Novel slab ballastless track structure

A slab-type ballastless track, a new technology, applied in the direction of track, road, ballast layer, etc., can solve the problems of poor maintainability of track slab longitudinal connection structure, difficulty in construction quality control, poor adaptability of long-span bridges with anti-deformation ability, etc. To achieve the effect of reducing the corner warpage of the unit slab track structure, considering reasonable structural design and force, and reducing waste of raw materials and social resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

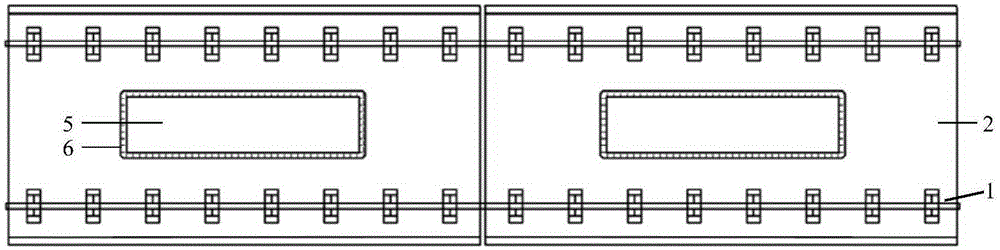

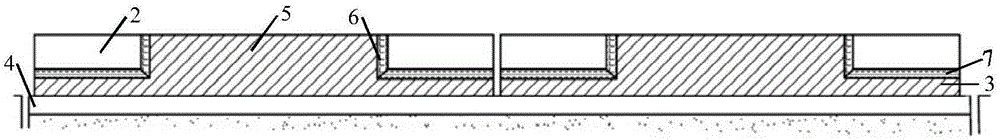

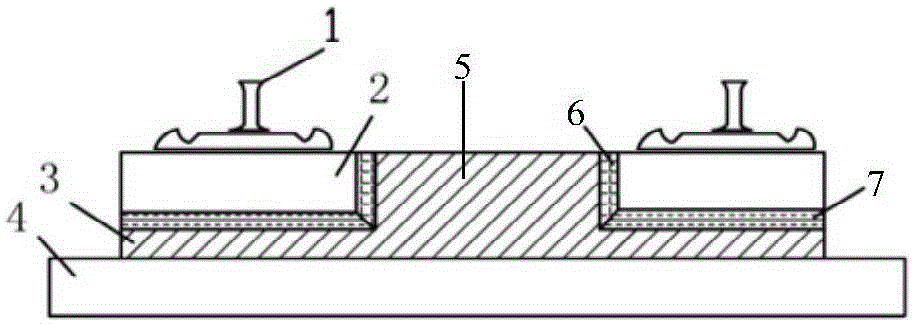

[0037] A new type of slab ballastless track provided by the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0038] The novel slab ballastless track according to the invention comprises a steel rail 1 , at least one prefabricated track slab unit and at least one base 4 . Each of the at least one prefabricated track slab unit is composed of a prefabricated track slab 2 and an adjustment layer 3 and is arranged on a corresponding base. In each prefabricated track slab unit, the adjustment layer 3 is arranged on the base 4, and the prefabricated track slab 2 is arranged on the adjustment layer 3 and at least one through hole is formed in the middle, and the adjustment layer 3 is provided with corresponding fittings on each The limiting boss 5 in the through hole has a shape corresponding to the shape of the through hole, and the steel rail 1 is arranged on the prefabricated tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com