Discrete pile-water permeability concrete pile novel binary composite foundation and treatment method of composite foundation

A concrete pile, binary composite technology, applied in sheet pile wall, soil protection, infrastructure engineering and other directions, can solve the problems of small pile length, unsuitable for deep liquefied foundation earthquake resistance, low stiffness and strength of bulk material piles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

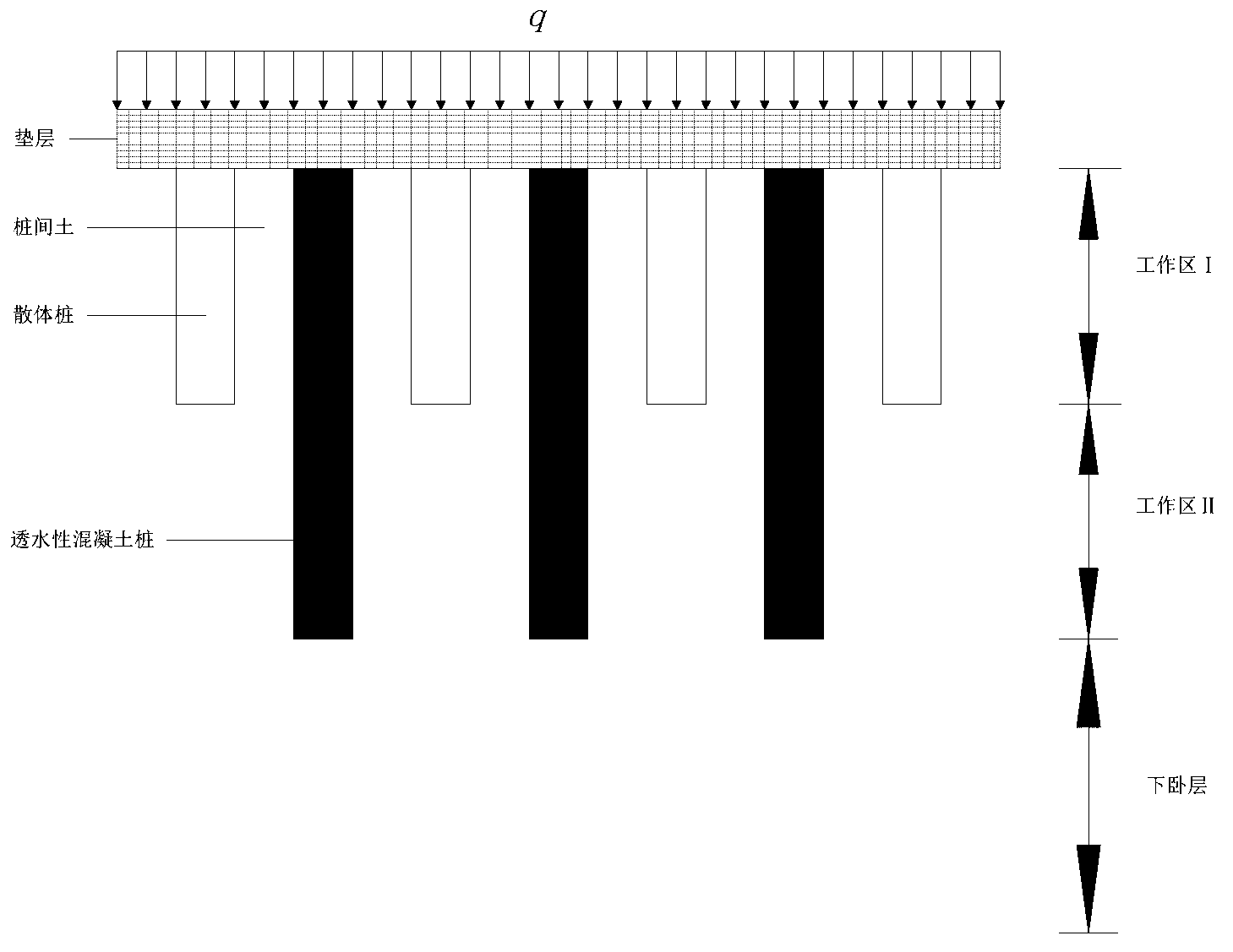

[0059] The foundation of a highway is mainly composed of pre-Quaternary bedrock and Quaternary alluvial-diluvial loose accumulation layers. Below the surface are sandy soil, gravel and other strata. The following sequence is: silty clay, silt, silt, fine sand, medium sand, coarse sand, gravel sand, round gravel, bedrock. The main problems are: ①The bearing capacity of the natural foundation is low, and the project requires the bearing capacity of the foundation to be above 250kPa; ②There is a possibility of liquefaction under the action of earthquakes. However, the simple gravel pile composite foundation cannot meet the above requirements, and the gravel pile permeable concrete pile composite foundation can be used for treatment.

[0060] The gravel piles and permeable concrete piles are arranged in triangular rows. It is required to lay gravel cushion on the foundation surface with a thickness of 40cm. It is required to construct bulk piles first during construction, and th...

example 2

[0064] A commercial building has 13 floors above the ground. The foundation adopts a raft foundation. The thickness of the raft is 0.9m, the depth of the bottom of the raft is 1.6m, and the design value of the base load is 300kPa. According to the engineering geological survey report, the foundation of the building is as follows from top to bottom: ① Miscellaneous fill: 0-1.6m thick, which is construction waste and fill; ② Silty clay: 1.6-7m thick, with a characteristic value of bearing capacity of 150kPa ; ③ Clay: 7-14m thick, characteristic value of bearing capacity is 210kPa; ④ Mudstone: buried depth 14-20m, characteristic value of bearing capacity of foundation is 2100kPa. Due to the insufficient bearing capacity of the natural foundation, it needs to be treated.

[0065] The foundation can be treated by the method of sand pile-permeable concrete pile combined long and short pile composite foundation. The short piles are medium sand piles with a length of 6m and a hole di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pile diameter | aaaaa | aaaaa |

| Pile length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com