Patents

Literature

32results about How to "Form factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

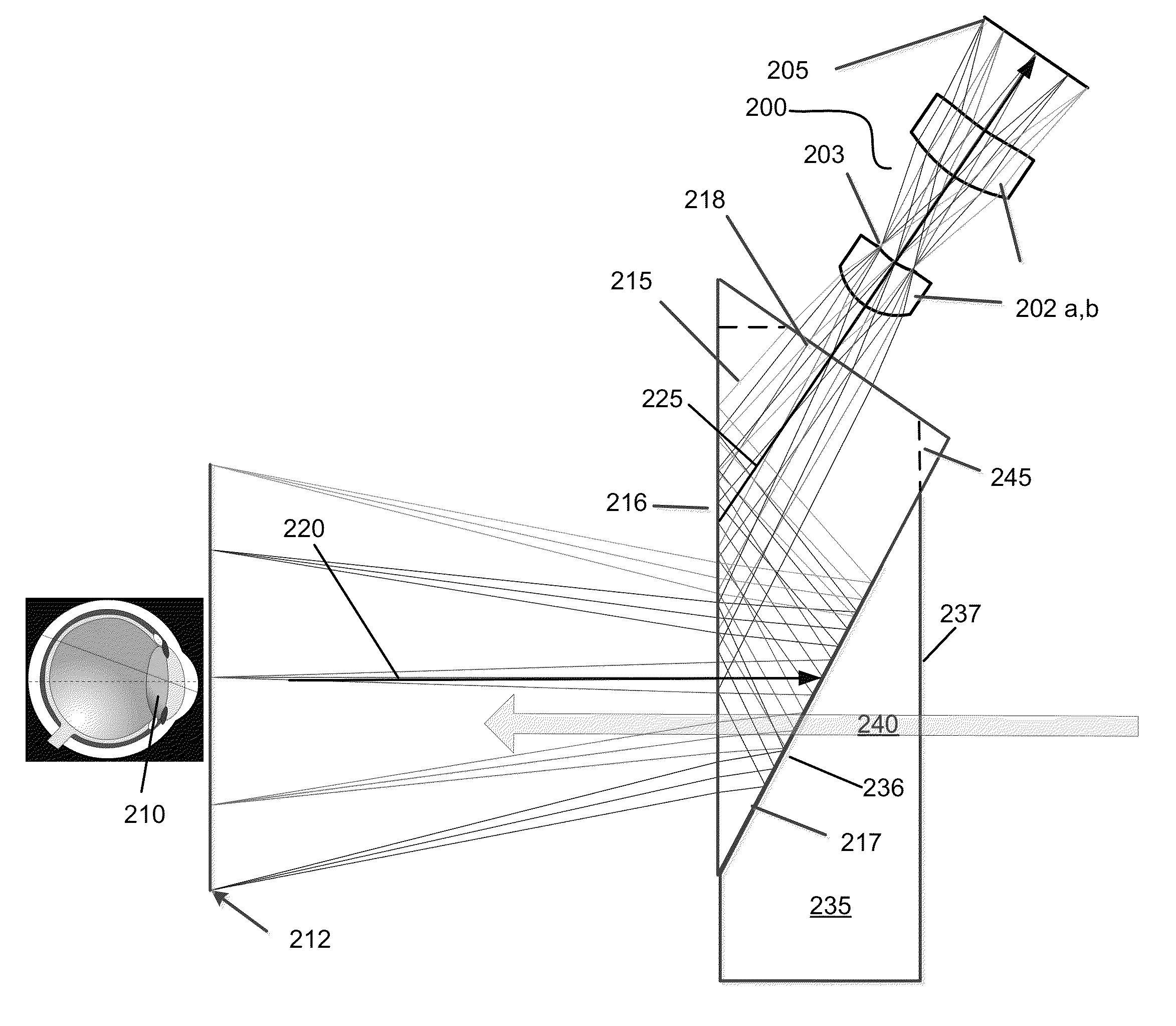

