Pressurization type liquid ring vacuum pump water return system with rotating film and water return method thereof

A liquid ring vacuum pump and vacuum pump technology are applied in the return water system of a pressurized liquid ring vacuum pump and the return water field of a pressurized liquid ring vacuum pump return water system, which can solve the problem that the temperature of the liquid ring is difficult to drop, the working condition of the vacuum pump is over-temperature, The problems such as the reduction of the pumping capacity, to achieve the effect of reducing the heat transfer end difference, reducing the temperature of the liquid ring, and reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

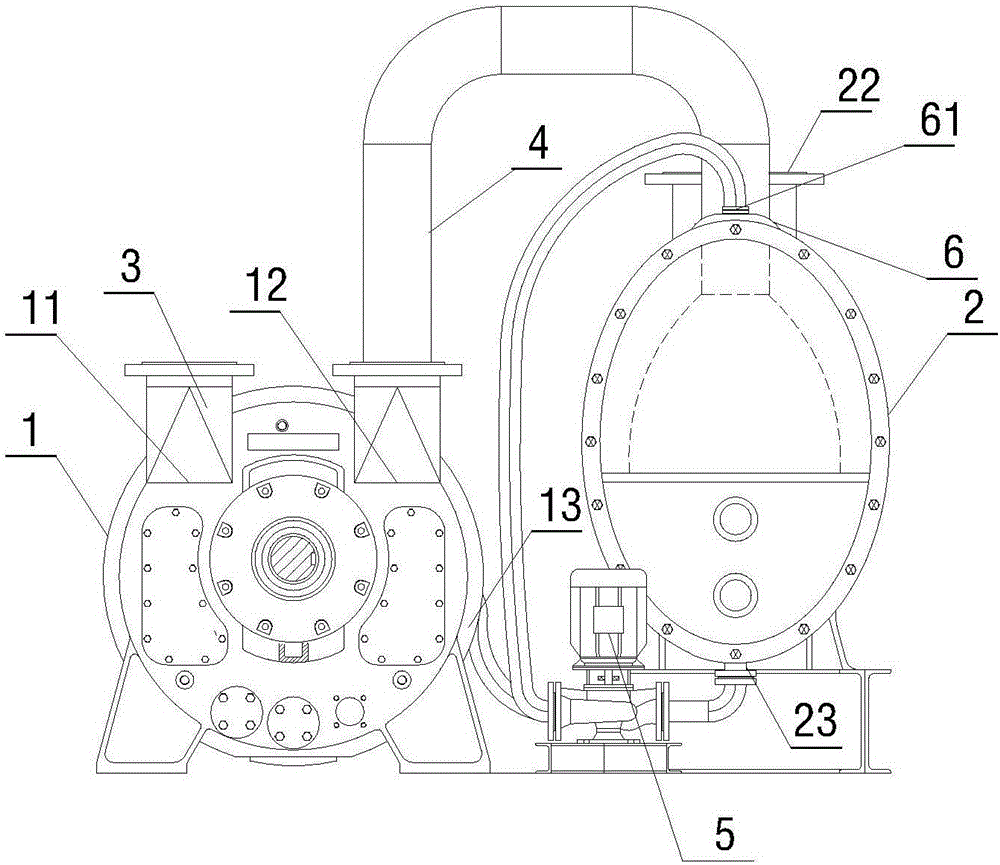

