Patents

Literature

41results about How to "Reduced risk of cavitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

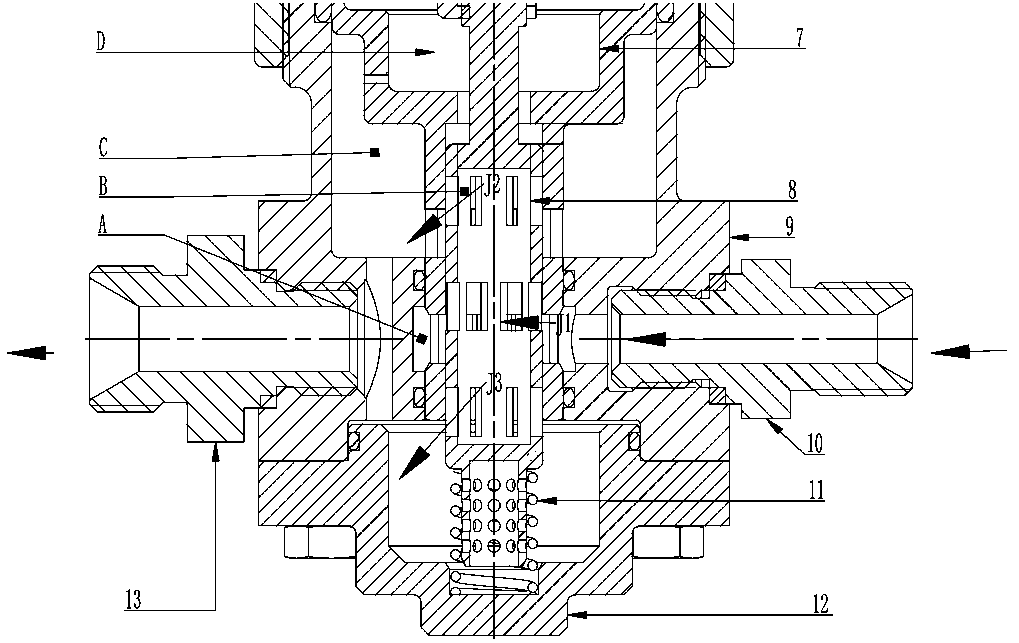

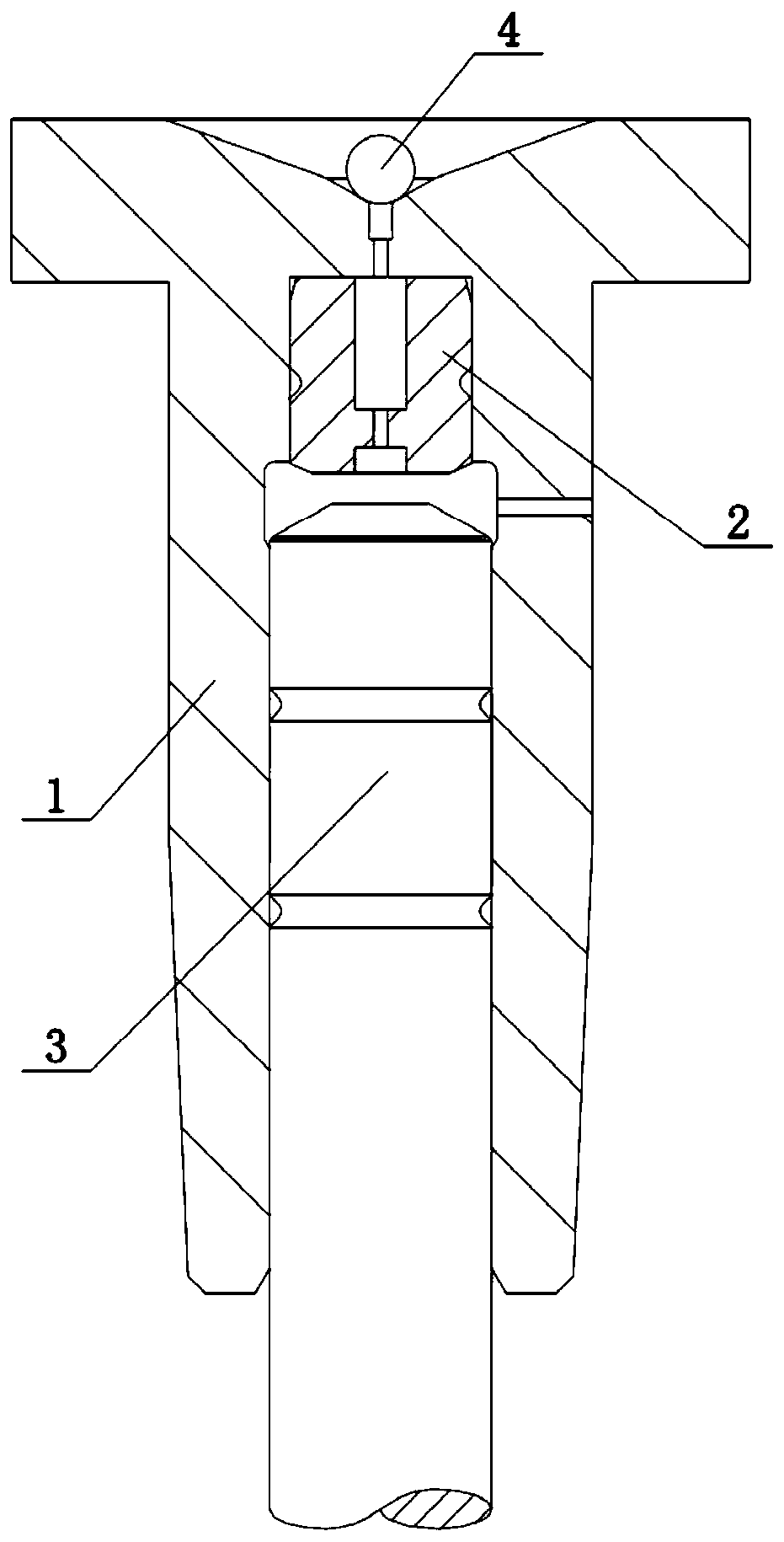

Backwater system and backwater method of liquid ring vacuum pump

ActiveCN105782058AReduce disturbanceReduce resistanceRotary piston pumpsRotary/oscillating piston pump componentsCavitationEngineering

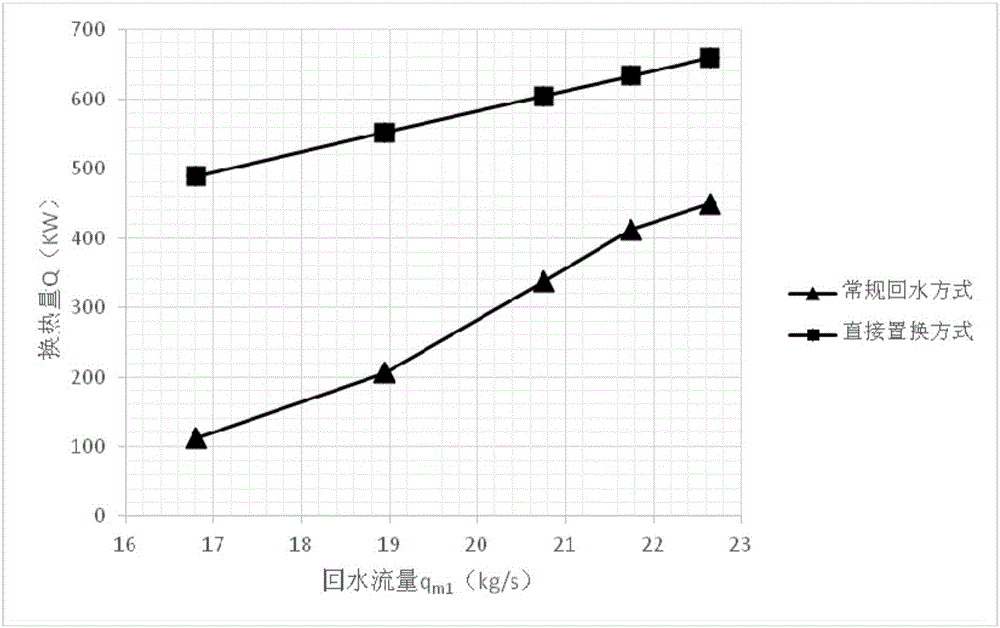

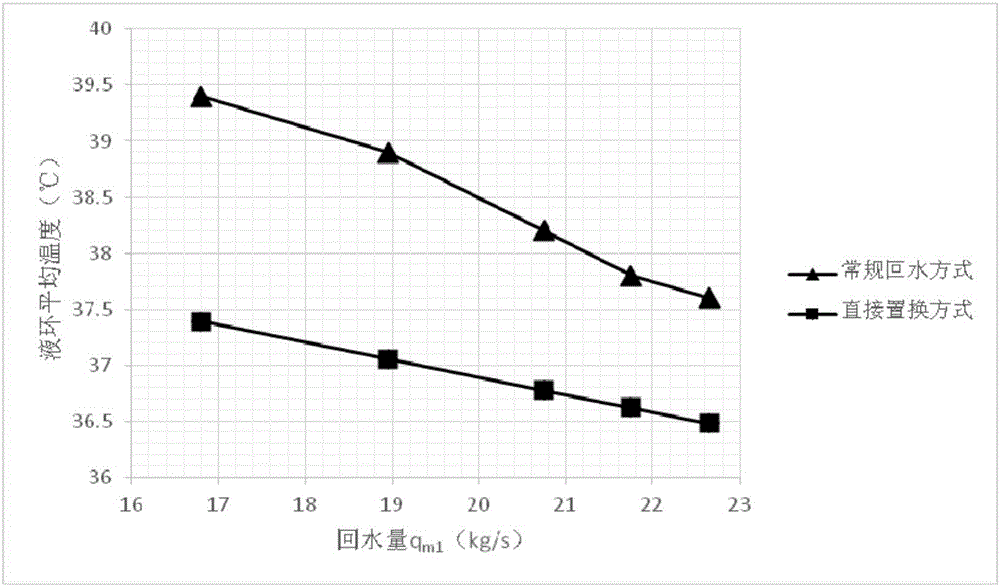

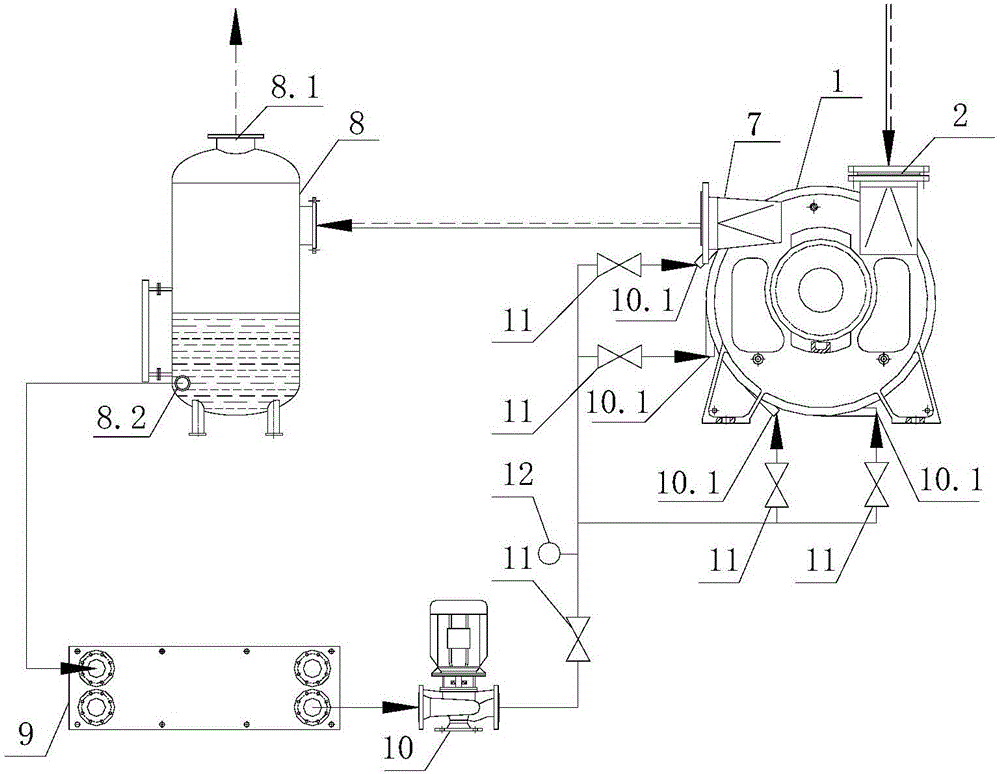

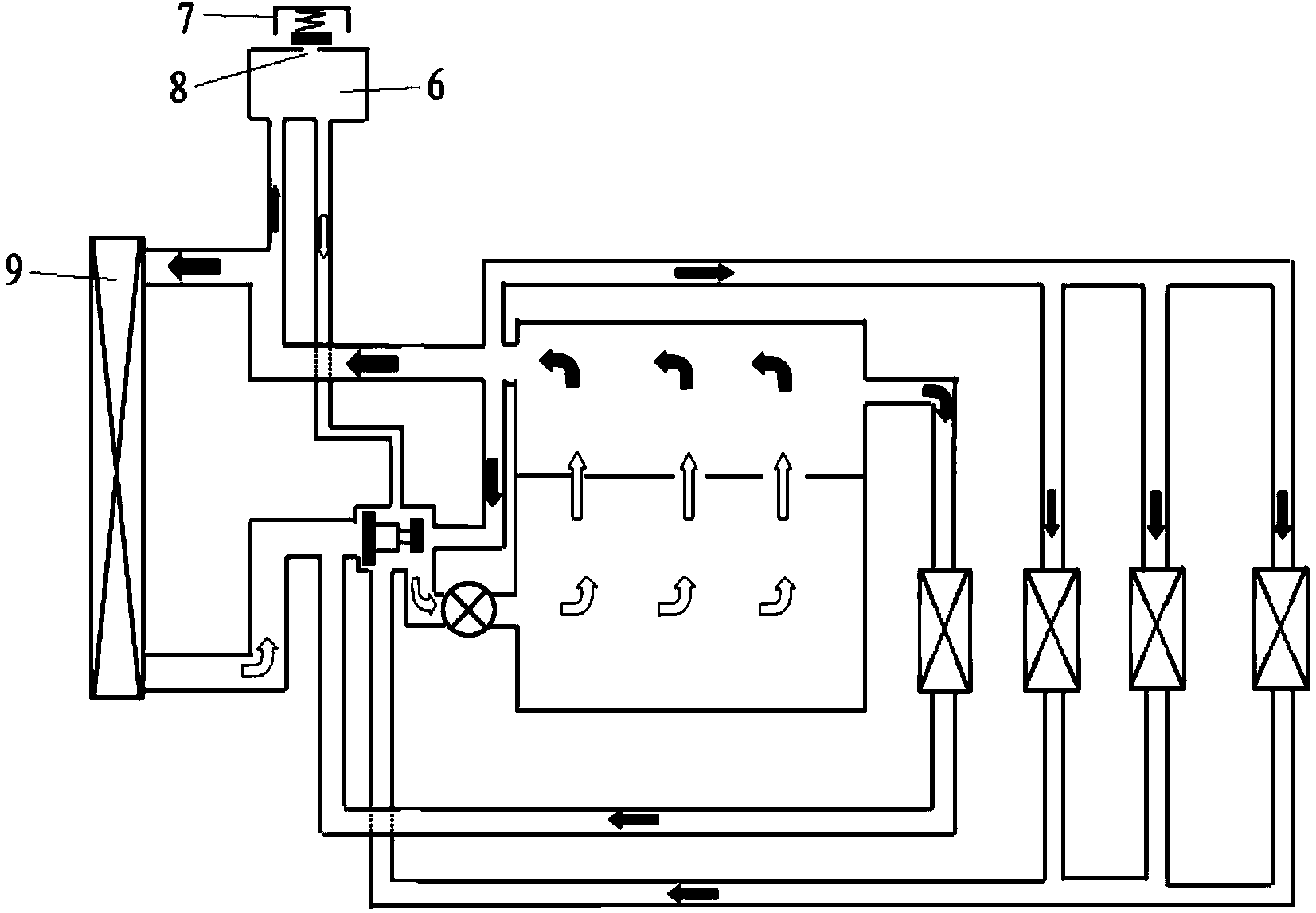

The invention discloses a backwater system and a backwater method of a liquid ring vacuum pump. The backwater system comprises a vacuum pump body (1) and an external gas-water separator (8). The backwater system is characterized in that the other end of the gas-water separator (8) is connected with a heat exchanger (9), a booster pump (10) is connected to the tail of the heat exchanger (9), a plurality of pipelines are connected to the booster pump (10) and are connected with a backwater inlet (10.1) in the cylinder wall of the vacuum pump body (1), a flow monitoring device (11) is connected to each pipeline, and a pressure monitoring device (12) is connected to the pipeline behind the booster pump (10). The defect that cavitation easily occurs in a cavity due to the limit to the temperature and vapor pressure of working liquid in prior art is overcome, and the backwater system has the advantages that the working liquid is effectively supplemented, and the temperature of a liquid ring is reduced.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

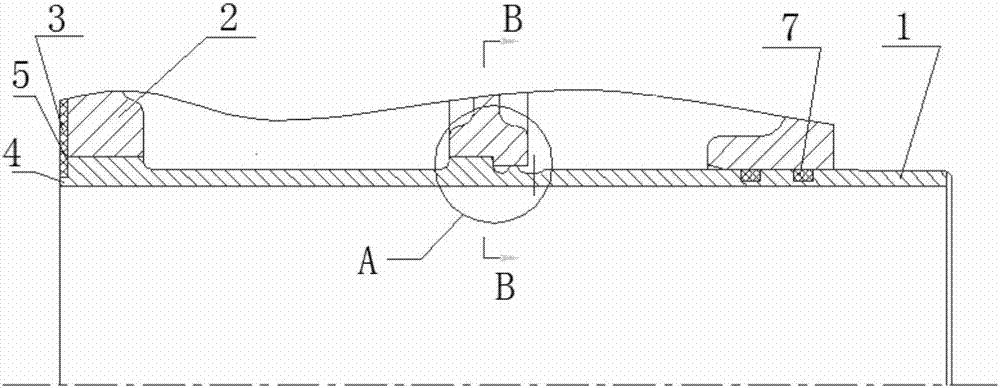

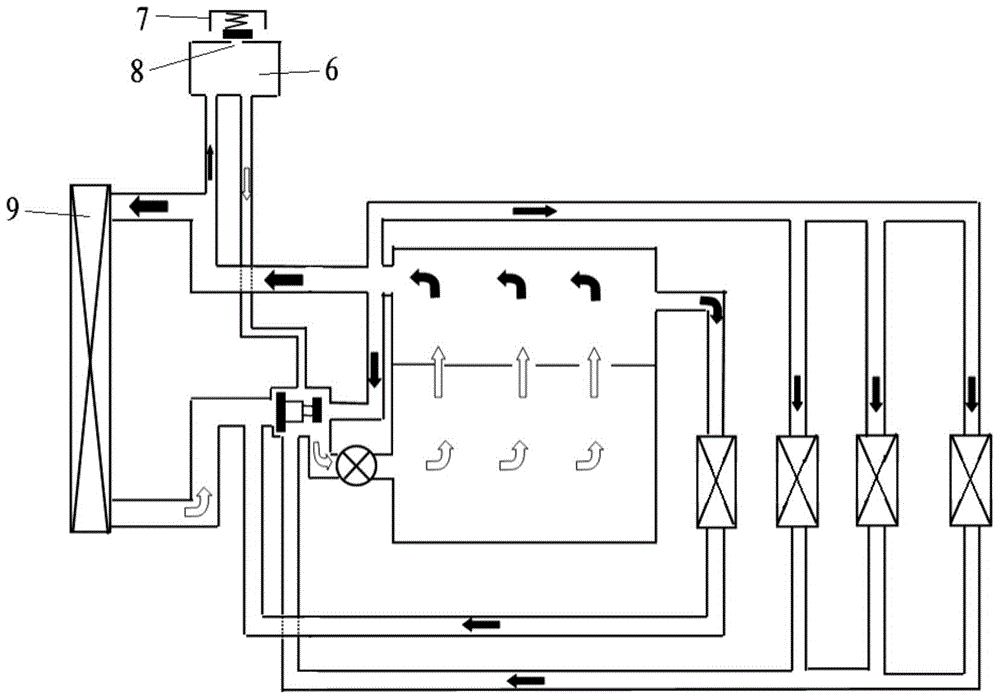

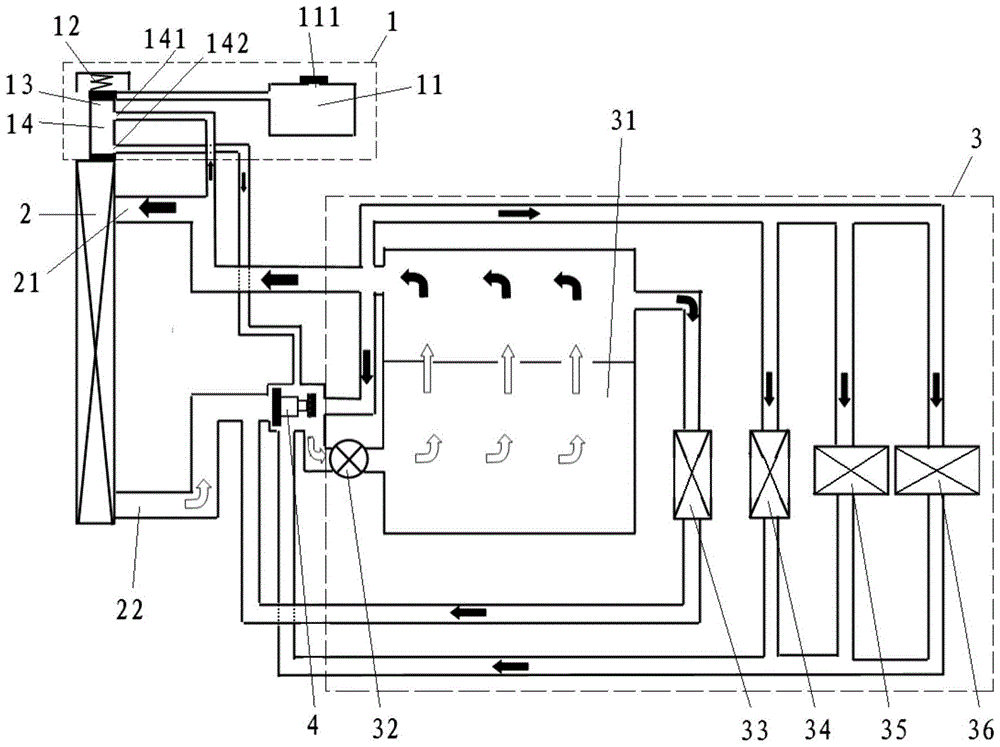

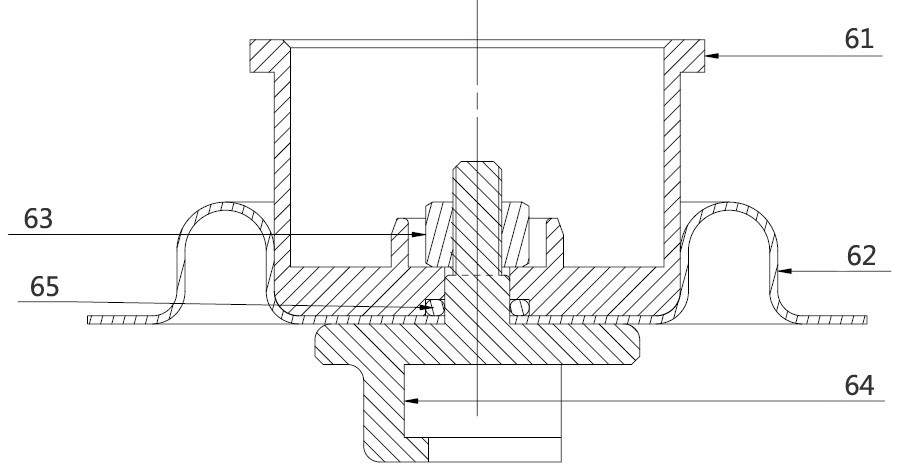

Expansion tank assembly and cooling circulation system

ActiveCN103485879AExtend your lifeReduced risk of cavitationMachines/enginesEngine cooling apparatusExpansion tankExpansion chamber

The invention provides an expansion tank assembly comprising an expansion tank, an expansion chamber and a pressure cap. The expansion tank connected with the expansion chamber is provided with an outlet communicated with the atmosphere, the expansion chamber is provided with a filling port, the pressure cap is connected with the filling port, the expansion chamber higher than a liquid level of a cooler is provided with a circulating liquid inlet port and a circulating liquid outflow port, and the pressure cap is a two-way pressure valve and controls communication and isolation of the expansion chamber and the expansion kettle. The small expansion chamber in series connection with the expansion tank is added, so that any restrictions on arrangement of the expansion tank are avoided, and great convenience is brought to arrangement of a cooling system and an engine compartment; besides, the expansion chamber participates in cooling circulation, so that the expansion tank assembly has good cooling performance.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

