Method for operating fuel injector and fuel injector

A technology of fuel injectors and functions, which is applied in the direction of fuel injection devices, special fuel injection devices, charging systems, etc., which can solve the problems of installation space and energy demand, and achieve the effect of large stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

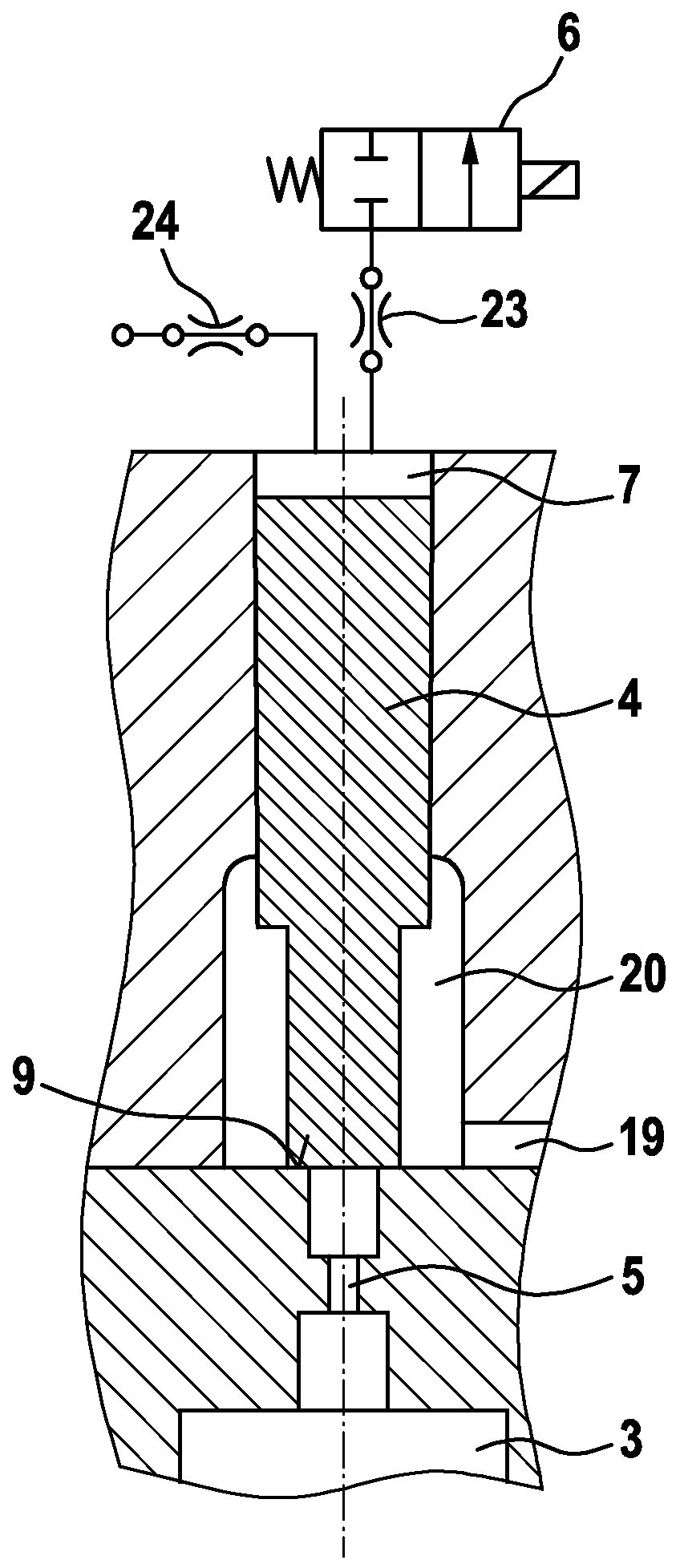

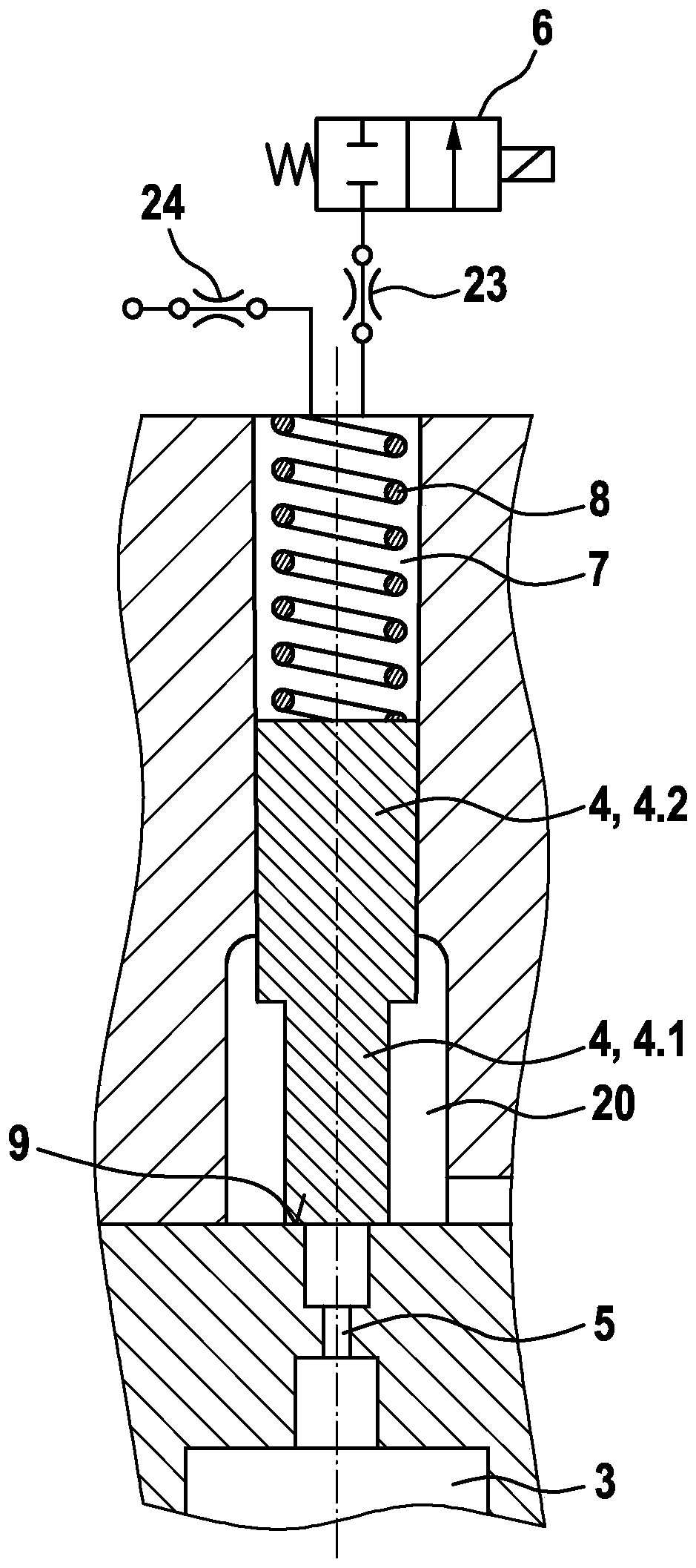

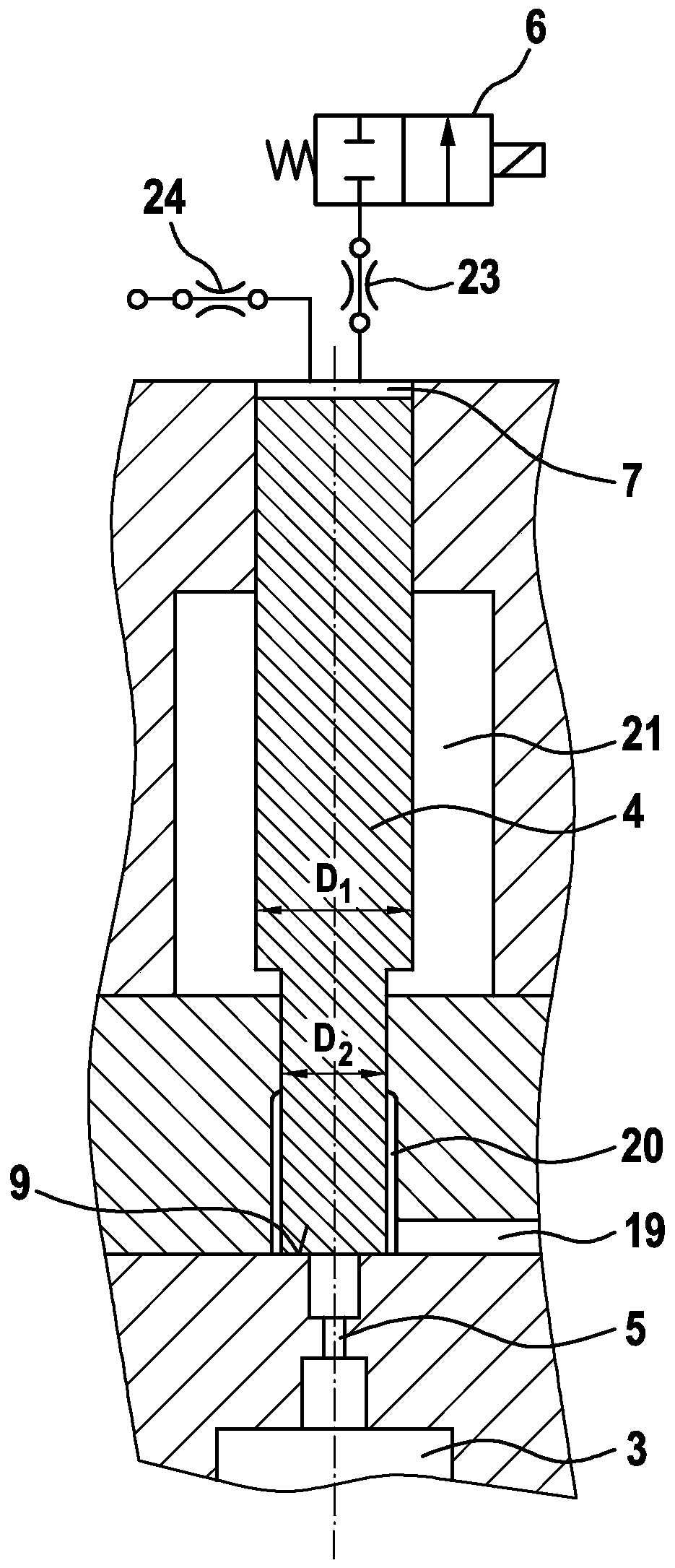

[0032] The fuel injector of the present invention may be similar to Figure 6 The embodiment of the fuel injector shown in , wherein a difference is made with regard to the hydraulic control of the outer nozzle needle 1 , which is designed as a hollow needle. The area is in Figure 6 marked by a dotted border. described in more detail below Figure 1 to Figure 5 All about the area.

[0033] From figure 1 A first preferred embodiment of the hydraulic control of the nozzle needle 1 is known. The hydraulic control takes place by means of a pilot control piston 4 , via the position of which the control pressure can be varied in a control chamber 3 , which is delimited by the nozzle needle 1 . This means that the control pressure present in the control chamber 3 acts on the nozzle needle 1 and exerts a hydraulic pressure on the nozzle needle 1 in the closing direction. Therefore, the control pressure in the control chamber 3 must be reduced in order to open the nozzle needle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com