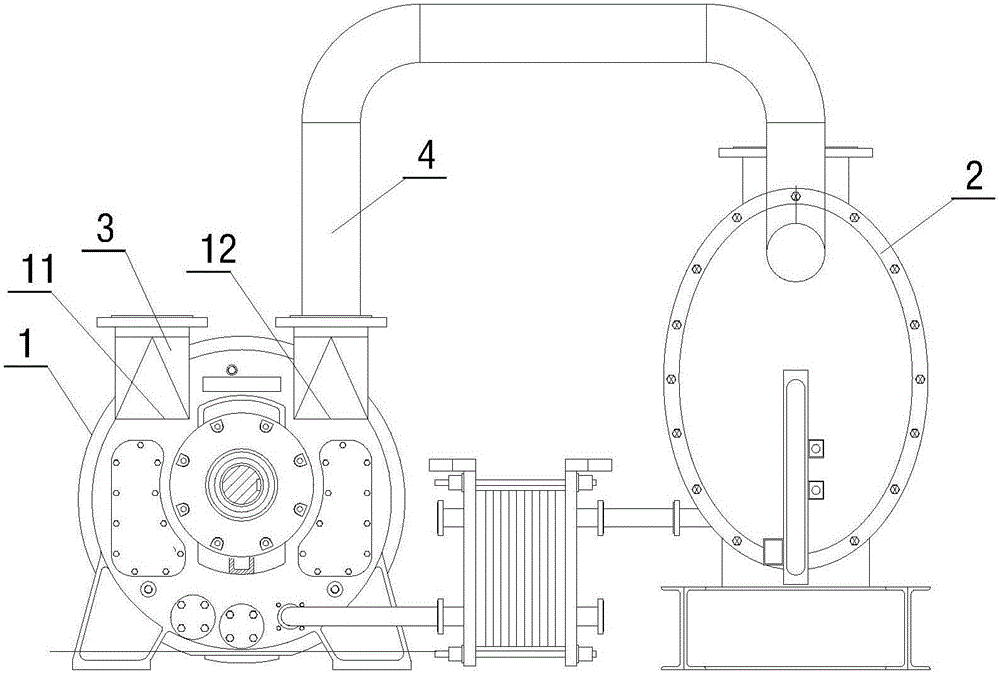

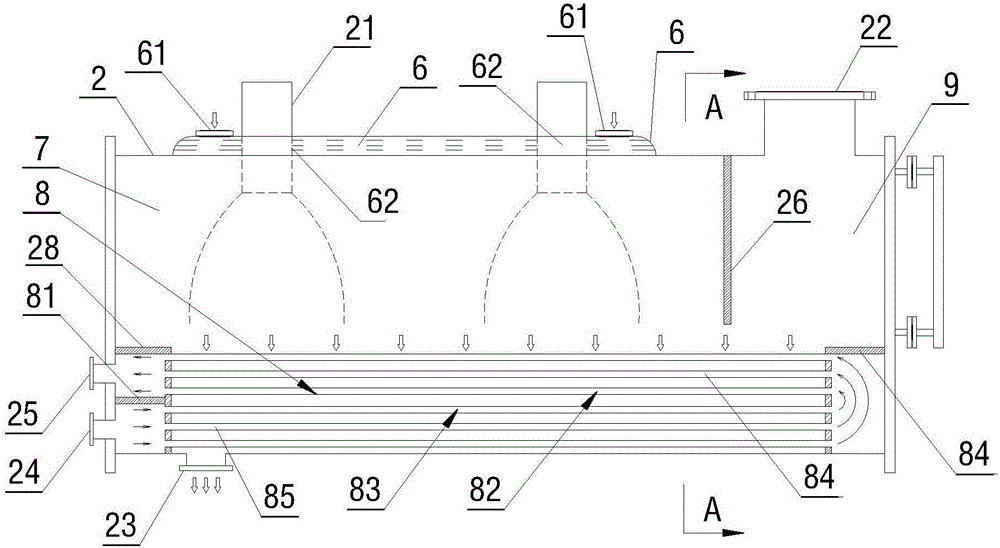

[0038] Referring to the accompanying drawings, it can be seen that the return water system of a pressurized liquid ring vacuum pump with a rotating membrane includes a vacuum pump body 1, a gas-water separator 2, an inlet material pipe 3 and an outlet material pipe 4; the upper end of the vacuum pump body 1 is provided with a pump body material inlet 11 and pump body material outlet 12, the lower end of the vacuum pump body 1 is provided with a water return port 13, the upper end of the gas-water separator 2 is provided with a separator material inlet 21 and a separated gas outlet 22, and the lower end of the gas-water separator 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com