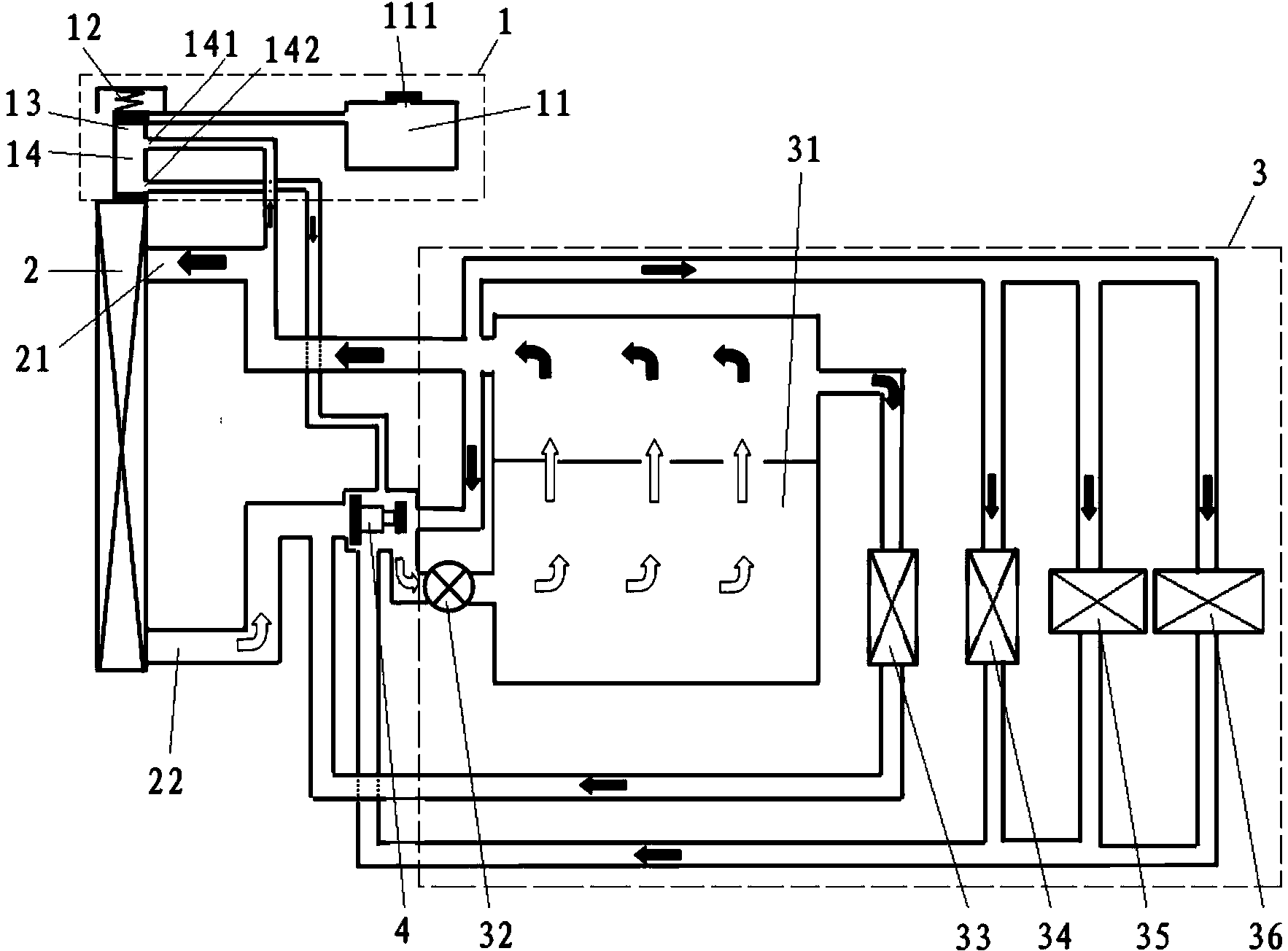

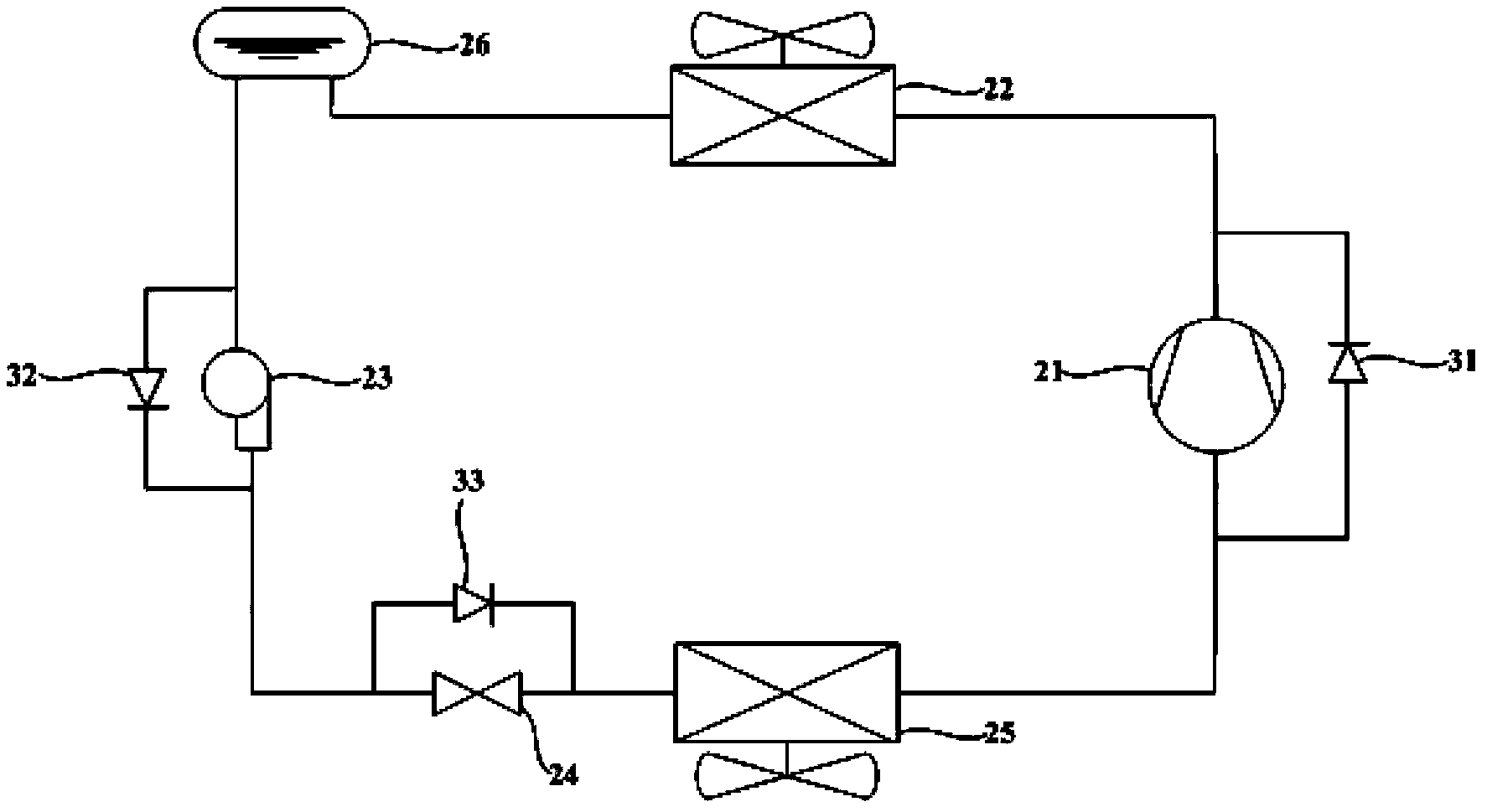

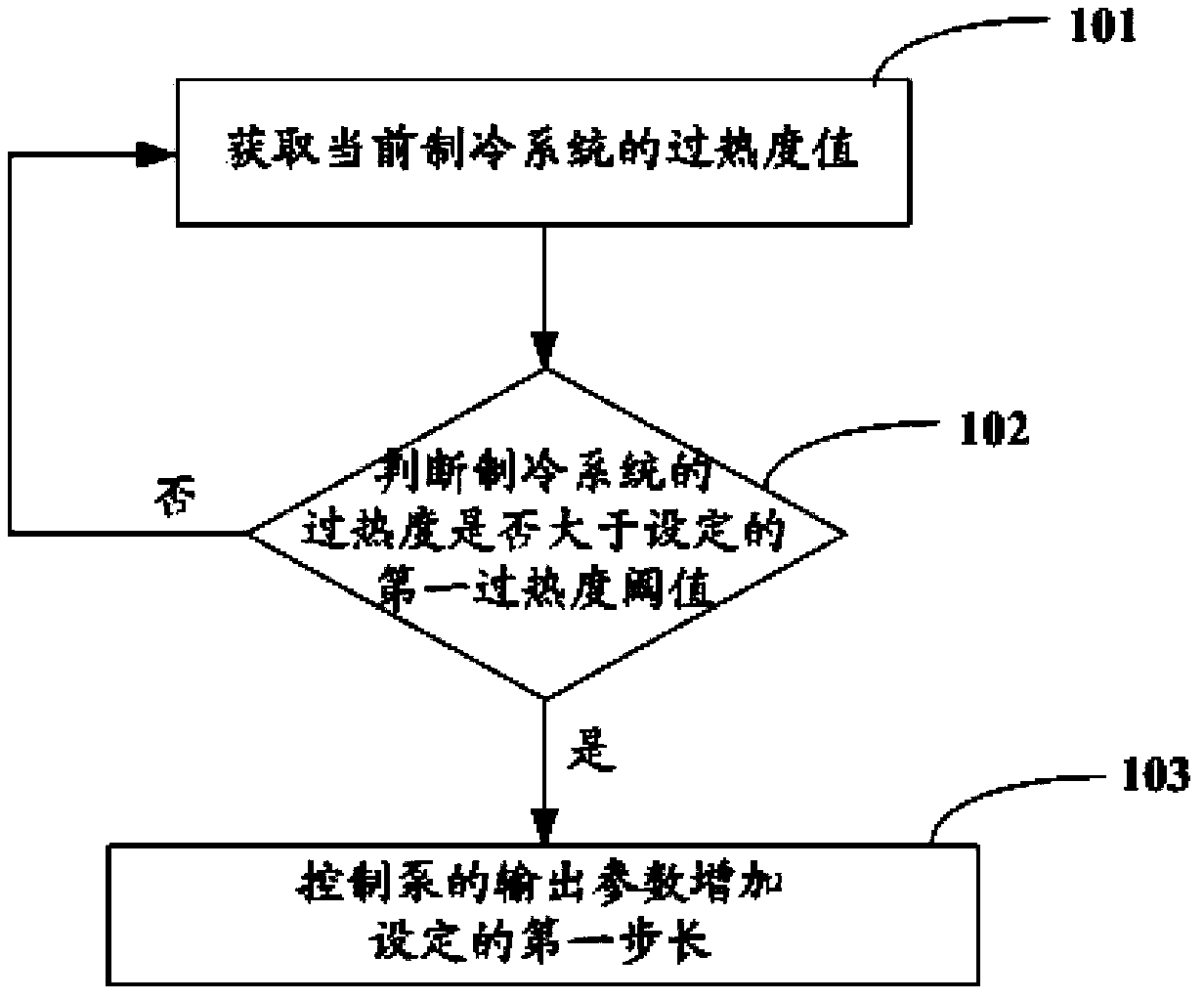

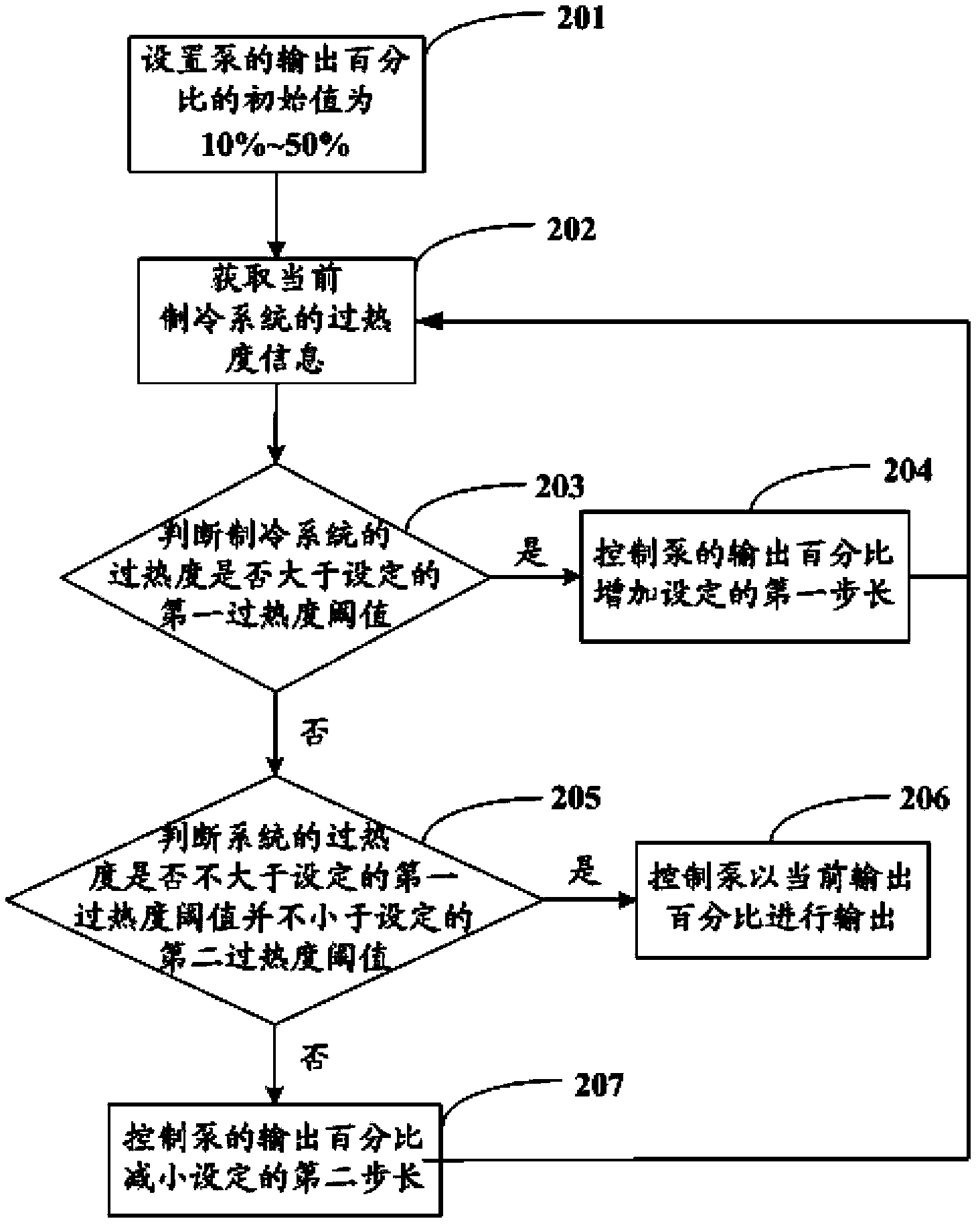

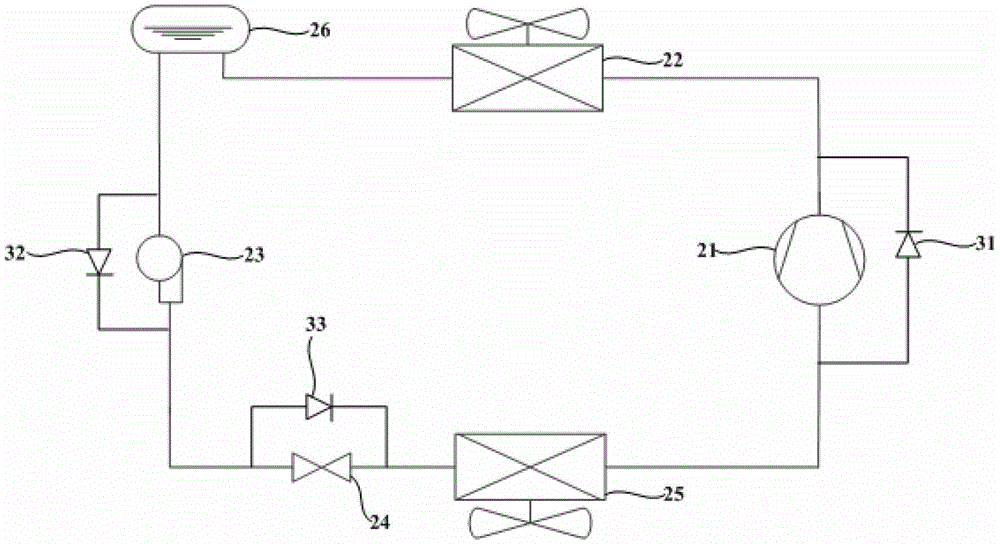

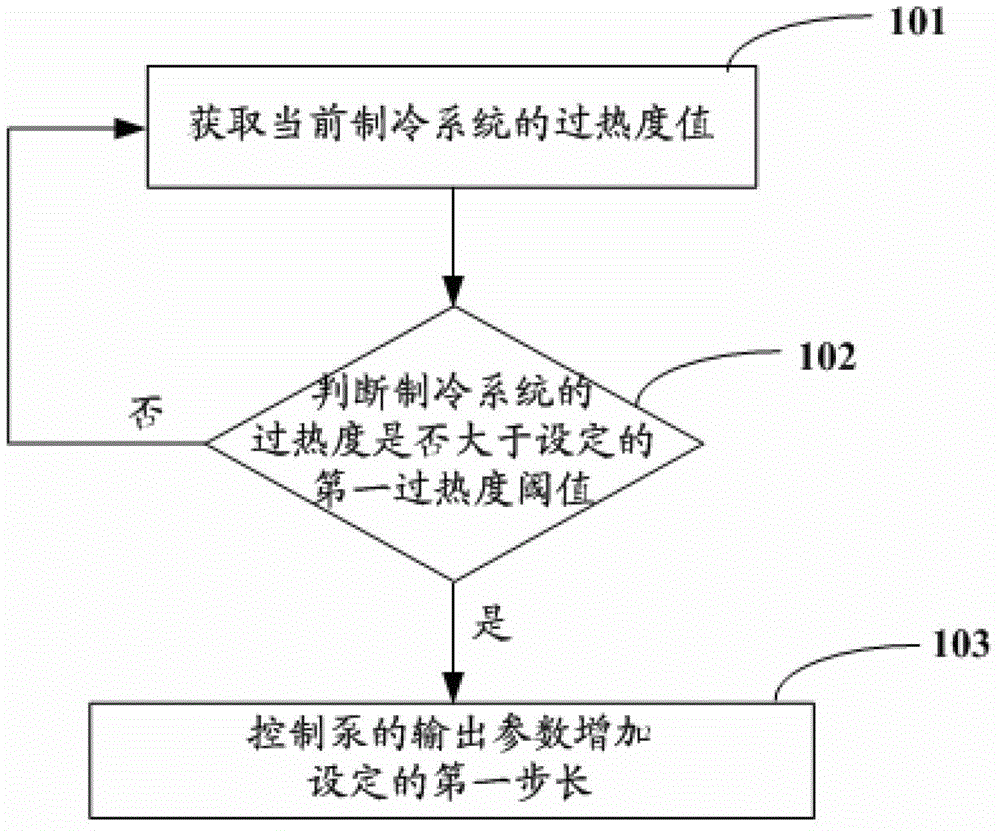

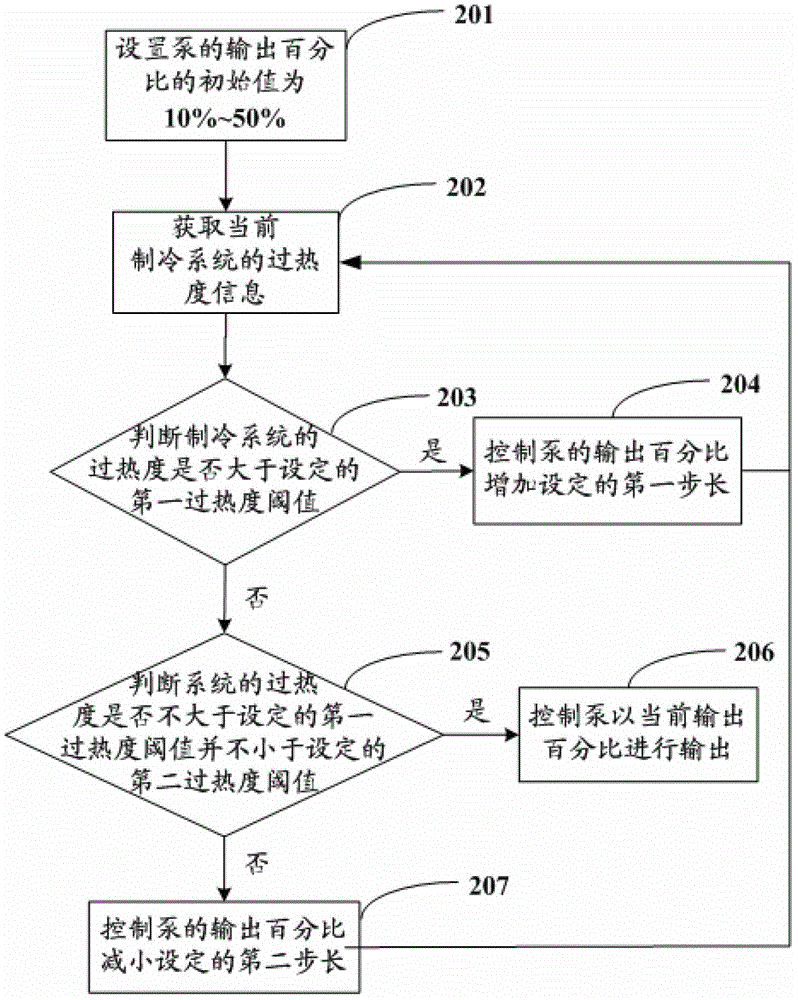

Pump start control method, pump start control device, pump start control system and refrigerating system

ActiveCN104251581AReduce shockReduced risk of cavitationRefrigeration safety arrangementStreamflowCavitation

The invention relates to the technical field of refrigeration and discloses a pump start control method, a pump start control device, a pump start control system and a refrigeration system. The pump start control method comprises the following steps: acquiring the superheat degree value of the current refrigeration system; when the superheat degree value of the refrigeration system is greater than a set first superheat degree threshold, controlling output parameters of a pump to increase a set first step length. According to the pump start control method, during pump start, the superheat degree is adopted as a parameter to gradually increase the output of the pump, so that impact of a large-flow refrigerant on the pump can be avoided, the cavitation risk during pump start is reduced, and the pump reliability is enhanced.

Owner:EMERSON NETWORK POWER CO LTD

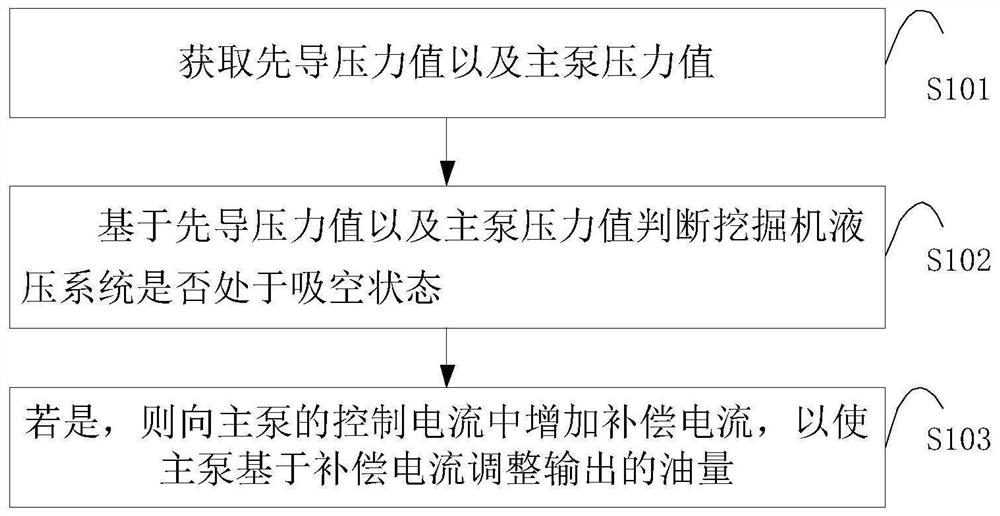

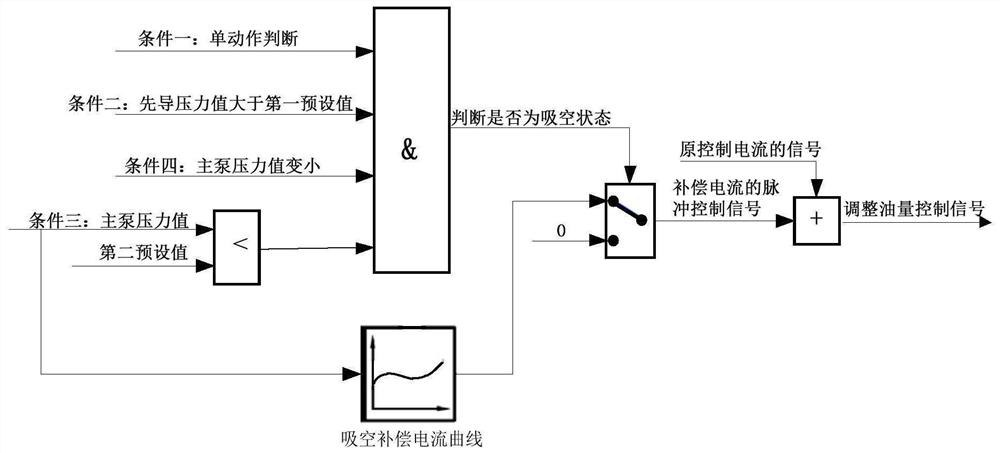

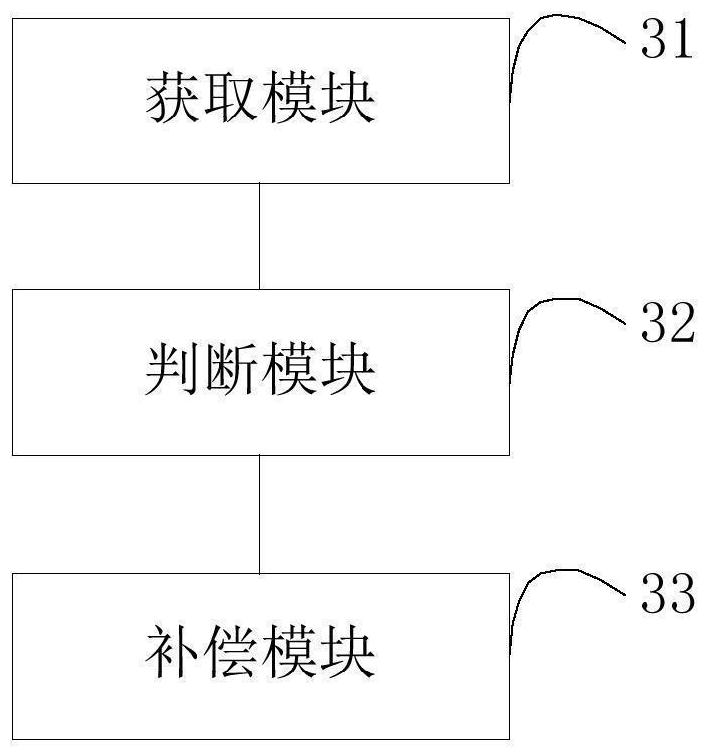

Excavator hydraulic system anti-air-suction controlling method and controlling device and excavator

PendingCN111733919AReduced risk of cavitationSoil-shifting machines/dredgersProcess engineeringOil supply

The invention discloses an excavator hydraulic system anti-air-suction controlling method and controlling device and an excavator. The controlling method comprises the steps that: a pilot pressure value and a main pump pressure value are acquired; whether an excavator hydraulic system is in an air sucking status is judged based on the pilot pressure value and the main pump pressure value; and if the excavator hydraulic system is in the air suck status, compensating current is added to controlling current of a main pump to enable the main pump to adjust output oil amount based on the compensating current. Electric signals replace traditional hydraulic signals in judging whether the hydraulic system is in an air sucking status; the air sucking risk is lowered in a manner that oil supply amount is actively added; and the technical effects that precise judgment on whether the hydraulic system is in an air sucking status can be realized without adding extra controlling components and that the air sucking risk is lowered via linear addition of the oil supply amount to the system.

Owner:WEICHAI POWER CO LTD +1

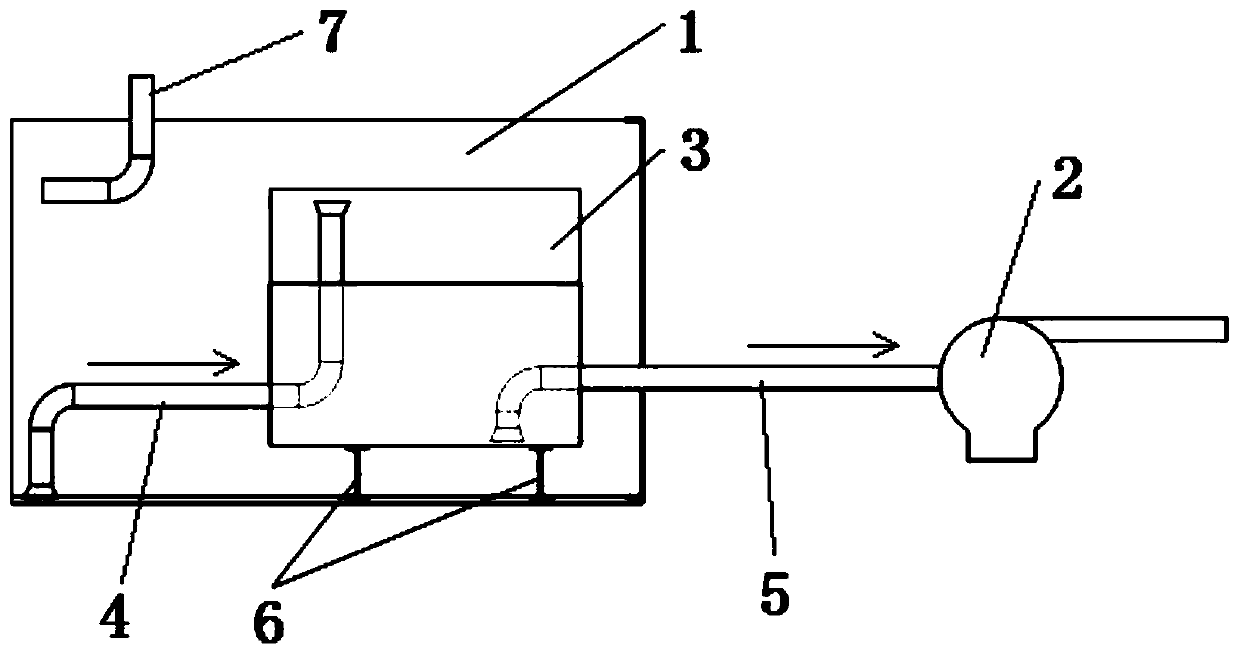

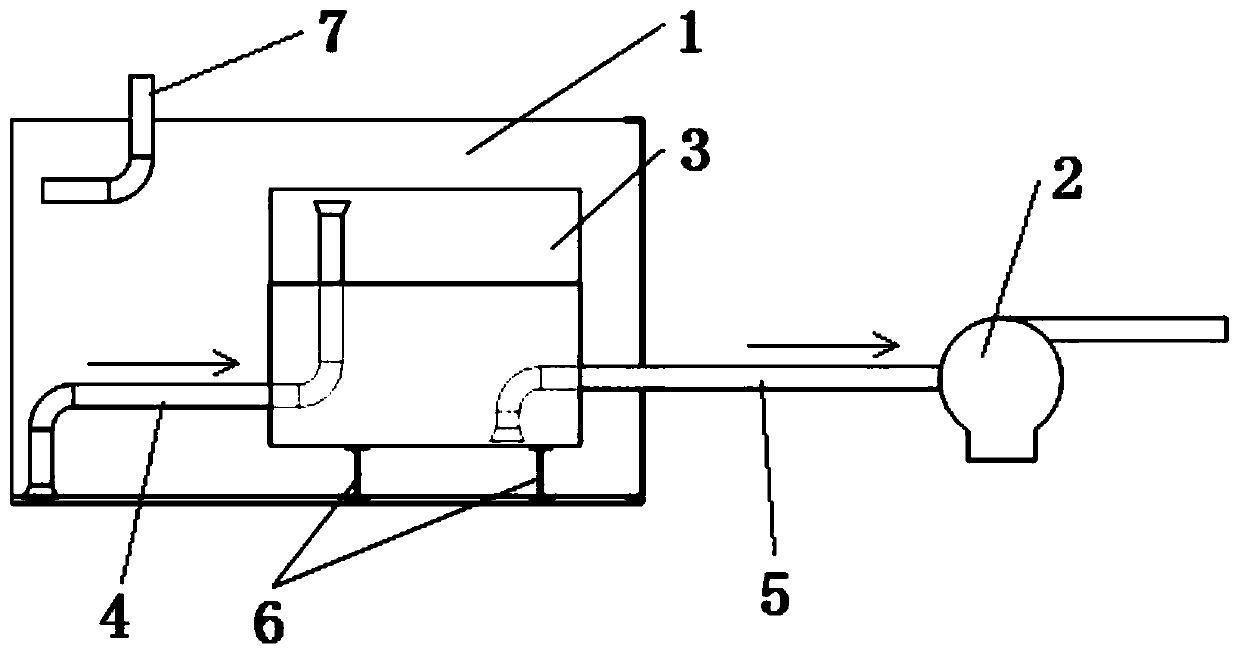

Oil transportation heat management integrated system for controlling fuel oil temperature rise of high-speed aircraft

ActiveCN111259488AReduced risk of cavitationReduce boost pressureGeometric CADWeight reductionFlight vehicleFuel tank

The invention provides an oil transportation heat management integrated system for controlling fuel oil temperature rise of a high-speed aircraft. The oil transportation heat management integrated system comprises a main oil tank, a built-in oil tank, an oil pump, a first oil pipe, a second oil pipe, a supporting frame and an air inlet pipe. Oil tank pressurized gas enters the main oil tank from the gas inlet pipe to provide pressure for fuel oil in the main oil tank, so that the fuel oil is conveyed to the built-in oil tank from the main oil tank through the first oil pipe, then is conveyed to the oil pump through the second oil pipe, and finally is supplied to an engine through the oil pump. According to the technical scheme, the built-in oil tank is arranged in the main oil tank, the temperature of fuel oil at the flight tail section of the long-endurance high-speed aircraft can be effectively reduced, and the effects of reducing the cavitation risk of a fuel oil pump, reducing thepressurization pressure of a fuel oil tank, reducing the design difficulty of oil passing equipment, increasing available fuel oil heat sinks of an engine and the like can be achieved. The method canbe applied to high-speed aircrafts such as high-speed aircrafts and aerospace aircrafts.