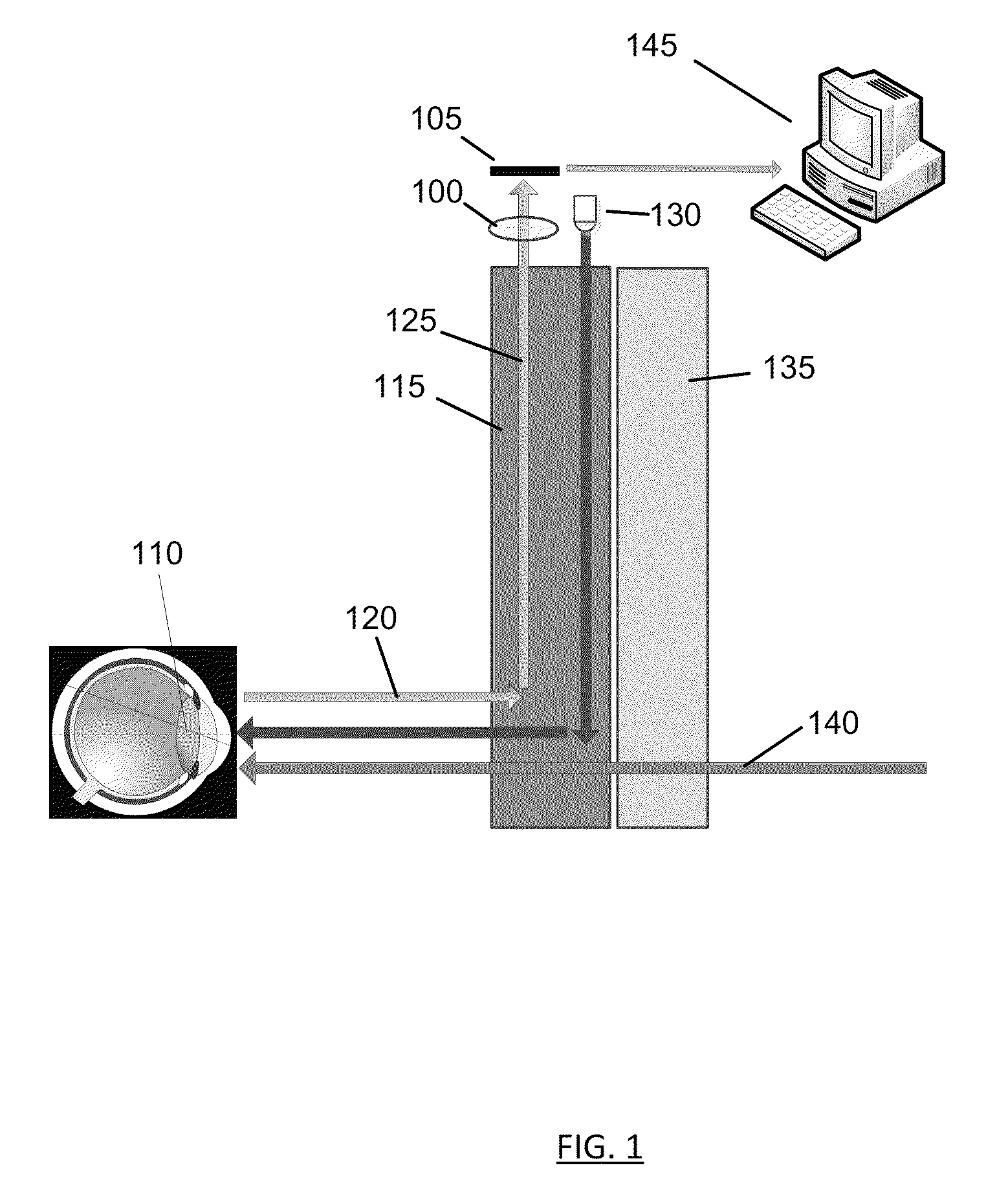

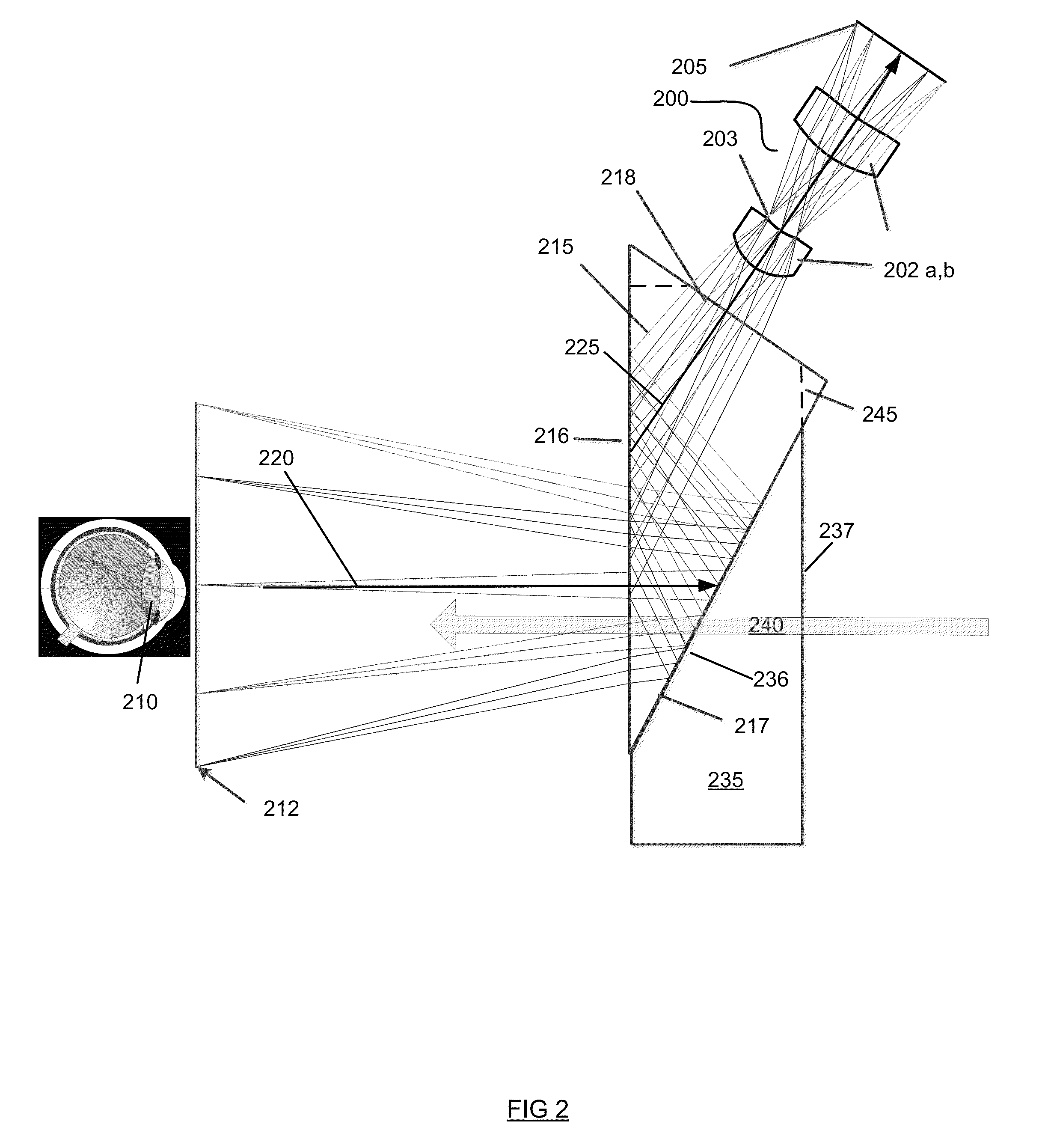

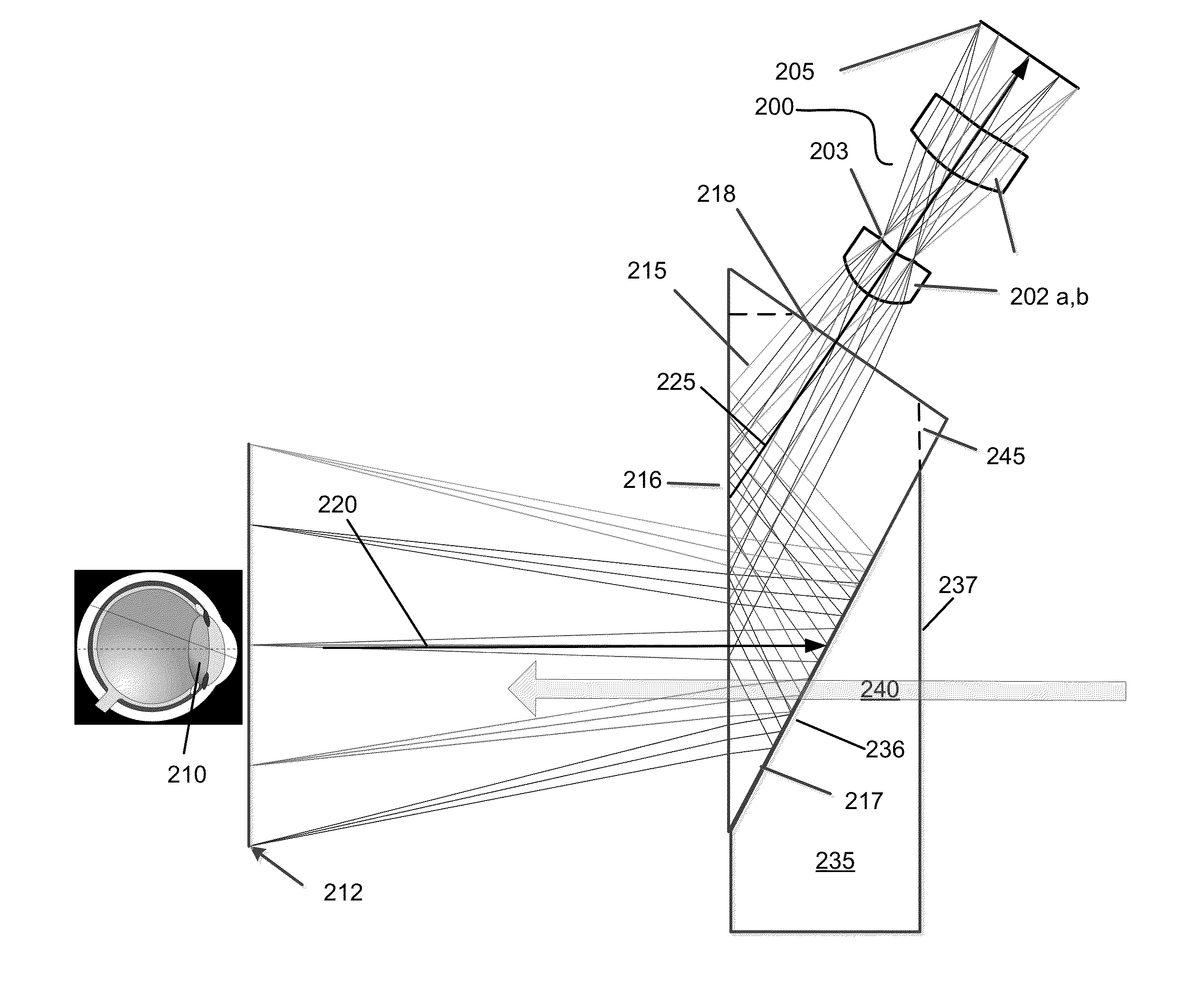

