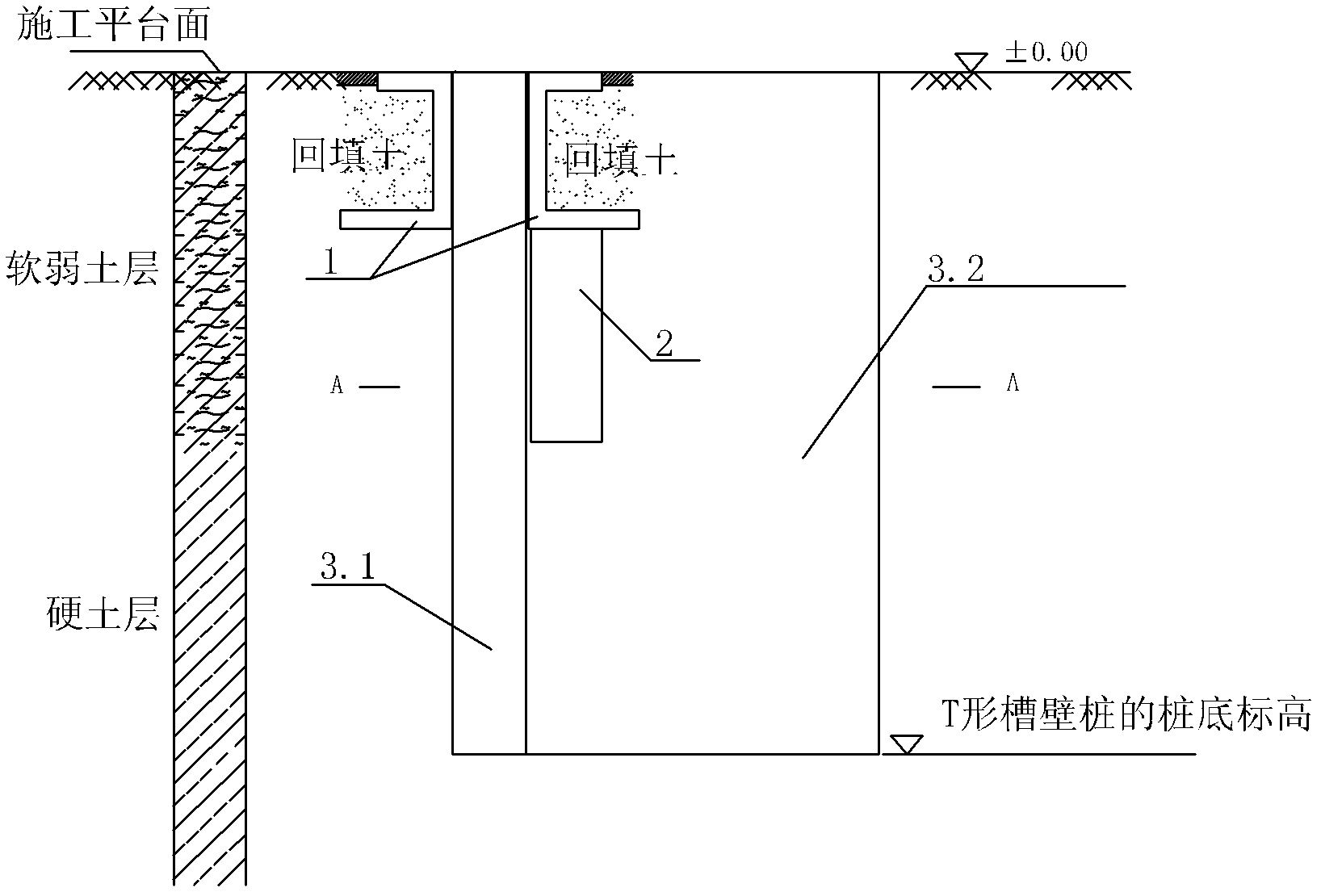

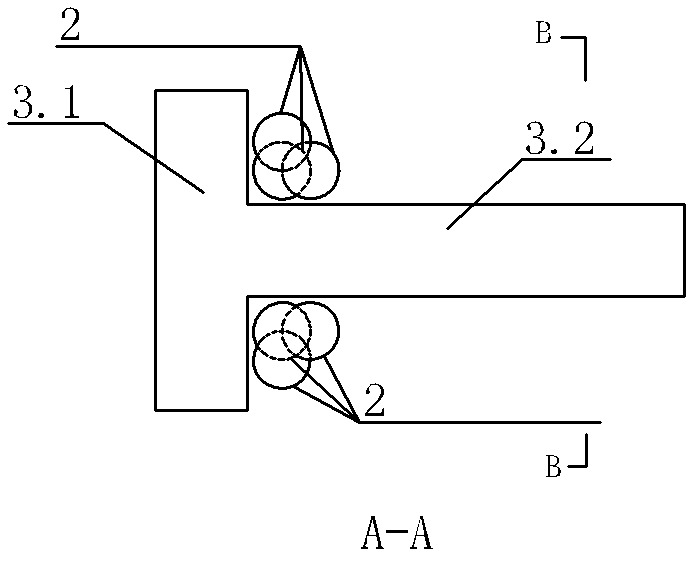

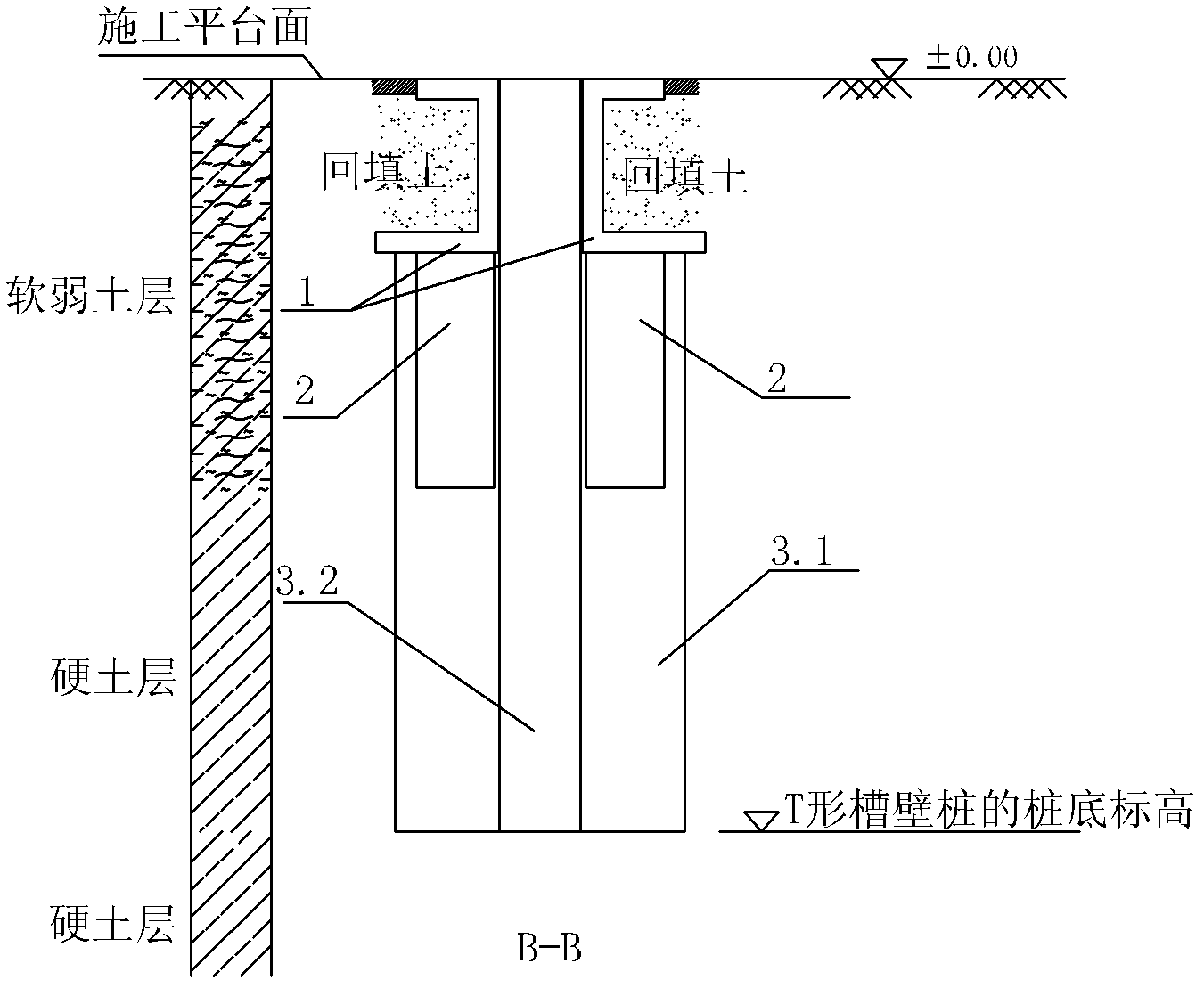

Ultra-deep T-shaped trench-wall pile in soft-toped hard-bottomed soil layer and trench forming method

A construction method and trough construction technology, applied in the field of building foundation engineering, can solve problems such as high cost, save materials and costs, reduce post-construction settlement and horizontal displacement, and reduce project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solution of the present invention will now be specifically described with a specific embodiment.

[0052] The shoreline of the second phase project of a coastal wharf has a total length of 1,200m, and the water depth at the front of the wharf is -17.5m (chart datum), which are four deep-water berth wharfs capable of berthing a new generation of super post-Panamax container ships. The ground elevation of the project site is 2.30-3.0m. The engineering strata are mainly sand and clay sediments of the Tertiary Miocene and marine sediments of the Quaternary Pliocene. The main soil layers are distributed from top to bottom: loose surface backfill Medium-fine sand and gravel, silty clay, interbedded silt-fine sand and silty silty clay, silty-fine sand, silty clay, plastic clay, fine-medium sand. On the whole, the stratum is relatively complex. The thickness of the upper backfilled loose soil layer, soft plastic muddy soil layer and silty sand layer is up to 45m, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com