Stranded carbon fiber composite core soft aluminum wire and fabrication method thereof

A carbon fiber and stranded technology, which is applied to the stranded carbon fiber composite core soft aluminum wire and its production field, can solve the problems that it is difficult to ensure the smooth progress of the project, the isolation performance cannot be satisfied, the safety cannot be guaranteed, etc. Safety and construction convenience, improved structural strength and flexibility, and good drape performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

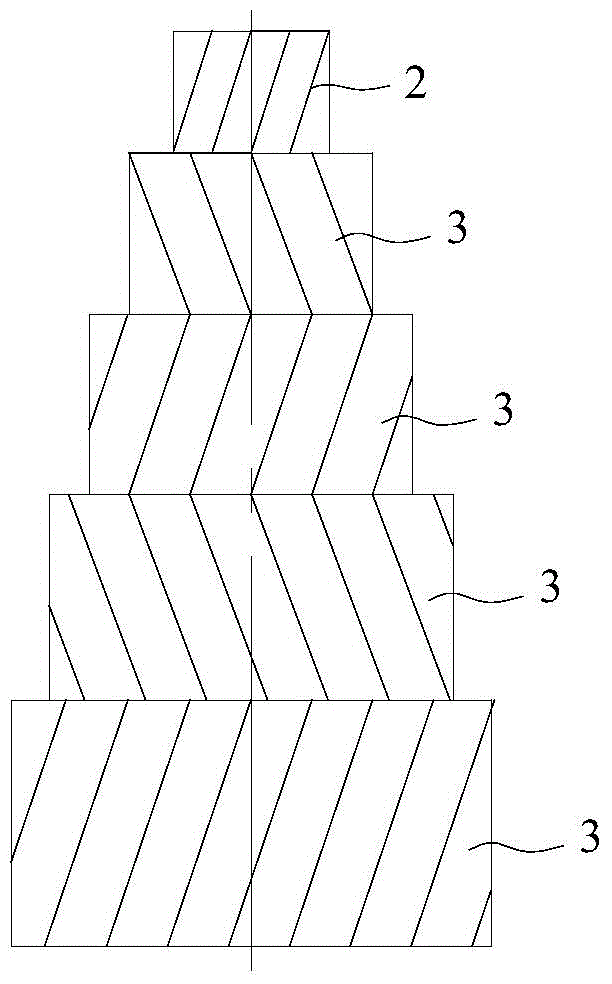

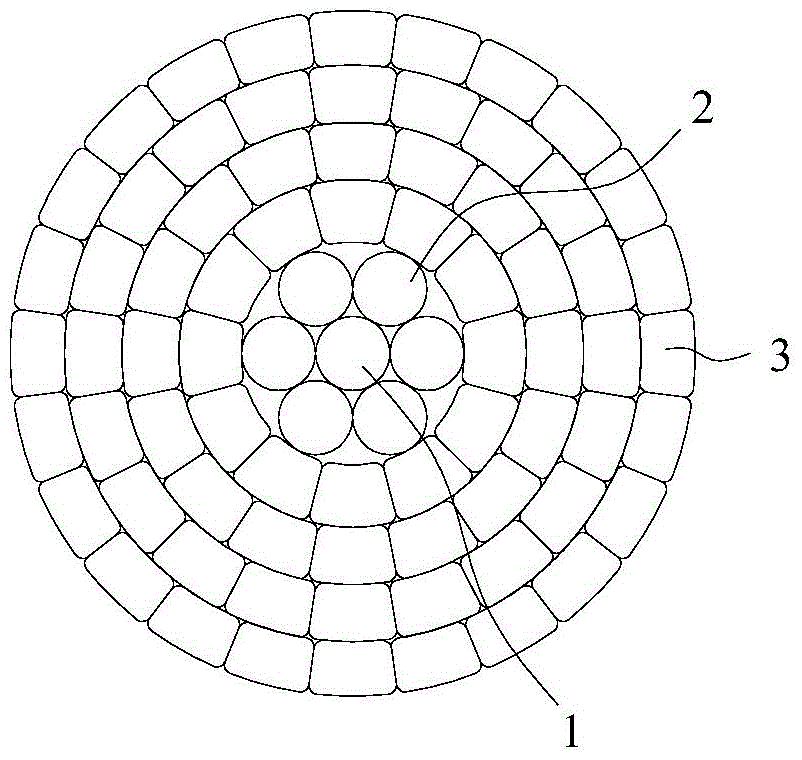

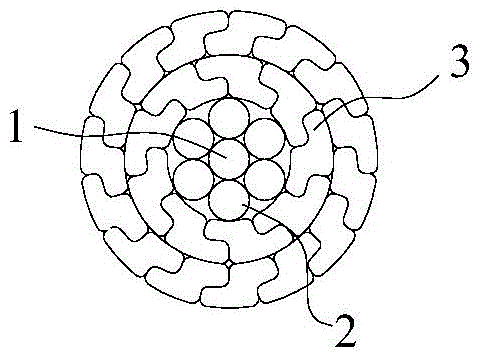

[0032] The present invention provides a stranded carbon fiber composite core annealed aluminum wire, which includes a wire core and a conductive layer covering the wire core, the wire core includes a carbon fiber main core 1 and several helically tightly twisted carbon fiber cores The carbon fiber secondary core 2 outside the main core 1, the conductive layer includes at least one annealed aluminum wire layer, and the annealed aluminum wire layer includes several annealed aluminum wires 3 tightly twisted in a helical shape outside the wire core. The twisting direction of the soft aluminum conductor 3 of the soft aluminum conductor layer close to the wire core is opposite to that of the carbon fiber secondary core 2 .

[0033] When the conductive layer includes at least two annealed aluminum wire layers, the twisting directions of the annealed aluminum wires 3 in two adjacent annealed aluminum wire layers are opposite.

[0034] refer to figure 1 , figure 2 , the carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com