Owner:BEIJING AEROSPACE TECH INST

A fluid-dispensing circuit with check valves

InactiveCN1671615AExtension of timeRealize self-cleaningPositive displacement pump componentsCheck valvesEngineeringCheck valve

Owner:赛皮尔斯色料设备股份有限公司

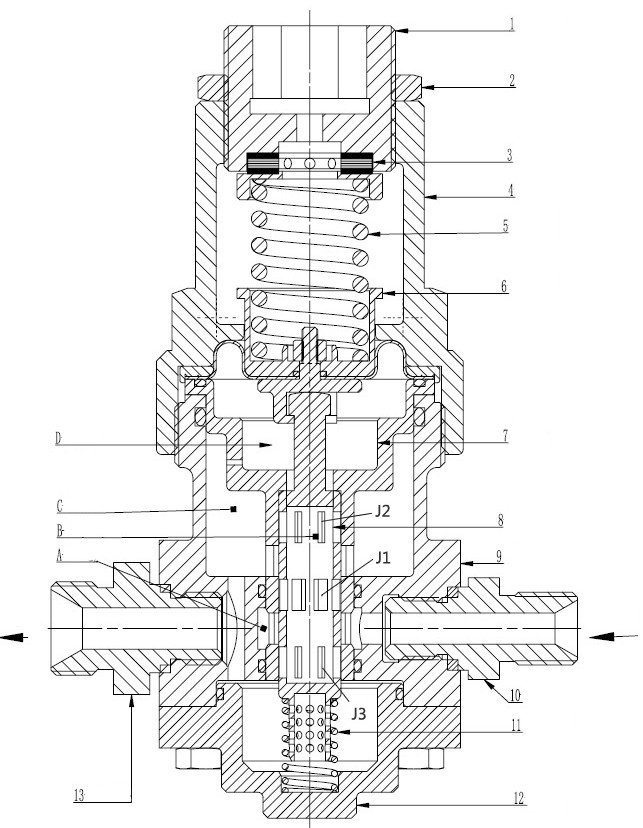

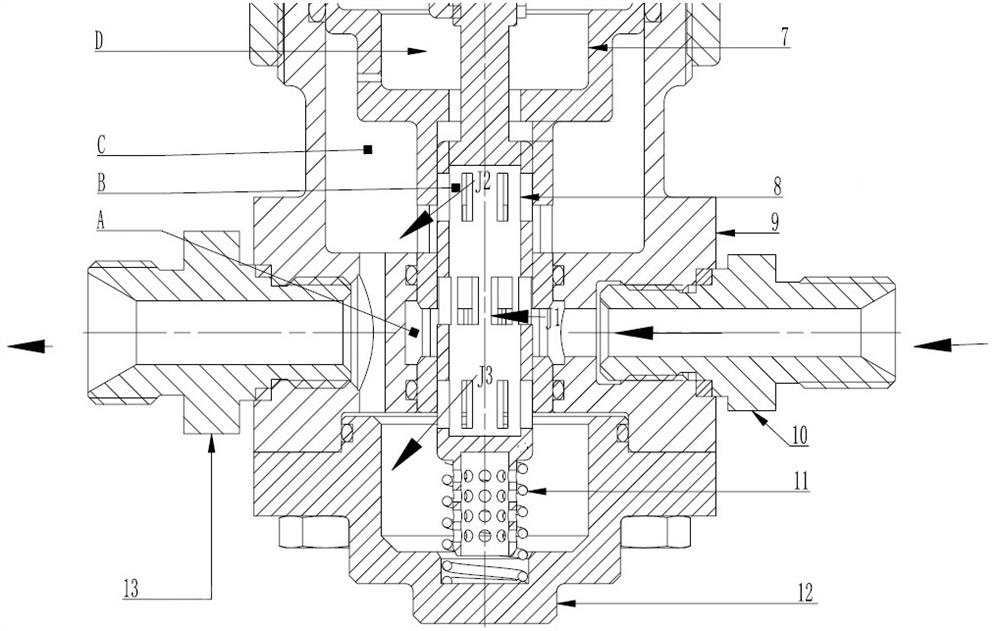

Multi-stage throttling labyrinth pressure reducing valve

ActiveCN110131477ASmooth pressure regulationPrecise pressure regulationValve members for absorbing fluid energyEqualizing valvesCavitationEngineering

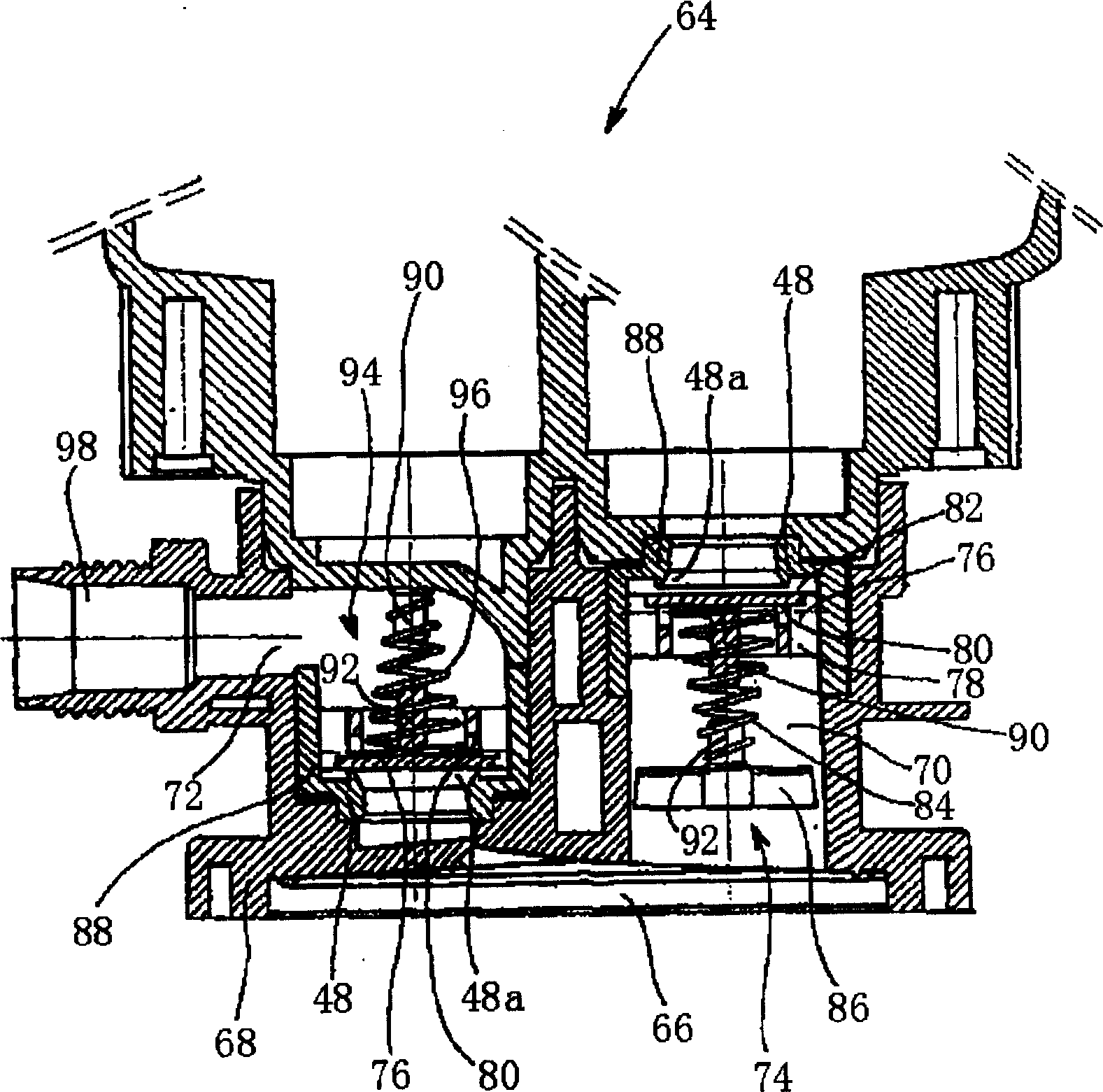

The invention provides a multi-stage throttling labyrinth pressure reducing valve which comprises a spring cover, a shell and a lower end cover. An adjusting nut is arranged at the upper end of the spring cover, an adjusting spring is arranged between the adjusting nut and a valve element, a return spring is arranged between the valve element and the lower end cover, the valve element is located in a sliding sleeve, the sliding sleeve is fixed in the shell, the shell forms a high-pressure cavity of an inlet and an outlet, a transition cavity is formed in the valve element, the shell and the sliding sleeve form a low-pressure cavity I, the lower end cover and the valve element form a low-pressure cavity II, the sliding sleeve and the valve element are correspondingly provided with upper throttling ports which communicate with the low-pressure cavity I and the transition cavity, the sliding sleeve and the valve element are correspondingly provided with middle throttling ports which communicate with the high-pressure cavity and the transition cavity, and the valve element is provided with a lower throttling port which communicates with the low-pressure cavity II and the transition cavity. The multi-stage throttling labyrinth pressure reducing valve has the advantages that pressure regulation is smooth and accurate, the anti-interference capability of the valve is improved, the structure is simple, maintenance is convenient, the service life is long, the cavitation risk of primary throttling high pressure difference is reduced, medium pressure feedback is more sensitive, and precision is higher.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

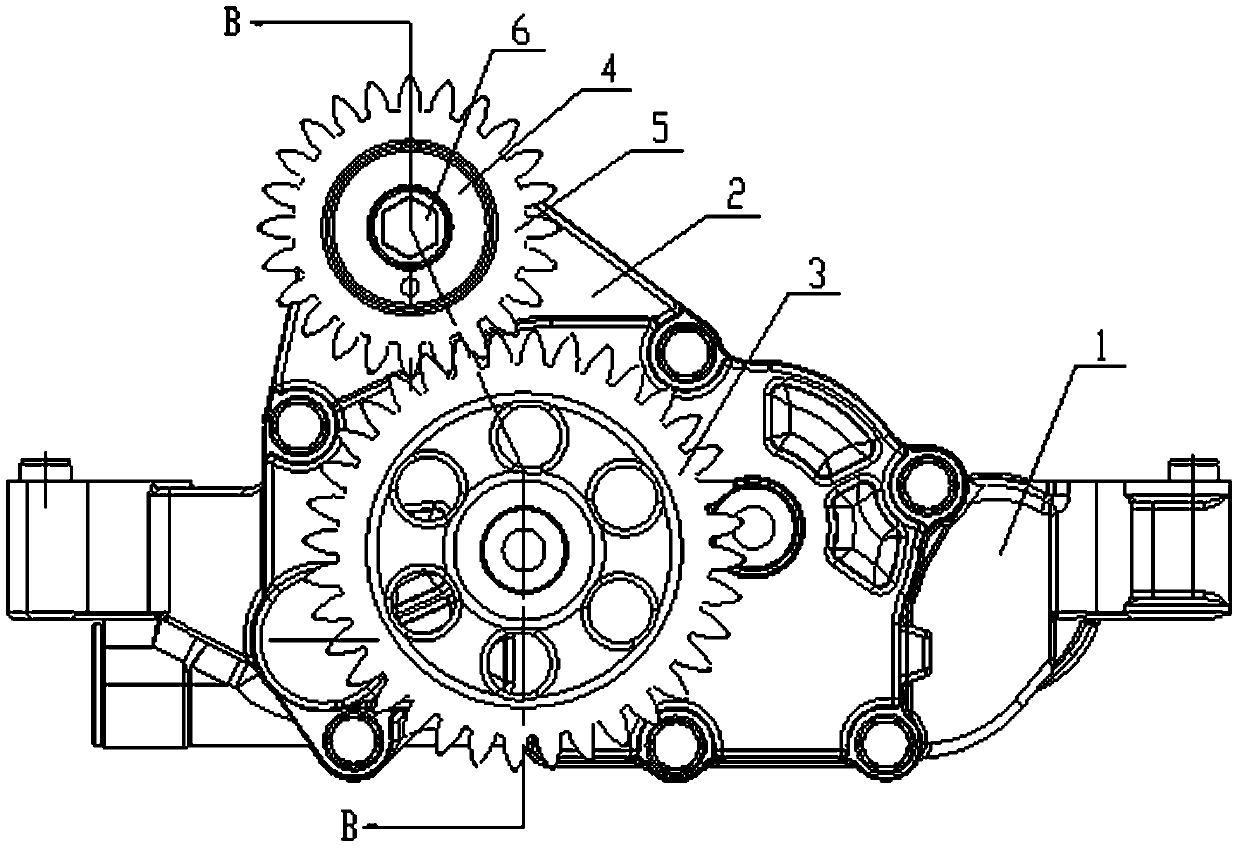

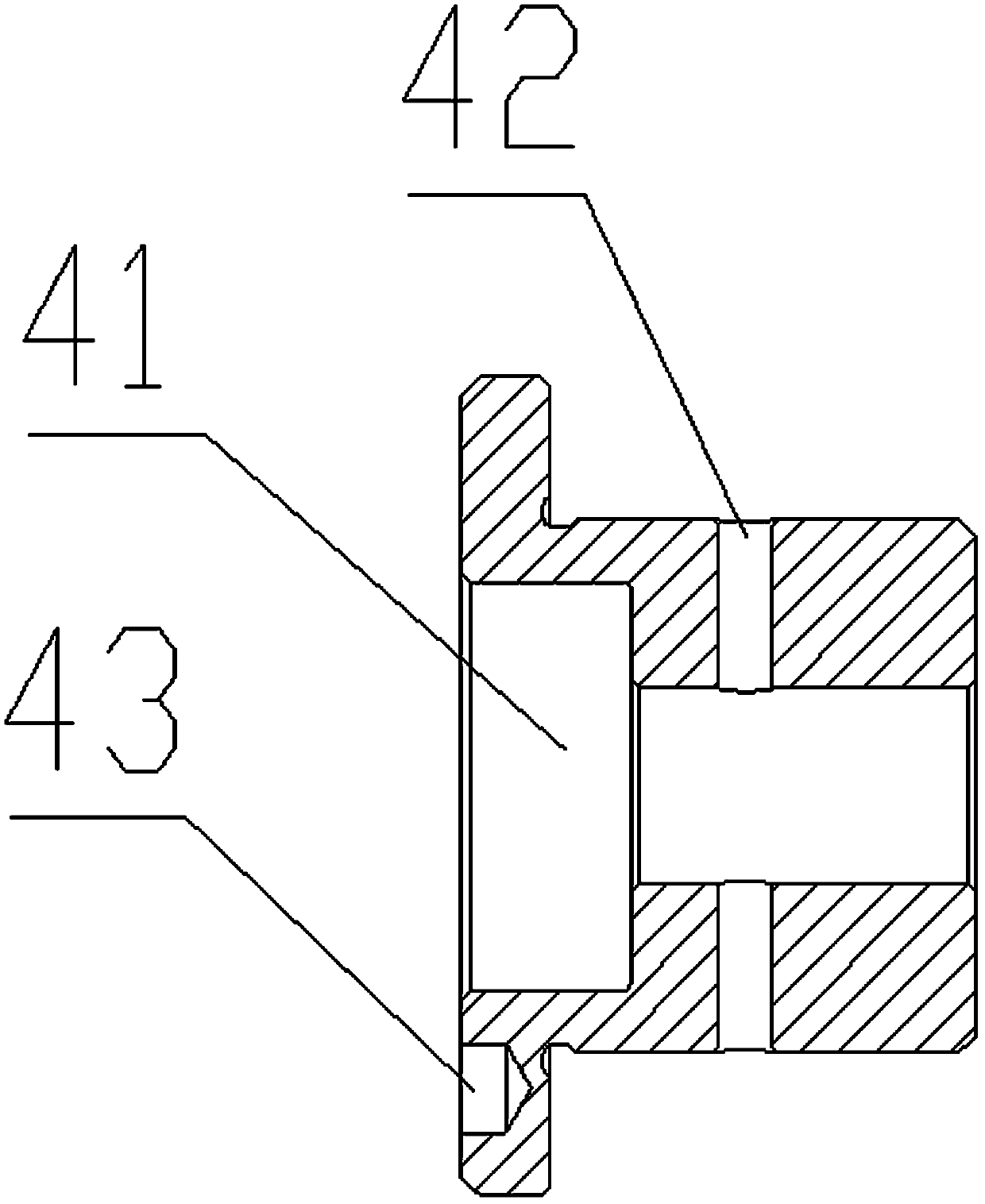

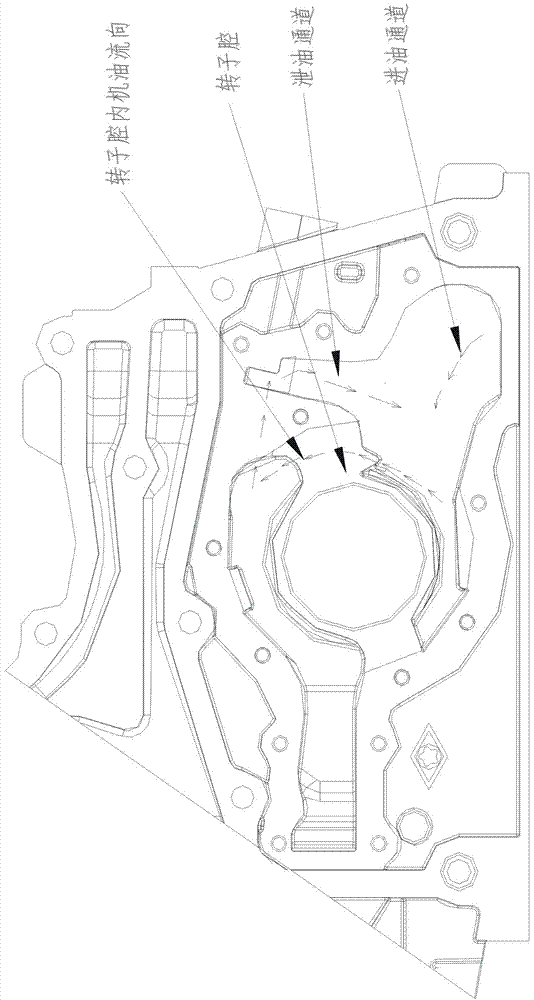

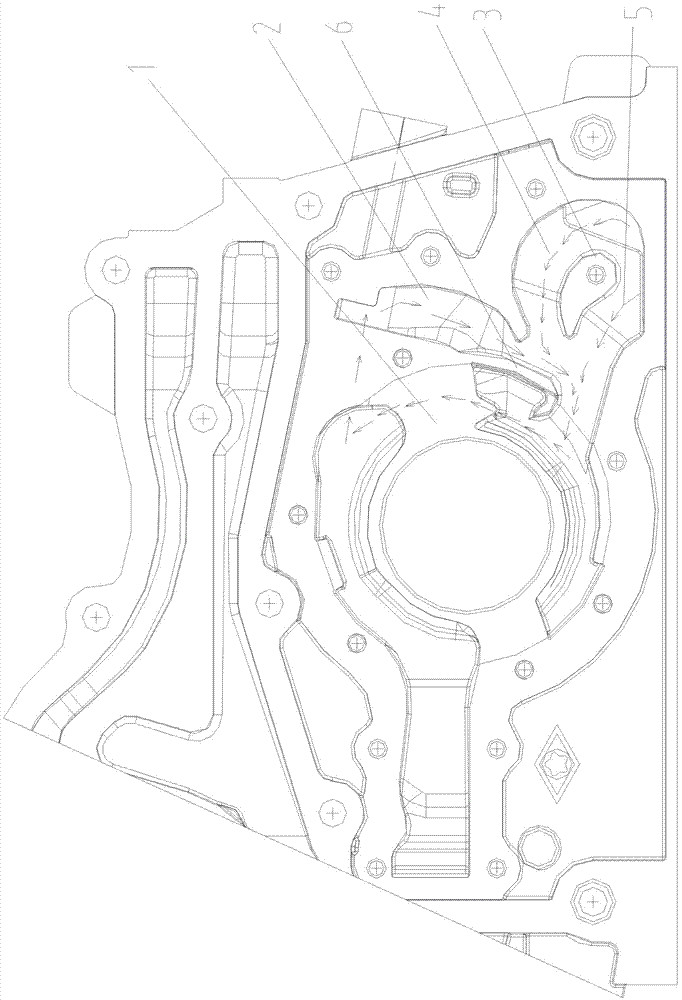

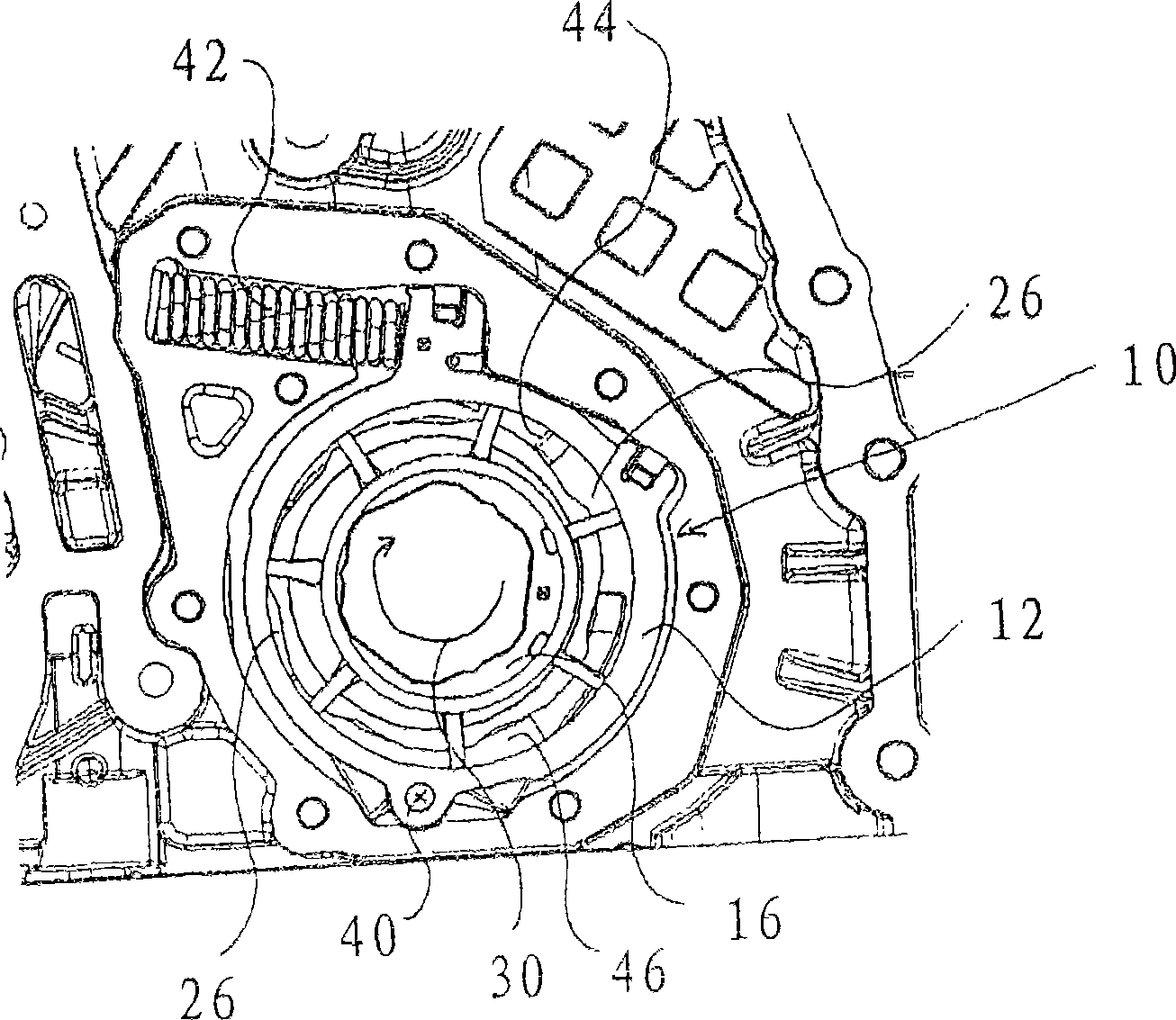

Structure-optimized machine oil pump with idle gear

PendingCN109827061AReduce weightAchieve oil circulationEqualizing valvesRotary piston pumpsEngineeringHigh pressure

The invention provides a structure-optimized machine oil pump with an idle gear. The machine oil pump comprises a pump body, a pump cover, an idle gear shaft, the idle gear and a bolt; an oil cavity is formed in the pump body; an idle gear shaft mounting hole is formed in the pump cover; the idle gear shaft is provided with an axial bolt mounting hole and a lubricating through hole intersected with the bolt mounting hole; the idle gear sleeves the idle gear shaft; a screw plug fixes the idle gear shaft on the pump cover; the diameter of the bolt is smaller than the aperture of the bolt mounting hole of the idle gear shaft; an annular gap is formed between the bolt and the inner wall of the bolt mounting hole; an oil passing groove is formed in the side, near an oil cavity, of the round hole bottom surface of the idle gear shaft mounting hole; an inclined oil hole communicating with the oil cavity is drilled in the pump cover through the oil passing groove; high-pressure oil in the oilcavity flows into a gap between an idle gear bushing and the idle gear shaft through the inclined oil hole, the oil passing groove, the annular gap and the lubricating through hole in sequence; and oil leakage grooves are formed in two end surfaces of a shaft table of the idle gear.

