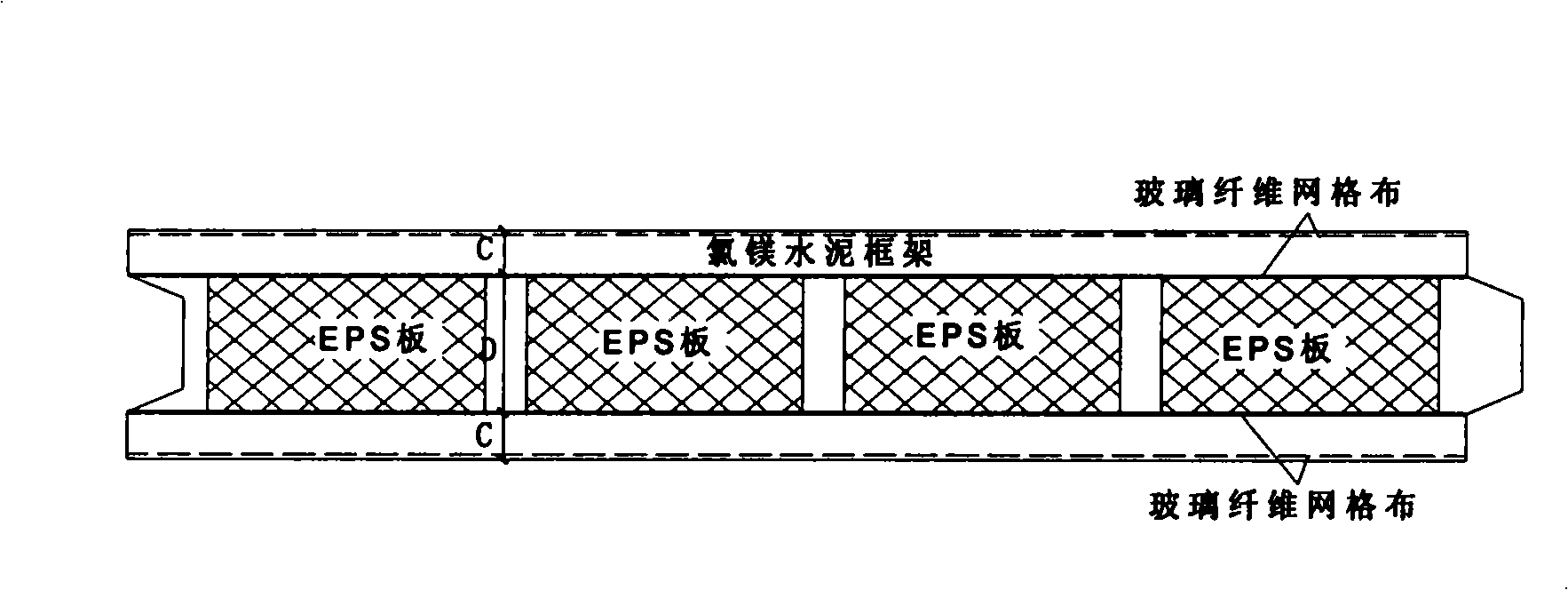

Light composite internal partition plate

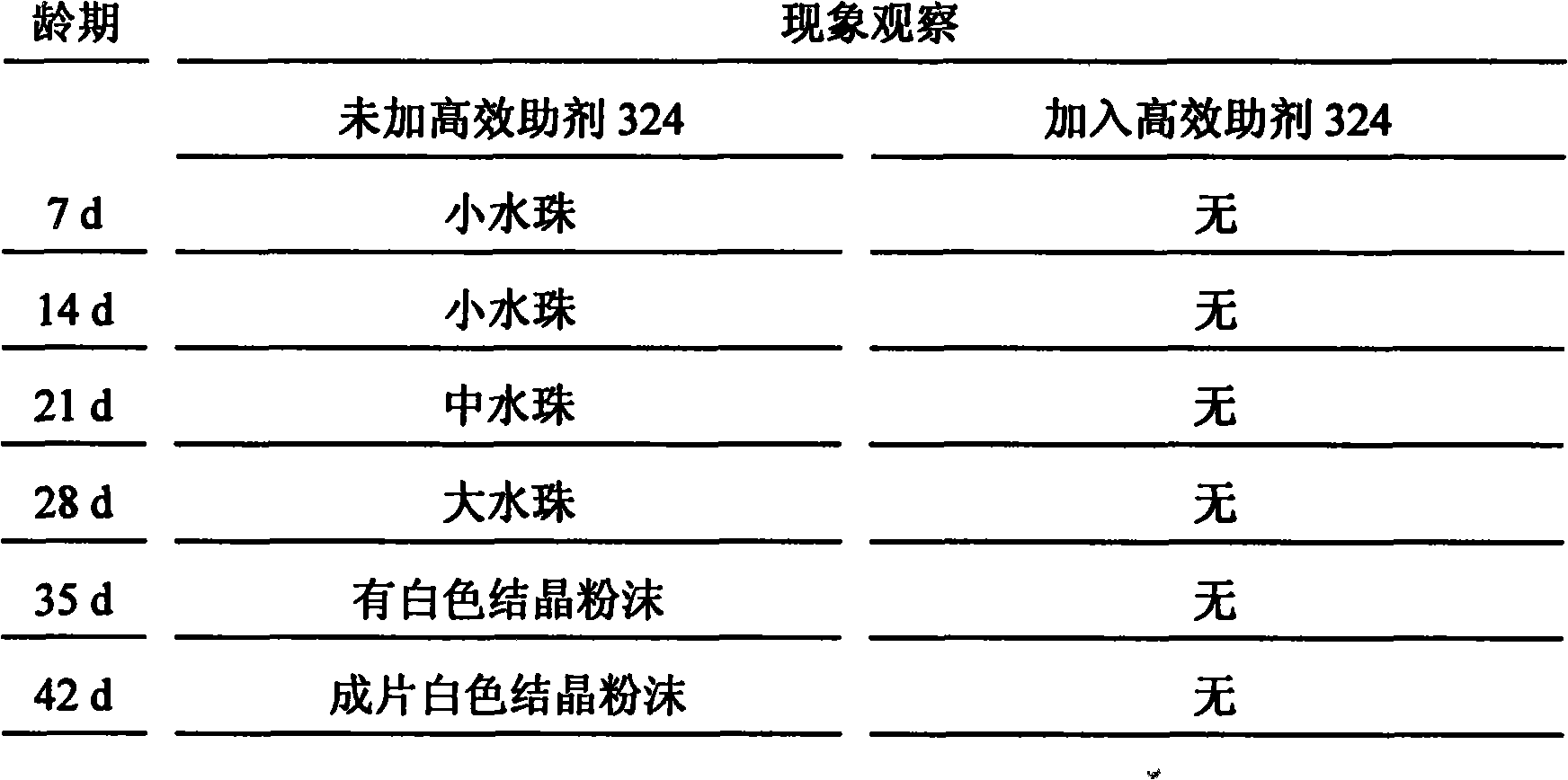

A kind of interior partition wall and lightweight technology, which is applied in the direction of walls, building components, sustainable waste treatment, etc., can solve the problems of reduced strength of wallboards and high water absorption of products, so as to reduce uneven deformation of the board surface and low density , Inhibit the effect of moisture absorption and return to halogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

