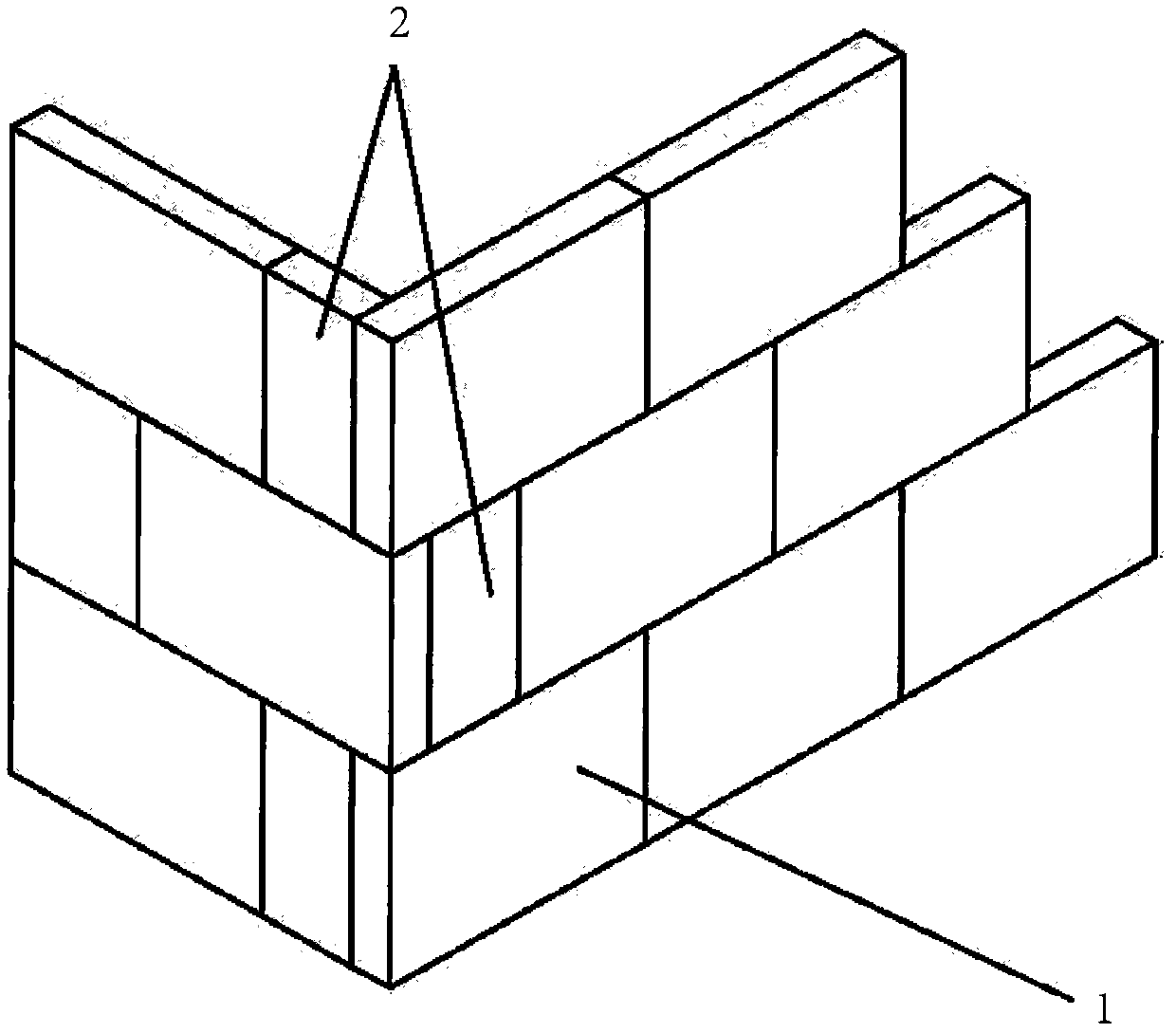

Green and environment-friendly wall system

A green and environmentally friendly, wall technology, applied in the direction of walls, building components, applications, etc., can solve the problems of unsatisfactory operability of adhesives, affecting project quality, low curing strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Preparation of gypsum blocks:

[0094] Weighing materials:

[0095] ● Natural gypsum powder 100Kg

[0096] ● Sodium methyl siliconate 0.8Kg

[0097] ● Diatomaceous earth 1.8Kg

[0098] ● PP fiber 0.1Kg

[0099] ● Perlite 1.5Kg

[0100] ● Sodium Lauryl Sulfate 1.9Kg

[0101] Put the natural gypsum powder and 77Kg water into the mixer through the automatic metering system, start the mixer, and stir for 1 to 2 minutes to make a slurry, and the mixed gypsum slurry is poured into the vertical mold cavity of the molding machine. Automatic scraping, and then the hydraulic jacking machine ejects the mold cavity, and then starts the gypsum block space fixture, clamps the gypsum block group, walks along the vertical fixture track, and grabs the gypsum block by the automatic fixture to make the gypsum block The block is out of the mold. The resulting gypsum blocks are cube-shaped wall materials with grooves and keys all around.

[0102] When natural drying is adopted, the ...

Embodiment 2

[0110] Preparation of gypsum blocks: weighing and preparing materials:

[0111] ● Desulfurization gypsum powder 100Kg

[0112] ● Sodium methyl siliconate 2.0Kg

[0113] ● Diatomaceous earth 3.2Kg

[0114] ● PP fiber 0.01Kg

[0115] ● Perlite 2.0Kg

[0116] ● Sodium Lauryl Sulfate 2.7Kg

[0117] Put the natural gypsum powder and 90Kg water into the mixer through the automatic metering system, start the mixer, and stir for 1 to 2 minutes to make a slurry, and the mixed gypsum slurry is poured into the vertical mold cavity of the molding machine. Automatic scraping, and then the hydraulic jacking machine ejects the mold cavity, and then starts the gypsum block space fixture, clamps the gypsum block group, walks along the vertical fixture track, and grabs the gypsum block by the automatic fixture to make the gypsum block The block is out of the mold. The resulting gypsum blocks are cube-shaped wall materials with grooves and keys all around.

[0118] The artificial drying m...

Embodiment 3

[0125] Preparation of gypsum blocks:

[0126] Weighing materials:

[0127] ● Desulfurization gypsum powder 100Kg

[0128] ● Sodium methyl siliconate 1.2Kg

[0129] ● Diatomaceous earth 2.5Kg

[0130] ● PP fiber 0.1Kg

[0131] ● Perlite 1.8Kg

[0132] ● Sodium Lauryl Sulfate 2.2Kg

[0133] Put the natural gypsum powder and 95Kg water into the mixer through the automatic metering system, start the mixer, and stir for 1 to 2 minutes to make a slurry, and the mixed gypsum slurry is poured into the vertical mold cavity of the molding machine. Automatic scraping, and then the hydraulic jacking machine ejects the mold cavity, and then starts the gypsum block space fixture, clamps the gypsum block group, walks along the vertical fixture track, and grabs the gypsum block by the automatic fixture to make the gypsum block The block is out of the mold. The resulting gypsum blocks are cube-shaped wall materials with grooves and keys all around.

[0134] When natural drying is adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com