Owner:HUNAN OIL PUMP

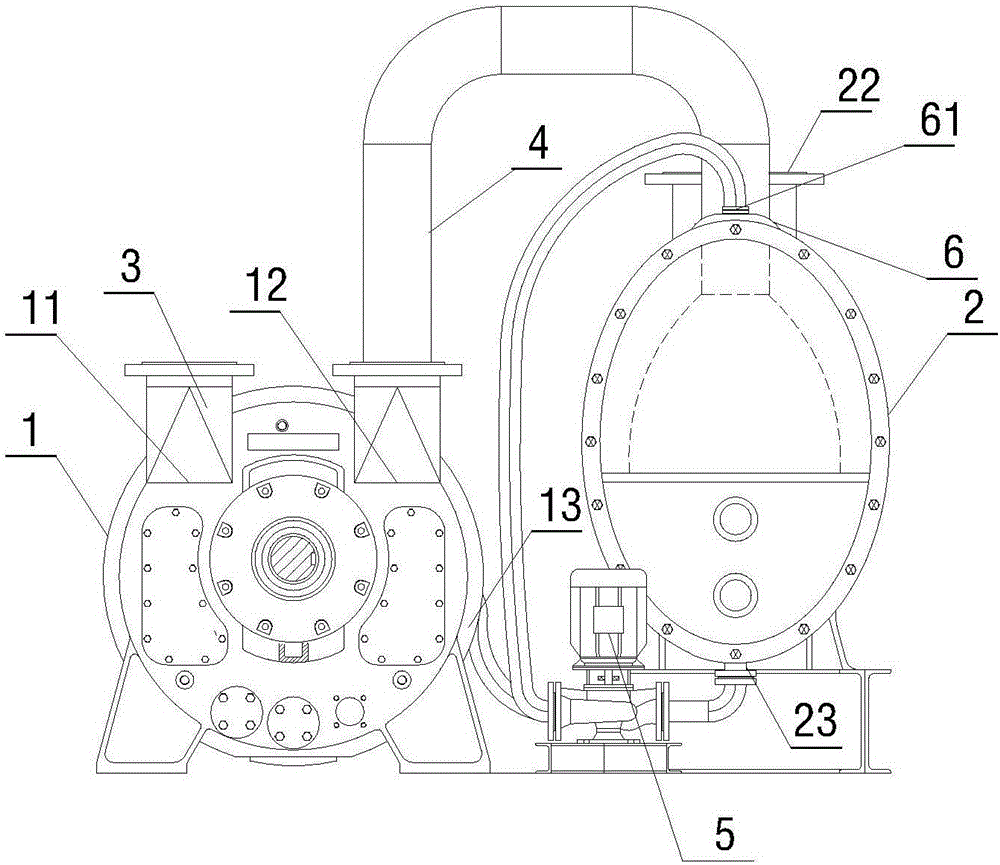

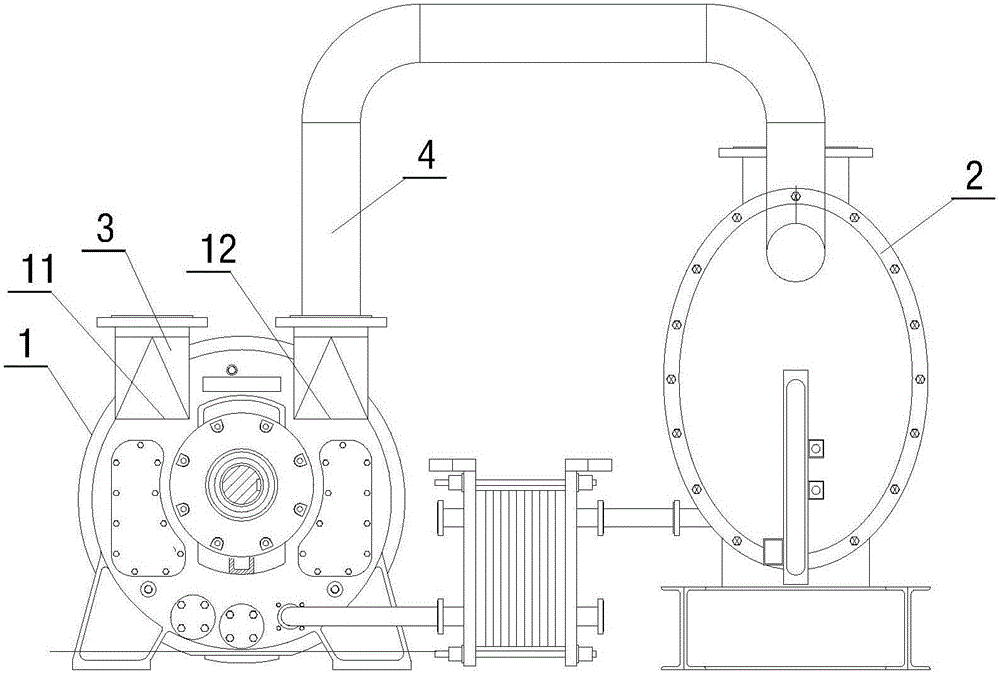

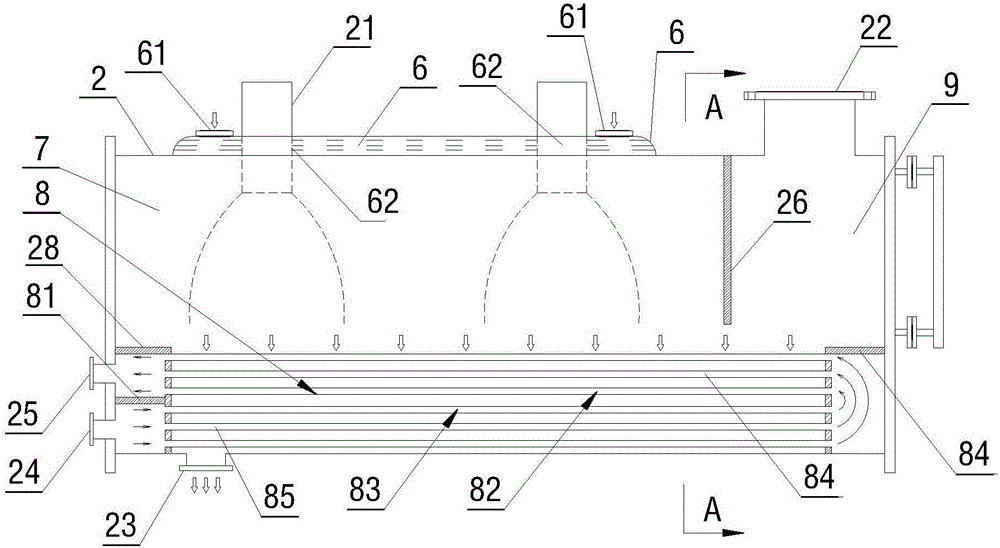

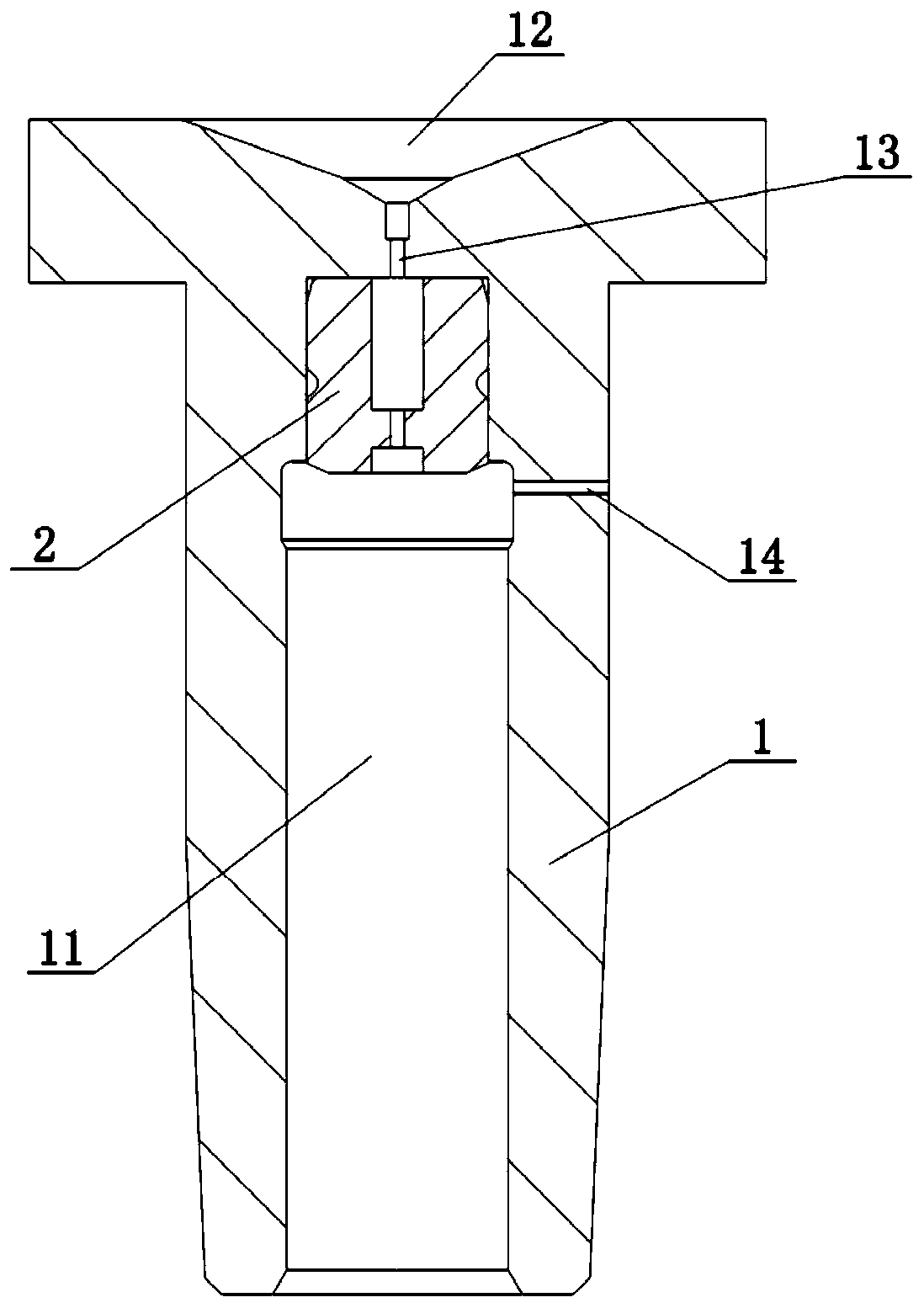

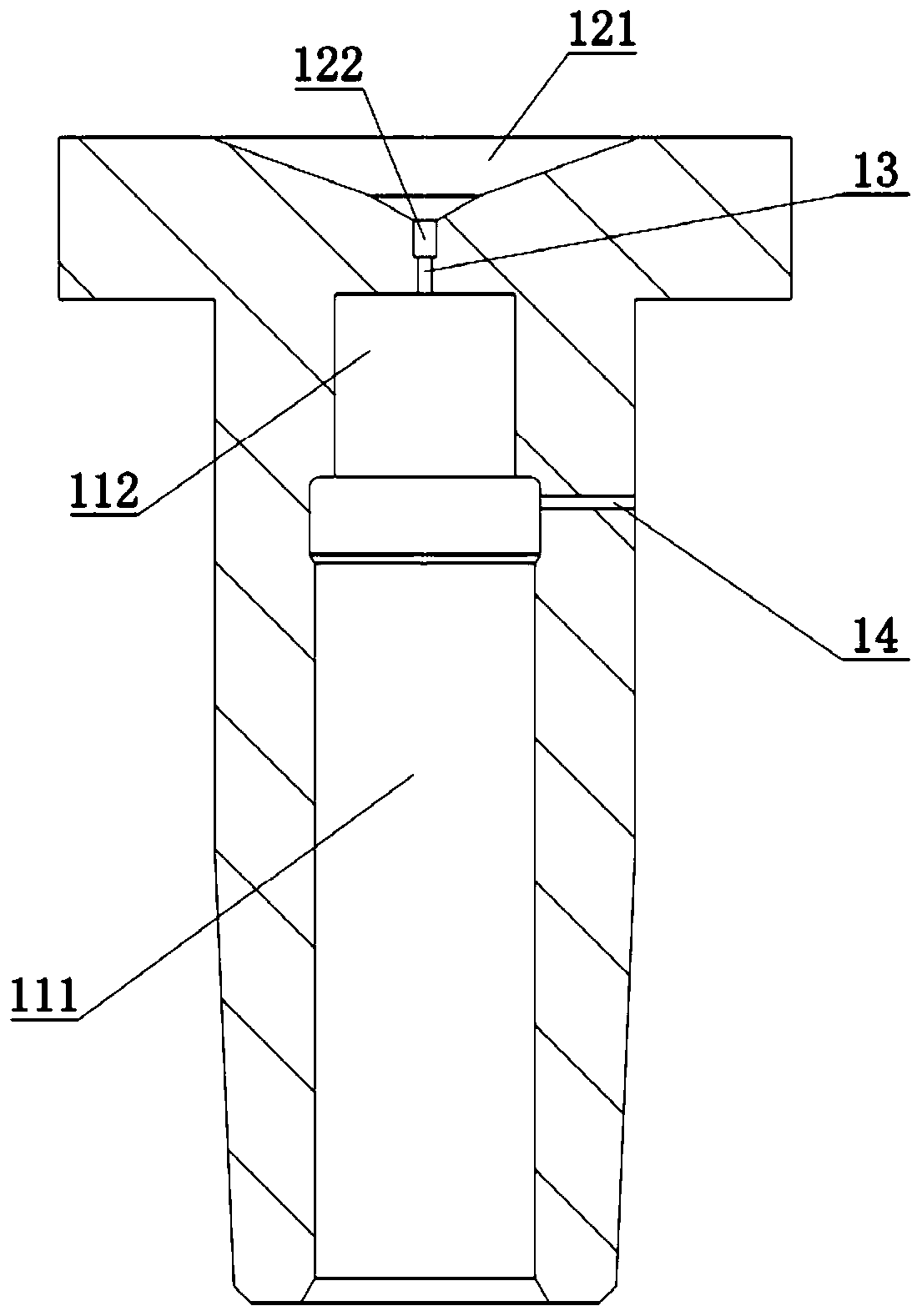

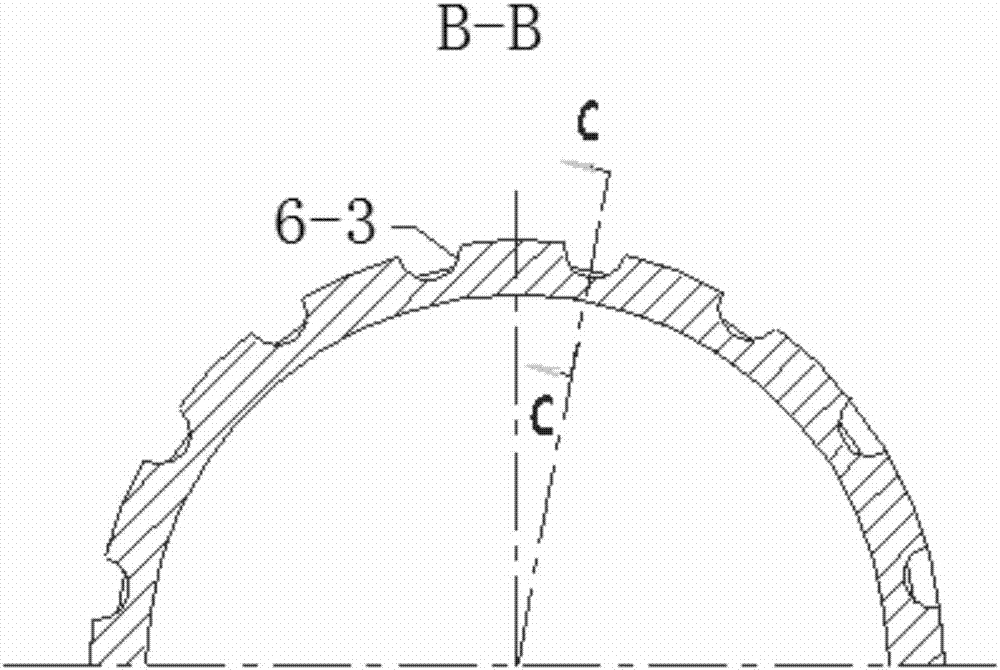

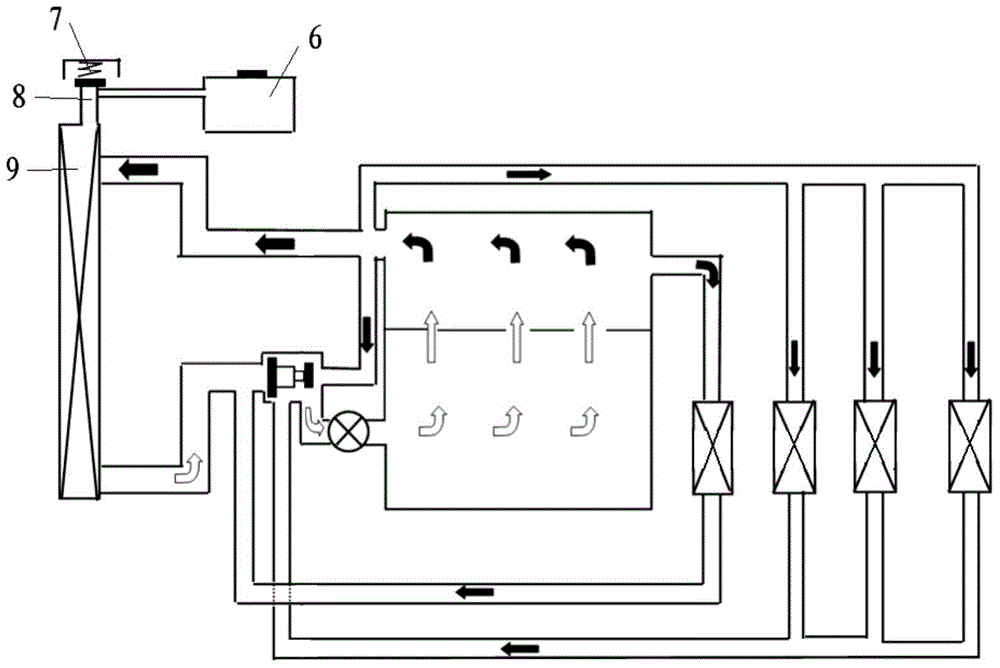

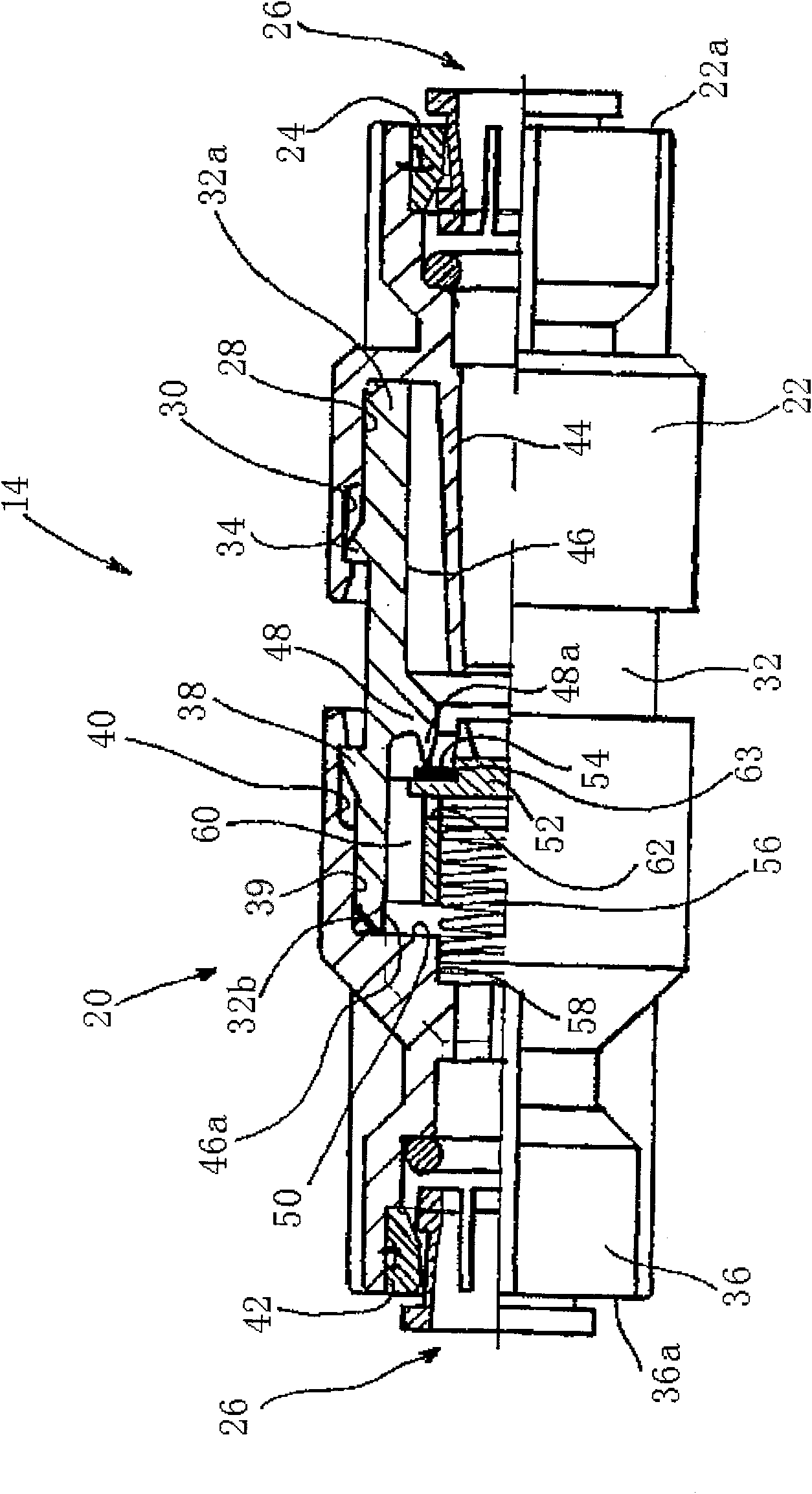

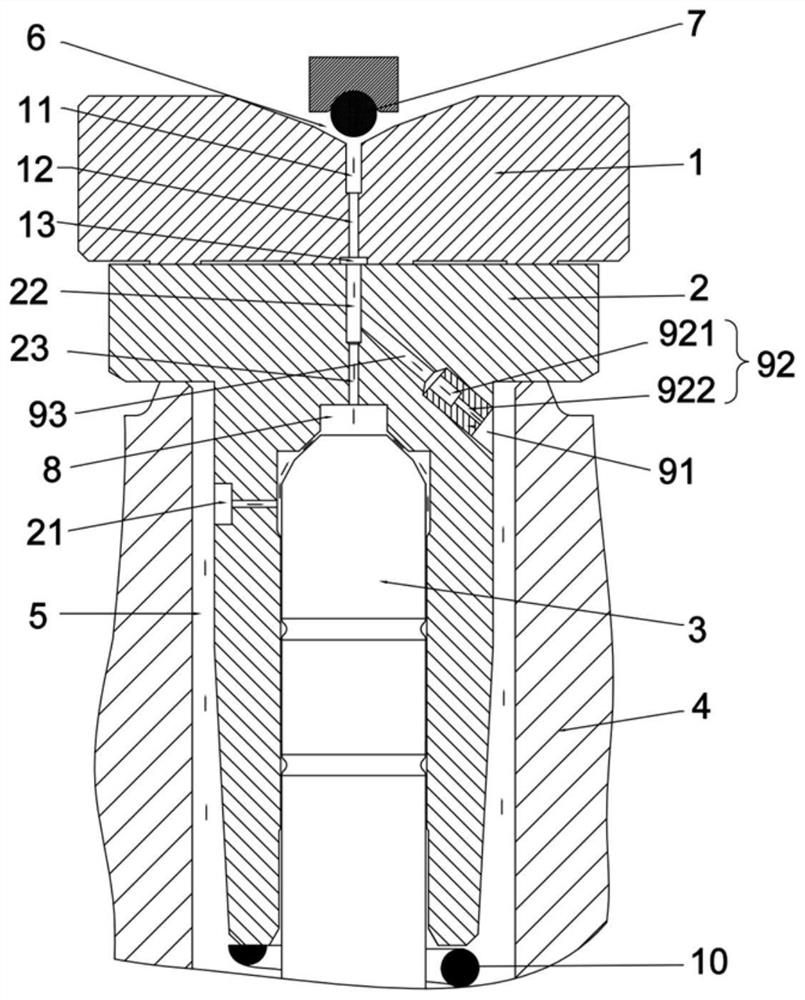

Pressurization type liquid ring vacuum pump water return system with rotating film and water return method thereof

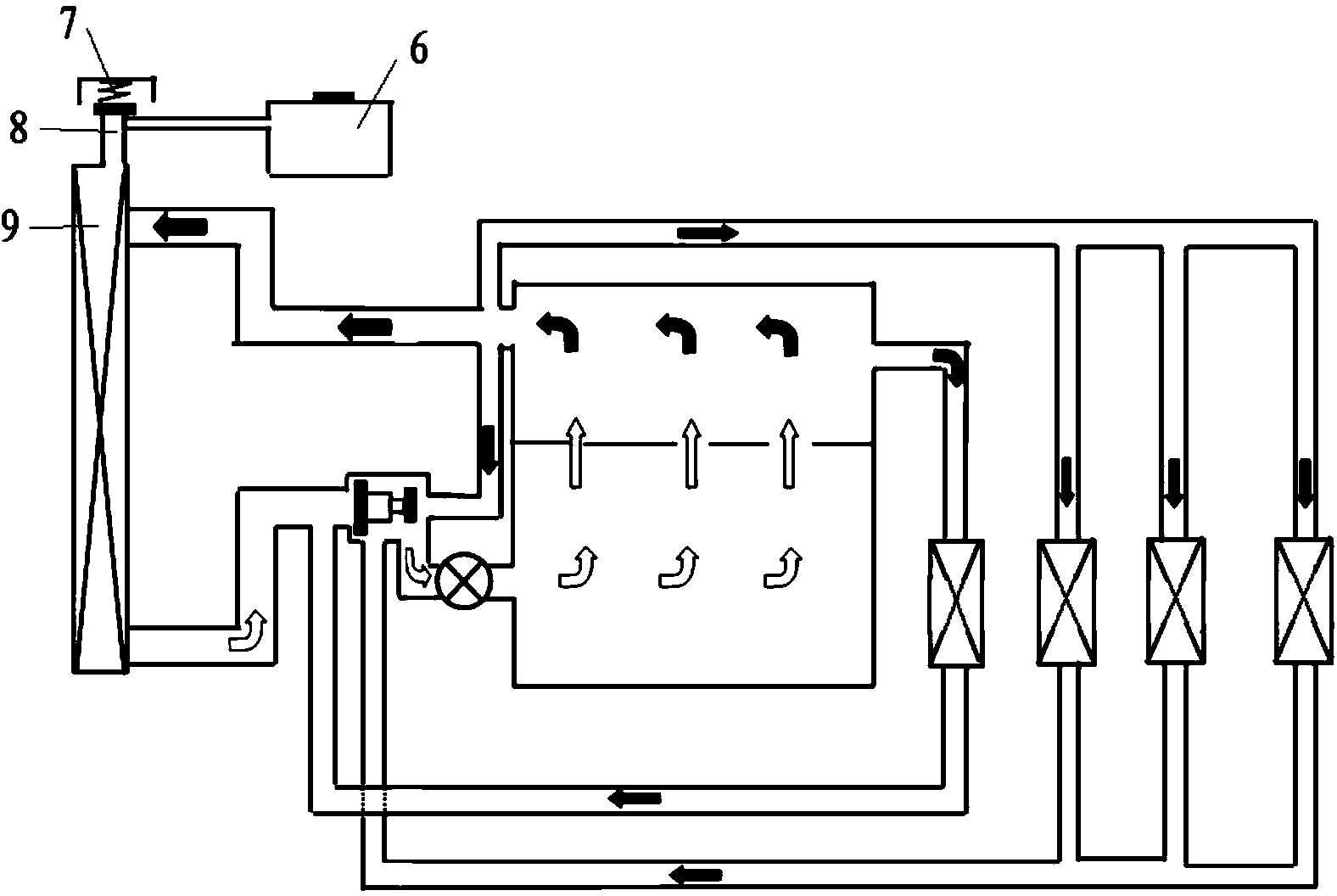

ActiveCN106523366AReduce disturbanceReduce resistanceRotary piston pumpsRotary/oscillating piston pump componentsThermodynamicsEngineering

The invention discloses a pressurization type liquid ring vacuum pump water return system with a rotating film, and relates to the liquid ring vacuum pump water return system applied in the fields of chemical engineering, machinery, exploration, electric power and the like. The liquid ring vacuum pump water return system comprises a vacuum pump body, a vapor-water separator, a feeding pipe, a discharging pipe, a pressurization pump, a rotating film area, a cooling liquid inlet, a vapor-water separation area, a heat exchange area, a commutating area, a flow guide plate, a gas-phase passage and an annular separating plate, wherein a rotating film tube is installed in the rotating film area, and the tube wall of the rotating film tube is provided with rotating film holes; a heat exchange separating plate is installed in the heat exchange area, and a heat exchange liquid inlet communicates with a water inlet of a lower heat exchange pipe; a heat exchange liquid outlet communicates with a water outlet of an upper heat exchange pipe; and the input end of the pressurization pump communicates with a separating liquid outlet, and the output end of the pressurization pump communicates with a water return port and the cooling liquid inlet. By means of the pressurization type liquid ring vacuum pump water return system with the rotating film, water return fluid disturbance can be reduced, and resistance is lowered. The invention further relates to a water return method of the pressurization type liquid ring vacuum pump water return system with the rotating film.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

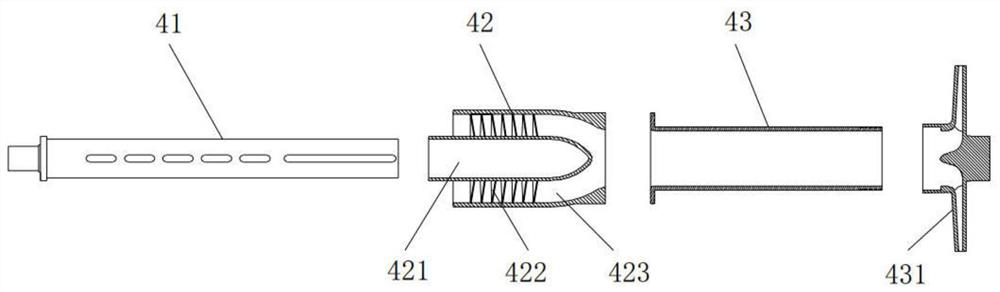

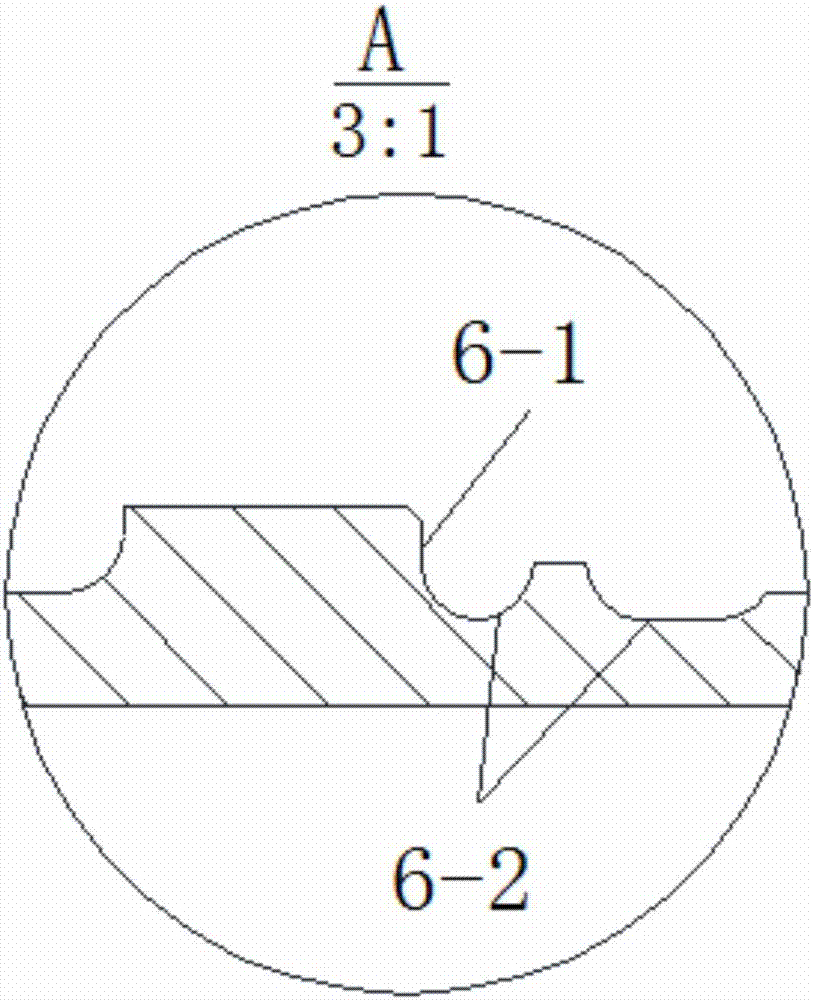

Fuel injection valve sleeve assembly

InactiveCN110529317AImprove reliabilityReduce flow rateMachines/enginesSpecial fuel injection apparatusEngineeringMachining

The invention belongs to the technical field of fuel injectors, and discloses a fuel injection valve sleeve assembly which comprises a valve sleeve body and a throttling sleeve, wherein an operation groove and a control groove are respectively formed at two opposite sides of the valve sleeve body, the operation groove is communicated with the control groove through a first throttling hole, and anoil inlet hole communicated with the outside is formed in the side wall of the operation groove; the throttling sleeve is clamped at the bottom of the operation groove or the control groove, a secondthrottling hole and an inner side counter bore are formed at the two opposite sides of the throttling sleeve respectively, and an opening at one end of the second throttling hole is located in the inner side counter bore; the inner side counter bore is communicated with the first throttling hole, and the hole diameter of the first throttling hole and the hole diameter of the second throttling holeare both smaller than that of the inner side counter bore. According to the fuel injection valve sleeve assembly, because of the split clamping design of the valve sleeve body and the throttling sleeve, the machining and manufacturing difficulty and cost are reduced, and the secondary throttling can be achieved with lower cost.

Owner:FAW JIEFANG AUTOMOTIVE CO

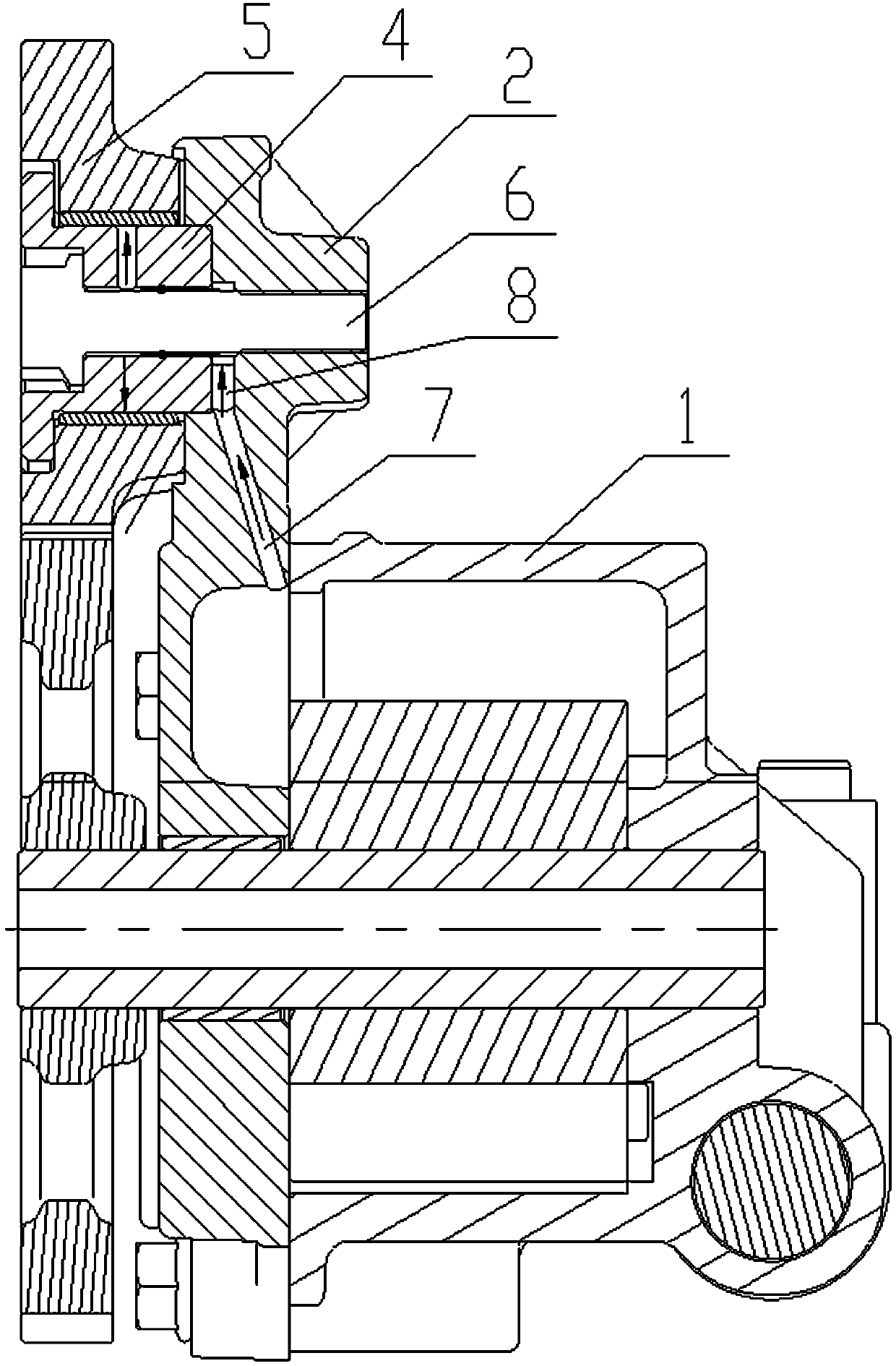

Improved engine oil cooling module shell

ActiveCN107061971AReduce shockAvoid enteringLubricating pumpsLubrication elementsInlet channelCavitation

The invention discloses an improved engine oil cooling module shell which is provided with an engine oil pump rotor cavity, an oil drainage channel and an oil inlet channel. An extending oil blocking separation plate is arranged on the side, close to the rotor cavity, of the outlet end of the oil drainage channel and is in a J shape, and the bending direction of the tail of the oil blocking separation plate is consistent with the flowing direction of engine oil in the rotor cavity. Through the structure, high-pressure oil in the oil drainage channel is blocked by the oil blocking separation plate and prevented from directly entering the rotor cavity, and the high-pressure oil must be fully mixed with inlet oil at the lower side and then enters the rotor cavity, so that impact of the high-pressure oil to a rotor is lowered; meanwhile, the lower end of the oil blocking separation plate is of a bent structure with the direction being approximate to the flowing direction of the oil in the rotor cavity, so that the oil inlet direction is guided to be consistent with the flowing direction of the oil in the rotor cavity, counter-impact is reduced, and the cavitation risk is lowered.