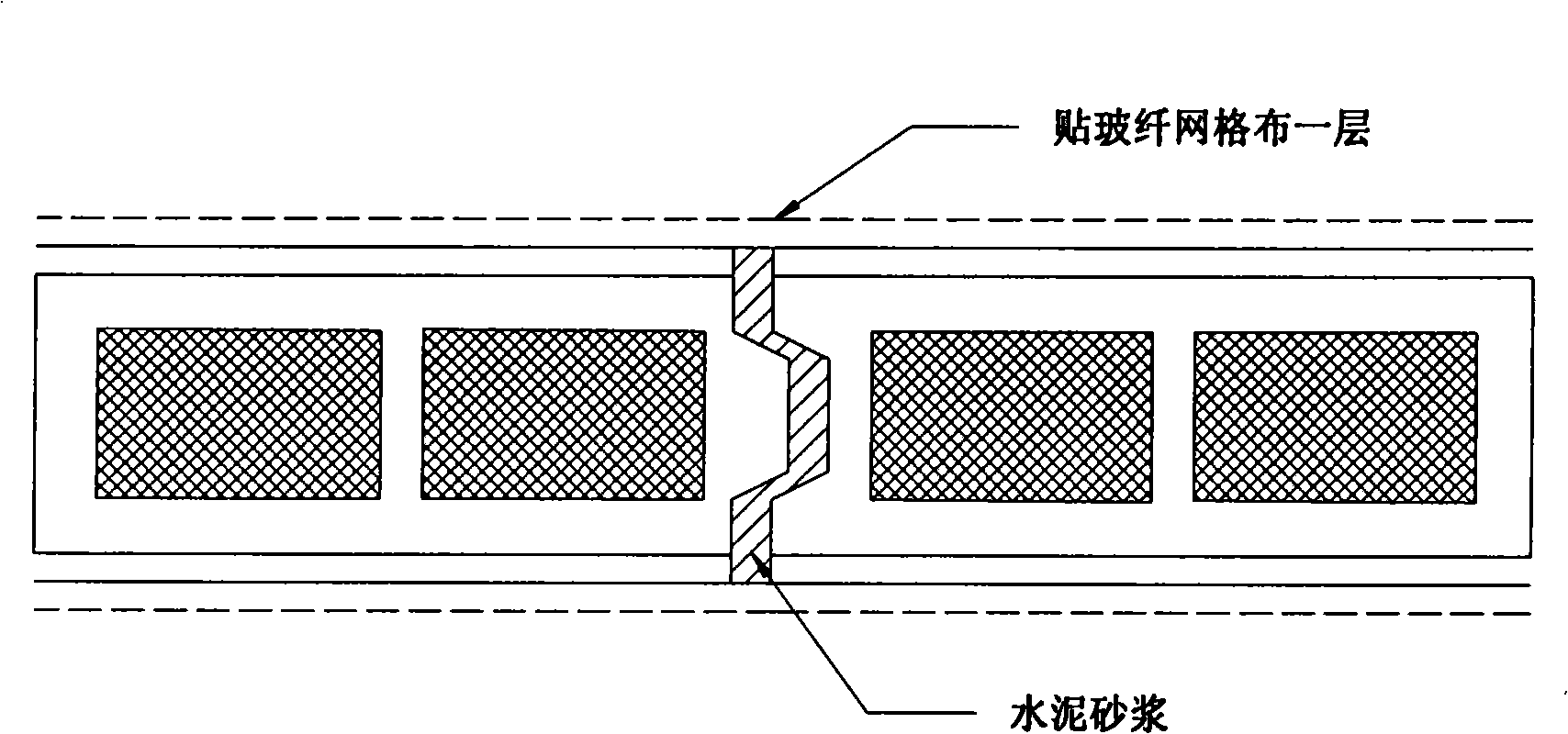

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, design bulk density 800-900kg / m 3 : The temperature is always 25-29°C; the magnesium oxide index is 83%; the loss on ignition is 4.0-5.0%, and the magnesium chloride is 20kg or MgCl 2 The Baume specific gravity of the solution is designed at 23-24 degrees, and at the same time add 80kg of magnesium oxide, 40kg of fly ash; 20kg of sawdust; when stirring, add an appropriate amount of high-efficiency additives about 500-600mL.

Embodiment 2

[0047] Embodiment 2, design bulk density 900-1000kg / m 3 : The temperature is always 20-25℃; the magnesium oxide index is 83%; the ignition loss is 4.0-5.0%, and the magnesium chloride is 20kg or MgCl 2 The Baume specific gravity of the solution is designed at 22-23.5 degrees, and at the same time add 75kg of magnesium oxide, 45kg of fly ash; 20kg of sawdust; when stirring, add an appropriate amount of high-efficiency additives about 400-500mL.

Embodiment 3

[0048] Embodiment 3, design bulk density 800-950kg / m 3 : The temperature is always 17-21°C; the content of magnesium oxide is 85%; the loss on ignition is 4.0-5.0%, and magnesium chloride 20kg or MgCl 2 The Baume specific gravity of the solution is designed at 24-25 degrees, and at the same time add 85kg of magnesium oxide, 35kg of fly ash; 20kg of sawdust; when stirring, add an appropriate amount of high-efficiency additives about 700-800mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com