Soft foundation fast separating and punning method

A technology of weak foundation and tamping method, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of limited precipitation depth, slow dissipation of pore water pressure, and inapplicability, achieving short construction time, obvious reinforcement effect, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Step 1. Water and gas separation integrated tube well layout

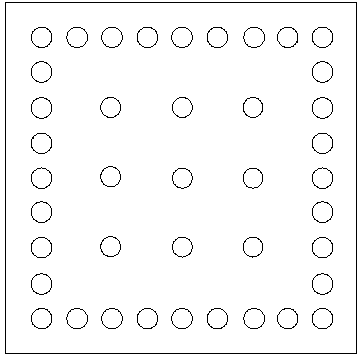

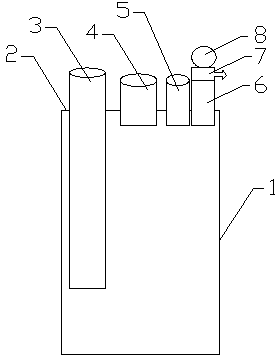

[0089] In this example, a high-strength PVC corrugated pipe with a diameter of 2500mm for the water-gas separation integrated tube well is used, and the depth of the soil is 10m, with a built-in 0.75KW submersible pump. Integrated tube wells, the peripheral integrated tube wells are arranged around the area to be reinforced with a well spacing of 10m; the inner integrated tube wells are arranged in the middle with a well spacing of 15m.

[0090] The setting and layout grid of water-gas separation integrated tube wells during actual construction should be determined according to the geological conditions revealed in the geological survey report.

[0091] In the process of setting up the integrated tube well, the groundwater and soil stratification conditions in the area to be reinforced are fully considered, and the filter holes of the integrated tube well are set in argillaceous silty clay with a small perme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com