Owner:HUNAN JIALI MACHINERY

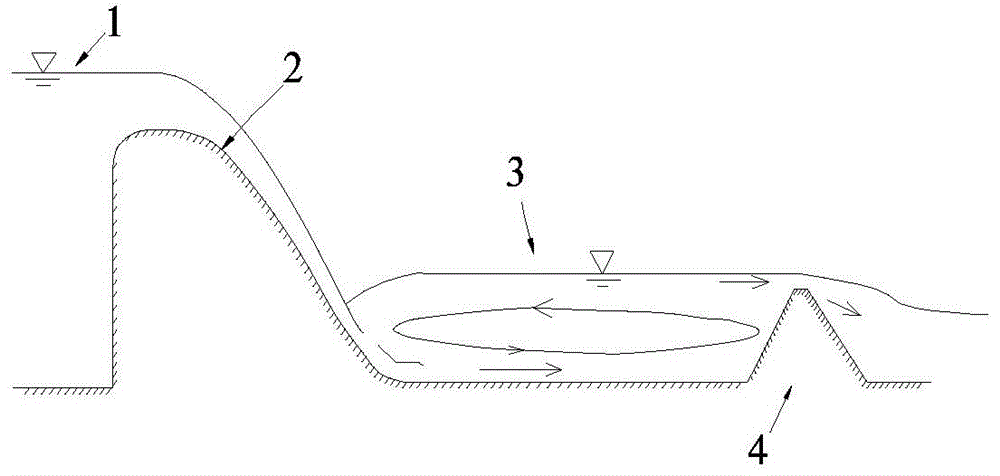

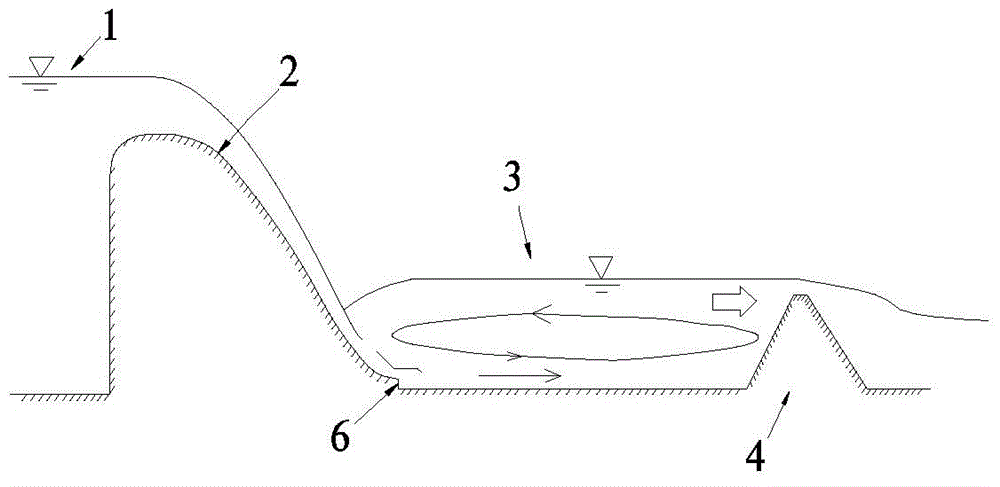

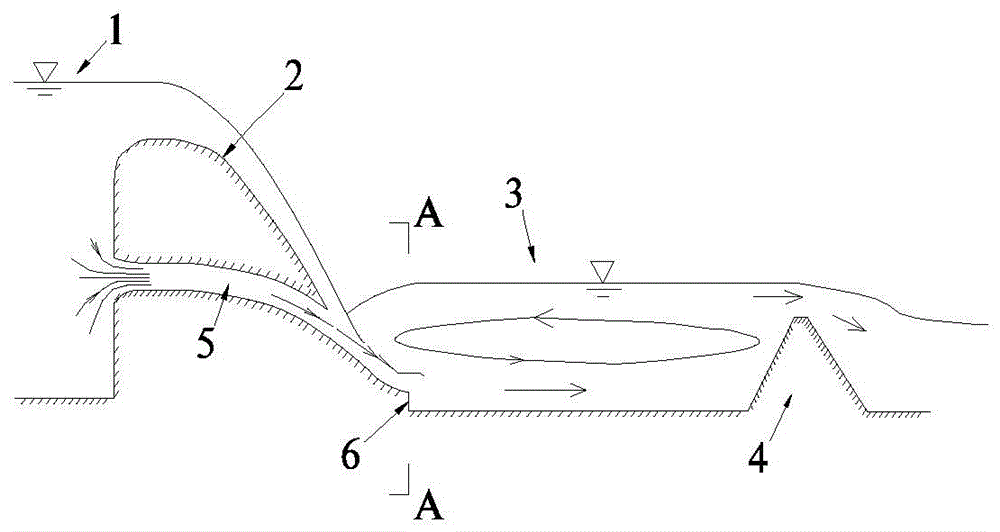

Classified pool-inlet high-dam flood discharge energy dissipater for bottom flow and energy dissipating method

The invention discloses a classified pool-inlet high-dam flood discharge energy dissipater for bottom flow. The classified pool-inlet high-dam flood discharge energy dissipater comprises a gravity dam and an absorption basin. At least two different elevation positions in a body of the gravity dam are provided with flow discharging channels extending downstream respectively, and falling banks are arranged below outlets of the flow discharging channels, wherein the falling banks are internally provided with ventilation galleries and ventilation holes. At least three levels of steps are sequentially arranged in the absorption basin from the upstream part to the downstream part. When flow passes through the top and the interior of the dam at the same time, the outlets of the flow discharging channels are sequentially located on vertical faces of the steps, with the corresponding level numbers from the upstream part to the downstream part, in the absorption basin from high to low according to the elevation of the outlets. When the flow only passes through the interior of the dam, the outlets of all the flow discharging channels are sequentially located on the vertical face at the starting position of the first-level step in the absorption basin and the vertical faces of the steps with the corresponding level numbers from the upstream part to the downstream part in the absorption basin from high to low according to the elevations of the outlets. With the energy dissipater, water in a reservoir enters the absorption basin from the flow discharging channels at the different elevations or from the top of the gravity dam and the flow discharging channels of the different elevations, and the water is scattered on the faces of the steps with the corresponding level numbers from the upstream part to the downstream part respectively in the absorption basin for energy dissipation.

Owner:SICHUAN UNIV

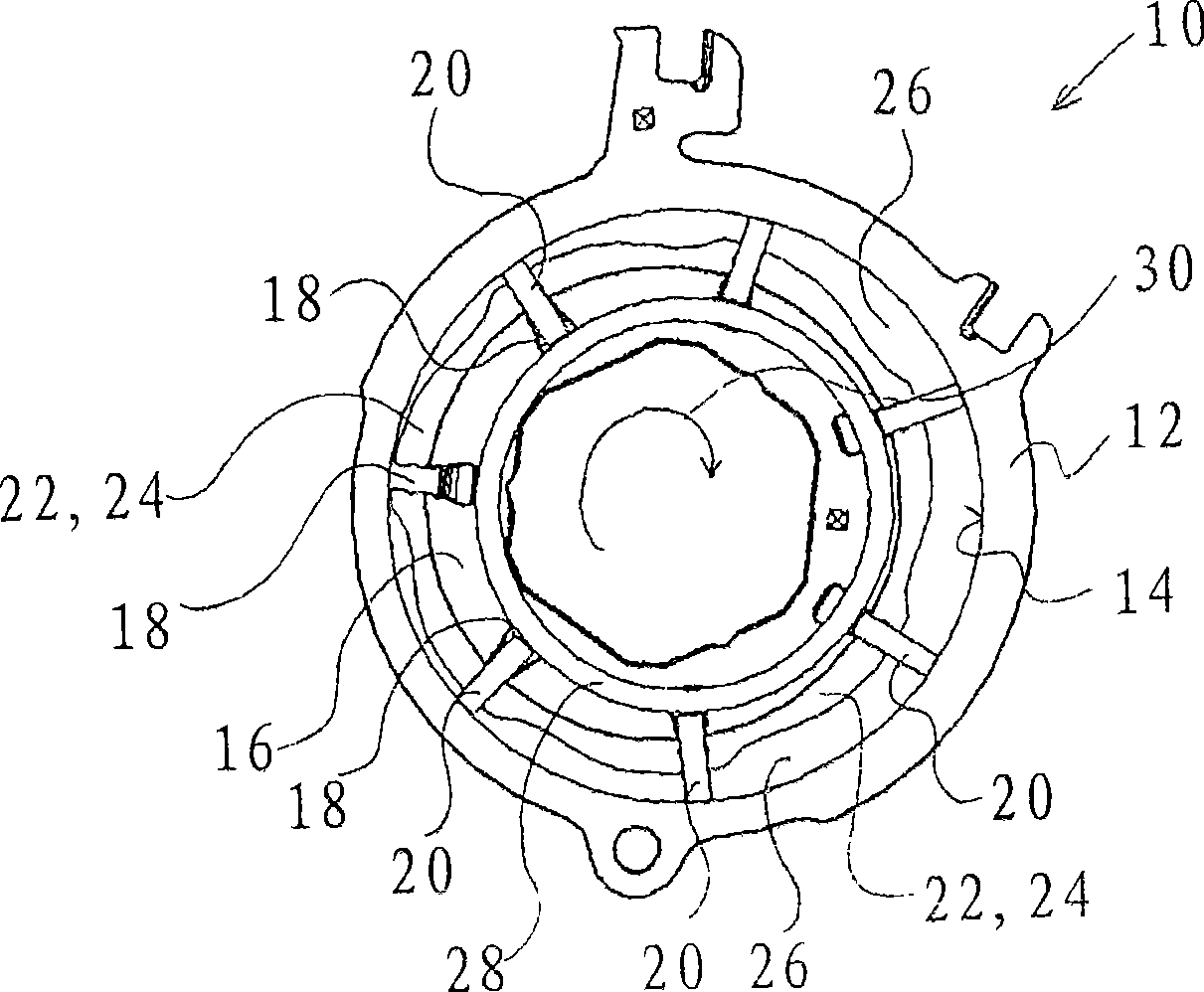

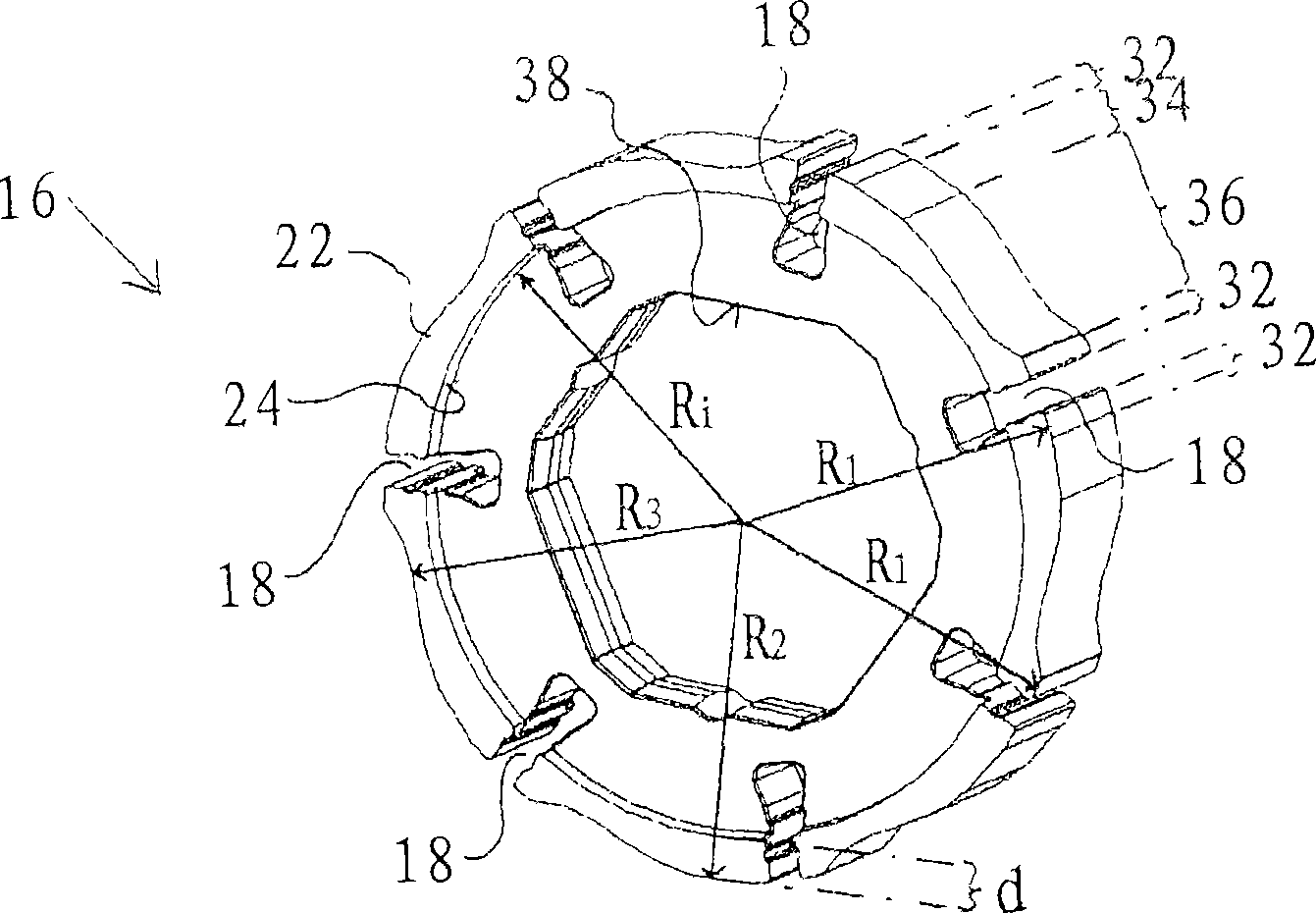

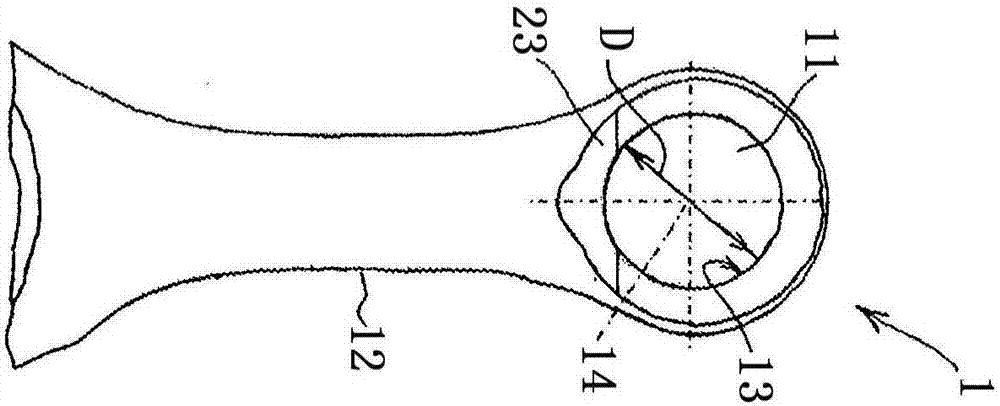

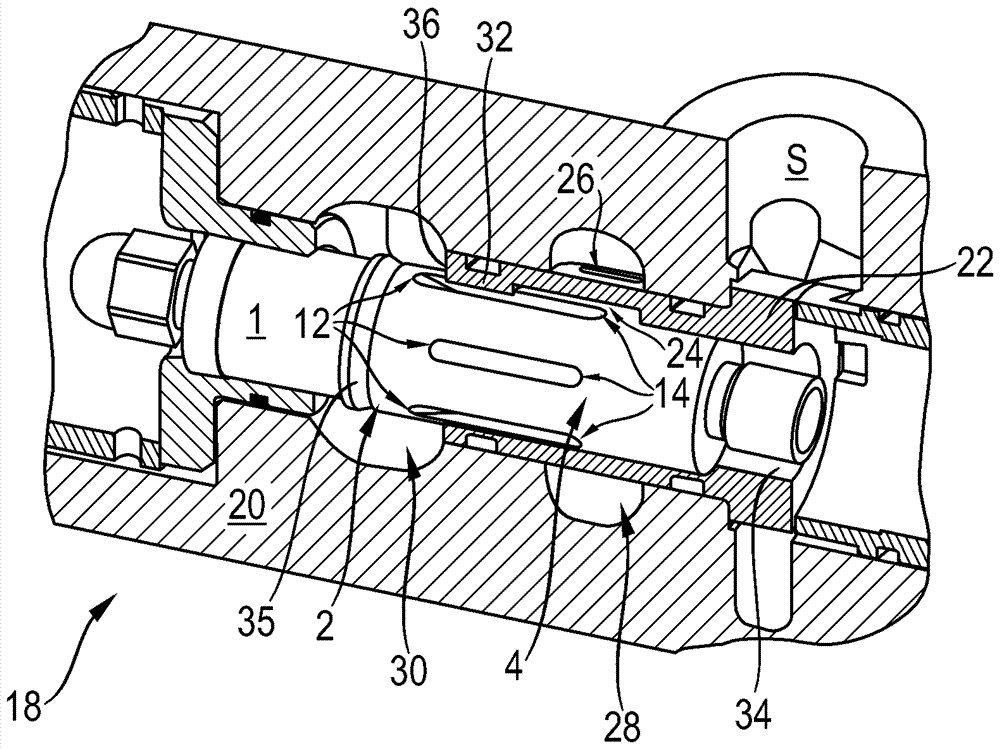

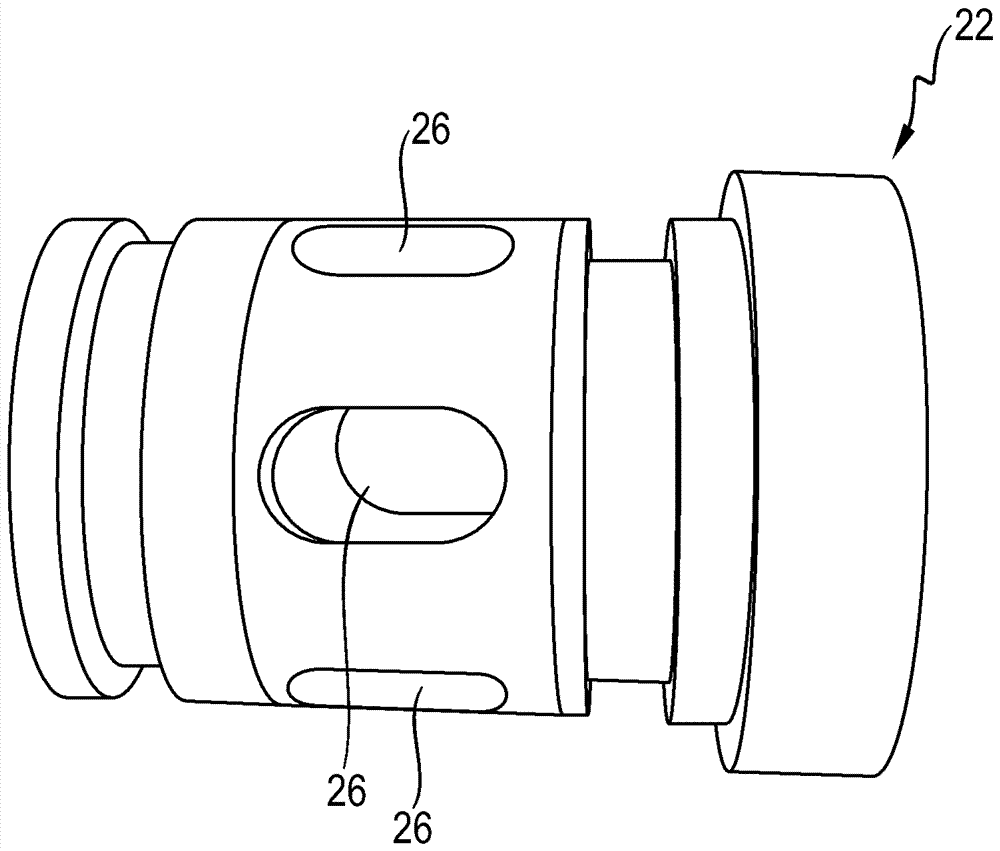

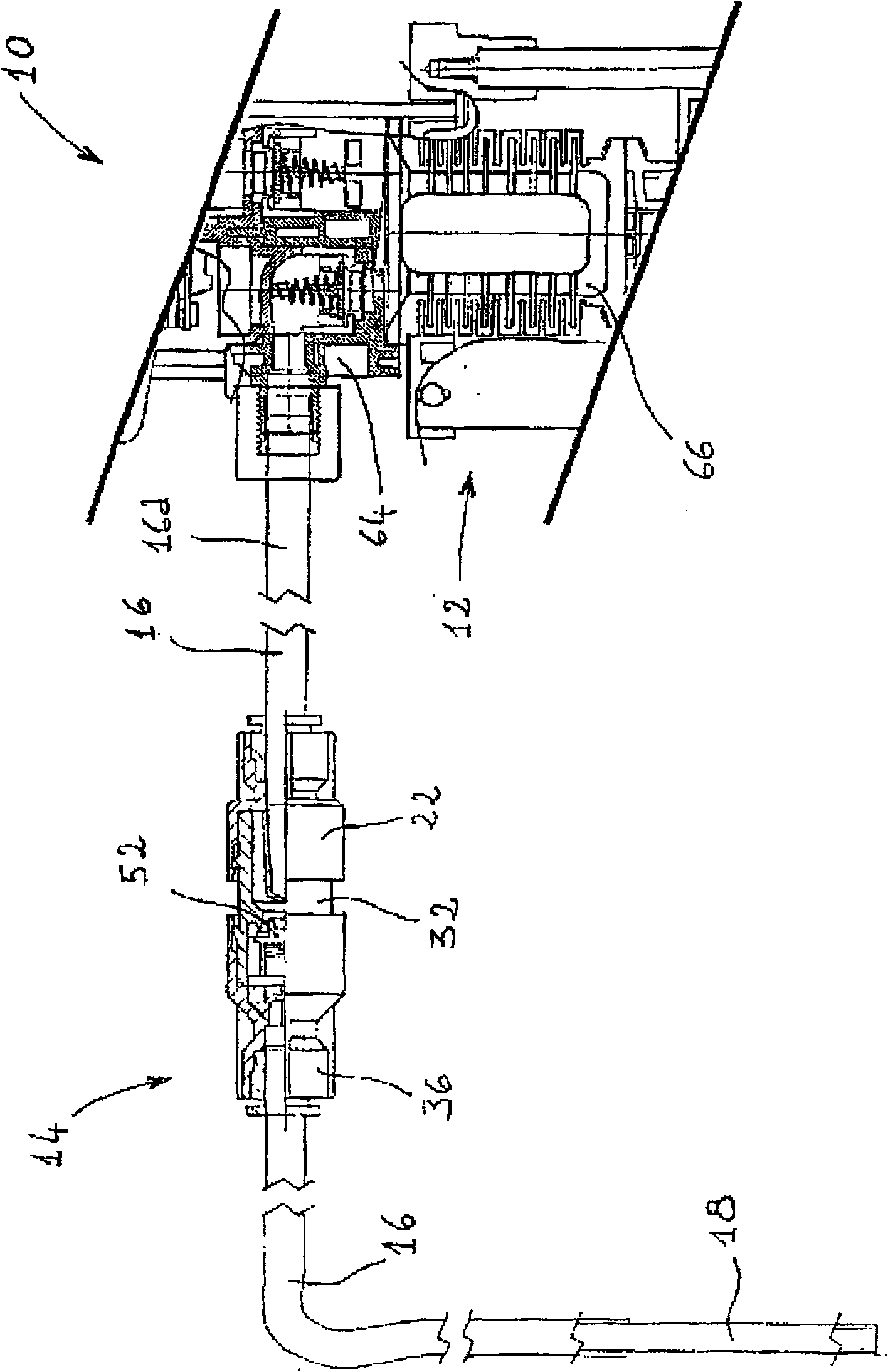

Pump impeller

InactiveCN101498300AAvoid pressing outIncrease speedPump componentsRotary piston pumpsImpellerEngineering

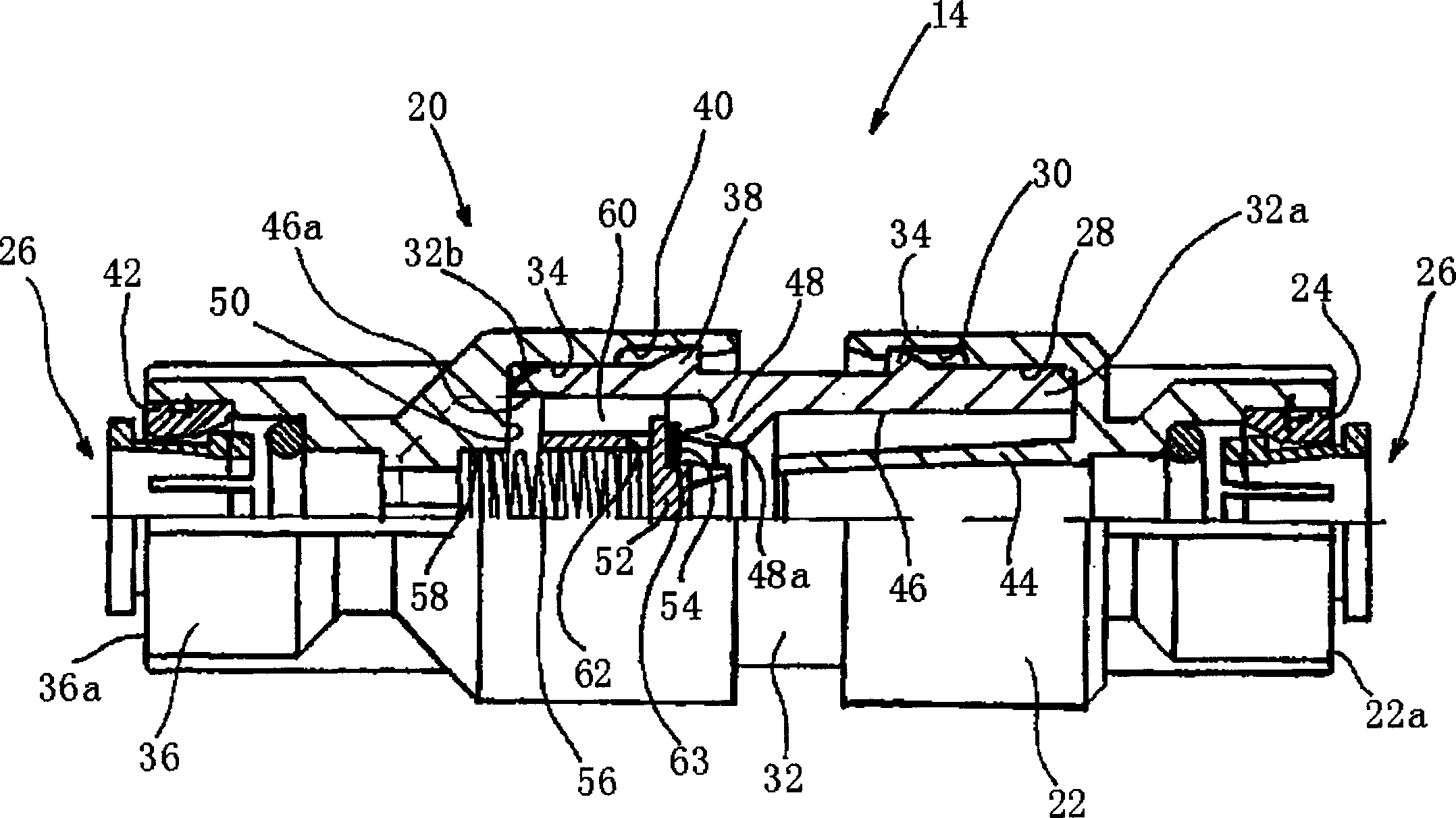

The invention relates to a pump impeller (16) of vane pump (10) comprising a plurality of vane troughs (18) for supporting pump vanes (20) at least moving radially and a chamber wall (22) formed between two adjacent vane troughs (18) for forming a convey chamber (26), characterized in that the chamber wall (22) has an axial protruding ring bank (24) that limits movement of a position ring (28) for radial movement of the pump vanes (20) and has a first wall block (32) that supports each pump vane (20) in the vane troughs (18) reliably, a second block (34) for forming thickness (d) of the ring bank (24) to support a sintering tool (16) reliably and a third block (36) for forming an enlarged conveying chamber volume. Therefore, the pump impeller (16) can be simply manufactured and has an enlarged convey amount when the structural space is identical.

Owner:GM GLOBAL TECH OPERATIONS LLC

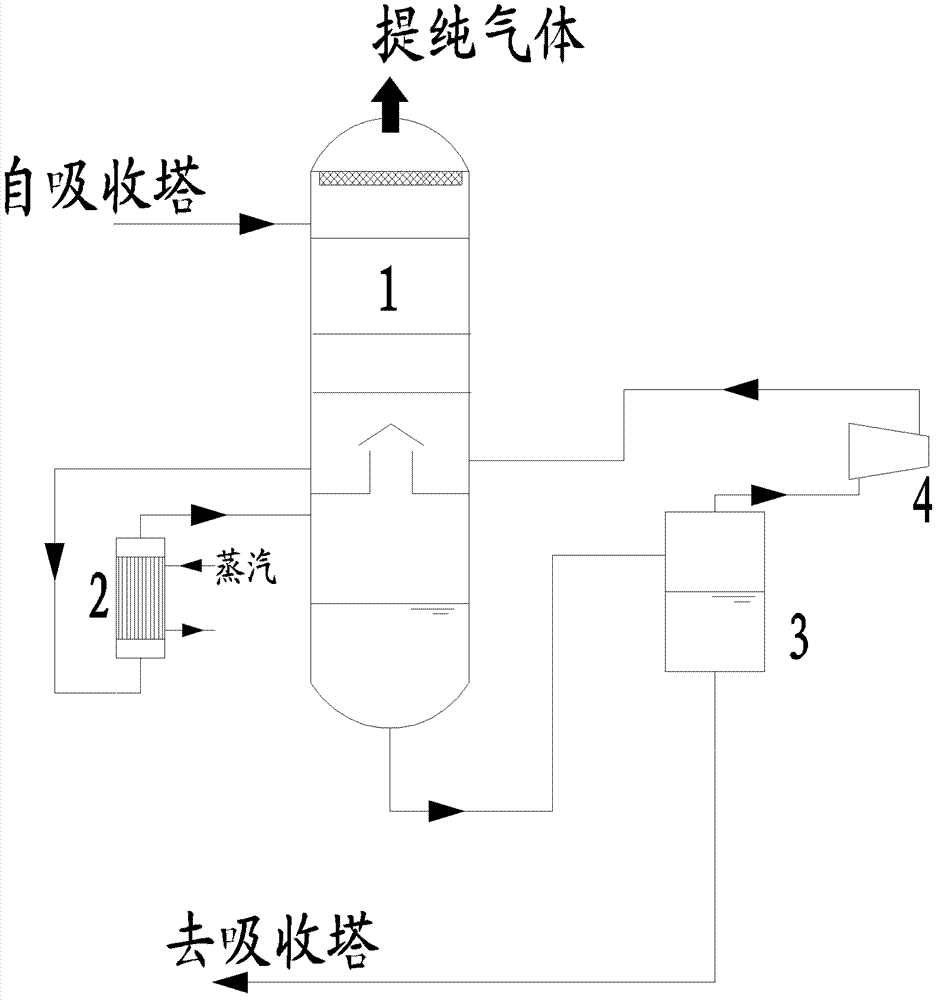

Regeneration system for smoke carbon dioxide capture solution

ActiveCN102350180BReduce solubilityHigh desorption rateProductsCarbon compoundsChemical industryVapor–liquid separator

The invention discloses a regeneration system for smoke carbon dioxide capture solution, comprising a regeneration tower, a reboiler and a gas-liquid separator, wherein the generation tower is communicated with an adsorption tower; the lower part of one side of the regeneration tower is communicated with the reboiler; the gas-liquid separator is communicated with the bottom of the regeneration tower; the bottom of the gas-liquid separator is communicated with the adsorption tower; the top of the gas-liquid separator is conducted with an air pump; and the lower parts of the other sides of the air pump and the regeneration tower are communicated. The regeneration system can be used for the fields of coal fired power plant boilers and chemical industry and is easier to release because of fully utilizing the residual heat of regeneration solution and utilizing the carbon dioxide under lower pressure, the desorption rate of the carbon dioxide is improved, the regeneration degree of the solution is improved, and the regeneration energy consumption for capturing the unit carbon dioxide is reduced.

