Top-down rigid pile compound foundation construction method

A composite foundation and construction method technology, which is applied in the direction of infrastructure engineering, roads, roads, etc., can solve the problems that the construction period and cost are greatly affected, the effect is difficult to guarantee, and the construction period is long, so as to control post-construction settlement and reduce material consumption. , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

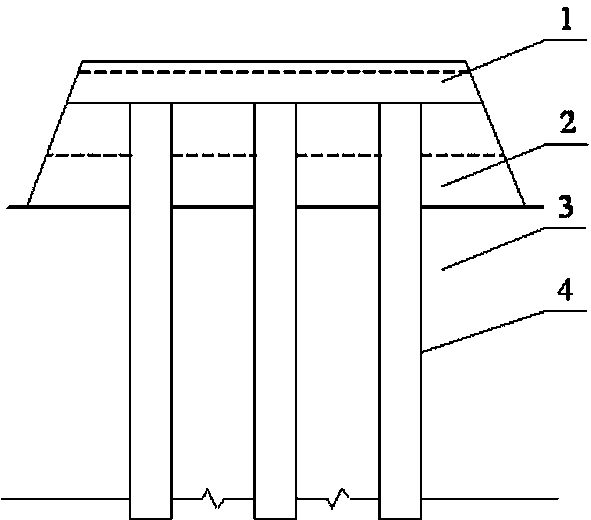

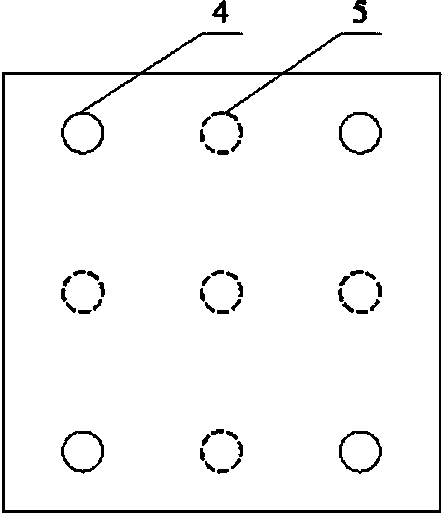

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0036] refer to Figure 1~Figure 2 Shown, the reverse method rigid pile composite foundation construction method of the present invention comprises the following construction steps:

[0037] 1) Subgrade 3 treatment at the bottom of the entire composite foundation:

[0038] ① Site cleaning: Level the ground of the subgrade, and use a road roller to roll before filling, so that the compactness of the subgrade 3 reaches 90%;

[0039] ②Install settlement plates every 30m on the top surface of the middle line of subgrade 3, and conduct subgrade settlement monitoring;

[0040] 2) After the subgrade 3 is leveled, the embankment 2 is filled on its upper part:

[0041] ① Select plain soil as the filling material of embankment 2, and the compaction degree of embankment 2 reaches 92%;

[0042] ②Fill plain soil in layers and carry out compaction test. Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com