High-strength self-leveling silane modified waterproof coating and preparation method thereof

A waterproof coating and silane modification technology, applied in polyether coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as unfavorable construction operations and high viscosity of coatings, and achieve improved network structure density and good compatibility , Improve the effect of construction convenience and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

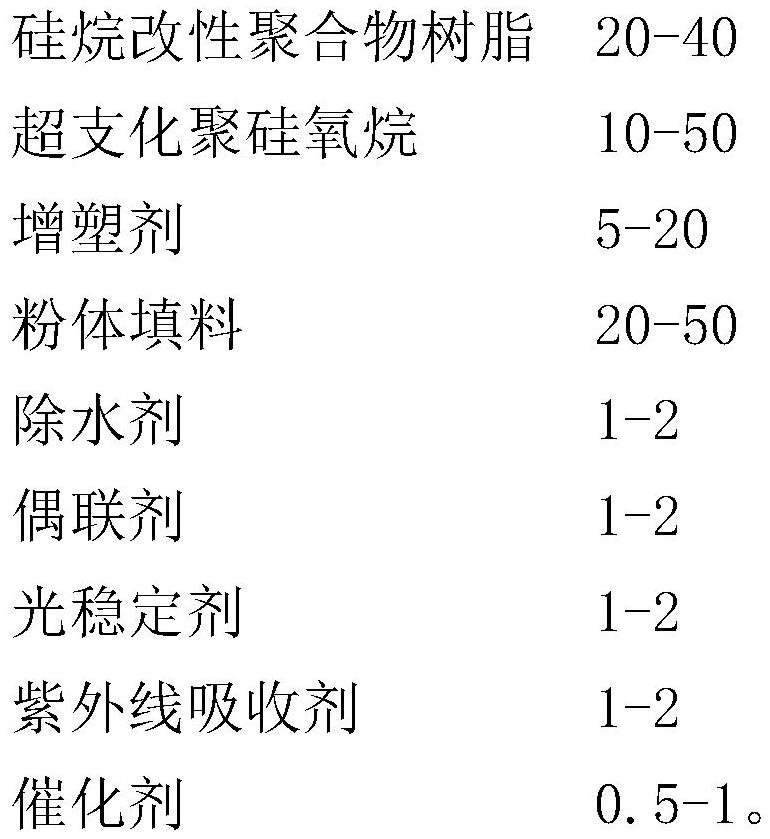

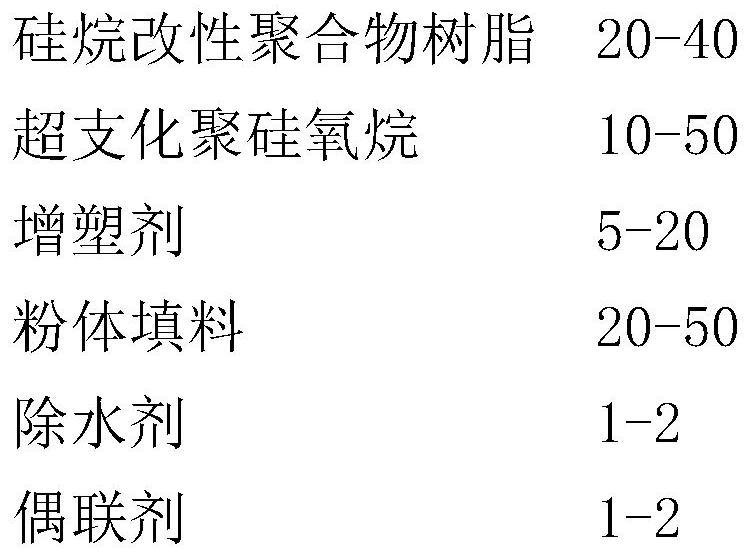

[0032]

[0033] (1) Add plasticizer and solid filler into the container, then stir for 3 hours at a temperature of 110°C, a vacuum of -0.08MPa, and 1200rpm, then cool down to 50°C and release the vacuum;

[0034] (2) Then add silane-modified polymer resin, hyperbranched polysiloxane resin and water-removing agent, and continue stirring and mixing for 20 minutes at normal temperature and pressure;

[0035] (3) Then add coupling agent, light stabilizer, ultraviolet absorber and catalyst in turn, after dispersing and mixing for 10 minutes, then stir for 5 minutes under vacuum degree of -0.08MPa, and finally remove the vacuum to obtain the high-strength self-flowing Flat silane coating.

[0036] The powder filler is mainly composed of heavy calcium and barium sulfate with a mass ratio of 3:1.

[0037] The silane-modified polymer resins are S203 and S303 from Zhonghua Trading (Shanghai) Co., Ltd., and the plasticizer is DINP from ExxonMobil.

Embodiment 2

[0039]

[0040] (1) Add plasticizer and solid filler into the container, then stir at 115°C, vacuum degree of -0.09MPa, 1500rpm for 2.5h, then cool down to 50°C and release the vacuum;

[0041] (2) Then add silane-modified polymer resin, hyperbranched polysiloxane resin and water-removing agent, and continue stirring and mixing at normal temperature and pressure for 25 minutes;

[0042] (3) Then add coupling agent, light stabilizer, ultraviolet absorber and catalyst in sequence, disperse and mix for 15 minutes, then stir for 10 minutes at a vacuum degree of -0.09MPa ~, and finally release the vacuum to obtain the high-strength Self-leveling silane coating.

[0043] The powder filler includes heavy calcium, light calcium and titanium dioxide in a mass ratio of 2:1:5.

[0044] The silane-modified polymer resin is SPUR 1015LM from Momentive High-tech Materials Group;

[0045] The preferred plasticizer is polyether PPG2000 from Wanhua Chemical Group.

Embodiment 3

[0047]

[0048] (1) Add plasticizer and solid filler into the container, then stir at 115°C, vacuum degree of -0.1MPa, 2000rpm for 2h, then cool down to 50°C and release the vacuum;

[0049] (2) Then add silane-modified polymer resin, hyperbranched polysiloxane resin and water-removing agent, and continue stirring and mixing for 30 minutes at normal temperature and pressure;

[0050] (3) Then add coupling agent, light stabilizer, ultraviolet absorber and catalyst in turn, after dispersing and mixing for 15 minutes, then stir for 5 minutes at a vacuum degree of -0.1MPa, and finally remove the vacuum to obtain the high-strength self-flowing Flat silane coating.

[0051] The powder filler includes heavy calcium, carbon black and barium sulfate at a mass ratio of 5:1:5.

[0052] The silane-modified polymer resin is Desmoseal SXP2636 from Covestro Polymers (China) Co., Ltd.; the plasticizer is polyether PPG3000 from Tianjin Petrochemical No. 3 Plant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com