CFRP-embedded-anode reinforcing-steel-bar-concrete cathode protection method and device

A reinforced concrete and cathodic protection technology, which is applied in the field of reinforced concrete cathodic protection, can solve problems such as troublesome construction, high energy consumption, and difficulty in guaranteeing bonding strength, and achieve the effects of reducing engineering costs, high bonding strength, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

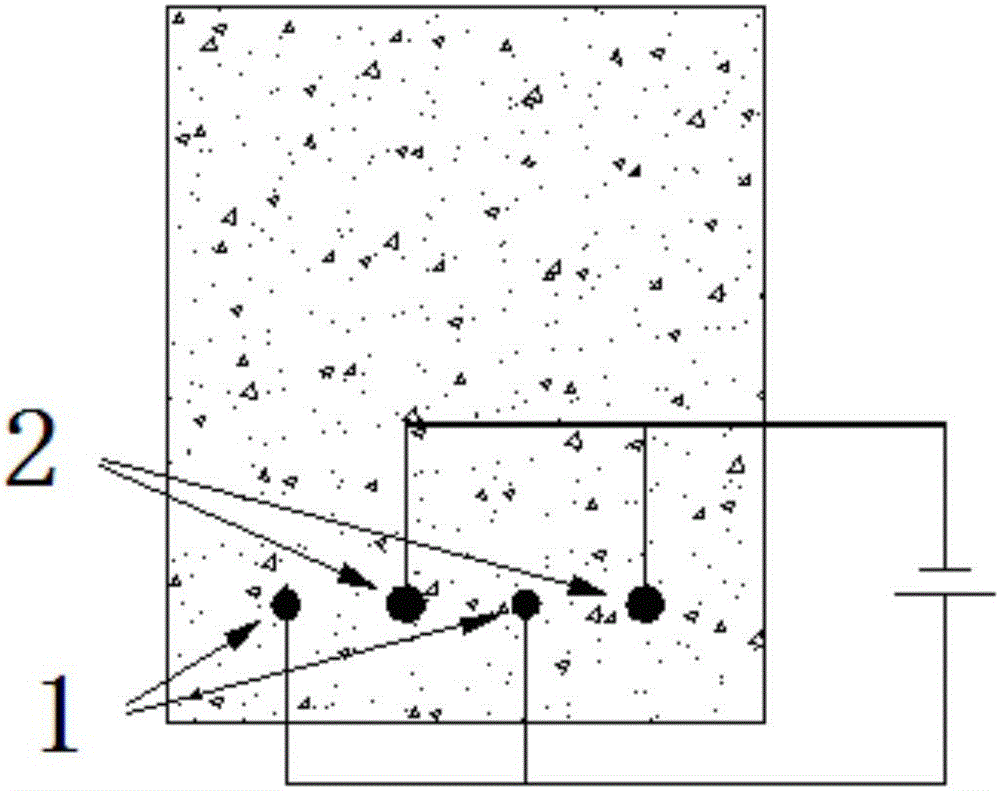

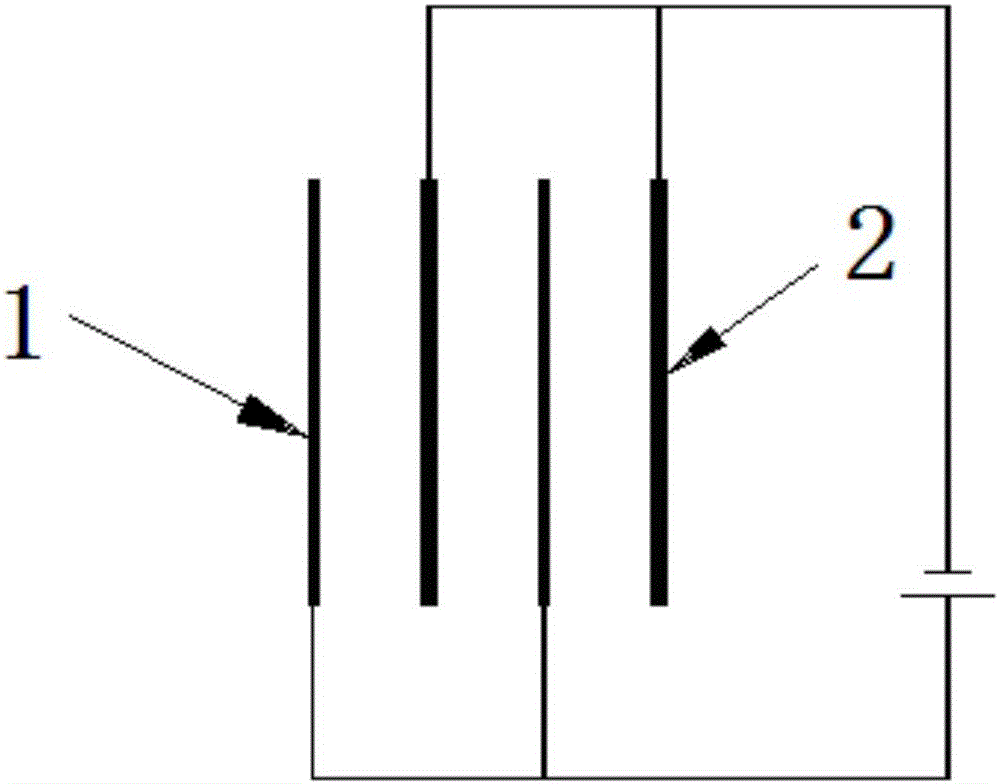

[0032] The concrete structure of embodiment 1 single-layer reinforcement is as figure 1 and figure 2 As shown, for a reinforced concrete structure with single-layer reinforcement, when the structure is poured (or component prefabrication), CFRP composite stress bars are arranged at intervals between the common steel bars, and then the CFRP composite stress bars and ordinary The steel bars are connected in parallel, and the CFRP composite stress bars are connected to the positive pole of the DC power supply, and the ordinary steel bars are connected to the negative pole of the DC power supply to form a cathodic protection circuit; Ordinary steel bars are arranged with one CFRP composite stress bar), or they can be arranged every two (every two ordinary