Metering pump module and gluing system

A metering pump and glue coating technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of low efficiency, long time of glue changing system, flow channel blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

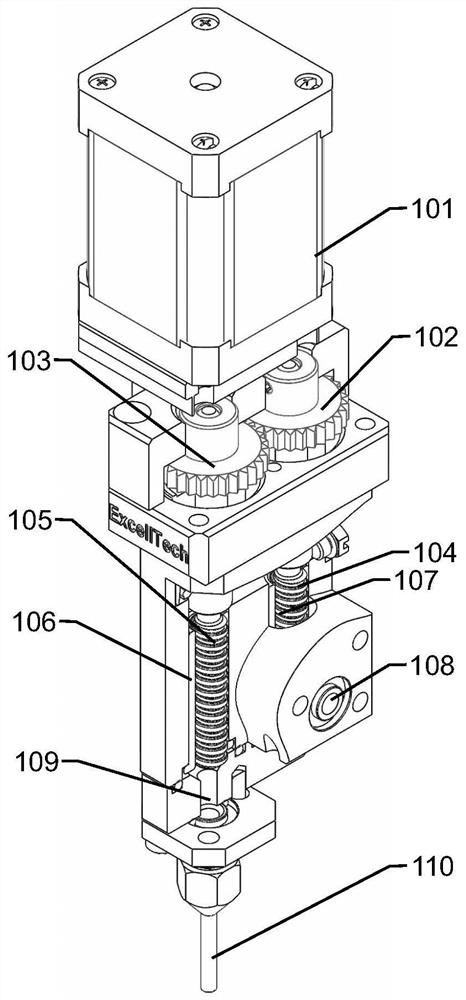

[0041] A novel metering pump module in this embodiment, such as figure 1 As shown, it includes: power unit 101, transmission device 102 and 103, inlet 108, outlet 109, first metering screw 104, second metering screw 105, first screw bushing 106, second screw bushing 107, gluing device 110;

[0042] The first metering screw 104 is located in the first screw bushing 106, the second metering screw 105 is located in the first screw bushing 107, and the gluing device 110 is connected to the outlet 109;

[0043] The first screw bushing 107 and the second screw bushing 106 are connected through a channel, the first screw bushing 107 is connected to the inlet 108, and the second screw bushing 106 is connected to the outlet 109;

[0044] When working, the fluid enters the first screw bushing 107 through the inlet, and the power device 101 drives the first metering screw 104 to rotate through the transmission device 102 to make the fluid flow and enter the passage, and the power device...

Embodiment 2

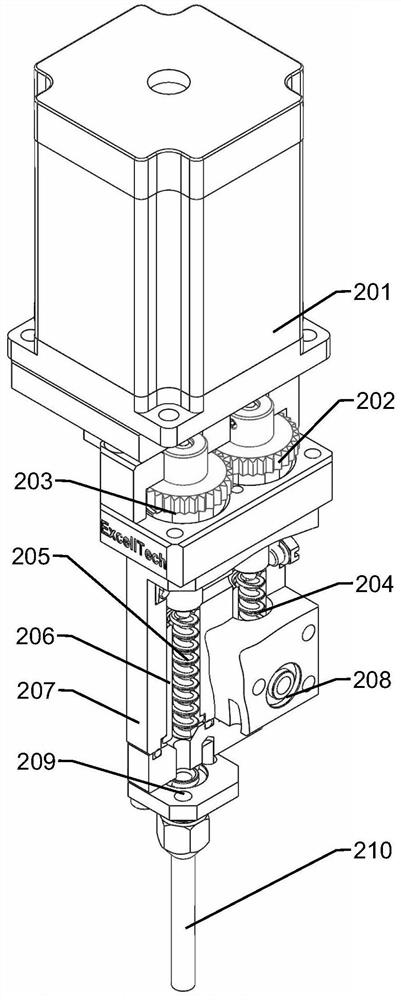

[0062] A novel metering pump module in this embodiment, such as figure 2 As shown, it includes: stepper motor 201, transmission gear 202 and transmission gear 203, glue inlet 208, glue outlet 209, pump body 207, first metering screw 204, second metering screw 205, screw bushing 206, outlet Rubber needle 210;

[0063] The pump body 207 is a supporting installation carrier for the transmission device and the screw bushing;

[0064] The first metering screw 204 and the second metering screw 205 are located in the screw bushing 206, and the glue outlet pillow 210 is connected with the glue outlet 209;

[0065] Described first screw bushing 207 and described second screw bushing 206 are connected by channel, and screw bushing 206 is connected with foot button 208, and described bushing 206 is connected with glue outlet 209;

[0066] When working, the fluid enters the first screw bushing 207 through the inlet, and the stepping motor 201 drives the first metering screw 204 to rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com