Carbon fiber reinforced polymer cable core with high elongation and production method thereof

A technology of composite materials and cable core materials, which is applied in the direction of cable/conductor manufacturing, power cables, cables, etc., and can solve problems such as fiber strength loss and excessive twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

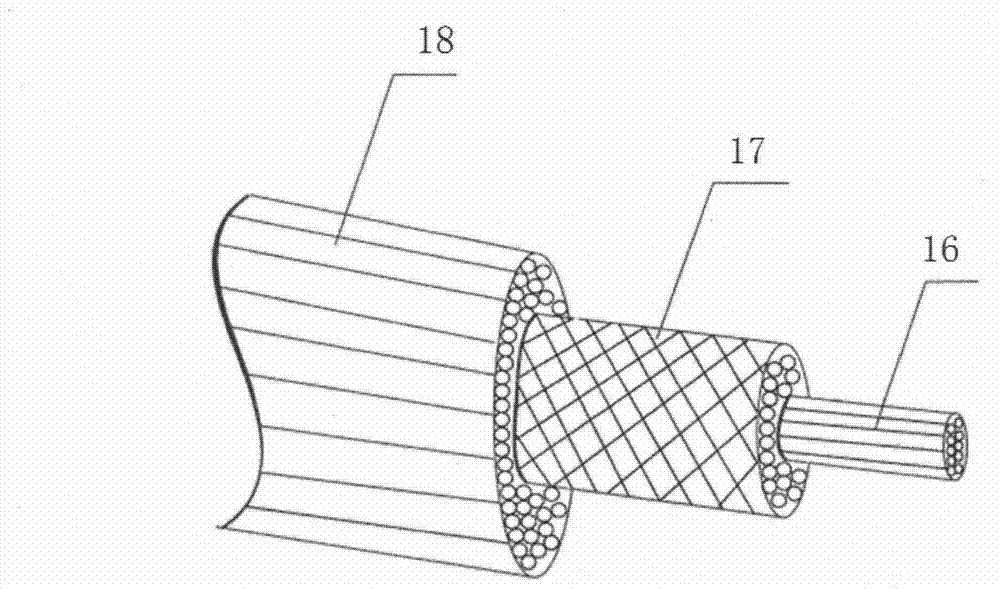

[0021] Such as figure 1 As shown, a carbon fiber composite cable core structure is composed of an aramid fiber layer 16 , a 2D braided carbon fiber layer 17 and a glass fiber insulation layer 18 . A 2D woven carbon fiber layer 17 is provided inside the glass fiber insulating layer 18 . An aramid fiber layer 16 is provided inside the 2D woven carbon fiber layer 17 .

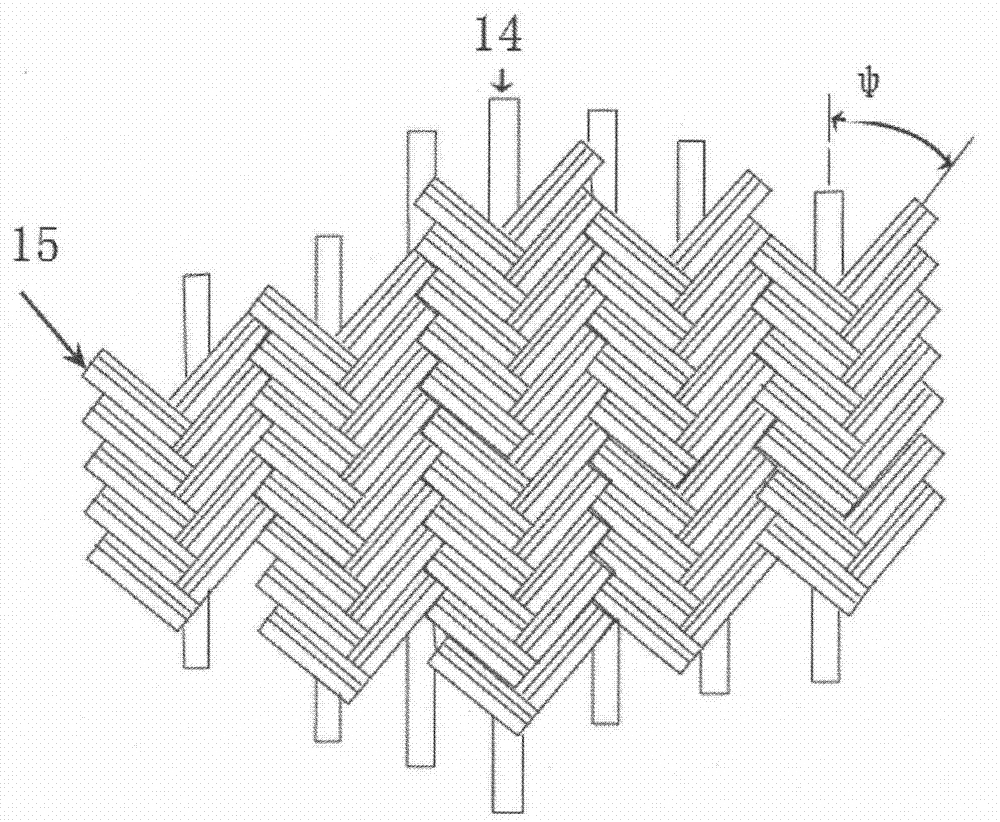

[0022] Such as figure 2 As shown, the 2D braided carbon fiber layer 17 adopts a rope structure, and the rope structure is composed of an axial yarn 14 and a braided yarn 15 arranged outside the axial yarn 14, the axial yarn 14 adopts aramid fiber, and the braided yarn 15 Made of carbon fiber.

[0023] Its manufacturing method is:

[0024] (1) Specifications of raw materials: See Table 1 for technical specifications of fibers. The formulation of the resin is shown in Table 2.

[0025] Table 1

[0026]

[0027] Table 2

[0028] Material

epoxy resin

Hardener

Accelerator

Release a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com