Tube pile provided with posttensioned prestressing steel noose hole and posttensioned prestressing pulling tube pile

A post-tensioning prestressing, steel noose technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem of not seeing pullout-resistant pipe piles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

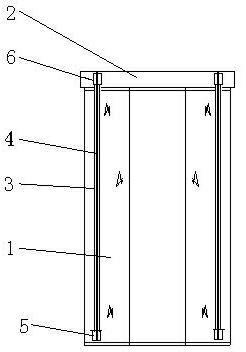

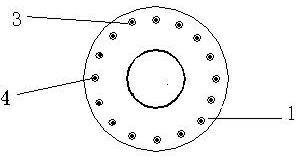

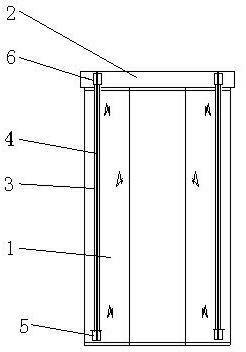

[0015] Such as figure 1 , 2 As shown, a pipe pile provided with a post-tensioned prestressed steel cable hole includes a pipe pile body 1, and a hole 3 is arranged on the inner circumference of the pile body 1 coaxially. Each hole center of the holes 3 is equidistant from the center of the pile body, and the holes 3 are equally divided into a circle in the pile body 1 .

Embodiment 2

[0017] Such as figure 1 , 2 As shown, the present invention includes a pipe pile body 1, and a cap surface 2 provided at the upper end of the pile body 1 . A week coaxial line is provided with hole 3 in pile body 1, post-tensioned prestressed steel cable 4 lower ends are provided with enlarging head 5, and upper end passes hole 3 that pile body 1 is established, is connected and fixed by connector 6 after stretching. The upper end of the steel rope 4 and the connecting piece 6 arranged thereon are buried in the bearing platform 2 .

[0018] Such as figure 2 As shown, each hole center of the hole 3 is equidistant from the center of the pile body 1, and the holes 3 are equally divided into a circle in the pile body 1.

[0019] In this embodiment, the connecting piece 6 is selected as an anchor clamp, and the expanding head 5 is selected as an extruded anchor.

[0020] The preparation process of the present invention: when the pipe pile is prefabricated, steel rope holes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com