An expansion kettle assembly and cooling circulation system

An expansion kettle and circulation system technology, which is applied to the cooling of engines, engine components, machines/engines, etc., can solve the problems of low cooling cycle efficiency, inconvenient arrangement of expansion kettles, etc., achieve good cooling capacity and reduce the risk of cavitation , good cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

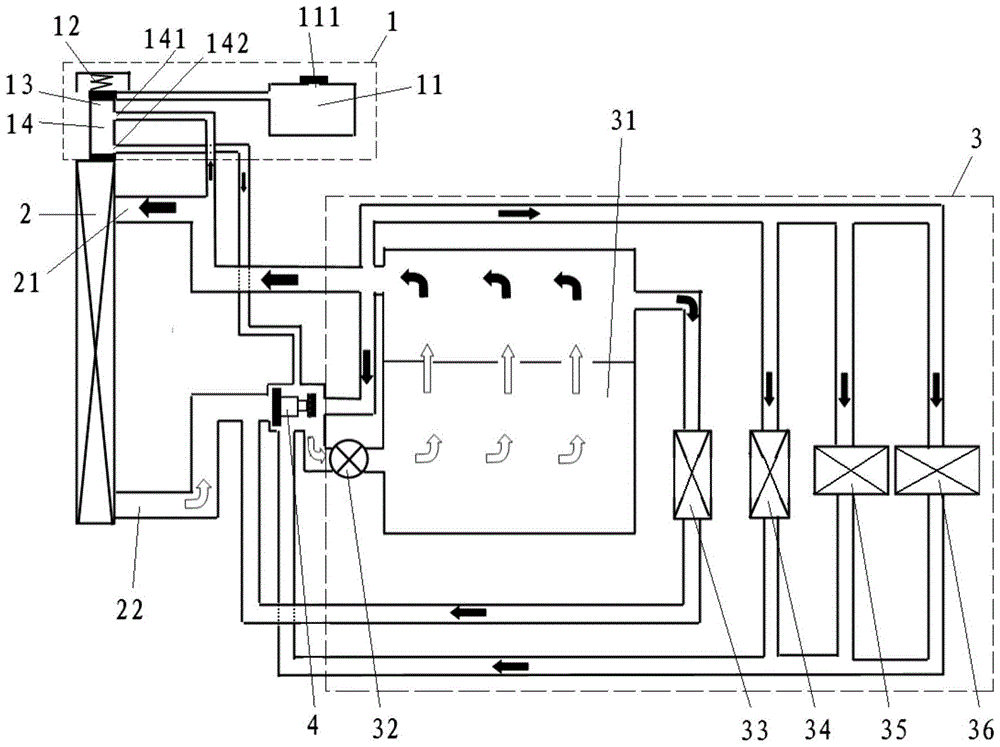

[0030] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Such as image 3 As shown, the expansion kettle assembly 1 includes an expansion kettle 11, an expansion cavity 14, and a pressure cover 12. The expansion kettle 11 has an outlet 111 communicating with the atmosphere, the expansion kettle 11 is connected to the expansion cavity 14, and the expansion cavity 14 has a filling port 13 The pressure cap 12 is connected to the filling port 13. The expansion chamber 14 has a circulating liquid inlet 141 and a circulating liquid outlet 142. The expansion chamber 14 is higher than the liquid level of the radiator 2, and the pressure cap 12 is a two-way pressure valve, which is controlled by the pressure cap 12 The expansion cavity 14 is connected and isolated from the expansion kettle 11.

[0032] In the normal state, the pressure cover 12 is closed and is not connected to the expansion kettle 11....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com