Owner:HUANENG CLEAN ENERGY RES INST +1

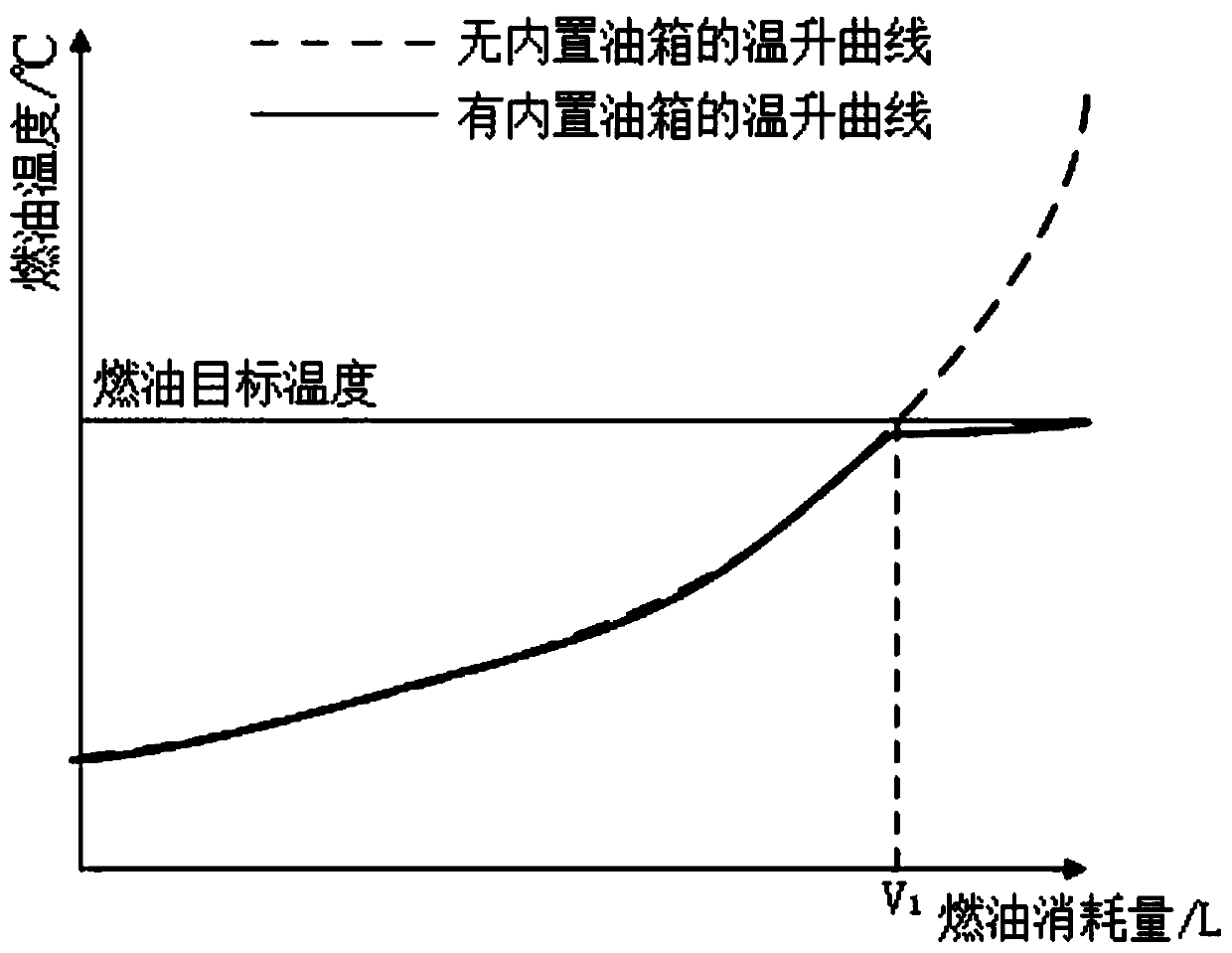

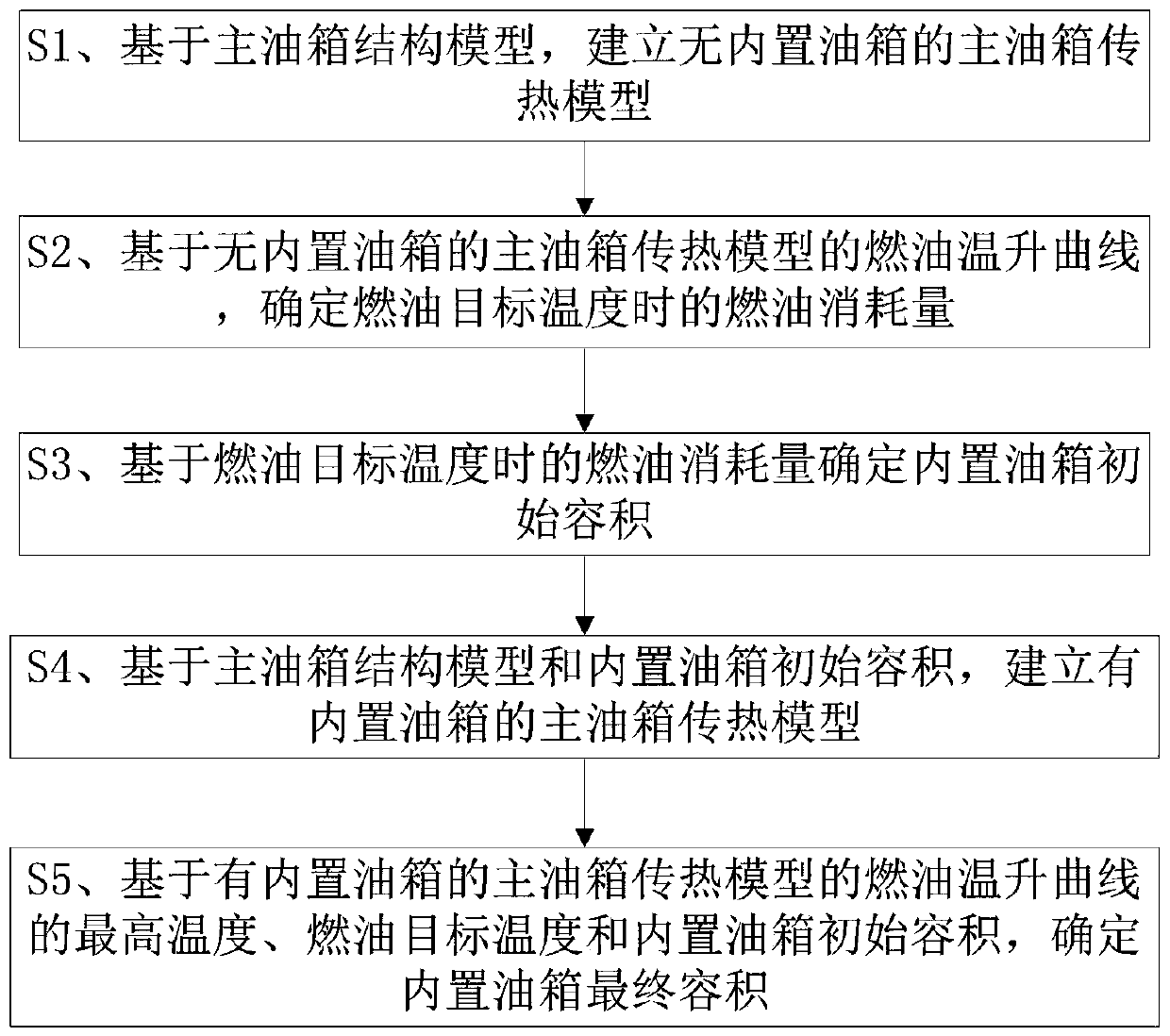

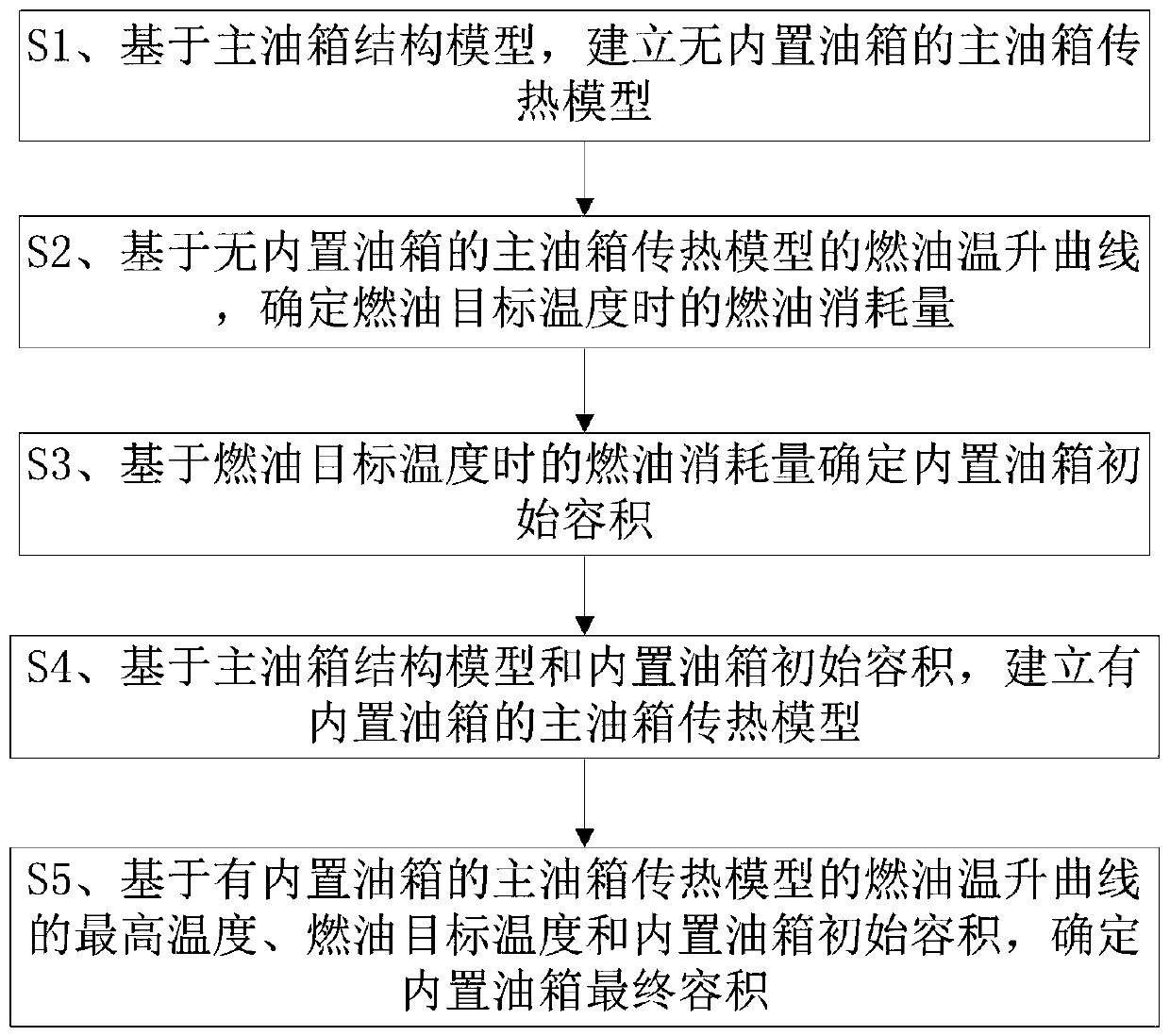

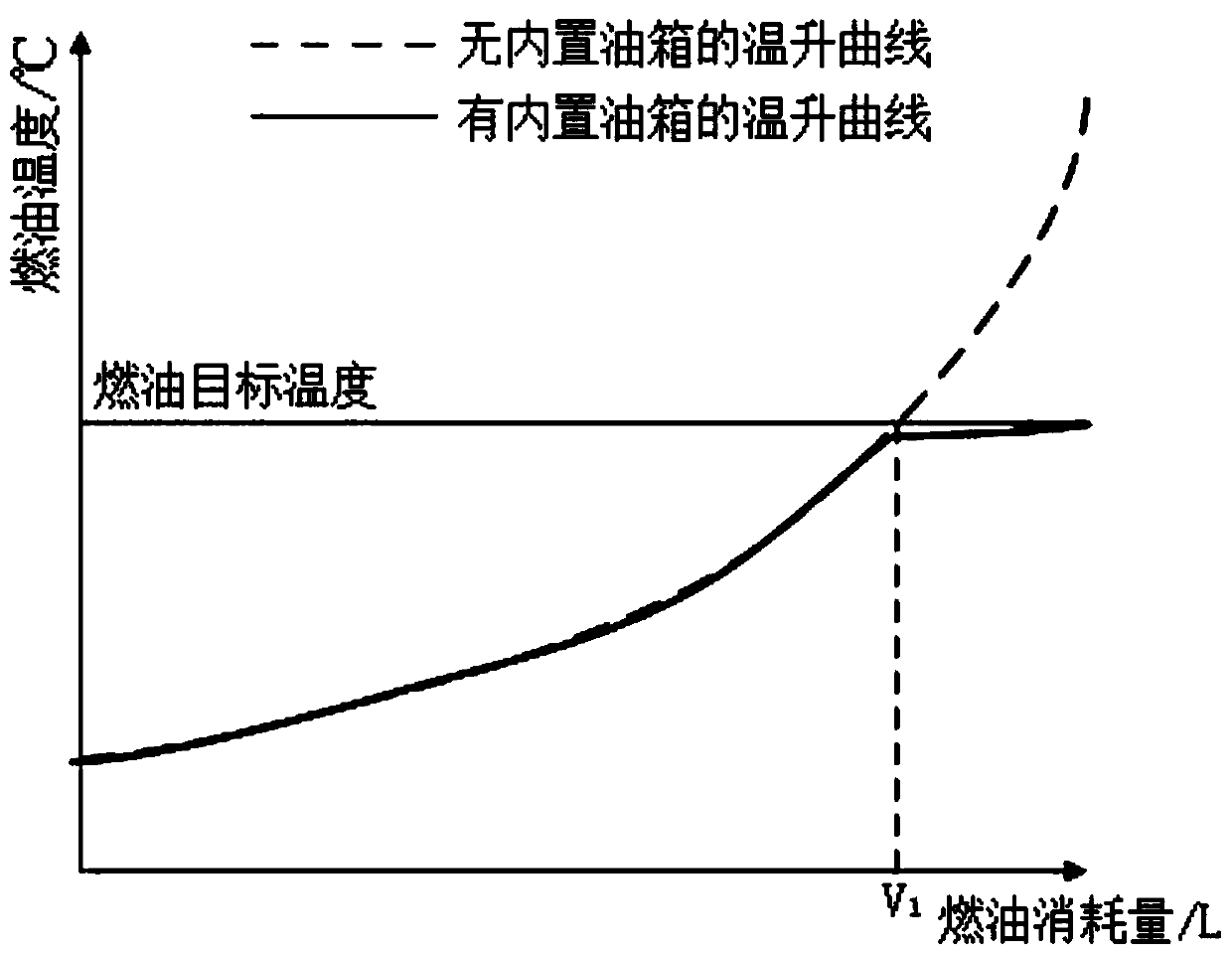

Oil transportation heat management system design method for controlling temperature rise of fuel oil of high-speed aircraft

ActiveCN111209632AReduced risk of cavitationReduce design difficultyGeometric CADDesign optimisation/simulationHeat managementFlight vehicle

The invention provides an oil transportation heat management system design method for controlling the temperature rise of fuel oil of a high-speed aircraft, and the method comprises the steps: building a main oil tank heat transfer model without a built-in oil tank based on a main oil tank structure model; based on the fuel temperature rise curve of the main oil tank heat transfer model without the built-in oil tank, determining the fuel consumption at the fuel target temperature; determining the initial volume of the built-in oil tank based on the fuel consumption at the target fuel temperature; based on the main oil tank structure model and the initial volume of the built-in oil tank, establishing a main oil tank heat transfer model of the built-in oil tank; and determining the final volume of the built-in oil tank based on the highest temperature of the fuel oil temperature rise curve of the main oil tank heat transfer model with the built-in oil tank, the fuel oil target temperature and the initial volume of the built-in oil tank. The method can effectively reduce the temperature of the fuel at the flight tail section of the long-endurance high-speed aircraft, and can achieve the effects of reducing the cavitation risk of a fuel pump, reducing the pressurization pressure of a fuel tank, reducing the design difficulty of fuel passing equipment, increasing the available fuelheat sink of an engine and the like.

Owner:BEIJING AEROSPACE TECH INST

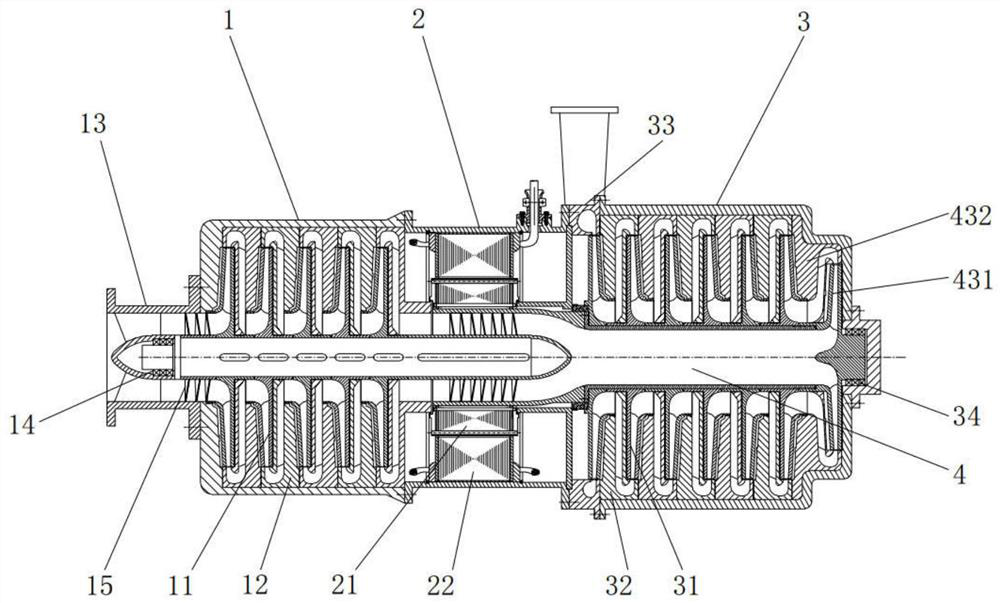

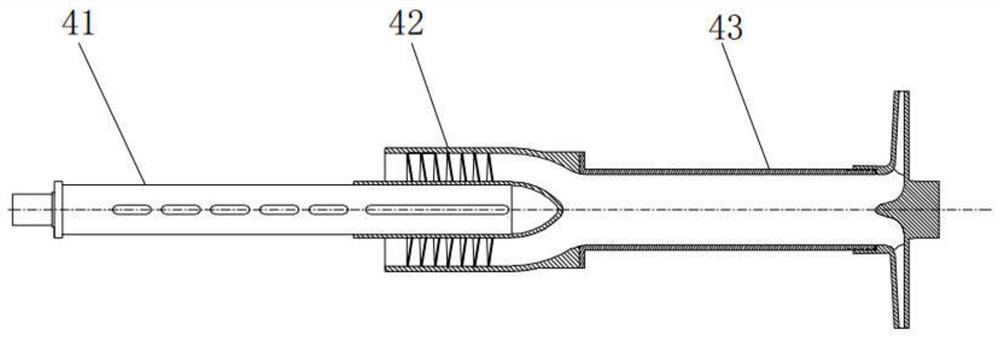

Multi-stage low-temperature centrifugal pump provided with built-in motor

ActiveCN112253492AImprove cooling effectImprove sealingPump componentsCooling/ventillation arrangementElectric machineryEngineering

The invention provides a multi-stage low-temperature centrifugal pump provided with a built-in motor. The multi-stage low-temperature centrifugal pump comprises a front shell, a motor shell and a backshell; a forward impeller and a forward guide vane are arranged in the front shell; the motor is arranged in the motor shell; a reverse impeller and a reverse guide vane are arranged in the back shell; the motor shell is located between the front shell and the back shell; an inlet horn pipe is arranged at the end of the front shell; an outlet volute is arranged between the back shell and the motor shell; the forward impeller, a motor rotor and the reverse impeller are connected in series through a rotating shaft assembly; the motor rotor is directly connected with the rotating shaft assemblyfrom the middle to drive the rotating shaft assembly to rotate so as to drive the forward impeller, the reverse impeller and an inducer to rotate. A low-temperature liquid enters a pump body from theinlet horn pipe, is pressurized by the forward impeller and the reverse impeller and is sprayed out of the outlet volute. According to the pump, the motor is arranged internally and is cooled throughthe low-temperature liquid, the overall sealing performance is good, the size is small, the weight is light, the structure is compact, and the pump is particularly applicable to conveying of low-temperature volatile liquids.

Owner:JIANGSU UNIV

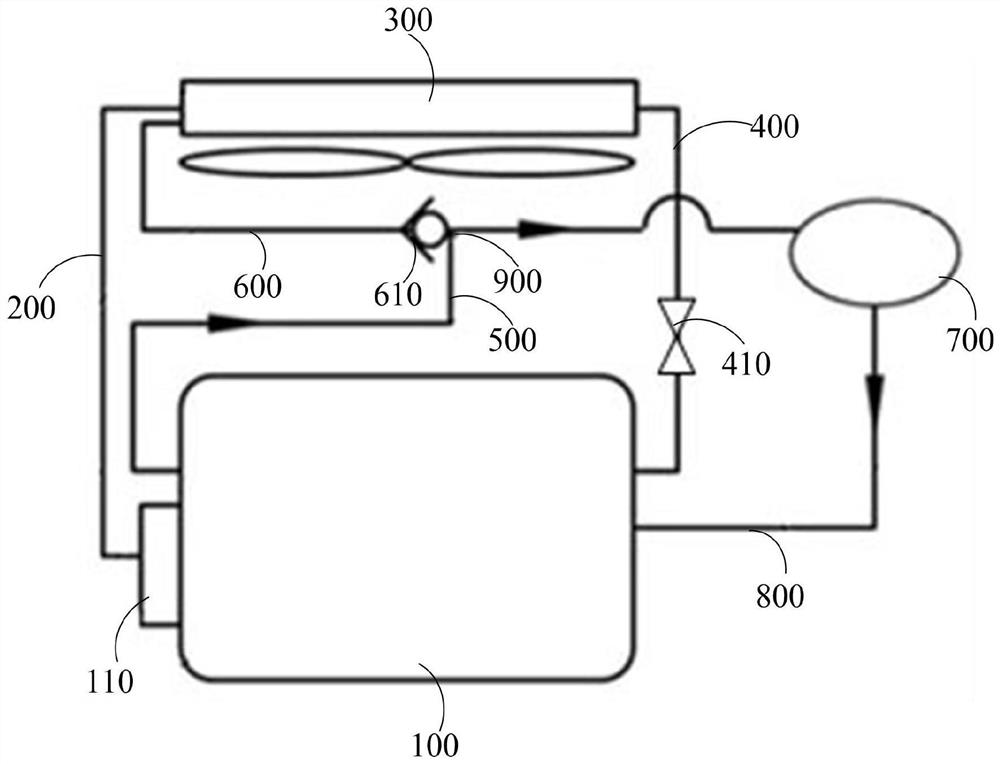

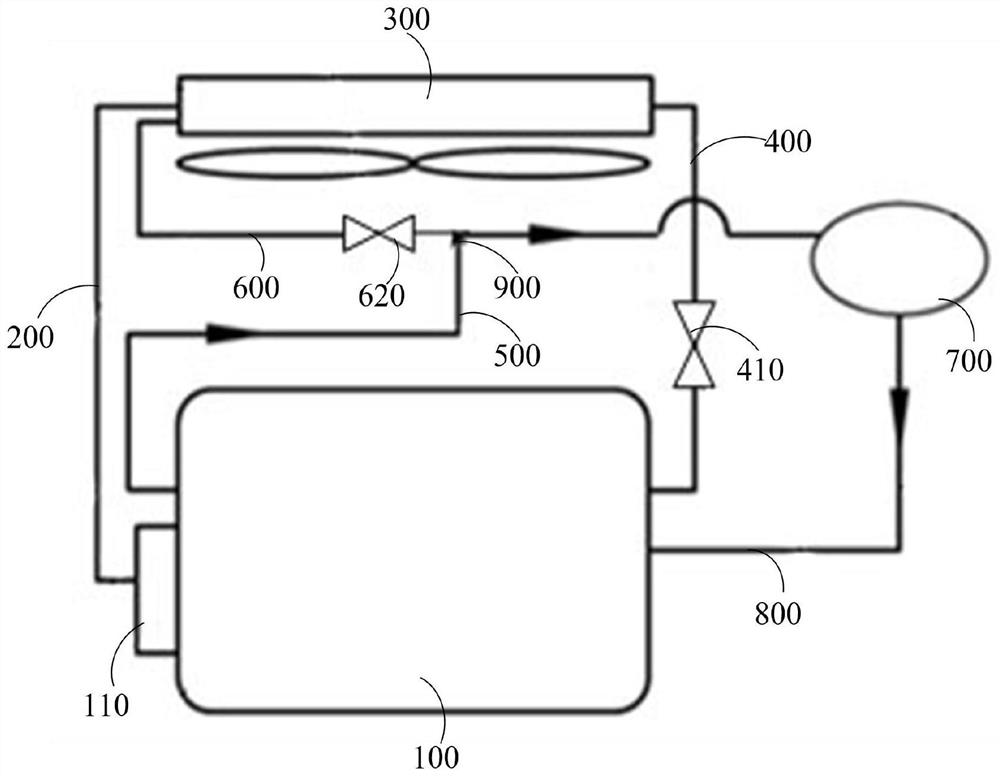

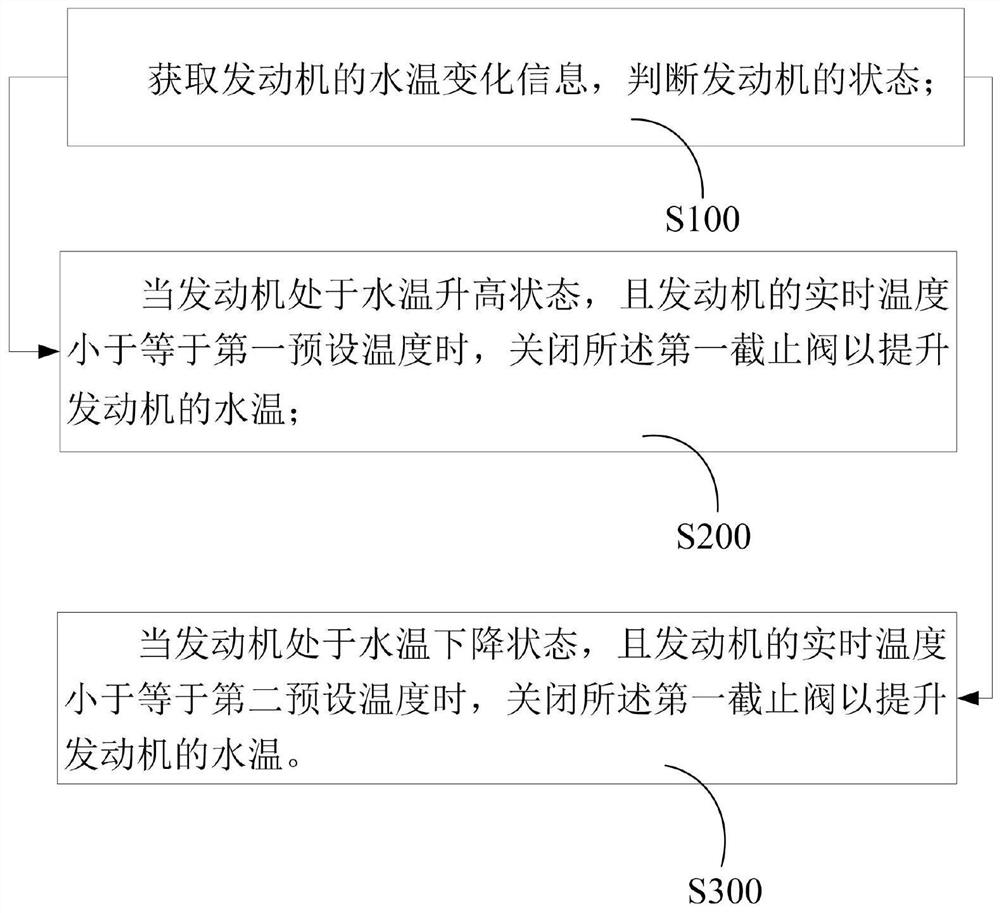

Engine cooling system and control method thereof

InactiveCN112459889AIncrease warm-up speedReduce temperature rise lossLiquid coolingCoolant flow controlPhysicsEngineering

The invention relates to an engine cooling system and a control method thereof. The engine cooling system comprises an engine heat dissipation mechanism and an engine degassing mechanism, wherein theengine heat dissipation mechanism comprises a temperature control valve, an engine water outlet pipeline connected with the temperature control valve, a radiator assembly connected with the engine water outlet pipeline, and an engine water inlet pipeline connected with the radiator assembly; the engine degassing mechanism comprises an engine degassing pipeline, a degassing chamber assembly connected with the engine degassing pipeline, a degassing chamber water outlet pipeline connected with the degassing chamber assembly, and a radiator degassing pipeline connected with a water inlet of the radiator assembly and the degassing chamber assembly; the radiator degassing pipeline is connected with the engine degassing pipeline through a three-way valve; a first stop valve is arranged on the engine water inlet pipeline; and a control valve for preventing reverse flow is arranged on the radiator degassing pipeline. By means of the engine cooling system and the control method thereof, the engine warming speed of an engine can be increased in the low-temperature starting process of the engine and the engine warming stage of the engine.

