A Subgrade Structure for Dealing with Deep Soft Soil Karst Foundation

A karst and soft soil technology, applied in the field of roadbed structure, can solve the problems of not being able to meet the roadbed structure at the same time, achieve the goal of stability and deformation control, control post-construction settlement, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

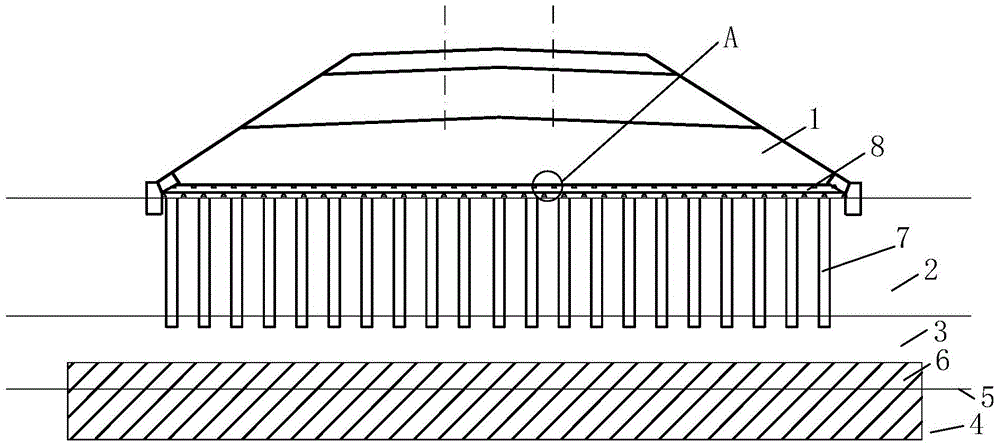

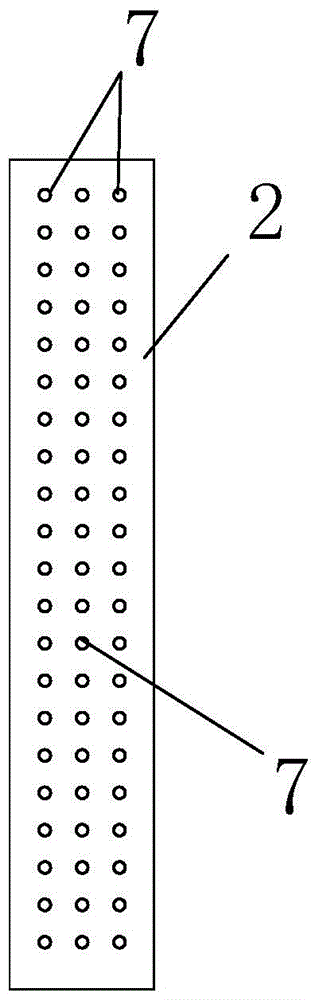

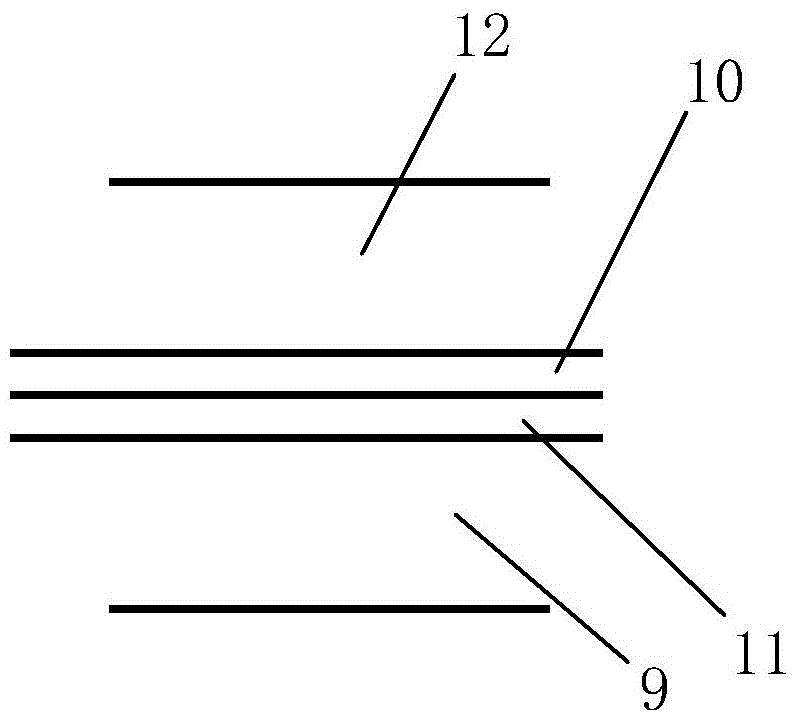

[0015] Such as Figure 1~3 The roadbed structure shown for processing deep and thick soft soil karst foundations includes a karst layer 4, a hard soil layer 3 located above the karst layer 4, a soft soil layer located above the hard soil layer 3, and a layer laid on top of the soft soil layer 2. The cushion layer 8, the roadbed 1 laid on the top of the cushion layer 8, the soft soil layer 2 at the bottom of the cushion layer 8 (the cushion layer 8 is used to ensure the common force of the pile and soil to form a composite foundation) along the line Multiple rows of jet grouting piles 7 are provided. Each row of jet grouting piles 7 includes a plurality of jet grouting piles 7 arranged side by side. The bottom of each jet grouting pile 7 penetrates the soft soil layer 2 and is inserted into the hard soil layer. 3. (The bearing capacity of the hard so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com