steel bars are arranged with a CFRP composite stress bar). After electrification, the charge (electrons) flows from the negative pole of the DC power supply to the common steel bar (cathode electrode) through the wire, which ma...

Embodiment 2

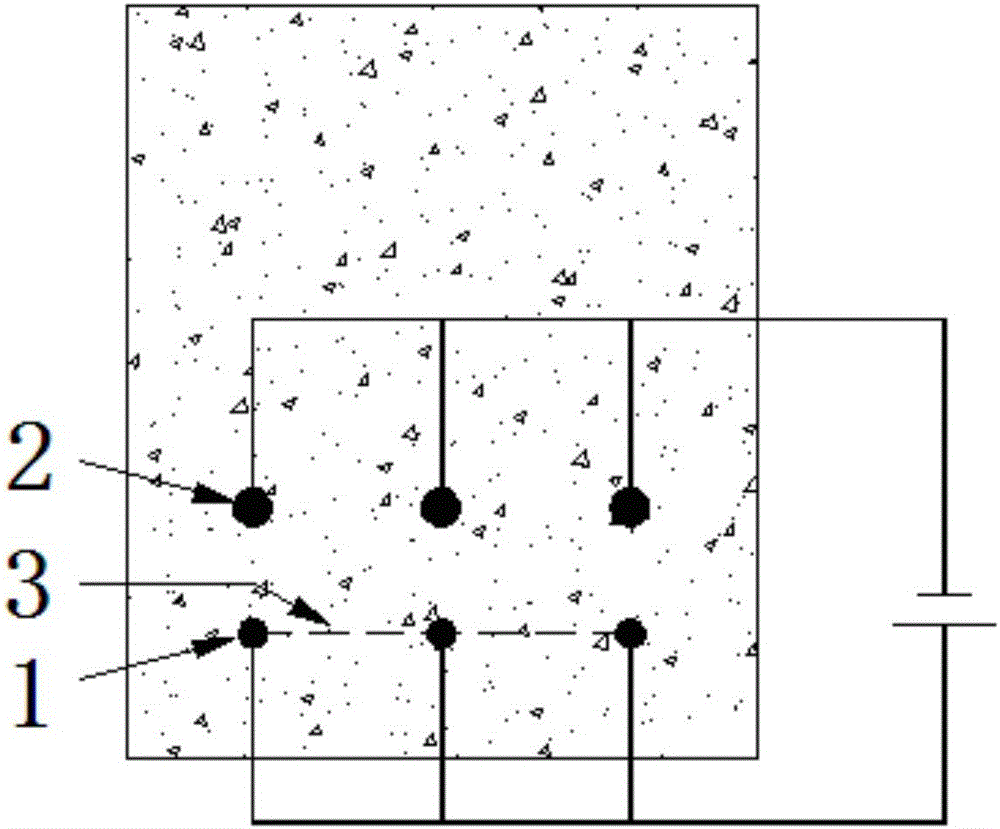

[0034] The concrete structure of embodiment 2 multi-layer reinforcement is as image 3 and Figure 4 As shown, for reinforced concrete structures with multi-layer reinforcement, in the process of pouring concrete (or component prefabrication), the carbon fiber wire-CFRP composite stress bars formed by connecting CFRP composite stress bars with continuous carbon fiber wire mesh are pre-embedded in the outer layer of the concrete structure. The number and spacing of the carbon fiber-CFRP composite stress mesh and the ordinary reinforcement layer can be adjusted according to the load on the structure and the change of environmental conditions. Due to the anode system of this device, the continuous carbon fiber wire-CFRP composite stress-reinforced mesh, and ordinary steel bars are directly installed on the structure before concrete pouring, which reduces the cathode in the cathodic protection circuit (continuous carbon fiber-CFRP composite stress-reinforced mesh) The distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com