Connecting rod

A connecting rod and channel technology, applied in the direction of connecting rod, connecting rod bearing, piston rod, etc., can solve the problems of decreased oil load capacity, fluid dynamic pressure loss, increased oil film thickness, etc., to improve the load capacity, simplify the manufacturing process, Avoid the effects of dry contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

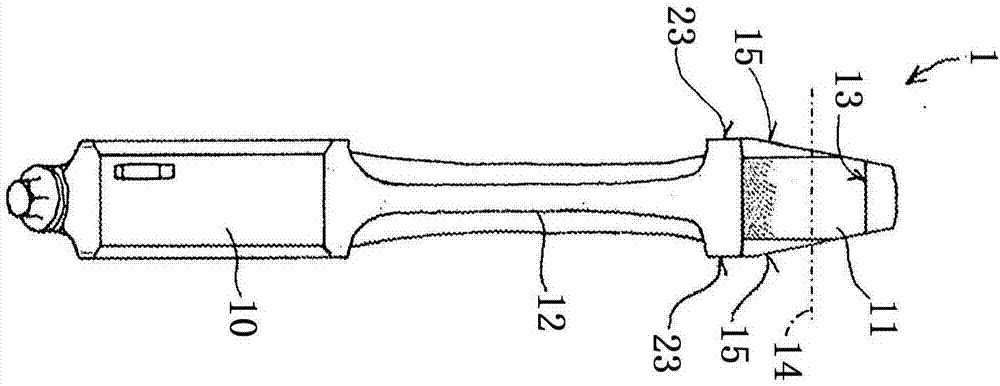

[0041] figure 1 Shown is a connecting rod 1 for an internal combustion engine with a large end channel 10 embodied to accommodate a pin journal of a crankshaft of the engine, and the connecting rod 1 comprising a small end channel 11 embodied for A piston pin housing the piston, a shaft 12 is arranged between the large end channel 10 and the small end channel 11 , and the shaft 12 forms the connection between the large end channel 10 and the small end channel 11 . Apart from the large end comprising two pieces, the connecting rod 1 according to the invention is designed as a one-piece construction, eg comprising a handle and cap arrangement.

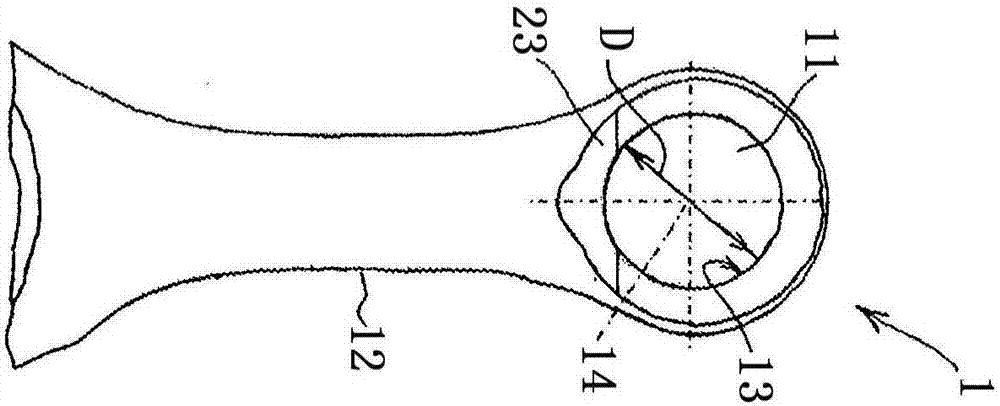

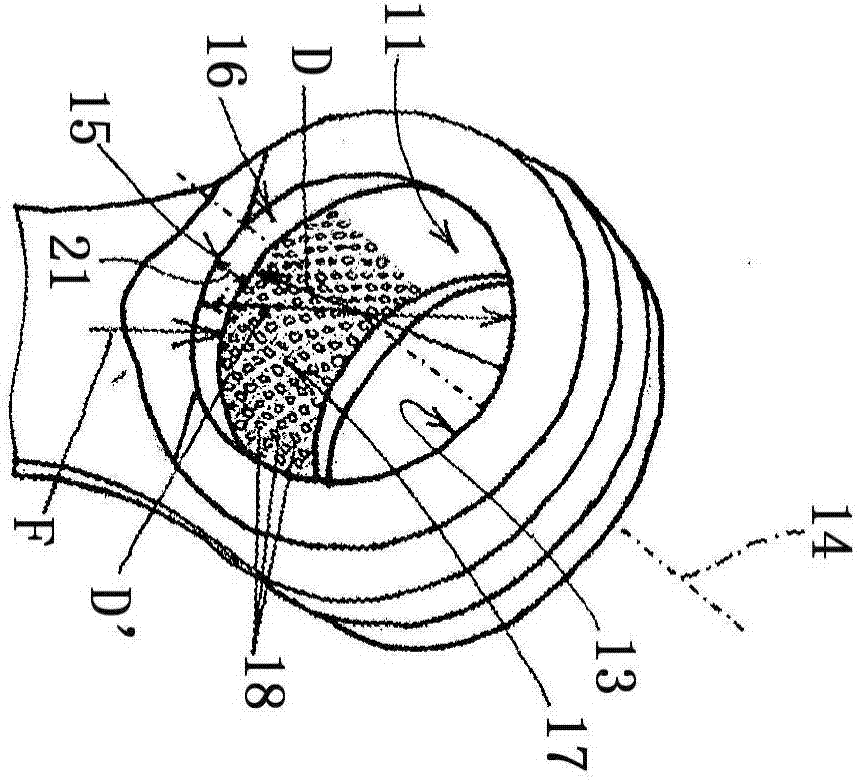

[0042] The small end channel 11 has an inner channel surface 13 which transitions via an opening edge 15 into a side wall 23 of the small end. Thus, the length of the small end channel 11 is defined by the length of the channel 11 along the channel axis 14 from side wall 23 to side wall 23 and from opening edge 15 to opening edge 15 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com