Casting-milling process method for manufacturing copper and copper alloy band

A technology of copper alloy strip material and processing method, which is applied in the direction of manufacturing tools, metal processing equipment, metal rolling, etc., can solve the problems of poor plastic deformation ability of as-cast structure, high cost of strip manufacturing, and high product manufacturing cost. Effects of reducing processing steps, improving rolling efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

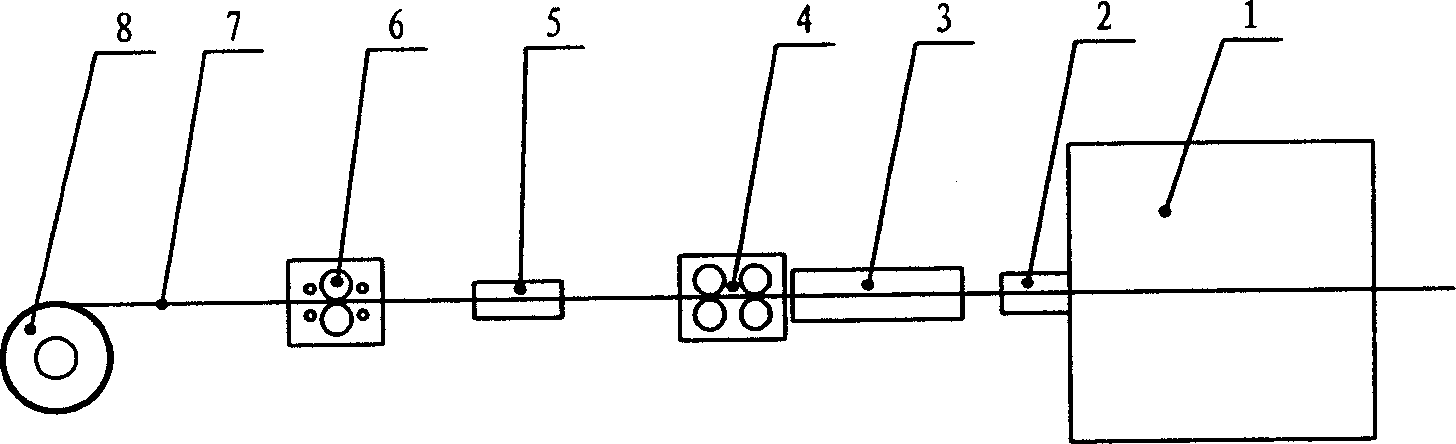

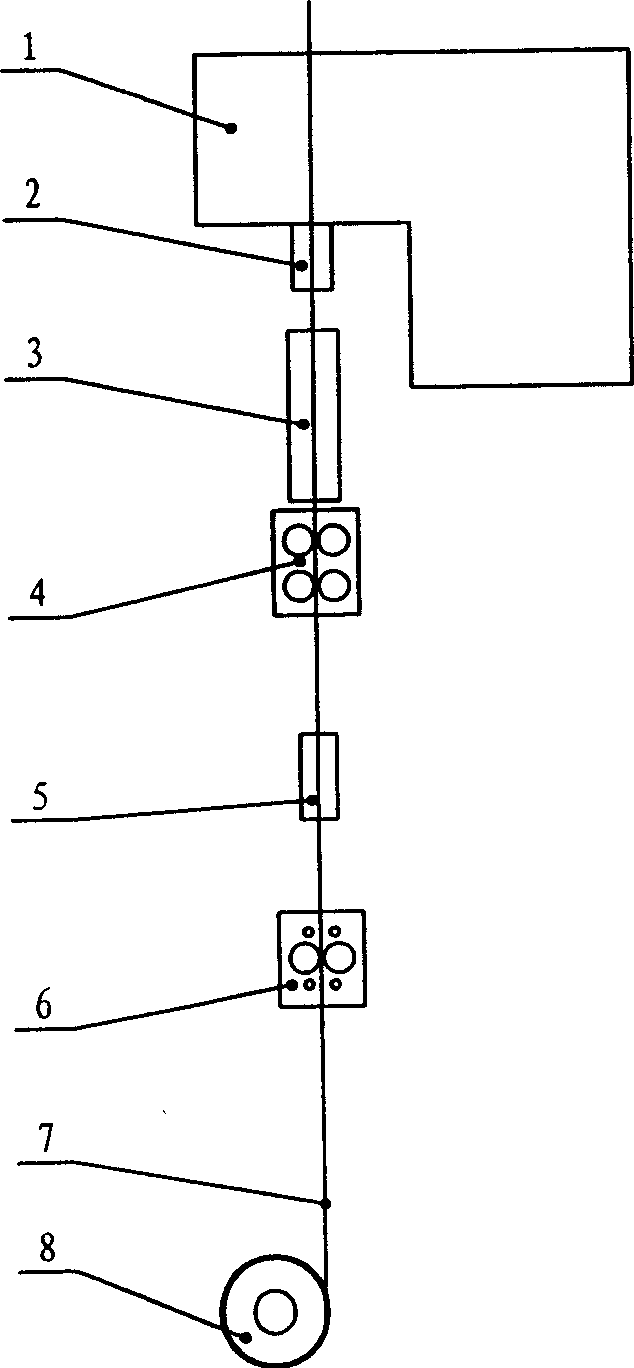

[0034] see figure 1 , figure 2 , In the figure: 1 is the continuous casting furnace, 2 is the crystallizer, 3 is the insulation cover, 4 is the strip mill, 5 is the water bath channel, 6 is the milling machine, 7 is the strip billet, and 8 is the coiler. According to a kind of cast-rolling processing method of manufacturing copper and copper alloy strip material provided by the present invention, comprises the following steps:

[0035] The first step, strip continuous casting, heat preservation, and uniform temperature treatment step: use a continuous casting machine with adjustable strip temperature to continuously cast copper and copper alloys into strips 7, and then exit the mold of the continuous casting machine under a protective atmosphere The strip blank 7 is subjected to heat preservation and uniform temperature treatment, so that the strip blank 7 is above the recrystallization initiation temperature of the corresponding material, preferably at a temperature of 450°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com