Construction method for cast-in-place pile through punching and base expanding and base expanding device

A technology for bottom-expanding cast-in-place piles and a construction method, which is applied to the field of punching and bottom-expanding cast-in-place piles, can solve problems such as inability to effectively clean up pile bottom sediment, and achieve the effects of facilitating production and maintenance, improving efficiency and reducing usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

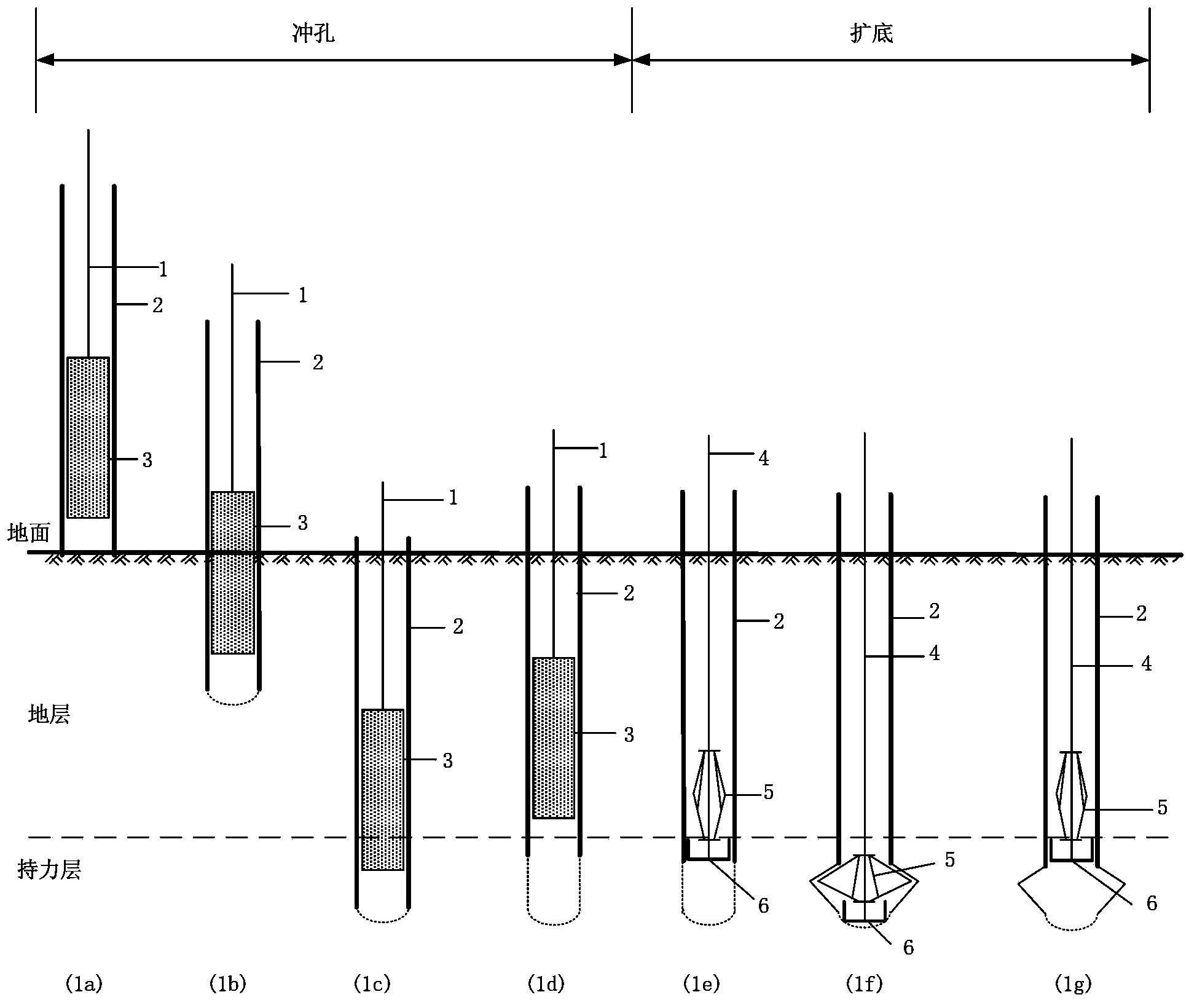

