Regeneration system for smoke carbon dioxide capture solution

A regeneration system, carbon dioxide technology, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of large steam consumption, solution circulation pump cavitation, affecting solution flow, etc., to improve heat exchange efficiency, reduce gas The effect of reducing the risk of corrosion and improving the desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

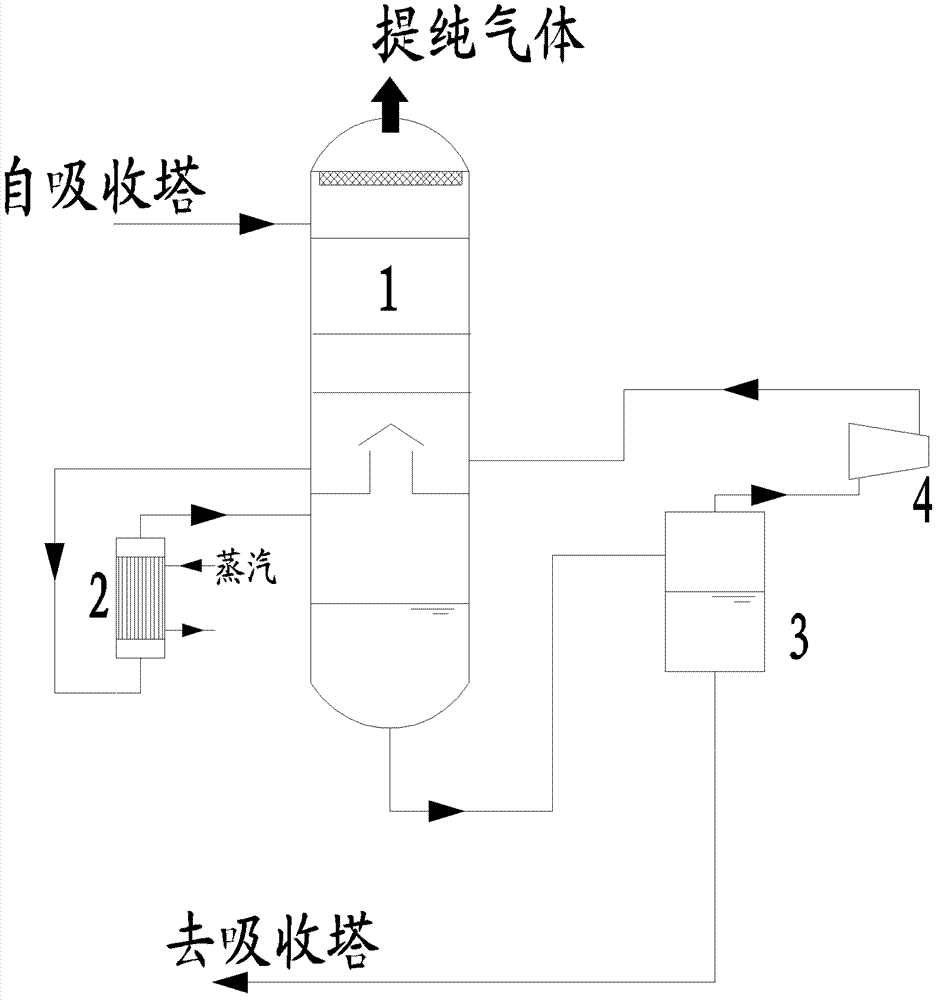

[0019] As shown in the accompanying drawings, a regeneration system of a flue gas carbon dioxide capture solution of the present invention includes a packed or plate distillation tower regeneration tower 1 connected to the absorption tower, and a vertical or vertical tower connected to the lower part of one side of the regeneration tower 1. Horizontal thermosyphon reboiler 2, reboiler 2 is provided with external steam as a heat source, and the pressure vessel connected to the bottom of regeneration tower 1 that can realize gas-liquid separation Gas-liquid separator 3, the bottom of gas-liquid separator 3 and the absorption tower The top is in communication with the air pump 4, the air pump 4 is a pump or turbine that can realize gas compression, and the air pump 4 is in communication with the lower part of the other side of the regenerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com