Owner:DONGFENG MOTOR CORP HUBEI

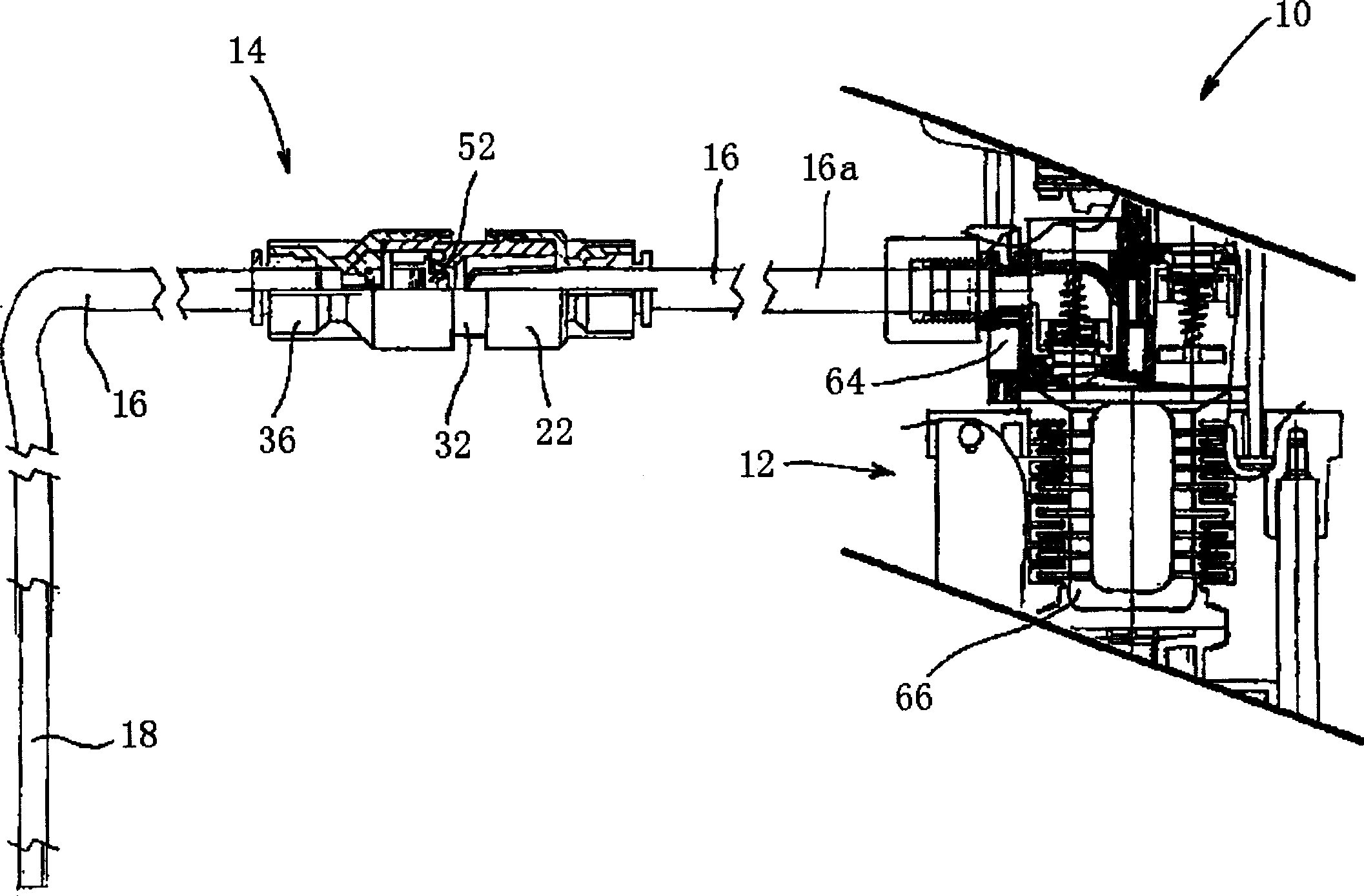

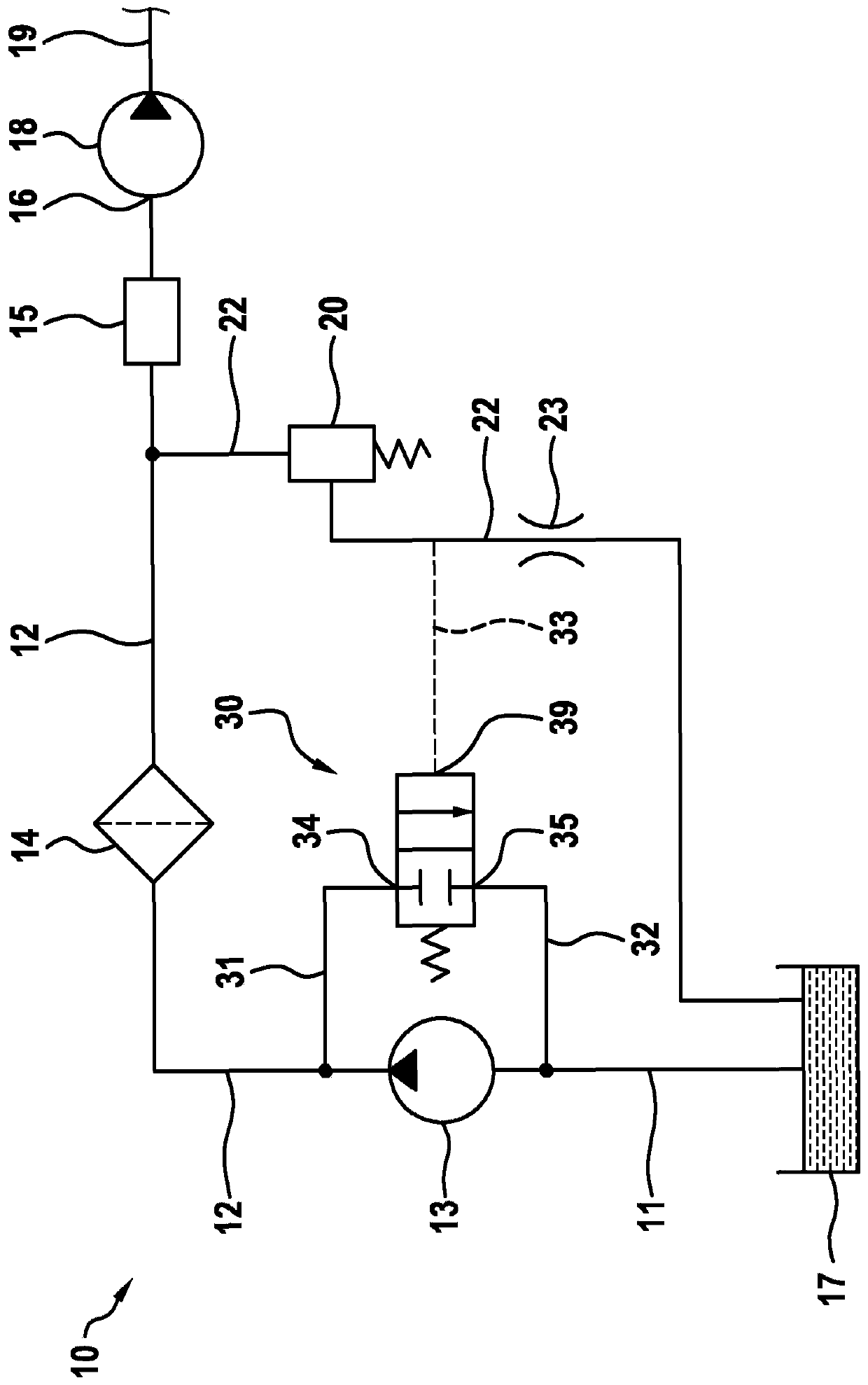

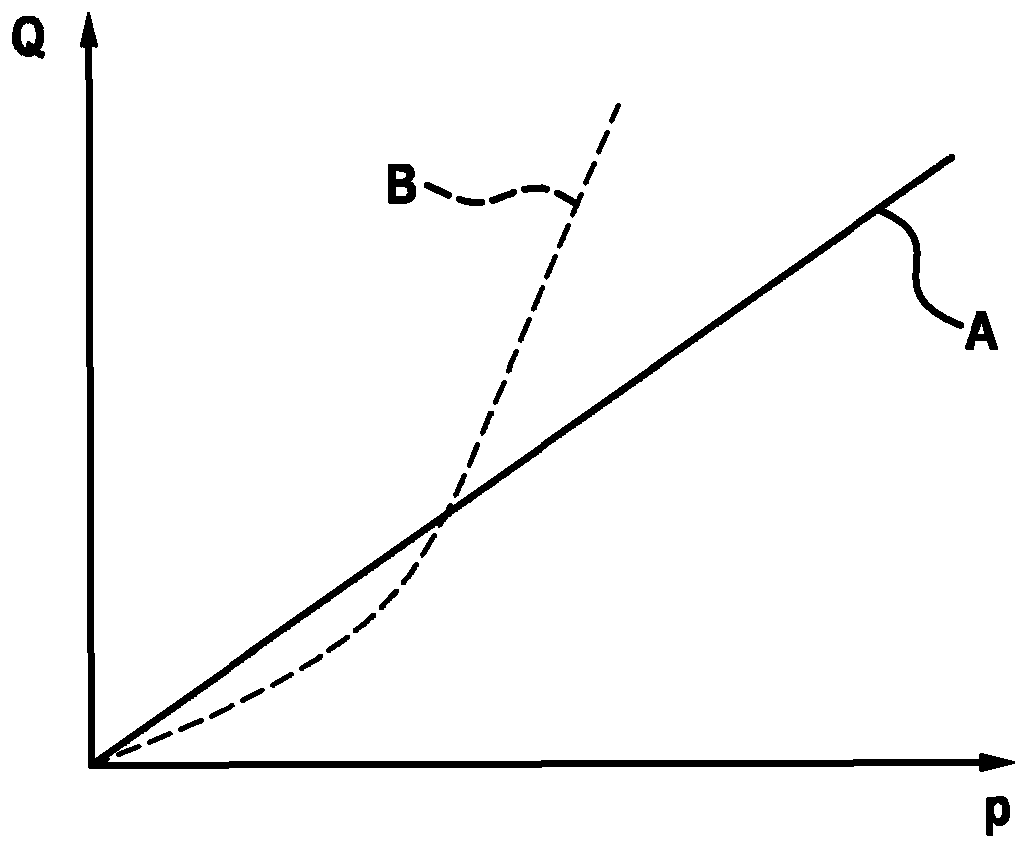

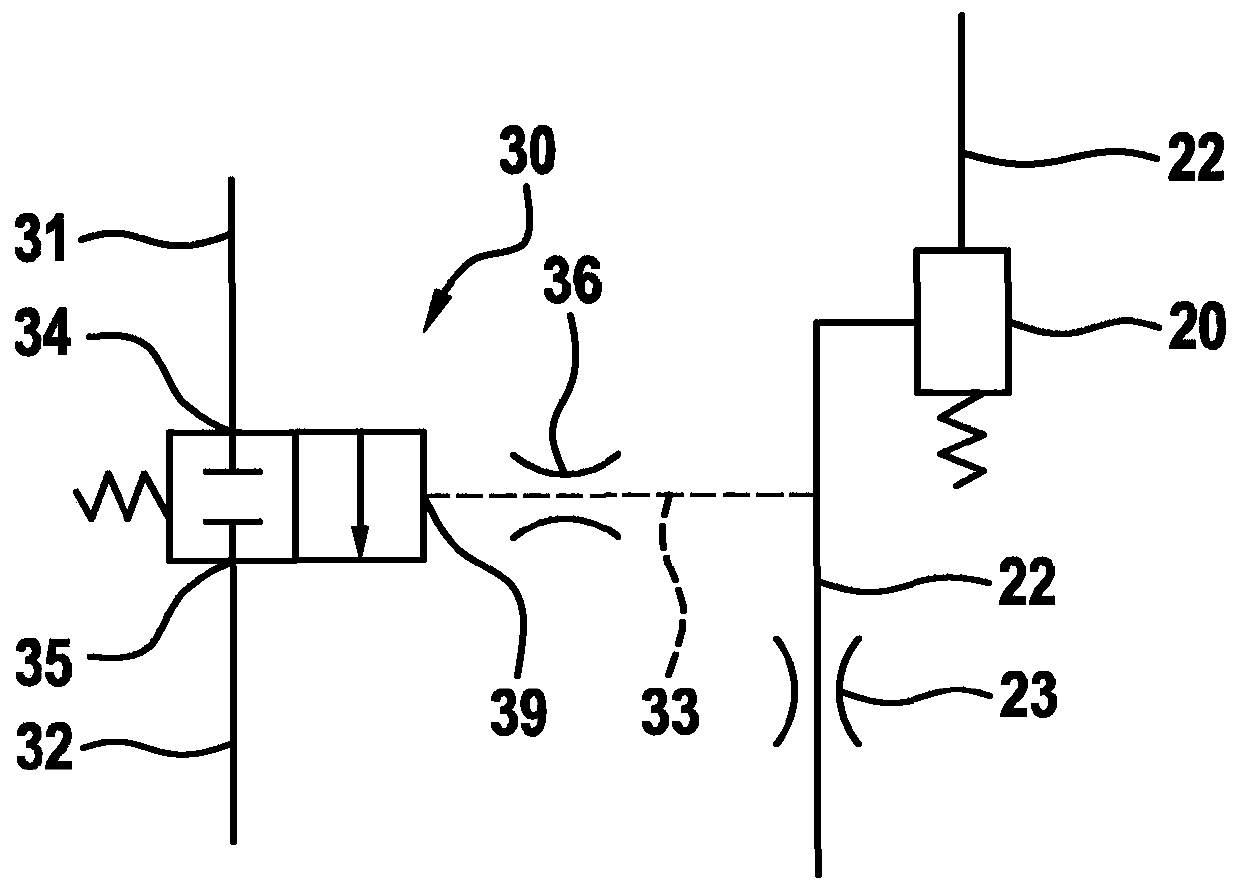

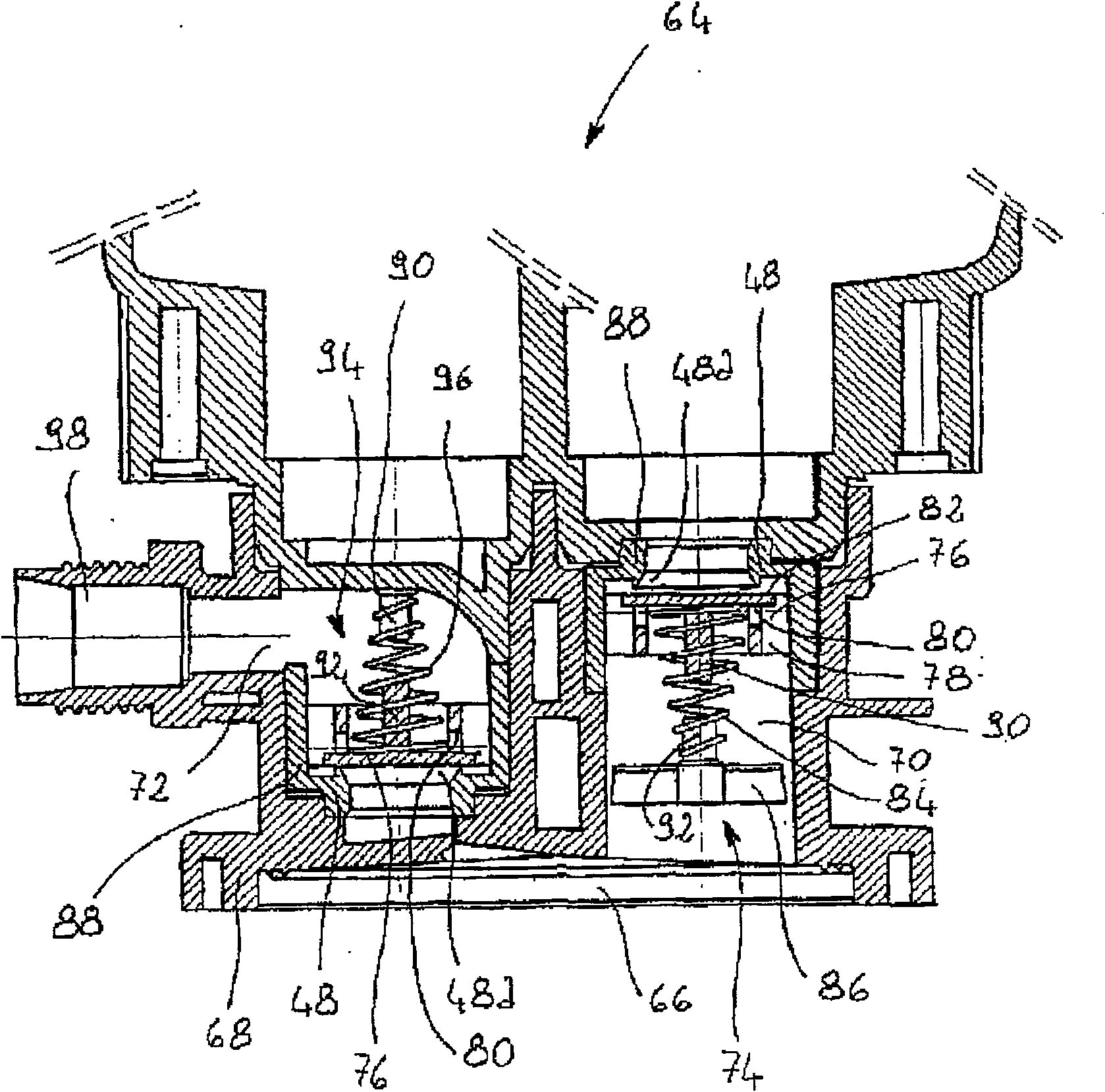

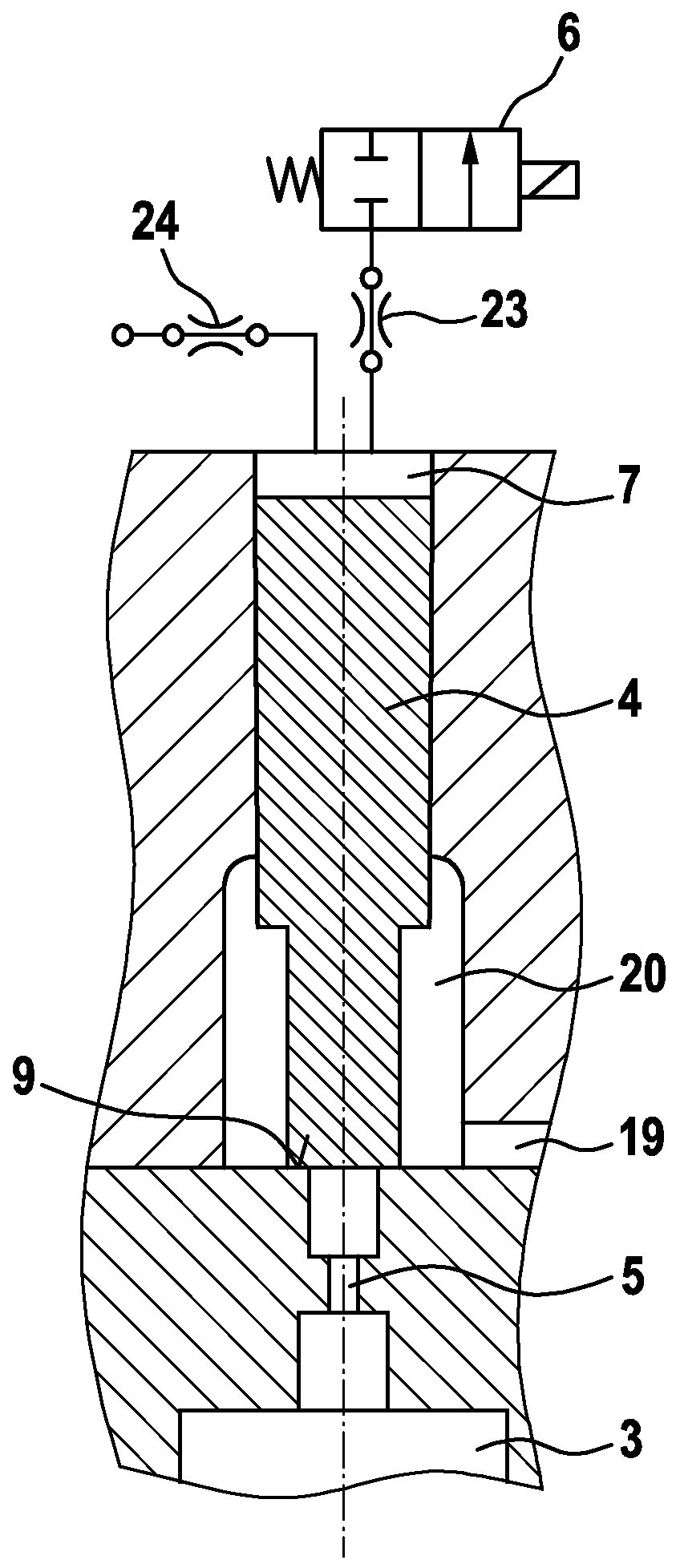

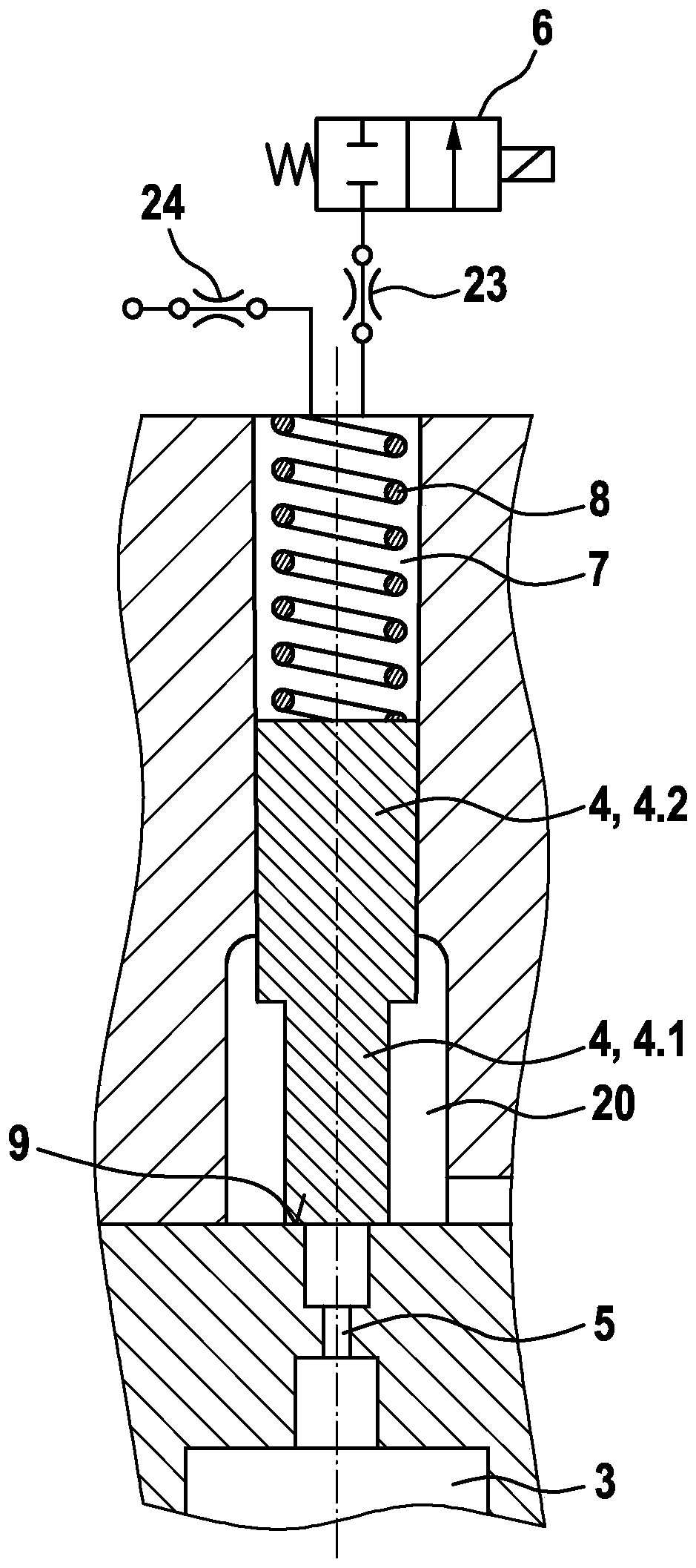

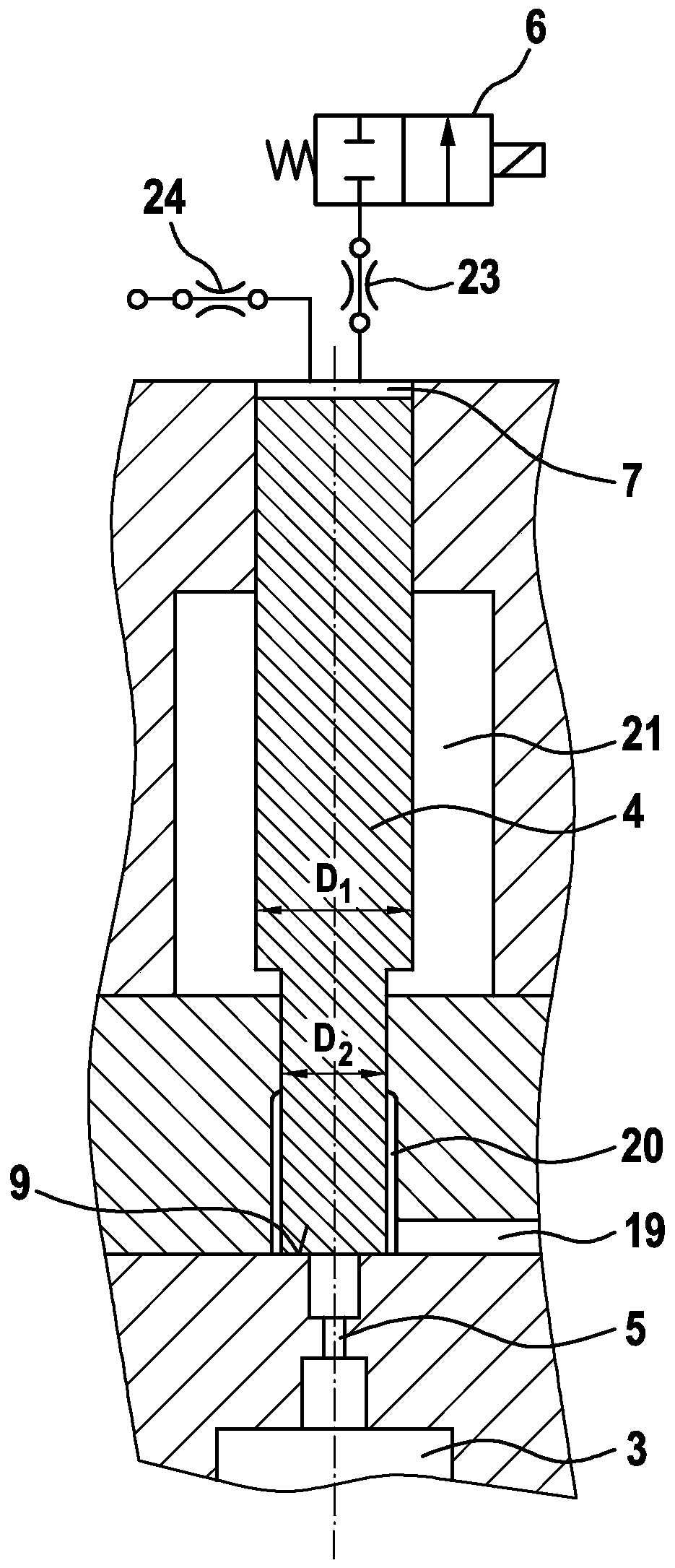

Low-pressure regulating system of a fuel delivery device of a fuel injection system and a discharge valve therefor

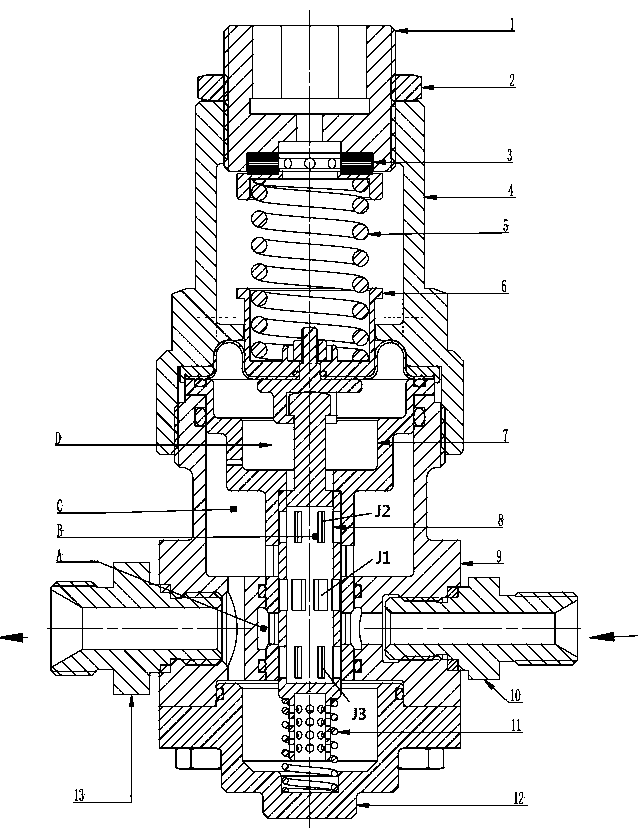

InactiveCN107002603BReduce variant diversityReduce filter flowElectrical controlMachines/enginesAutomatic controlFuel filter

The invention relates to a low-pressure automatic control system for a fuel-delivery device of a fuel-injection system. The low-pressure automatic control system is designed with: a delivery line (12) which forms a supply from a delivery pump (13) to a high-pressure pump (18); at least one fuel filter (14) arranged in the delivery line (12); and a controllable control element (15), also arranged in the delivery line (12), which element transfers a pre-selectable delivery flow to the high-pressure pump (18), an excess delivery amount that has been conveyed by the delivery pump (13) being carried away into a return flow line (22) by means of an overflow valve (20). A hydraulically controllable cut-off valve (30) is provided in addition to the controllable control element (15), said valve carrying away at least one portion of the excess delivery amount from the fuel line (12), upstream of the fuel filter (14) in the flow direction of the fuel.

Owner:ROBERT BOSCH GMBH

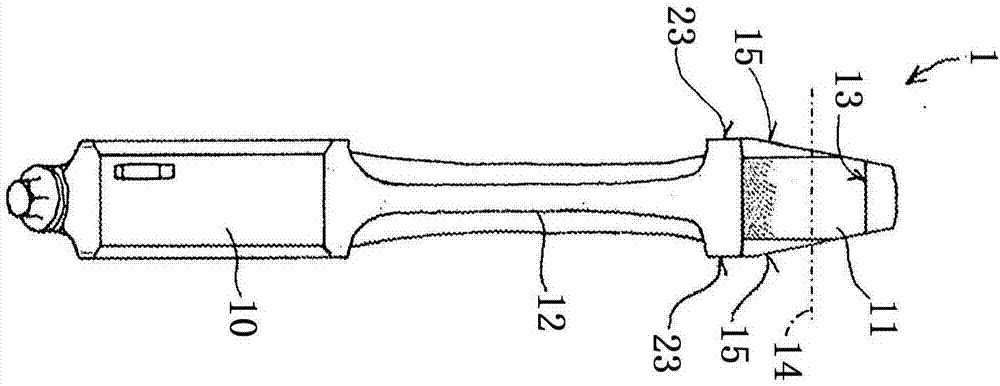

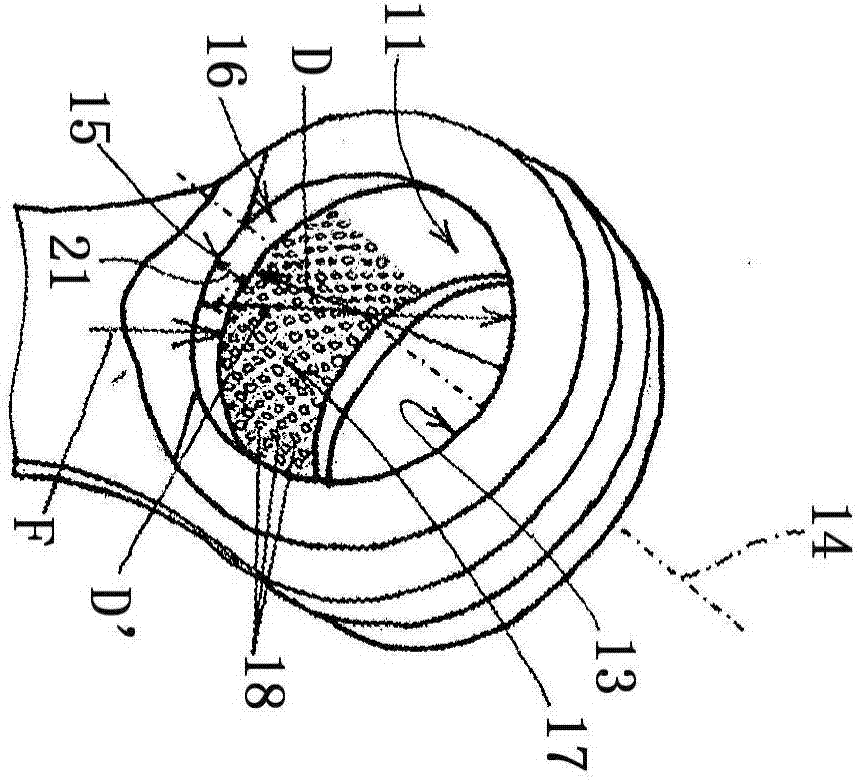

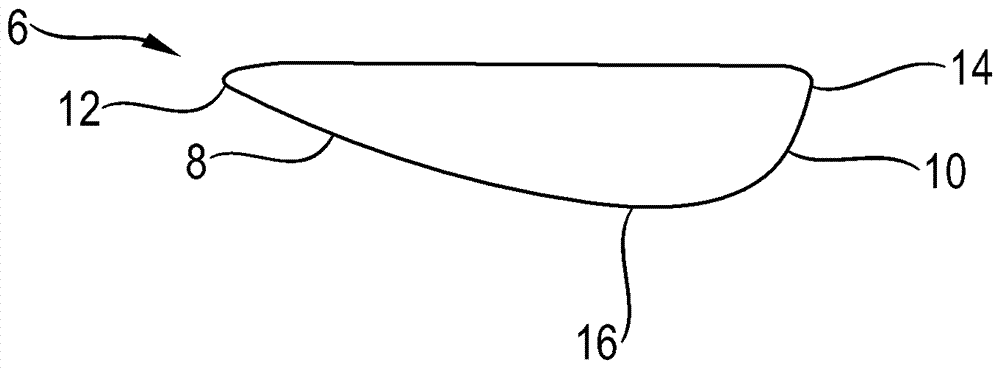

Connecting rod

InactiveCN107002742AImprove performanceFully adaptedConnecting rod bearingsConnecting rodsEngineeringInternal combustion engine

The present invention relates to a connecting rod (1) for an internal combustion engine, comprising: a big end passage (10) for receiving a pin journal of a crankshaft; a small end passage (11) for receiving a piston pin, the small end passage (11) extending along a passage axis (14) and delimited by opposed edges (15); a shaft (12) arranged between the big end passage (10) and the small end passage (11); said small end passage (10) comprising an inner passage surface (13) with a cylindrical surface portion having a first diameter (D); said small end passage (10) extending along said passage axis (14) between said opposed edges (15). According to the invention: said inner passage surface (13) comprising profiled regions (16) adjacent to each of said opposed edges (15) and extending at least over a part of the circumference of said opposed edges (15); said profiled regions (16) starting from said cylindrical surface portion and increasing into a maximum second diameter (D') at each of said opposed edges (15); - said inner passage surface (13) comprising a plurality of dimples (18) arranged in said cylindrical surface portion of said inner passage surface (13).

