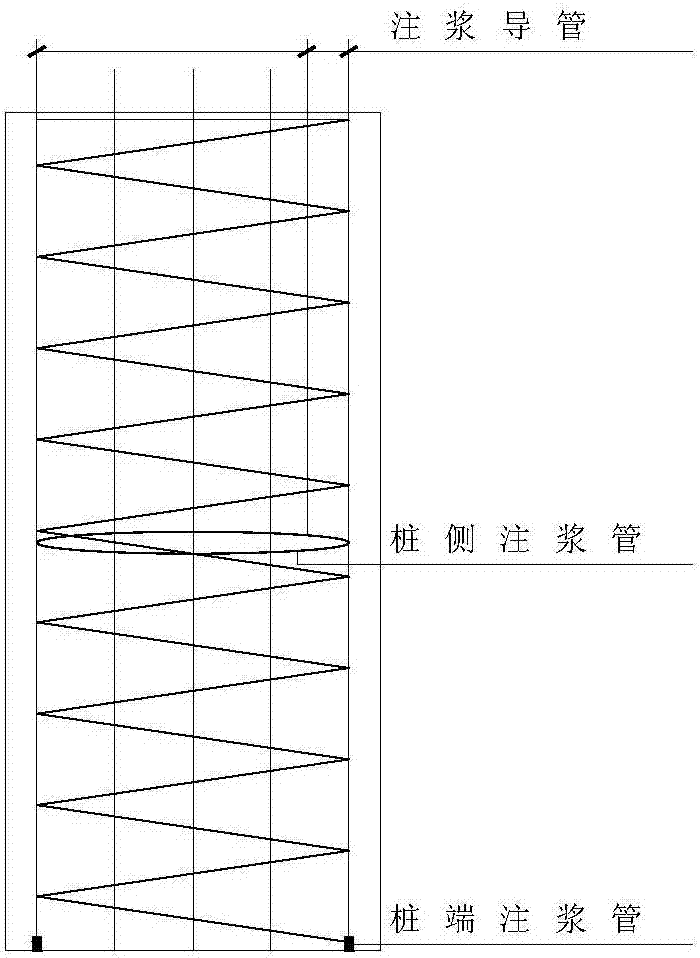

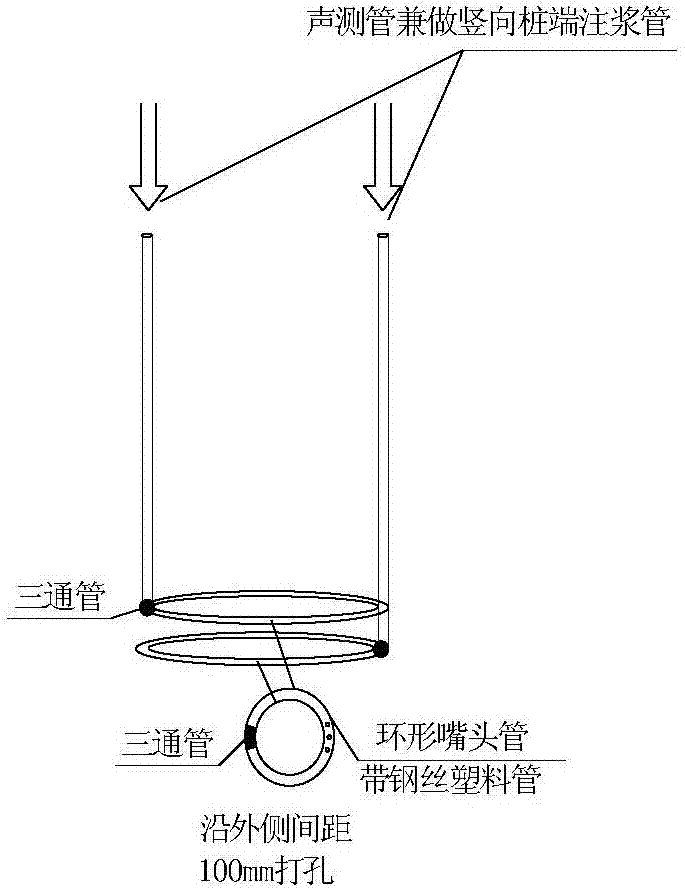

[0039] The grouting nozzle is arranged at the bottom or middle of the pile along the outer side of the reinforcement cage and arranged in a ring around the pile body.

[0040] The inner diameter of the grouting nozzle is The flexible high-pressure plastic pipe with steel wire is made of qualified materials and processed into a grouting nozzle at the construction site.

[0041] First, use Drill the holes with an axial distance of 100mm, and stagger them in a spiral cross shape along the pipe circumference. After drilling, clean the drill chips in the pipe, wrap them with two layers of waterproof tape, and wrap them tightly with iron wire.

[0042] Step 2 Grouting pipe installation

[0043] The gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com