Double-row bottom-expanded long and short combined anti-slide pile for slope supporting

A technology for anti-sliding piles and side slopes, which is applied in the field of double-row extended-bottom long-short combined anti-sliding piles for slope support, can solve the problems of large difference between internal force and deformation, and the front row piles cannot fully exert their anti-sliding ability. The effect of uniform force and deformation, reduction of landslide control cost, and large lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

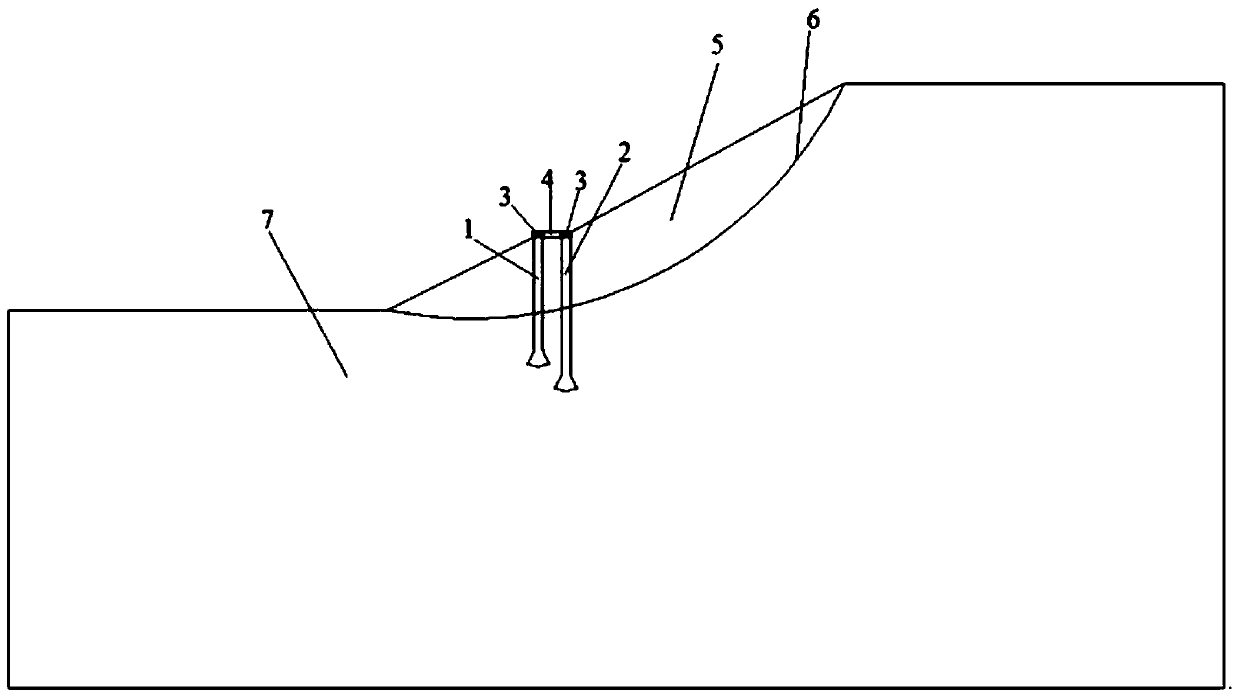

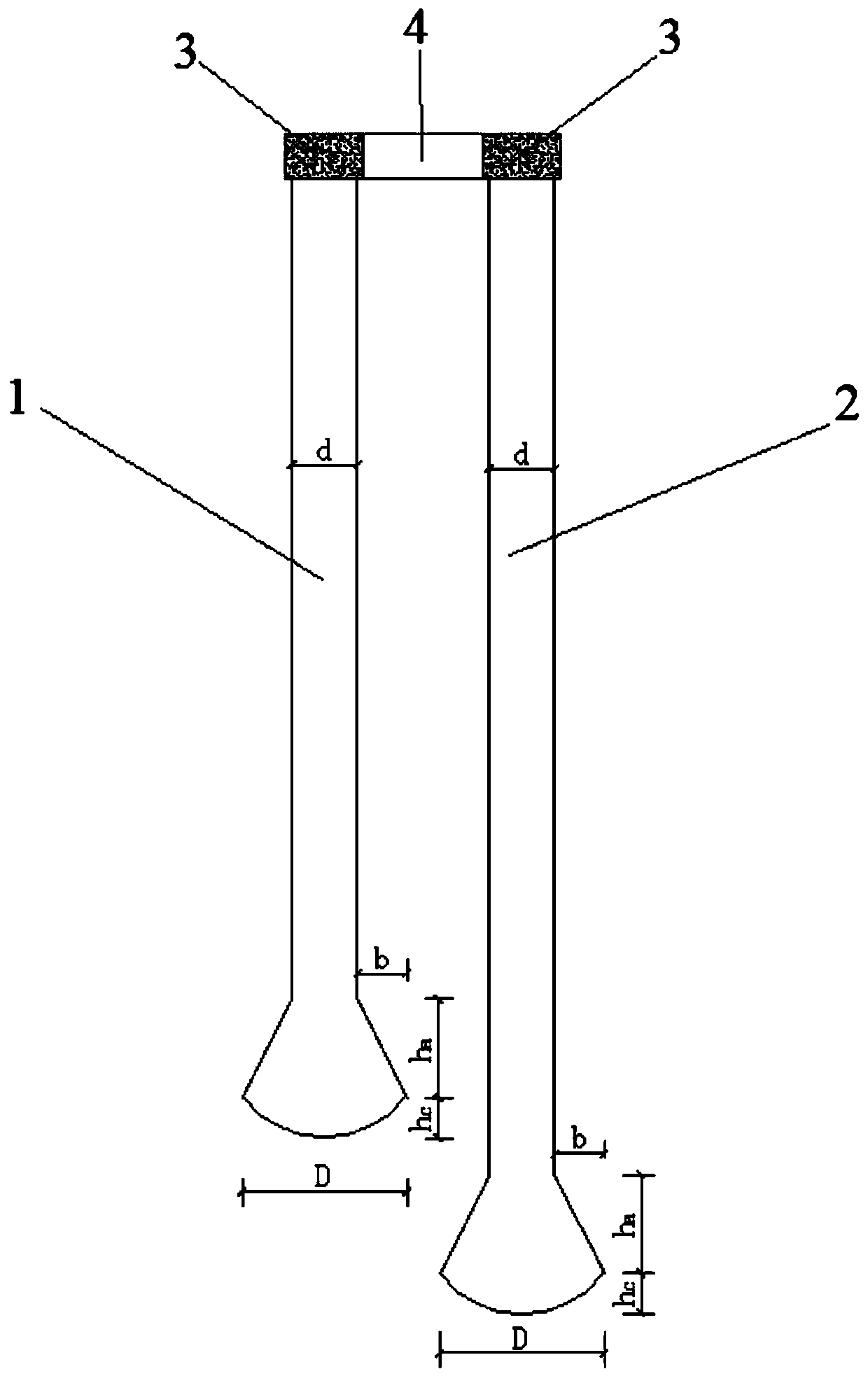

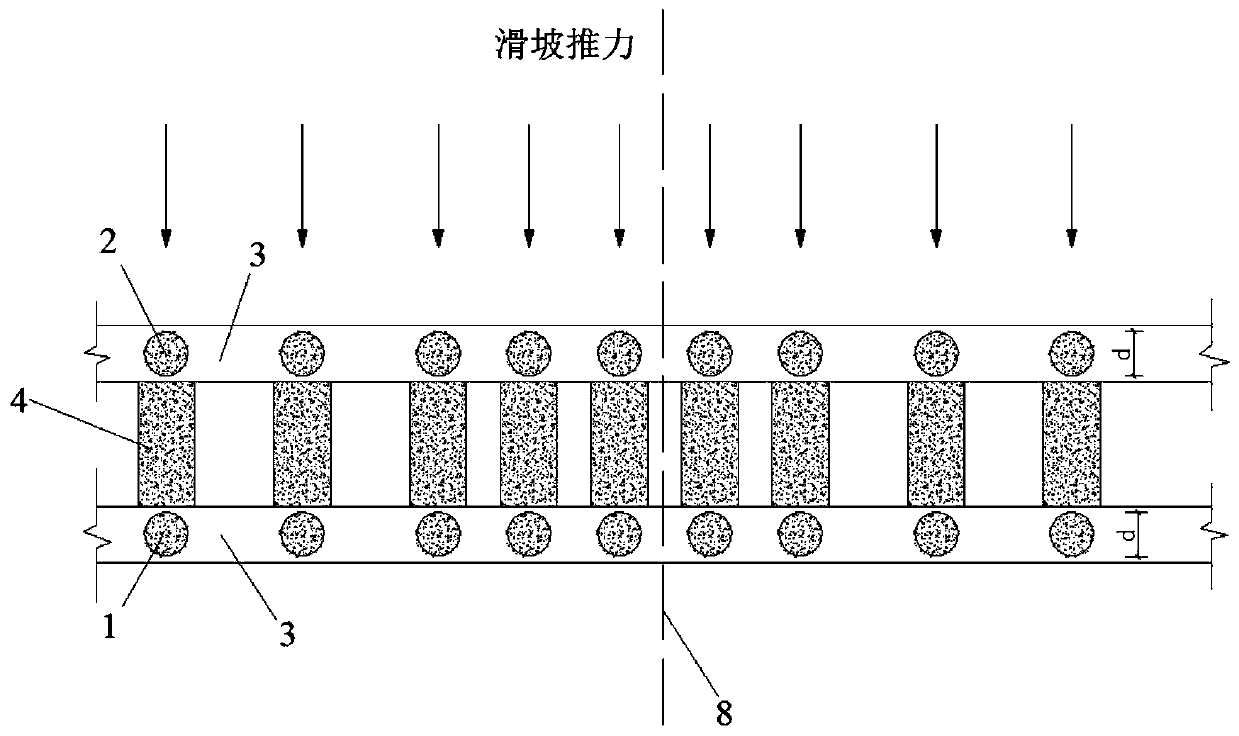

[0024] Such as Figure 1-3 As shown, this embodiment is a combination of double-row bottom-expanding anti-slide piles for slope support. Tie beams 4; the rear expanded bottom anti-slide piles 2 are located at the rear edge of the landslide body 5, the front expanded bottom anti-sliding piles 1 and the rear expanded bottom anti-sliding piles 2 are fixed by nine connecting beams 4 and along the landslide body 5 The sliding direction is set, and the surface of the 9 connecting beams 4 forms a horizontal plane; the front row of bottom expansion anti-slide piles 