Flat knitting machine with weft yarn, warp yarn and/or float yarn clearing and stitch pressing means

A flat knitting machine and warp technology, applied in the field of flat knitting machine control, can solve problems such as collision of flat knitting machine parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

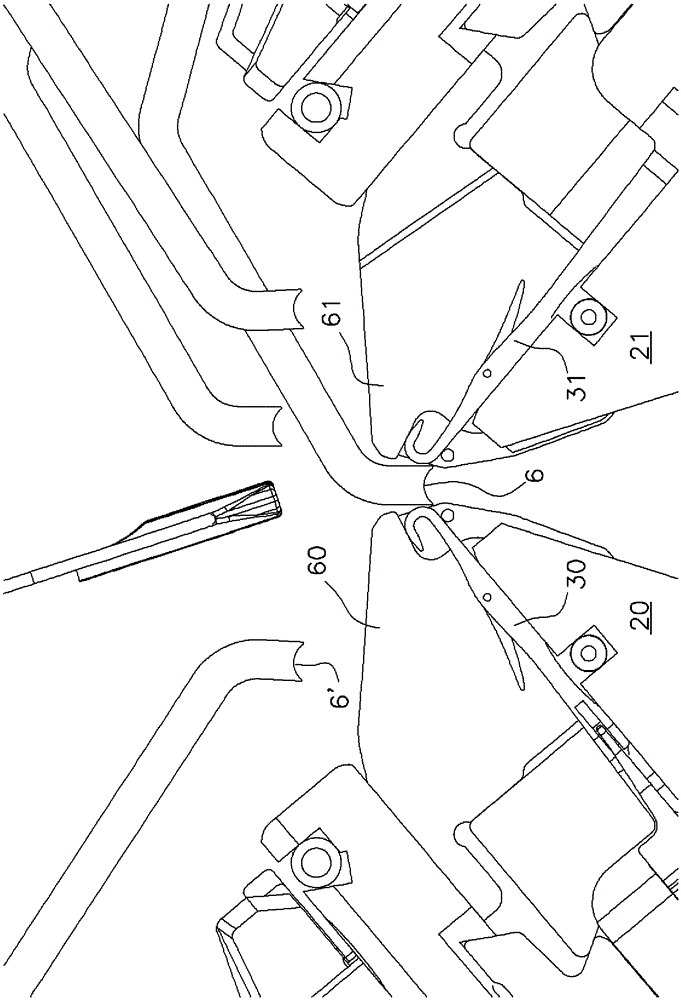

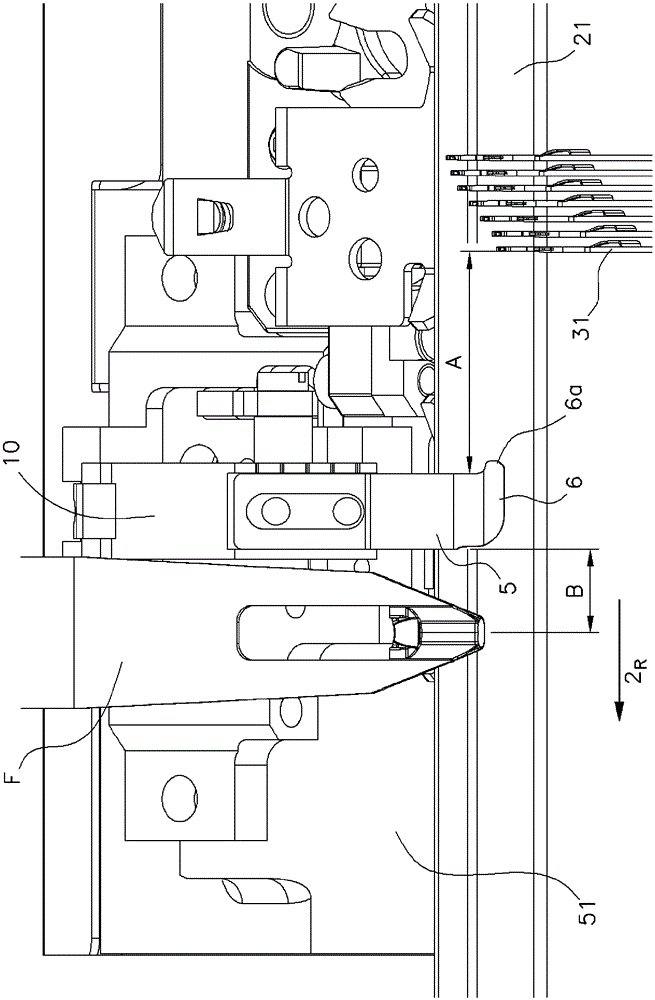

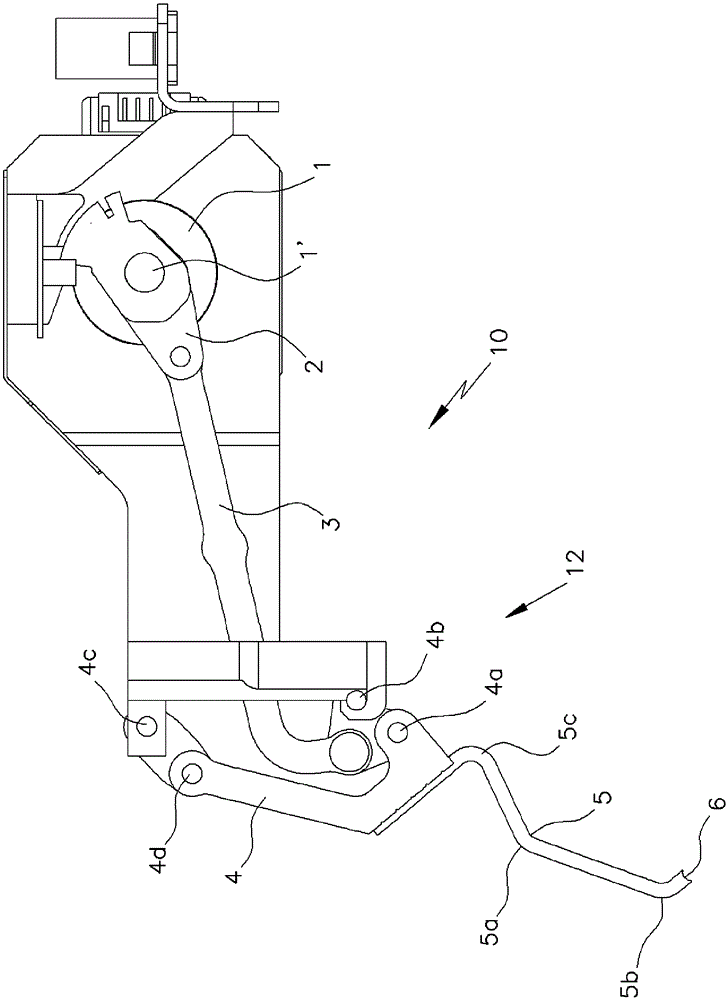

[0036] figure 1 A view is shown of a flat knitting machine 100 with front and rear needle beds 20 , 21 , each of which has a needle 30 , 31 mounted thereon for knitting to move back and forth relative to the knockout comb slot KS. Each needle bed 20 , 21 is associated with a triangular carriage 50 , 51 which can move along the needle bed 20 , 21 respectively. A knitting system with triangular base plates 40 , 41 is arranged on the triangular carriages 50 , 51 . The triangular base plates 40, 41 are considered to be part of the loop forming system. A knitting system preferably consists of two cams (front-rear needle beds). On the triangular carriages 50, 51, a plurality of knitting systems can be arranged front and back as viewed in the direction of movement of the triangular carriages 50, 51. Triangles for transmitting movement to the needles 30 , 31 are mounted on triangular bases 40 , 41 . The yarn feeder F is used to supply the yarn G to the needles 30,31. figure 1 Onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com