Owner:THYSSENKRUPP METALURGICA CAMPO LIMPO

Wet cylinder jacket of single-cylinder horizontal diesel engine

PendingCN107131070AHigh working reliabilityExtended service lifeCylinder headsCylindersStress conditionsCooling effect

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Valve piston, and slide valve having a valve piston

ActiveCN106931188AReliable bootControlled descent speedOperating means/releasing devices for valvesCheck valvesSpool valveEngineering

A valve piston includes a section that has a circular-cylindrical configuration with a constant diameter. A plurality of longitudinal grooves are made in the section with the grooves parallel to one another and distributed uniformly on the circumference. The remaining webs enable the section of the valve piston to be moved in the valve without tilting. Each longitudinal groove has one steeper flank and one less steep flank. The steeper flank is set against a pressure medium that flows in.

Owner:ROBERT BOSCH GMBH

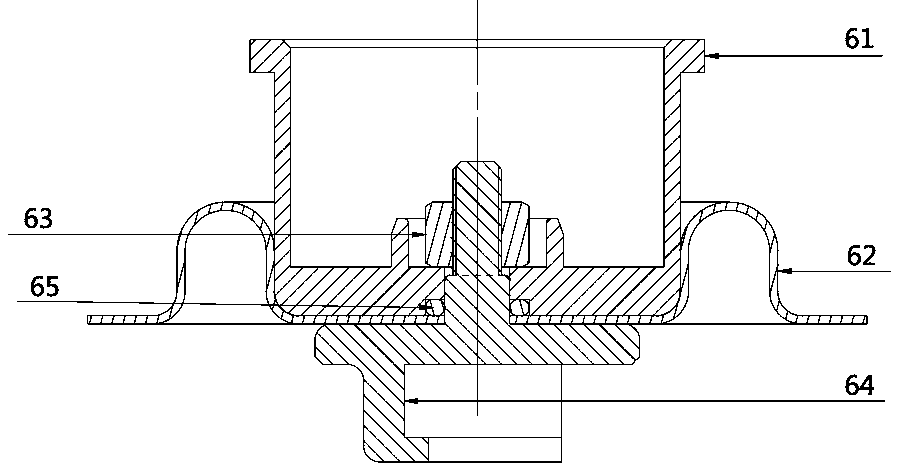

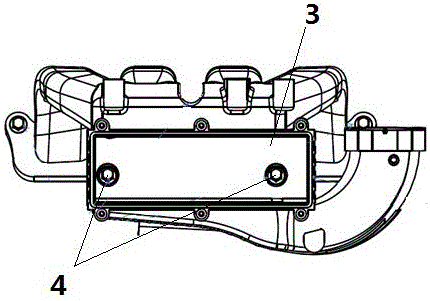

An expansion kettle assembly and cooling circulation system

ActiveCN103485879BExtend your lifeReduced risk of cavitationMachines/enginesEngine cooling apparatusSeries expansionEngineering

The present invention provides an expansion kettle assembly, the expansion kettle assembly includes an expansion kettle, an expansion chamber, and a pressure cover, the expansion kettle has an outlet communicating with the atmosphere, the expansion kettle is connected to the expansion chamber, and There is a filling port on the expansion chamber, the pressure cover is connected to the filling port, the expansion chamber has a circulating liquid inlet and a circulating liquid outlet, the expansion chamber is higher than the liquid level of the radiator, and the pressure The cover is a two-way pressure valve, and the pressure cover controls the communication and isolation between the expansion chamber and the expansion kettle. The present invention adds a very small expansion cavity connected in series with the expansion kettle, and there is no restriction on the arrangement of the expansion kettle, which greatly facilitates the arrangement of the cooling system and the engine compartment, and the expansion cavity participates in the cooling cycle, which has better heat dissipation performance .

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A fluid-dispensing circuit with check valves

InactiveCN100595127CImprove circuit performanceEasy to fillPositive displacement pump componentsCheck valvesEngineeringCheck valve

Owner:赛皮尔斯色料设备股份有限公司

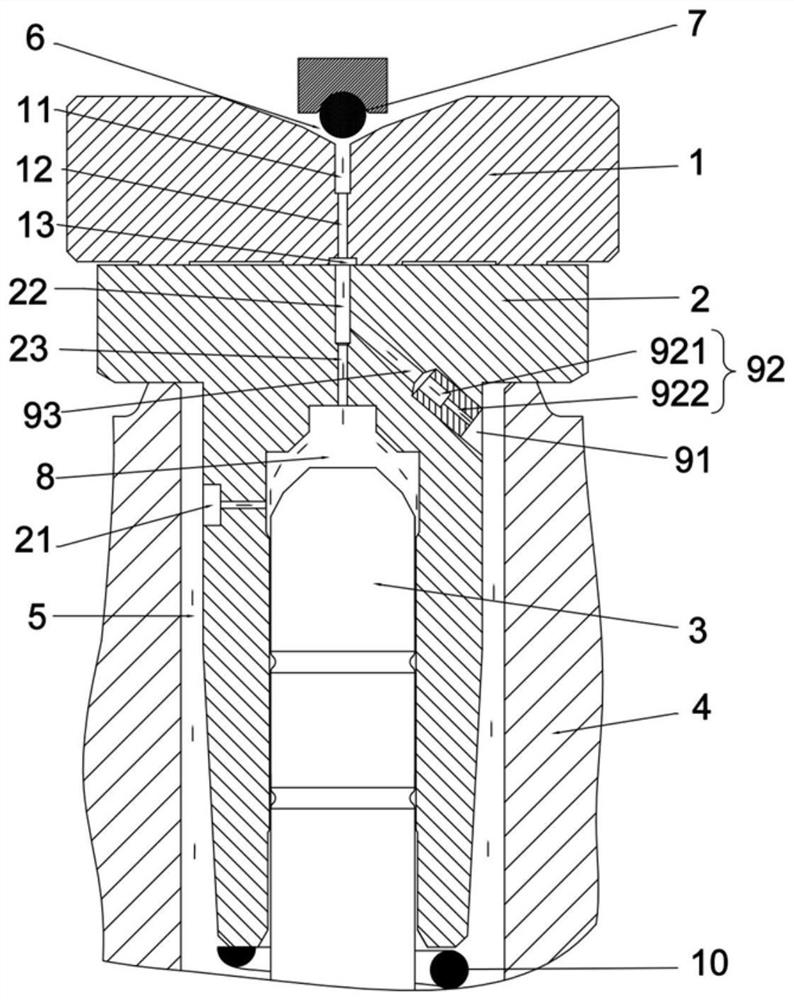

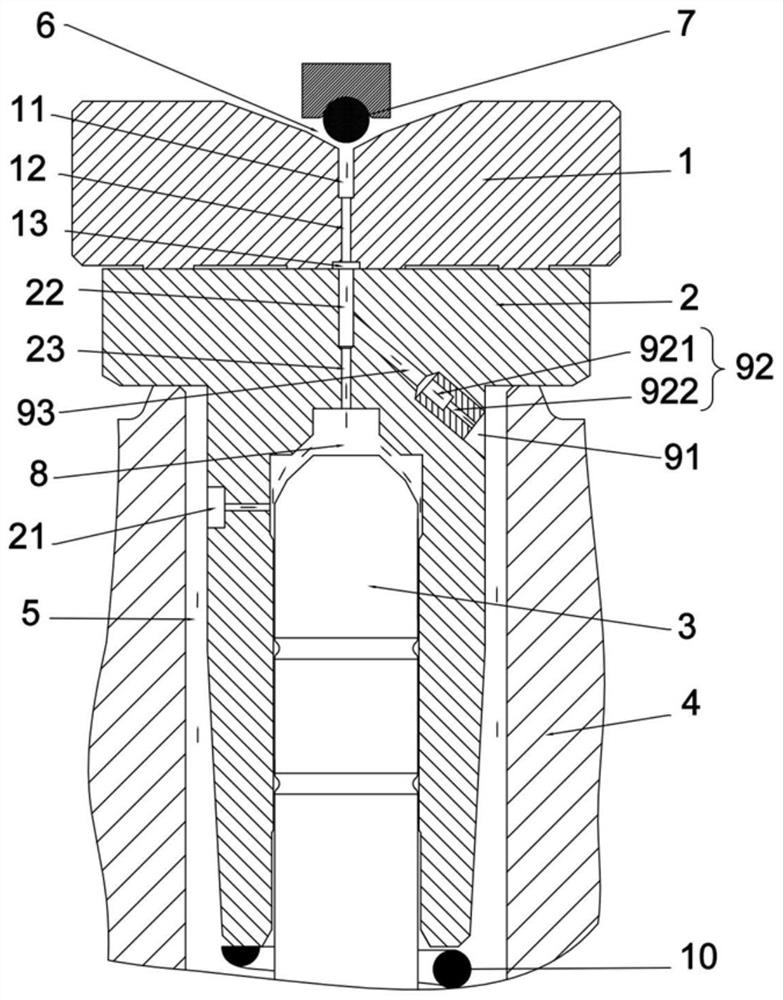

Fuel injection valve and diesel engine

ActiveCN111878274ASimple structureFew couplingsFuel injection apparatusMachines/enginesControl valvesControl theory

The invention discloses a fuel injection valve and a diesel engine, and belongs to the field of engine fuel injection valves. A control valve sleeve of the fuel injection valve is provided with an oiloutlet passage, and a throttle orifice plate is provided with a low-pressure oil passage, so that the cavitation risk of a sealing conical surface at the top of the throttle orifice plate is favorably reduced; a first throttling ring belt and a second throttling ring belt are successively formed between a long needle valve and the inner wall of the control valve sleeve in the ascending process ofthe long needle valve, the area of the first throttling ring belt and the area of the second throttling ring belt are gradually increased along with ascending of the long needle valve, and the firstthrottling ring belt and the second throttling ring belt jointly play a throttling role, so that the flow of high-pressure oil flowing into a control cavity from an oil inlet hole is rapidly reduced,the pressure of the control cavity is rapidly reduced, and the opening delay is shortened; and the area of the first throttling ring belt and the area of the second throttling ring belt are graduallydecreased along with descending of the long needle valve, the flow of the high-pressure oil flowing into the control cavity from the oil inlet hole is gradually increased, pressure in the control cavity is rapidly established, the closing speed of the long needle valve is increased, and the closing delay time is shortened.

Owner:FAW JIEFANG AUTOMOTIVE CO

Pump startup control method, device, system and refrigeration system

ActiveCN104251581BReduce shockReduced risk of cavitationRefrigeration safety arrangementCavitationControl system

The invention relates to the technical field of refrigeration and discloses a pump start control method, a pump start control device, a pump start control system and a refrigeration system. The pump start control method comprises the following steps: acquiring the superheat degree value of the current refrigeration system; when the superheat degree value of the refrigeration system is greater than a set first superheat degree threshold, controlling output parameters of a pump to increase a set first step length. According to the pump start control method, during pump start, the superheat degree is adopted as a parameter to gradually increase the output of the pump, so that impact of a large-flow refrigerant on the pump can be avoided, the cavitation risk during pump start is reduced, and the pump reliability is enhanced.

Owner:EMERSON NETWORK POWER CO LTD

Method for operating fuel injector and fuel injector

InactiveCN110566372AVariable control pressureIncrease the itineraryInternal combustion piston enginesFuel supply apparatusReciprocating motionControl room

The invention relates to a method for operating a fuel injector, in which the reciprocating motion of a nozzle needle (1) for releasing and closing at least one injection opening (2) is controlled hydraulically via a variable control pressure assigned to a control room (3) of the nozzle needle (1) and applied to the nozzle needle (1). According to the invention, the control pressure in the controlchamber (3) is changed with the aid of a likewise hydraulically controlled and reciprocable pilot control piston (4) which switches an outlet throttle (5) via which the control chamber (3) can be relieved. The invention also relates to a fuel injector particularly suitable for carrying out the method according to the invention.

Owner:ROBERT BOSCH GMBH

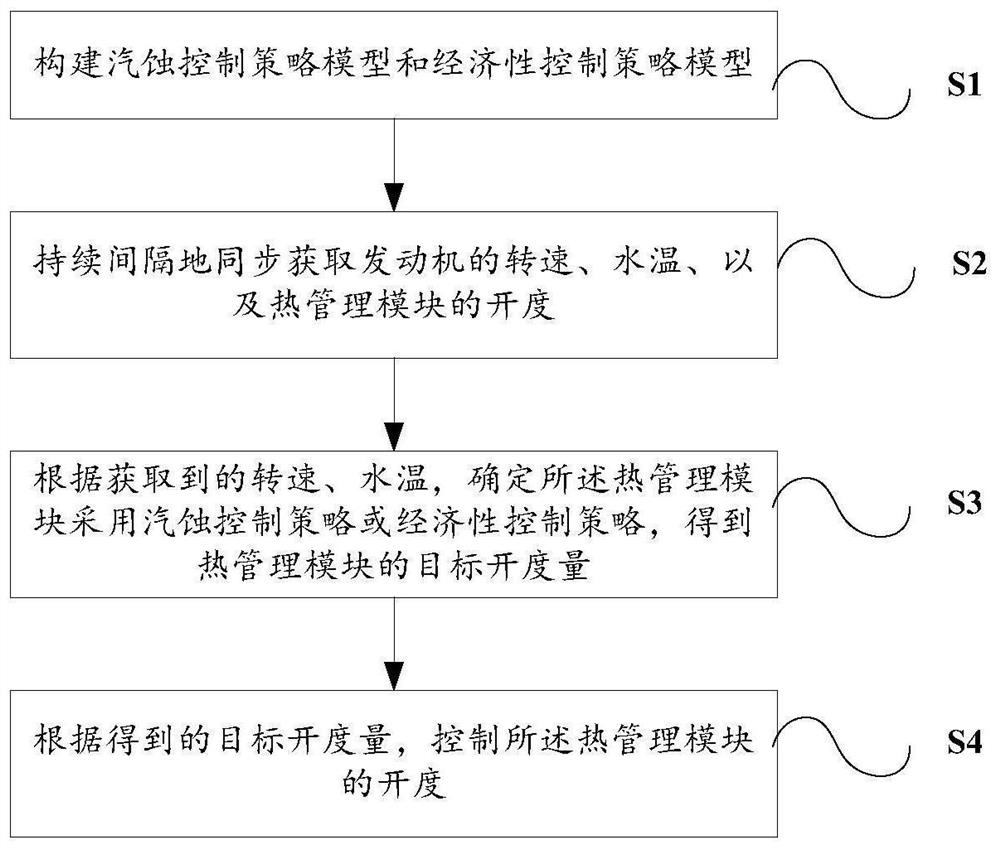

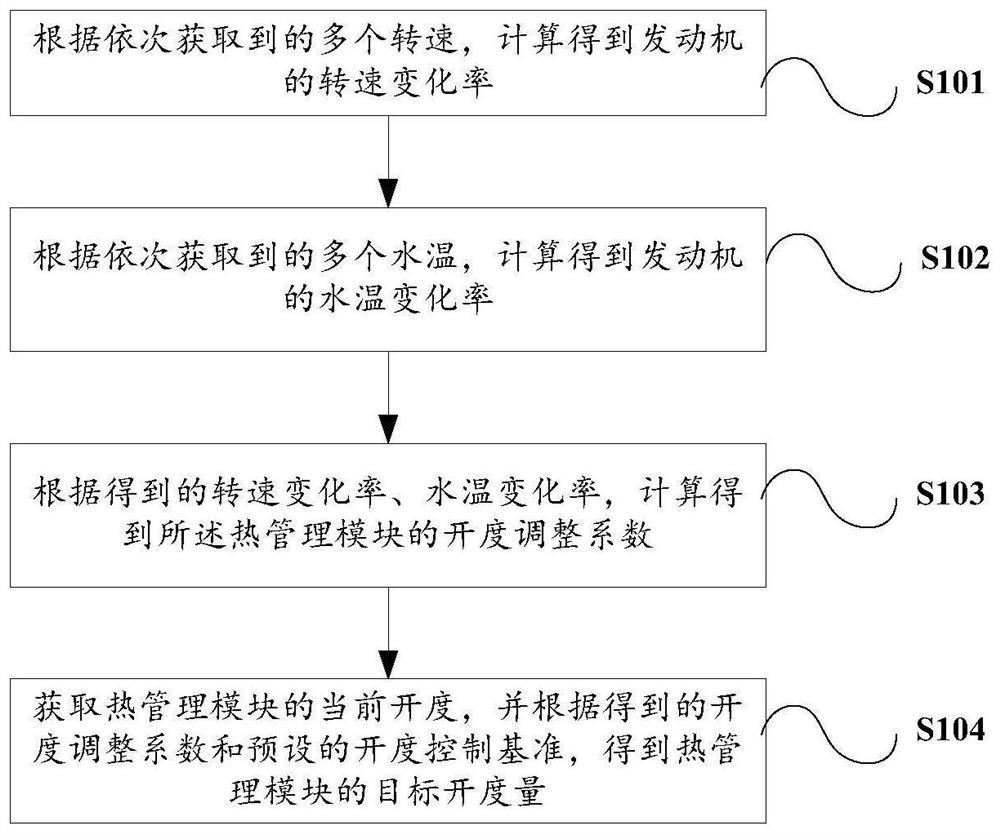

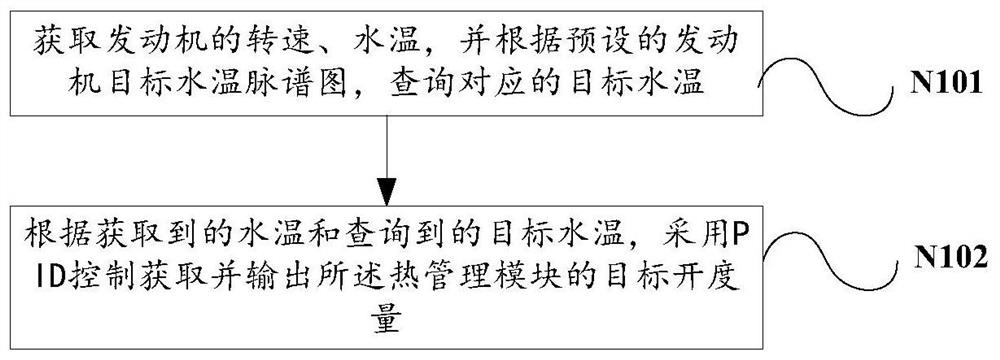

A control method and control system for an engine thermal management module

ActiveCN112177752BImprove reliabilityAvoid cavitationCoolant flow controlMachines/enginesThermodynamicsHeat management

The application discloses a control method and control system of an engine thermal management module, which relate to the technical field of engine cooling system control. The control method includes: constructing a cavitation control strategy model and an economical control strategy model. The parameters of the cavitation control strategy model include engine The parameters of the economic control strategy model include the engine speed and water temperature; the engine speed, water temperature, and the opening of the thermal management module are obtained synchronously at continuous intervals; according to the acquired Rotate speed, water temperature, determine the thermal management module adopts cavitation control strategy or economical control strategy, obtain the target opening of the thermal management module; according to the obtained target opening, control the opening of the thermal management module. This application judges whether the thermal management module adopts the cavitation control strategy according to the engine speed and water temperature, which can effectively reduce the risk of water pump cavitation of the engine and increase the reliability of the engine.

Owner:DONGFENG MOTOR CORP HUBEI

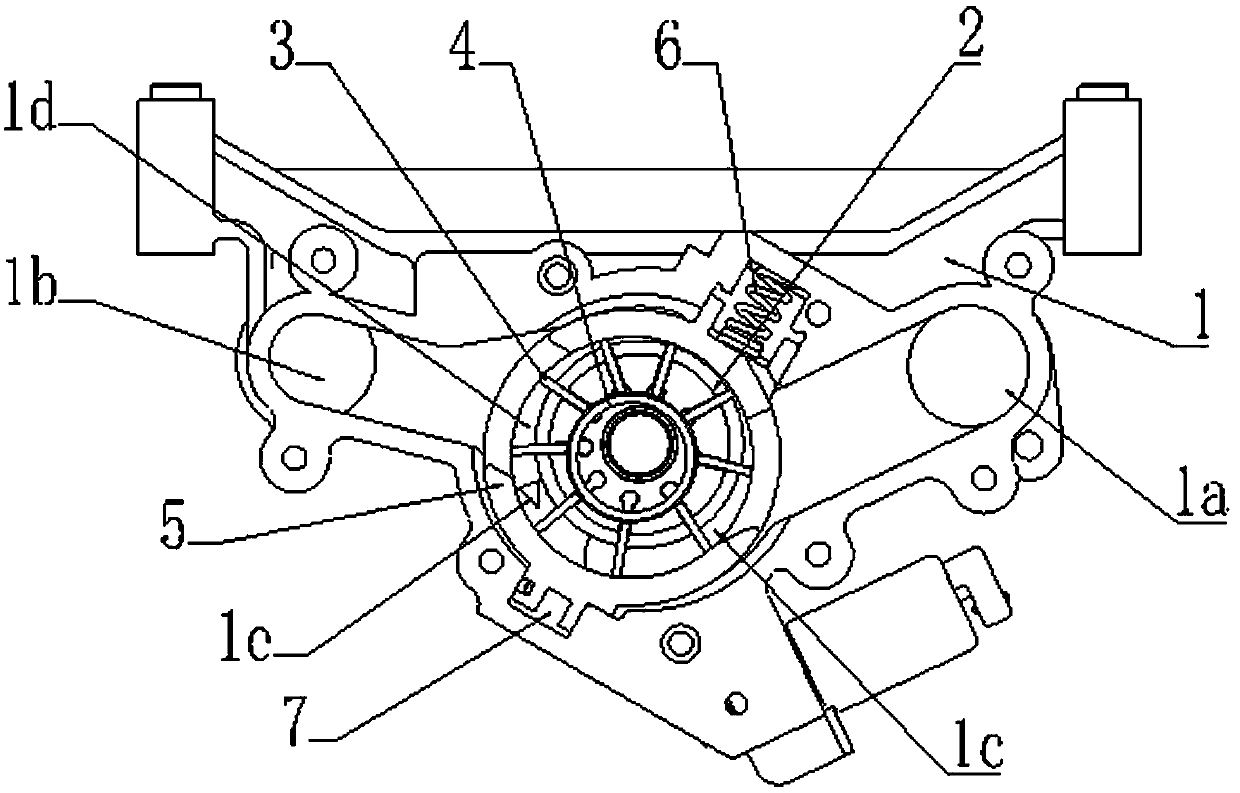

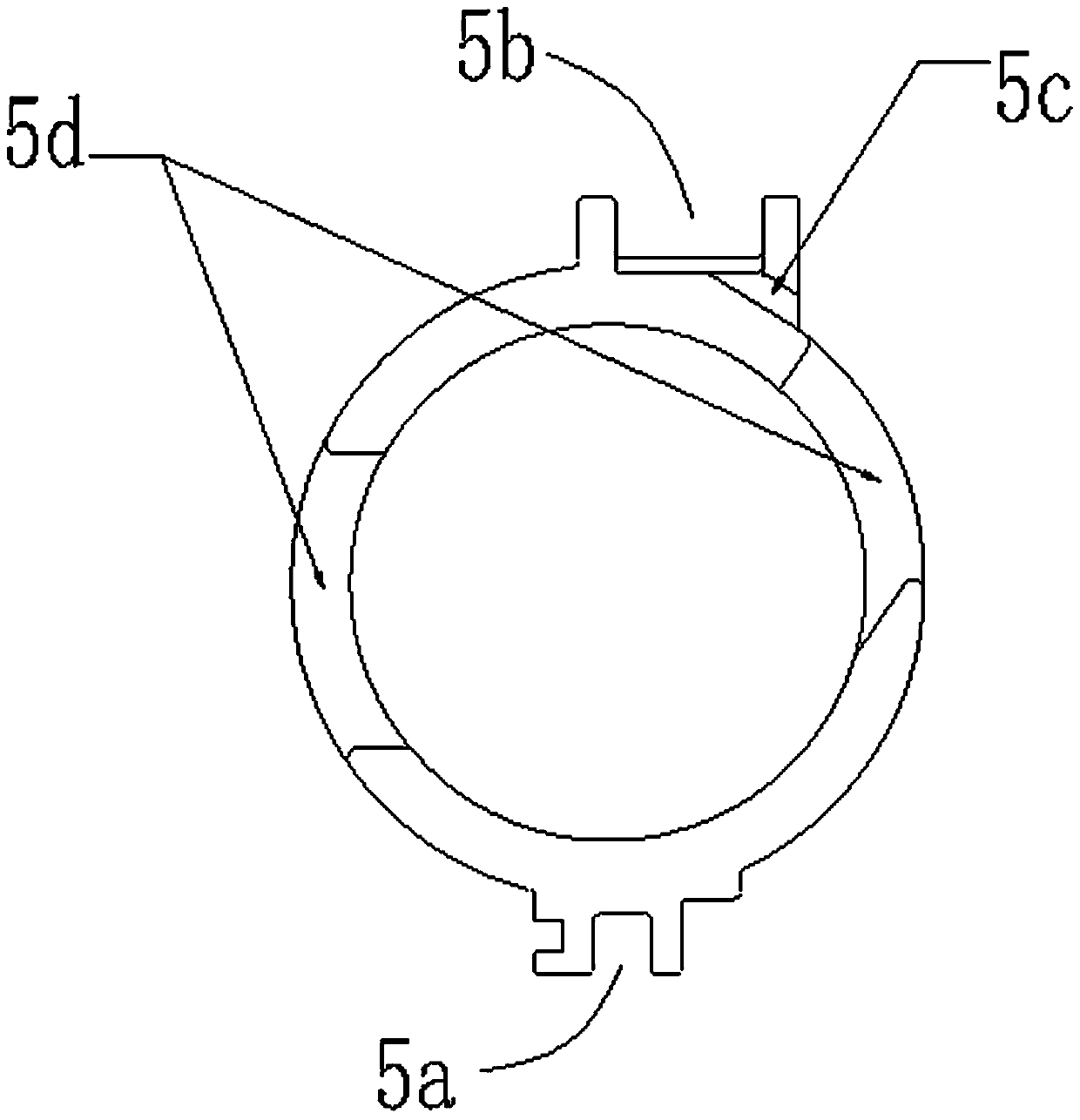

Commercial vehicle blade type variable pump

PendingCN111140761ALarge flow areaReduce flow rateLubricating pumpsVehicle componentsOil intakeCommercial vehicle

The invention provides a commercial vehicle blade type variable pump which comprises a pump body, a rotor, blades, a positioning ring, a variable sliding block and a variable spring. An oil inlet, anoil outlet and a rotor cavity are formed in the pump body, and a concave oil suction cavity and a concave oil pressing cavity are formed in the bottom of the rotor cavity. A first groove and a secondgroove which are staggered with the oil inlet and the oil outlet correspondingly are formed in the side wall of the rotor cavity, the variable sliding block is installed in the rotor cavity, a first U-shaped part embedded in the first groove and a second U-shaped part embedded in the second groove are arranged on the peripheral face of the variable sliding block, a feedback oil cavity is formed between the first groove and the first U-shaped part, and a spring cavity is formed between the interior of the second groove and the second U-shaped part and used for installing the variable spring. The positions of the feedback oil cavity and the spring cavity both incline towards the oil suction cavity, and under the action of oil pressure in the feedback oil cavity or the elastic force of the variable spring in the spring cavity, the variable sliding block can move in the rotor cavity in the radial direction, and therefore, the operation reliability of the oil pump can be improved.

Owner:HUNAN OIL PUMP

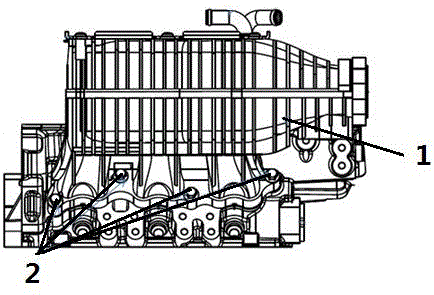

Arrangement method of integrated intercooler of air inlet manifold

InactiveCN105927432AGuarantee working reliabilityOptimize layoutInternal combustion piston enginesIntake silencers for fuelResonant cavityCavitation

The invention relates to an arrangement method of an integrated intercooler of an air inlet manifold. A resonant cavity of the air inlet manifold and an engine cylinder cover are fixed through bolts. According to the arrangement method, the resonant cavity of the air inlet manifold and the engine cylinder cover are fixed through the bolts creatively, the assembling space of an existing air inlet manifold bolt does not need to be considered any more during arrangement of the intercooler, the intercooler can be properly and reasonably arranged according to the flow direction of airflow and the position of an expansion box, the cavitation risk of a cooling system is effectively reduced, and the overall work reliability of an engine is guaranteed.

Owner:CHERY AUTOMOBILE CO LTD

A multi-stage throttling labyrinth pressure reducing valve

ActiveCN110131477BSmooth pressure regulationPrecise pressure regulationValve members for absorbing fluid energyEqualizing valvesInterference resistanceEngineering

The invention proposes a multi-stage throttling labyrinth pressure reducing valve, which includes a spring cover, a housing and a lower end cover. An adjusting nut is provided on the upper end of the spring cover, and an adjusting spring is provided between the adjusting nut and the valve core. There is a return spring between the covers, the valve core is located in the sliding sleeve, and the sliding sleeve is fixed in the housing, the housing forms a high-pressure chamber for the inlet and outlet, the valve core forms a transition chamber, the housing and the sliding sleeve form a low-pressure chamber I, and the lower end cover The low-pressure chamber II is formed with the spool. The sliding sleeve and the spool are correspondingly provided with an upper throttle port connecting the low-pressure chamber I and the transition chamber, and the sliding sleeve and the spool are correspondingly provided with a middle throttle port connecting the high-pressure chamber and the transition chamber. The spool is provided with a lower throttle port connecting the low-pressure chamber II and the transition chamber. The invention has the advantages of smooth and precise pressure regulation; improved anti-interference ability of the valve; simple structure, convenient maintenance and long service life; reduced cavitation risk of high pressure difference at the first level of throttling; more sensitive feedback medium pressure and higher precision .

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com