Carbon fiber reinforced polymer rope anchor

A technology for reinforcing composite materials and cable anchors, applied in the field of anchors, can solve the problems of high maintenance cost, high production cost, unreasonable internal force, etc., and achieves improved anchoring performance, reasonable internal force, and optimized distribution form. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

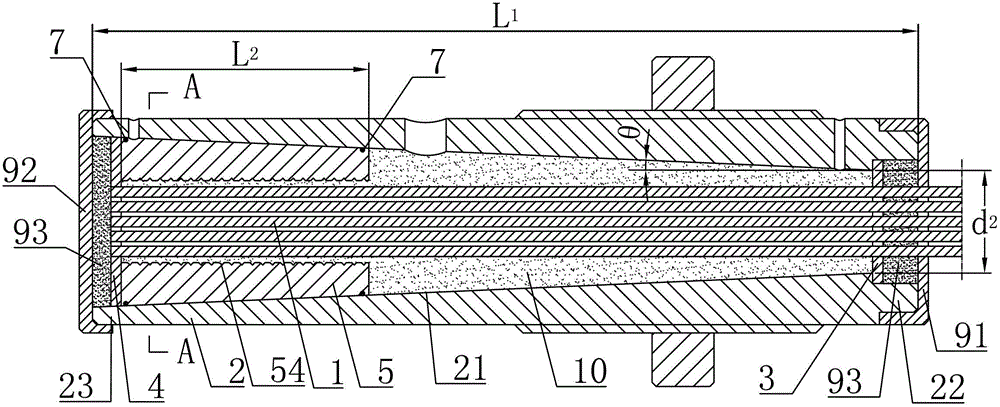

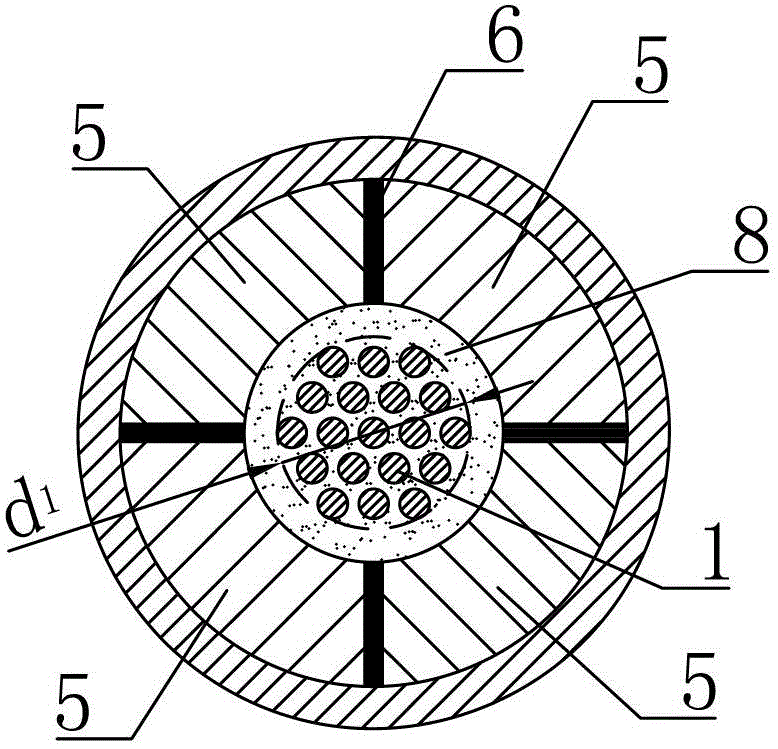

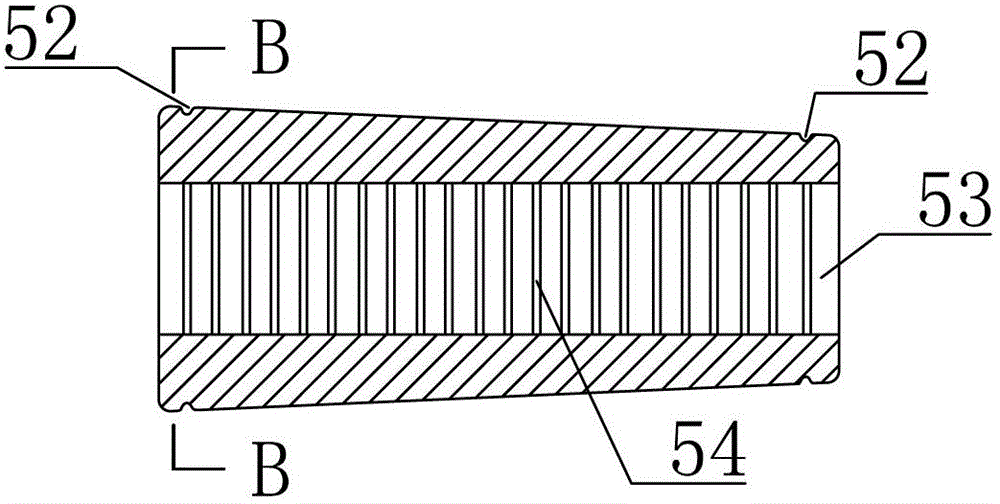

[0021] As shown in the figure, a carbon fiber reinforced composite cable anchor includes an anchor tube 2 for anchoring a CFRP cable 1, a first blocking plate 3, a second blocking plate 4 and a bonding medium 10, and the anchor tube 2 is coaxial A tapered through hole 21 is opened, and the diameter of the tapered through hole 21 is distributed from small to large from the loaded end 22 to the free end 23 of the anchor tube 2. The first blocking plate 3 is arranged at the small diameter end of the tapered through hole 21 , the second blocking plate 4 is arranged at the large-diameter end of the tapered through hole 21, the CFRP cable 1 passes through the first blocking plate 3 and the second blocking plate 4 in turn and is arranged in the tapered through hole 21, and the conical shape of the free end 23 A clip assembly surrounding the CFRP cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com