Thermal imaging defect detection method based on convolution auto-encoder image amplification

A convolutional self-encoding and defect detection technology, applied in the field of thermal imaging defect detection based on convolutional self-encoder image amplification, can solve problems such as limitations, improve quality, improve accuracy and reliability, and reduce image noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings.

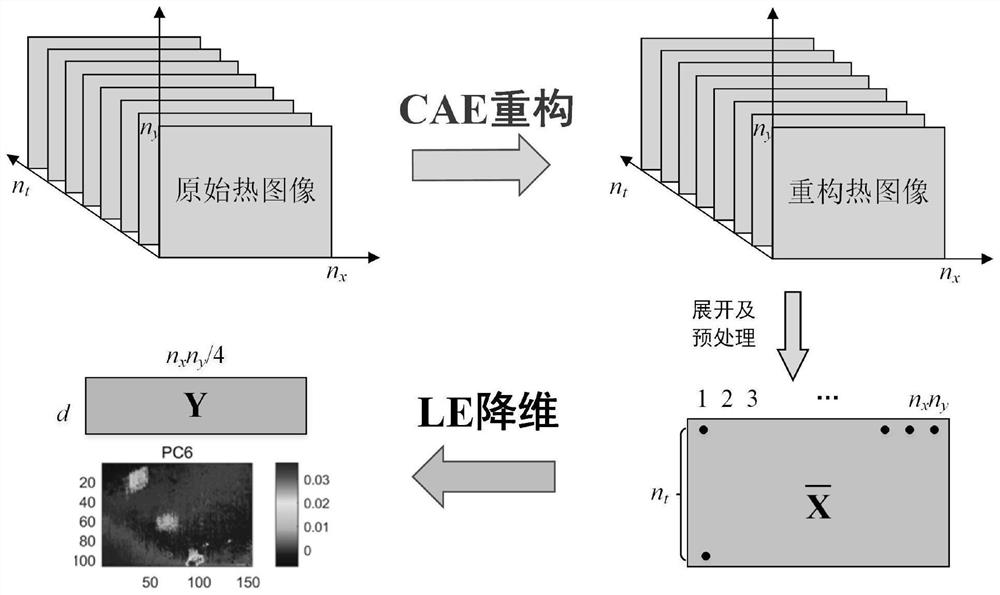

[0056] refer to Figure 1 to Figure 5 , based on the manifold learning thermal imaging defect detection method of autoencoder image enhancement, the method comprises the following steps:

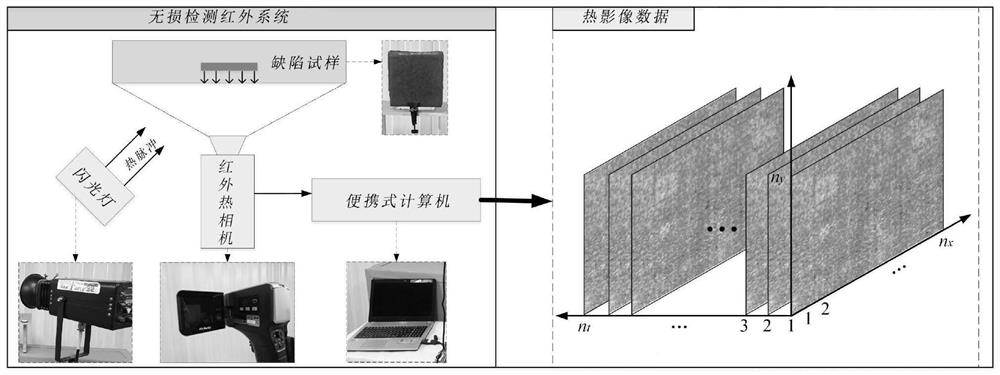

[0057] Step 1. Obtain the thermal image and thermal image data of the carbon fiber reinforced polymer composite material.

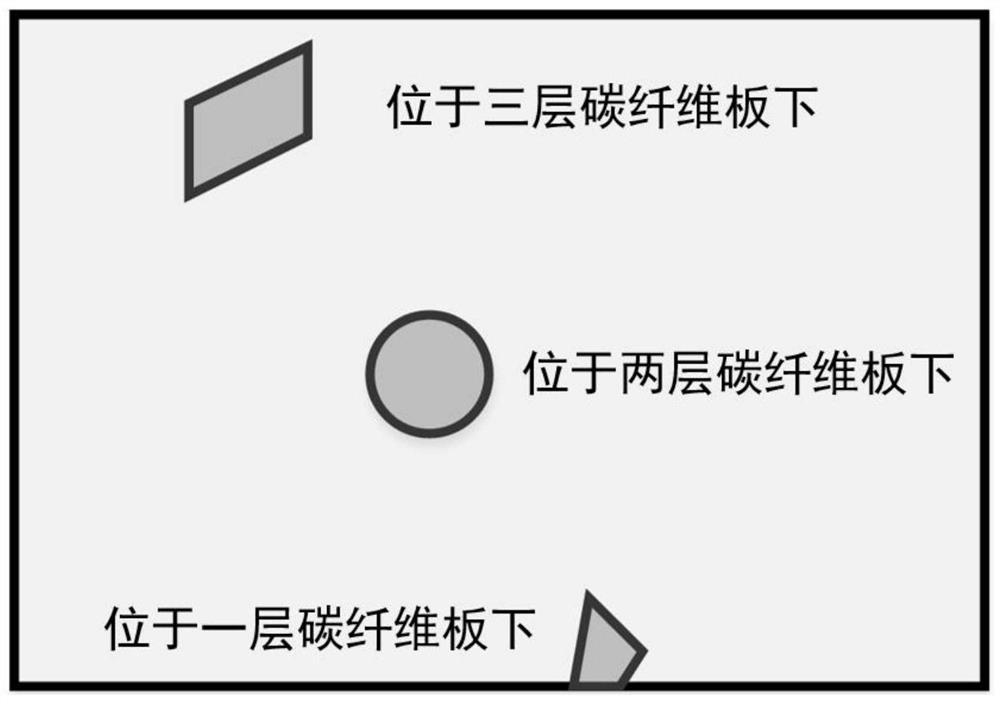

[0058] Resin transfer molding is used to manufacture rectangular carbon fiber reinforced polymer samples with a size of 18cm×18cm and thickness, and three polytetrafluoroethylene strips of trapezoidal, circular, and diamond shapes are inserted at different depths inside to simulate defects, and the size of each defect area about 3cm 2 . The IRT system is established, and the working flash excites the thermal pulse to heat the sample. After the thermal front touches the surface of the experimental sample and passes through the sample, an infrared thermal camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com