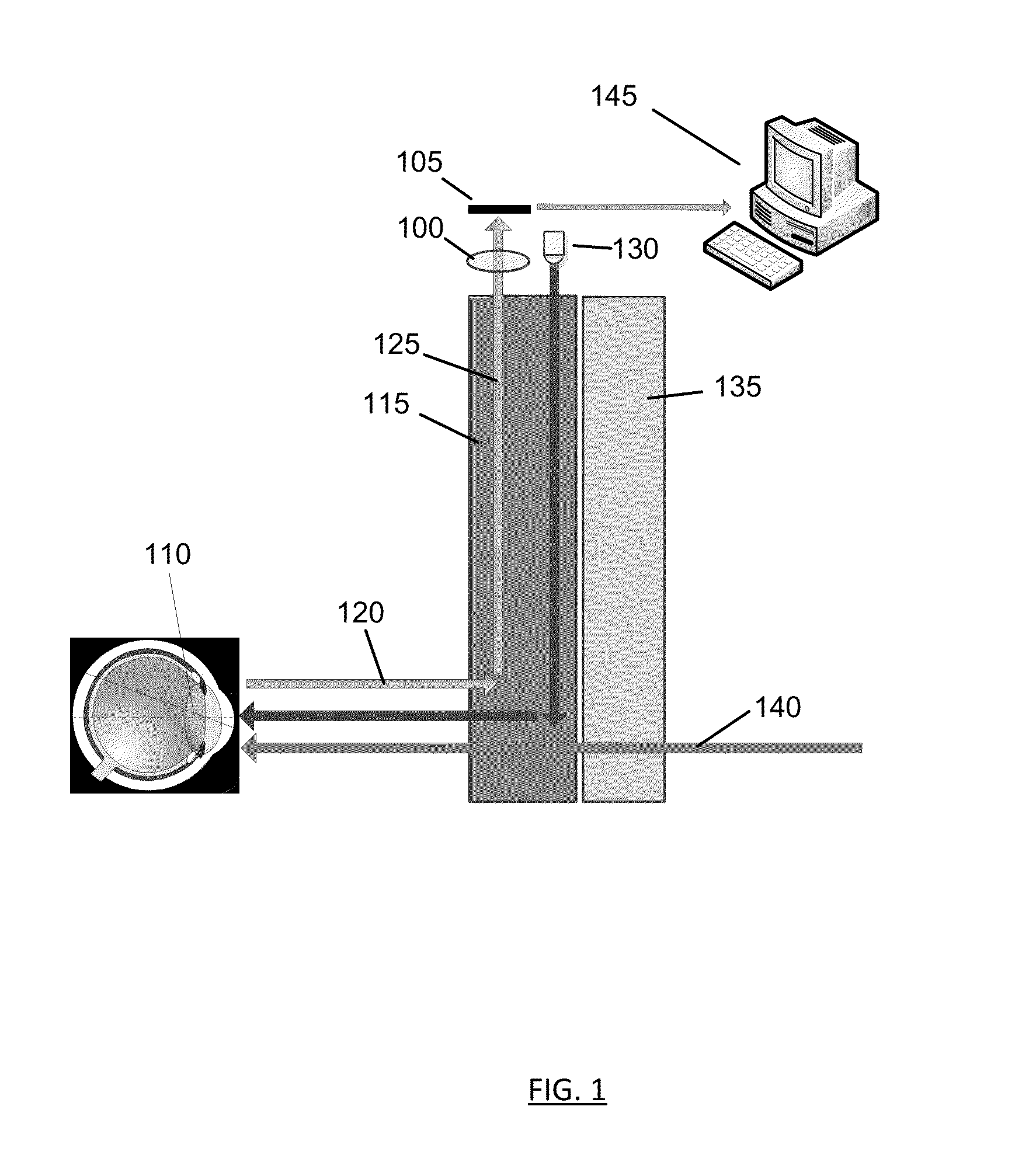

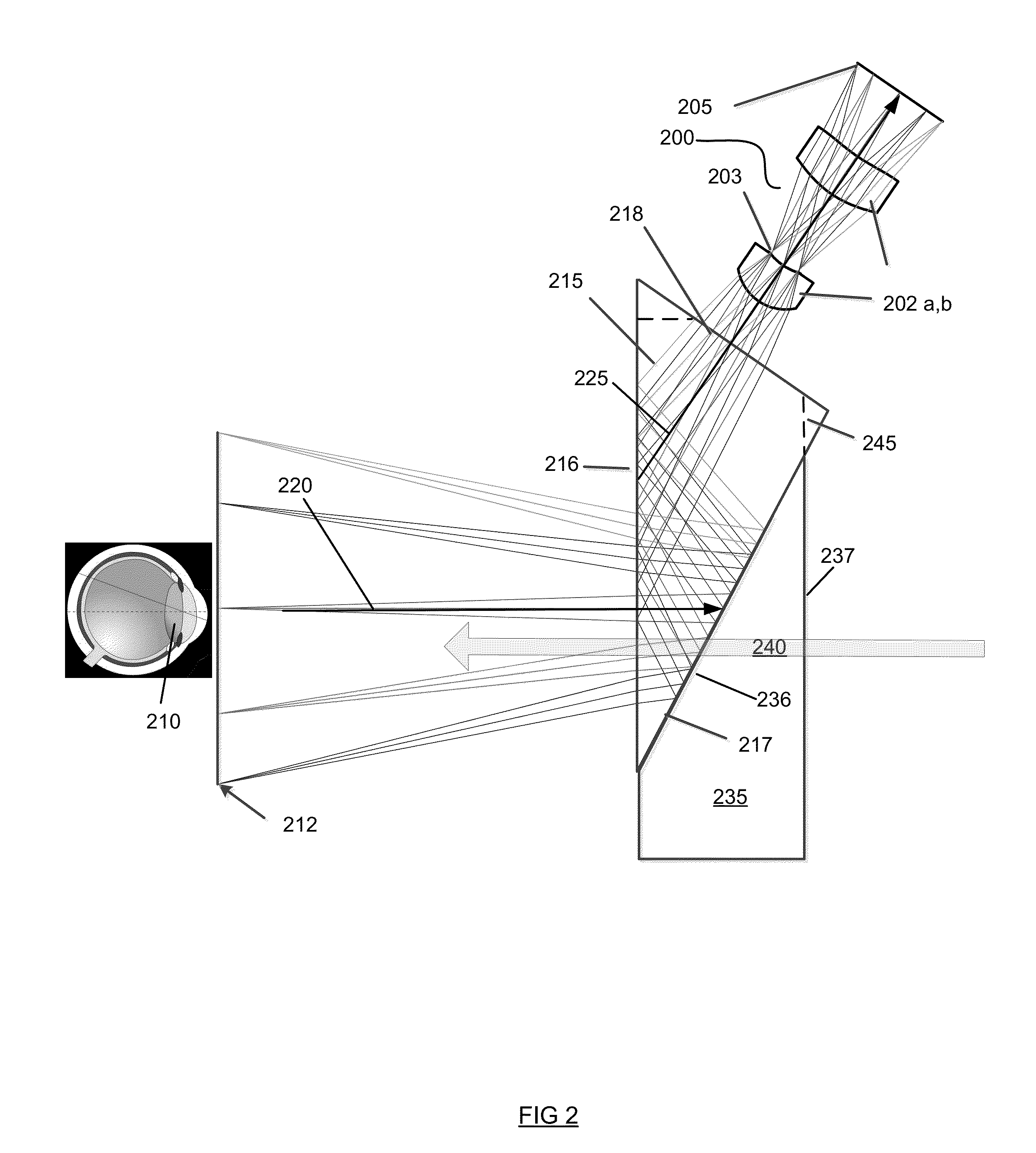

Compact eye imaging and eye tracking apparatus

ActiveUS9345402B2Minimal distortionImprove optical qualityPrismsAcquiring/recognising eyesTotal internal reflectionLight guide

An optical system for eye tracking is disclosed. The system includes a light guiding prism that guides light from an ocular object to an imaging system through multiple internal reflections. The light guiding prism may include one or more freeform surfaces having optical power.

