Integrally-arranged and externally-wrapped double-layered water discharging body and middle concrete combined pile and construction method

A drainage body and composite pile technology, applied in sheet pile walls, soil protection, foundation structure engineering, etc., can solve problems such as large deformation, affecting the bearing function of soil, and damage to adjacent pile structures, so as to achieve accelerated consolidation, The effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The design and construction requirements of pile concrete, the construction technical requirements of steel bar welding, the laying construction technology of embankment drainage main pipes, etc. will not be repeated in this embodiment, and the embodiments of the structure related to the present invention will be focused on.

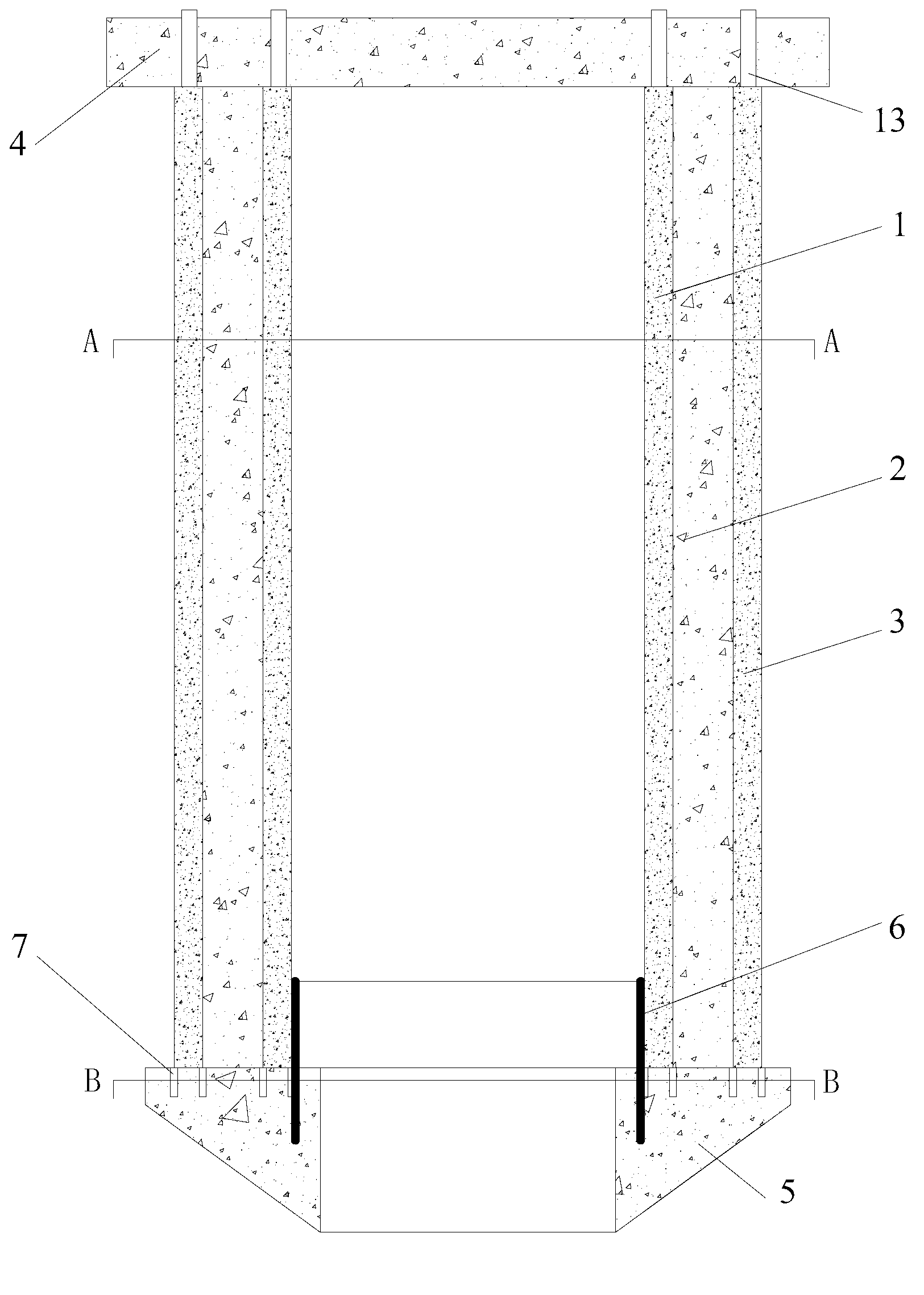

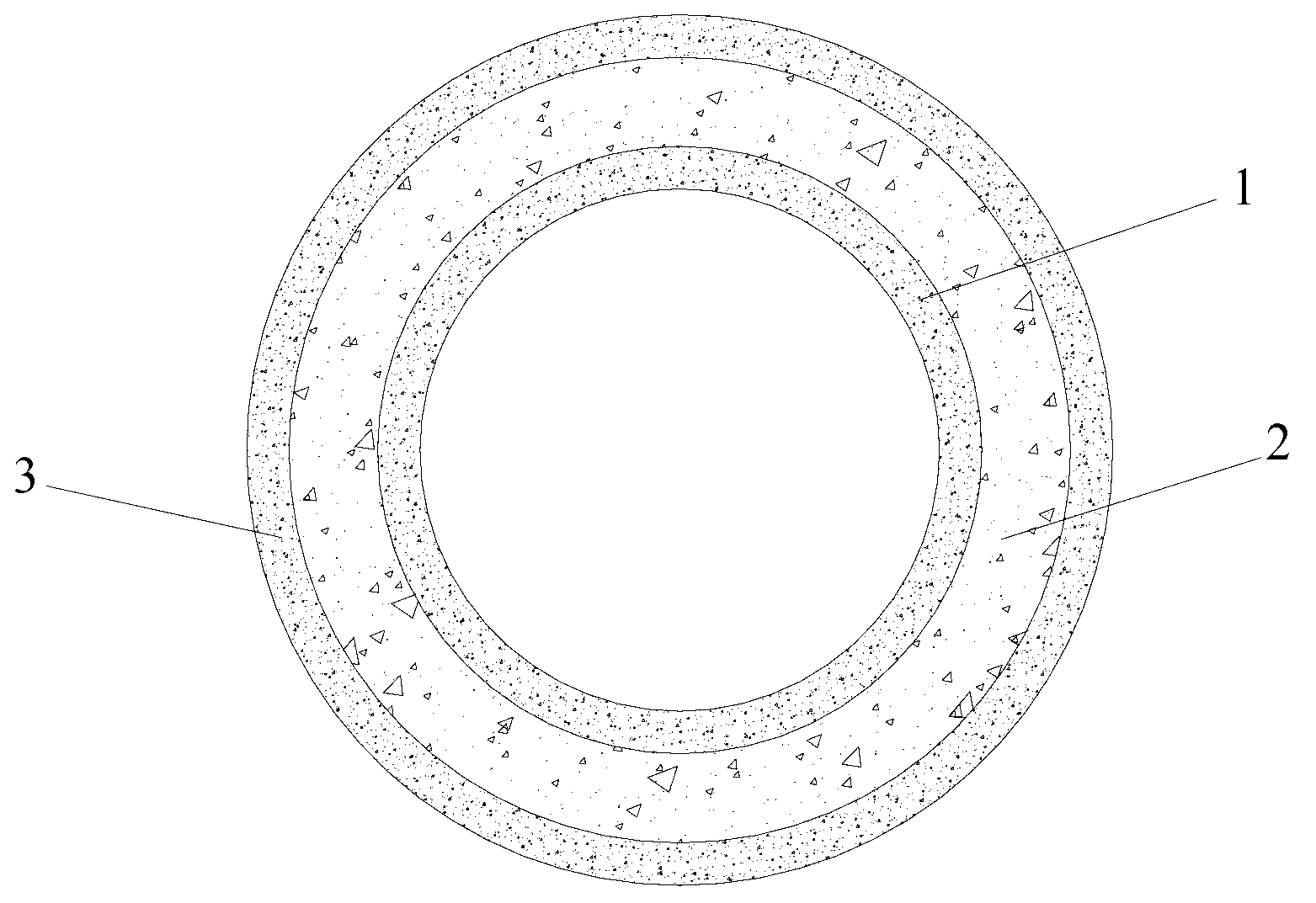

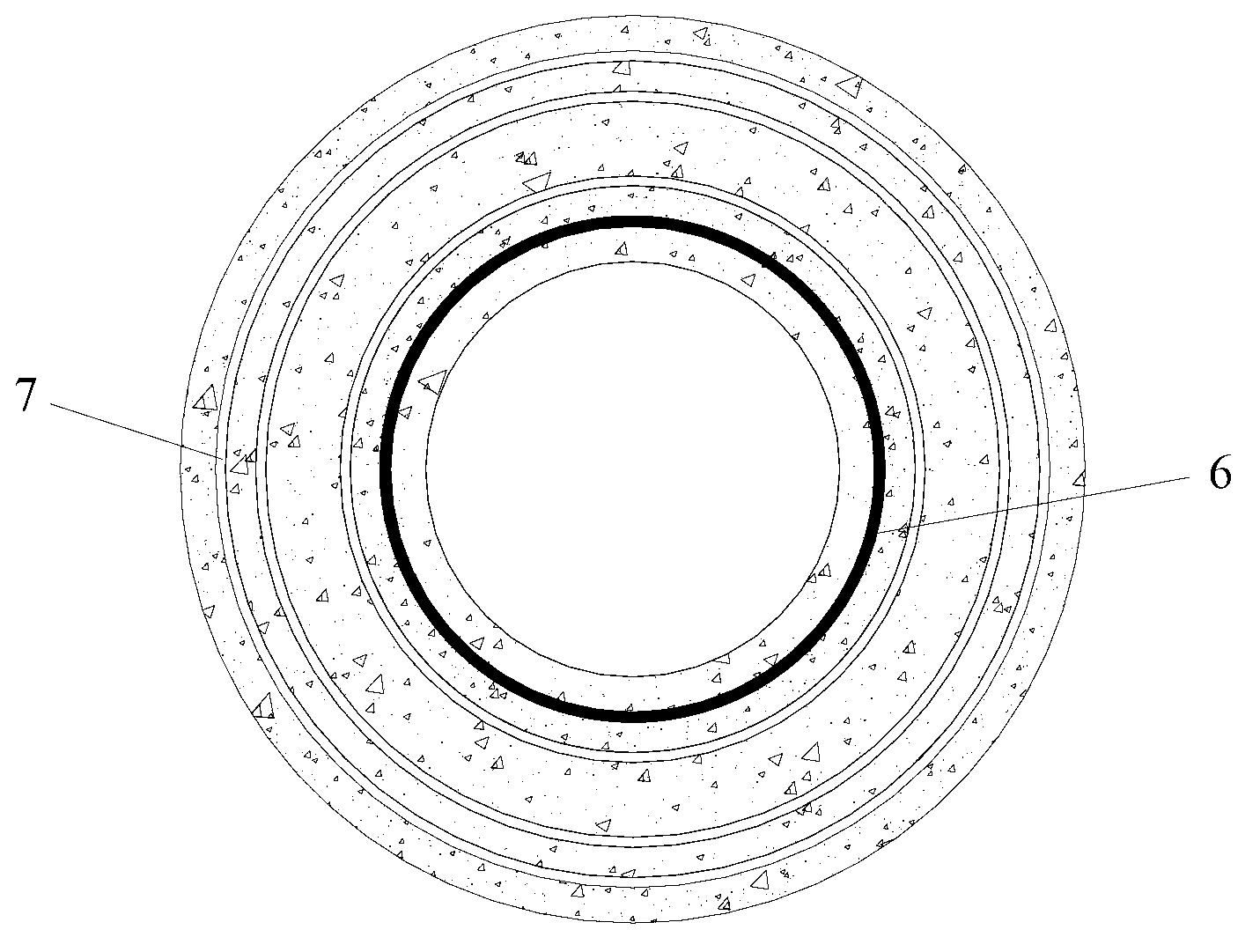

[0042] figure 1 It is a longitudinal sectional view of the composite pile with built-in and outsourced double-layer drainage body and intermediate concrete in the present invention, figure 2 yes figure 1 A cross-sectional view along line A-A, image 3 yes figure 1 Sectional view of the top surface of the pile point along the B-B line, such as Figure 1~3 The shown built-in outsourcing double-deck drainage body and intermediate concrete composite pile mainly consists of the inner annular drainage body 1 of the pile body, the cast-in-place concrete thin-walled pipe pile pile body 2, the outer annular drainage body 3 of the pile body, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com