Valve piston, and slide valve having a valve piston

A valve piston, slide valve technology, applied in the field of valve piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

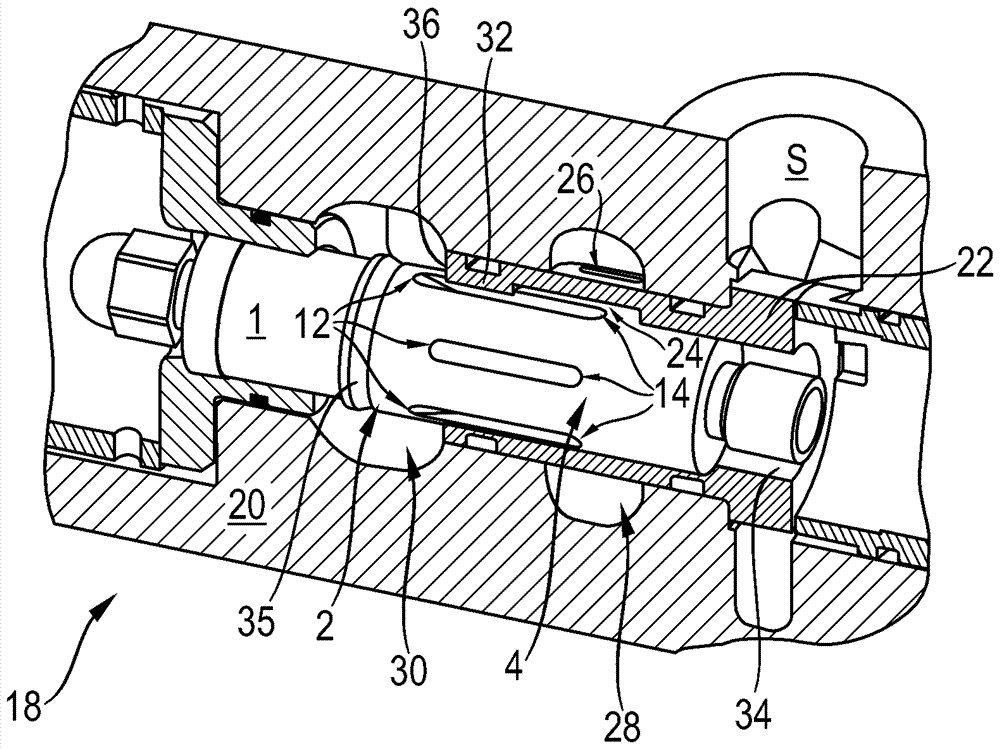

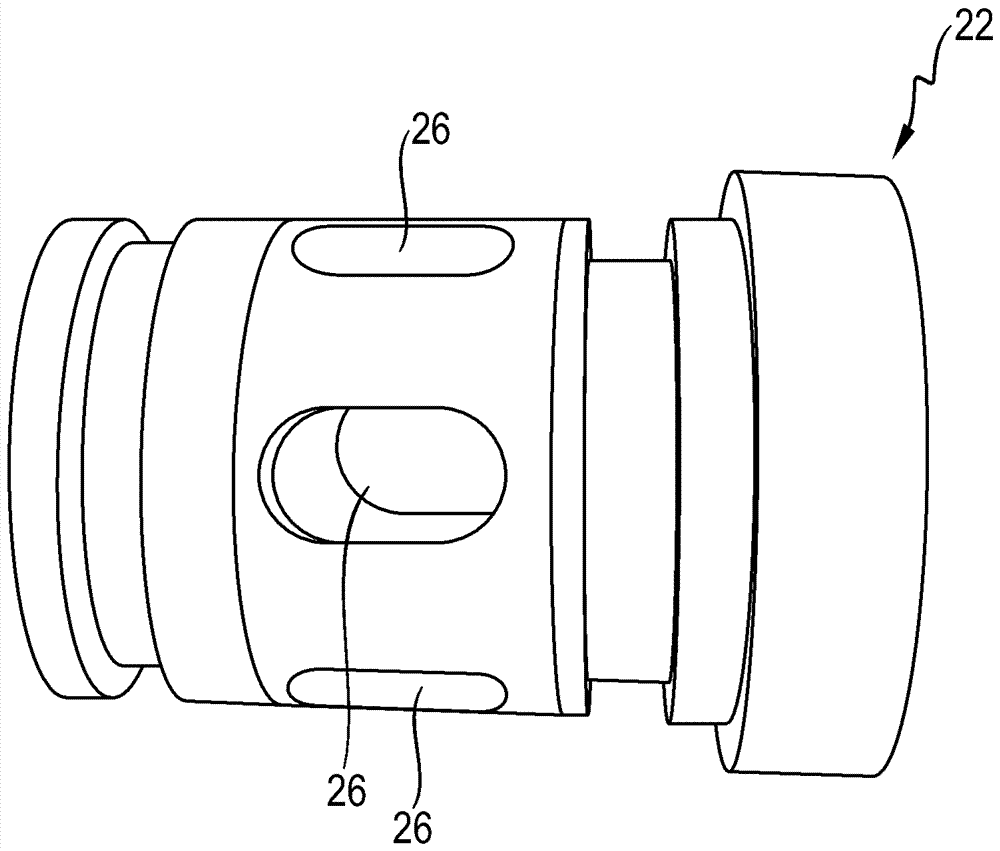

[0031] figure 1 Shown is a view of an embodiment of a valve piston 1 according to the invention. It has a cylindrical section with two axially spaced regions 2 , 4 , which are cylindrically designed over the entire surface and in this case have the same diameter. Between these two areas 2, 4, five longitudinal grooves 6 are evenly arranged on the circumference of the valve piston 1, and these longitudinal grooves are used to connect two ( figure 1 not shown in the pressure chamber.

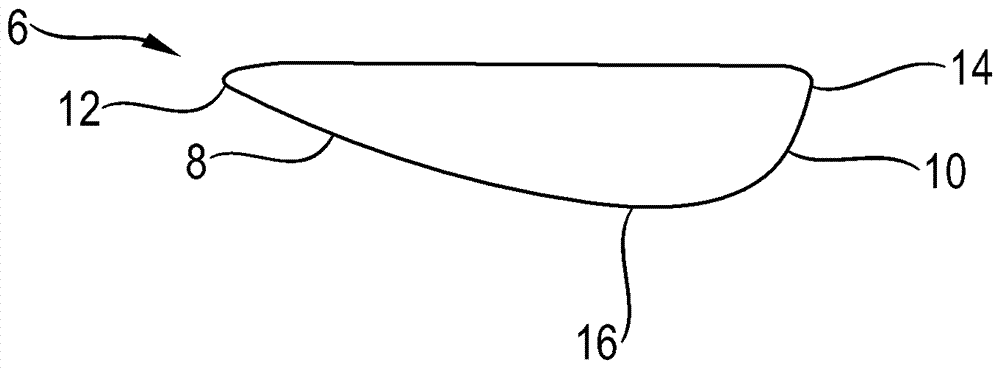

[0032] figure 2 The longitudinal groove 6 is shown in a cross-sectional view of the valve piston 1 . It can be seen here that its depth increases relatively slowly from the first region 2 , whereas its depth increases relatively rapidly from the second region 4 . This results in a relatively flat first edge 8 and a relatively steep second edge 10 . Starting from the first end section 12 , the first edge 8 initially descends approximately constantly, while the second edge 10 has a decreasing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com