1 and the rear row of bottom expansion anti-slide piles 2 are respectively composed of 9 bottom expansion anti-slide piles, and the bottom expansion anti-slide piles pass through The set (it is recommended to remove these three characters) pile top crown beam 3 is fixedly connected; the pile top crown beam 3 and the connecting beam 4 are vertically connected; 2 lengths. When the anti-slide piles 1 and 2 in the front row a...

Embodiment 2

[0026] Such as Figure 1-3 As shown, this embodiment is a combination of double-row bottom-expanding anti-slide piles for slope support. Tie beams 4; the rear expanded bottom anti-slide piles 2 are located at the rear edge of the landslide body 5, the front expanded bottom anti-sliding piles 1 and the rear expanded bottom anti-sliding piles 2 are fixed by nine connecting beams 4 and along the landslide body 5 The sliding direction is set, and the surface of the 9 connecting beams 4 forms a horizontal plane; the front row of bottom expansion anti-slide piles 1 and the rear row of bottom expansion anti-slide piles 2 are respectively composed of 9 bottom expansion anti-slide piles, and the bottom expansion anti-slide piles pass through The set (it is recommended to remove these three characters) pile top crown beam 3 is fixedly connected; the pile top crown beam 3 and the connecting beam 4 are vertically connected; 2 lengths. When the anti-sliding piles 1 and 2 in the front row...

Embodiment 3

[0028] Such as Figure 1-3 As shown, this embodiment is a combination of double-row bottom-expanding anti-slide piles for slope support. Tie beams 4; the rear expanded bottom anti-slide piles 2 are located at the rear edge of the landslide body 5, the front expanded bottom anti-sliding piles 1 and the rear expanded bottom anti-sliding piles 2 are fixed by nine connecting beams 4 and along the landslide body 5 The sliding direction is set, and the surface of the 9 connecting beams 4 forms a horizontal plane; the front row of bottom expansion anti-slide piles 1 and the rear row of bottom expansion anti-slide piles 2 are respectively composed of 9 bottom expansion anti-slide piles, and the bottom expansion anti-slide piles pass through The set (it is recommended to remove these three characters) pile top crown beam 3 is fixedly connected; the pile top crown beam 3 and the connecting beam 4 are vertically connected; 2 lengths. When the anti-sliding piles 1 and 2 in the front row a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com