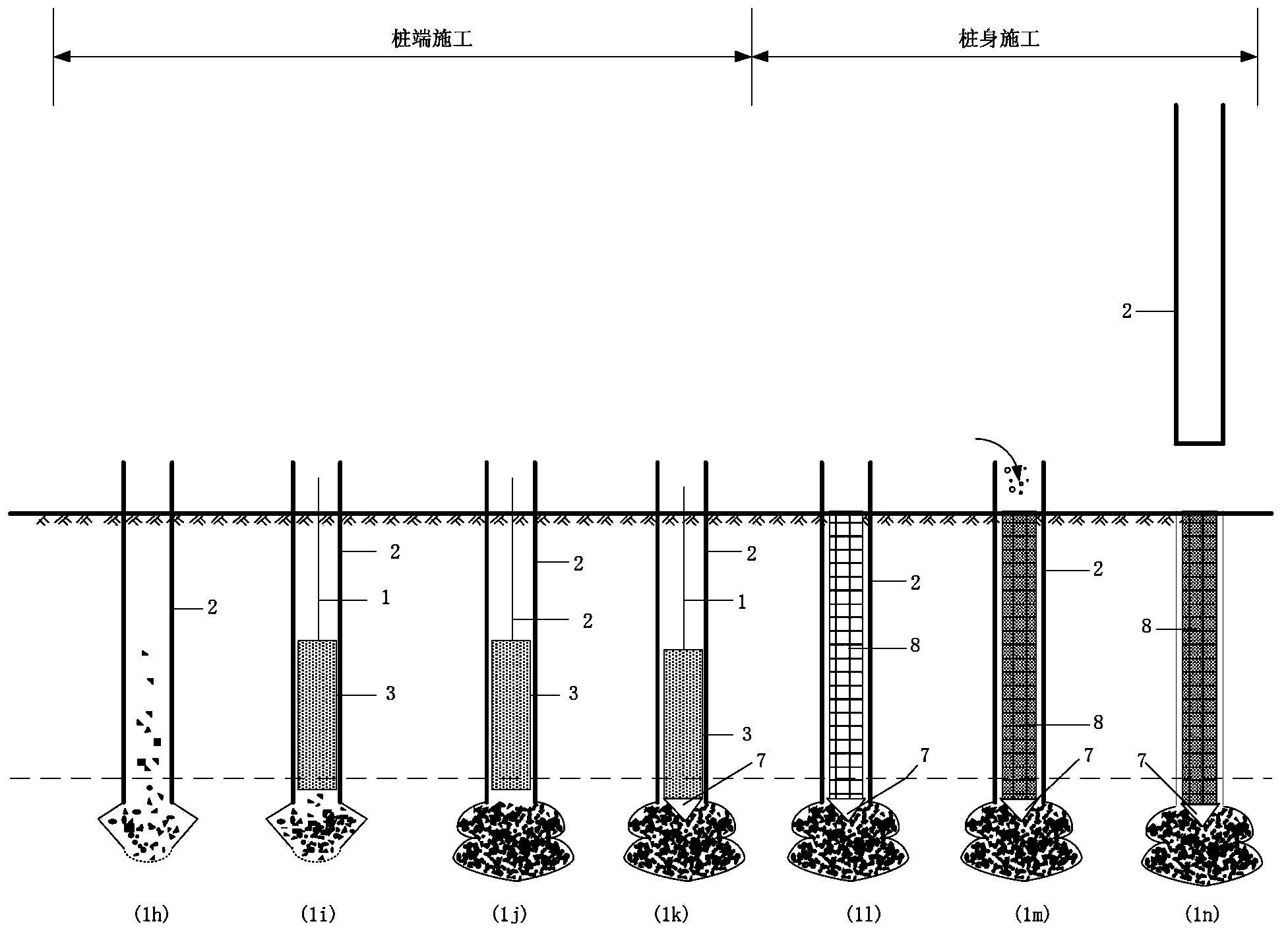

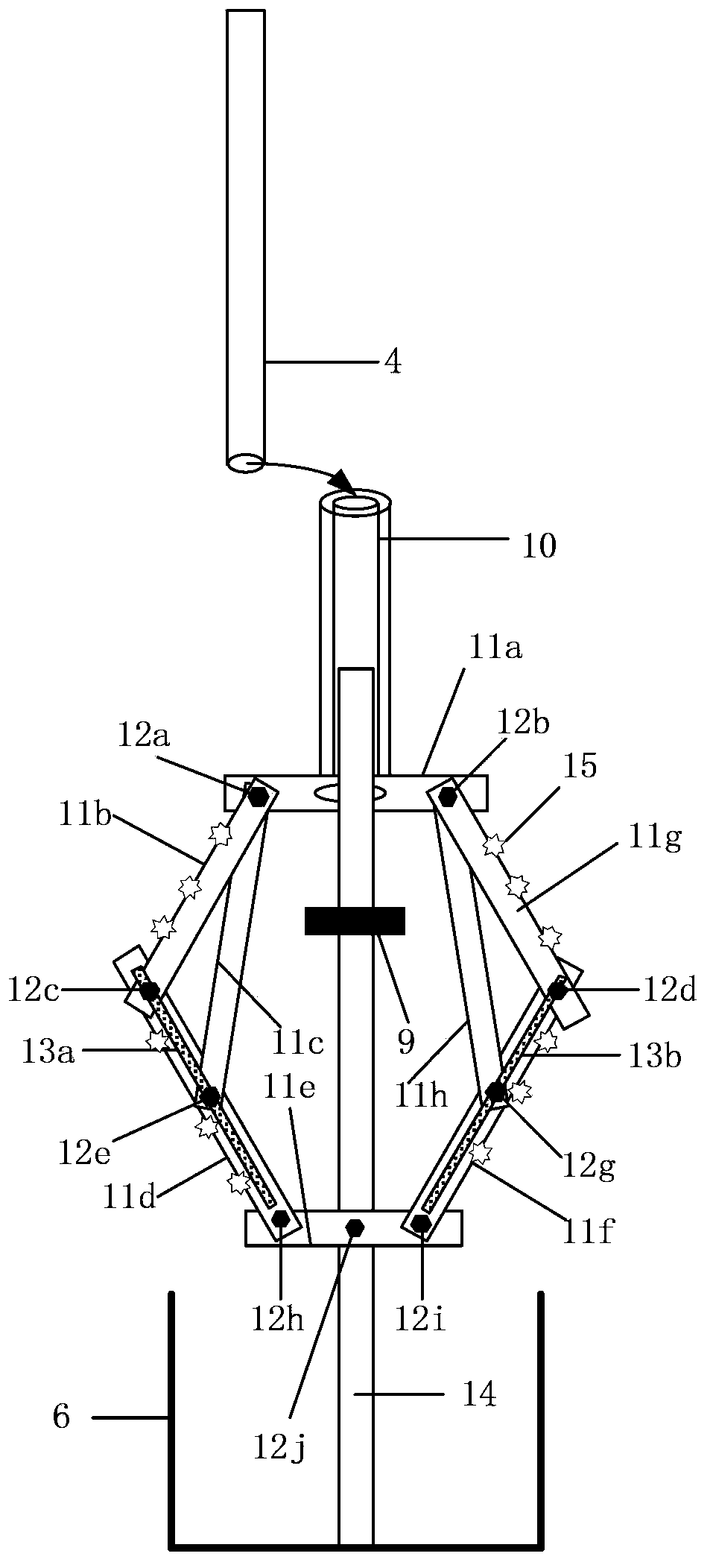

[0037] Below in conjunction with accompanying drawing, the construction method and device of the perforated and expanded bottom cast-in-place pile according to an embodiment of the present invention will be further described in detail.

[0038] A construction method for perforated and bottom-expanded cast-in-place piles, comprising the following steps:

[0039] 1) Punching. First, pre-determine the pile position in the foundation, press the steel casing 2 into the soil with hydraulic pressure, and put the heavy hammer 3 connected to the steel wire rope 1 into the casing 2 at the same time, through the up and down action of the heavy hammer 3, the soil layer will Tamping. Press the casing 2 to the design depth by pressing the casing 2 while using the heavy hammer 3 to ram the earth, then lift the steel wire rope 1 and the heavy hammer 3, and lift the casing 2 to a certain distance. The proposed distance is generally the height of the bottom expansion. 2 times.

[0040] 2) Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com