Owner:AUGMENTED VISION

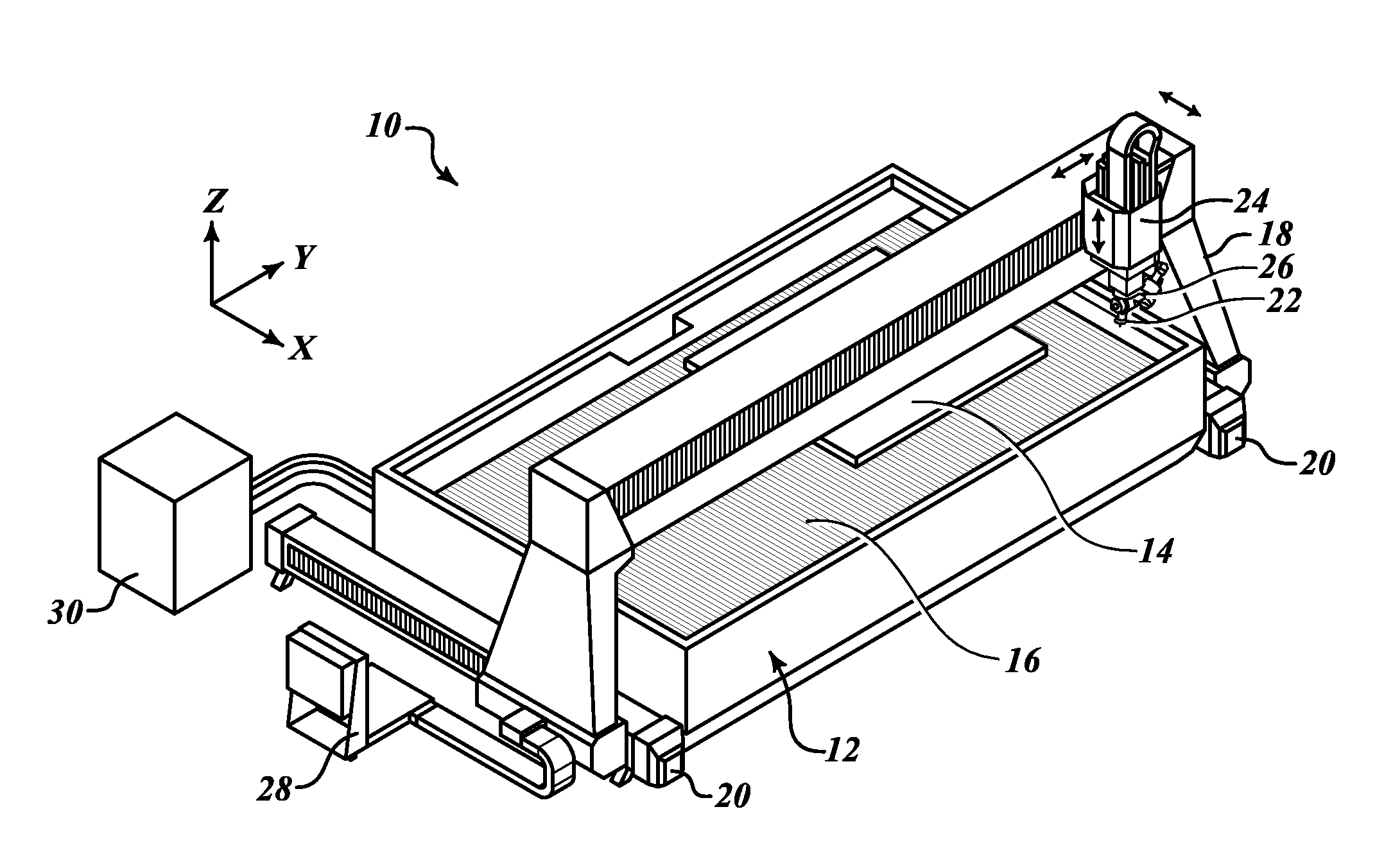

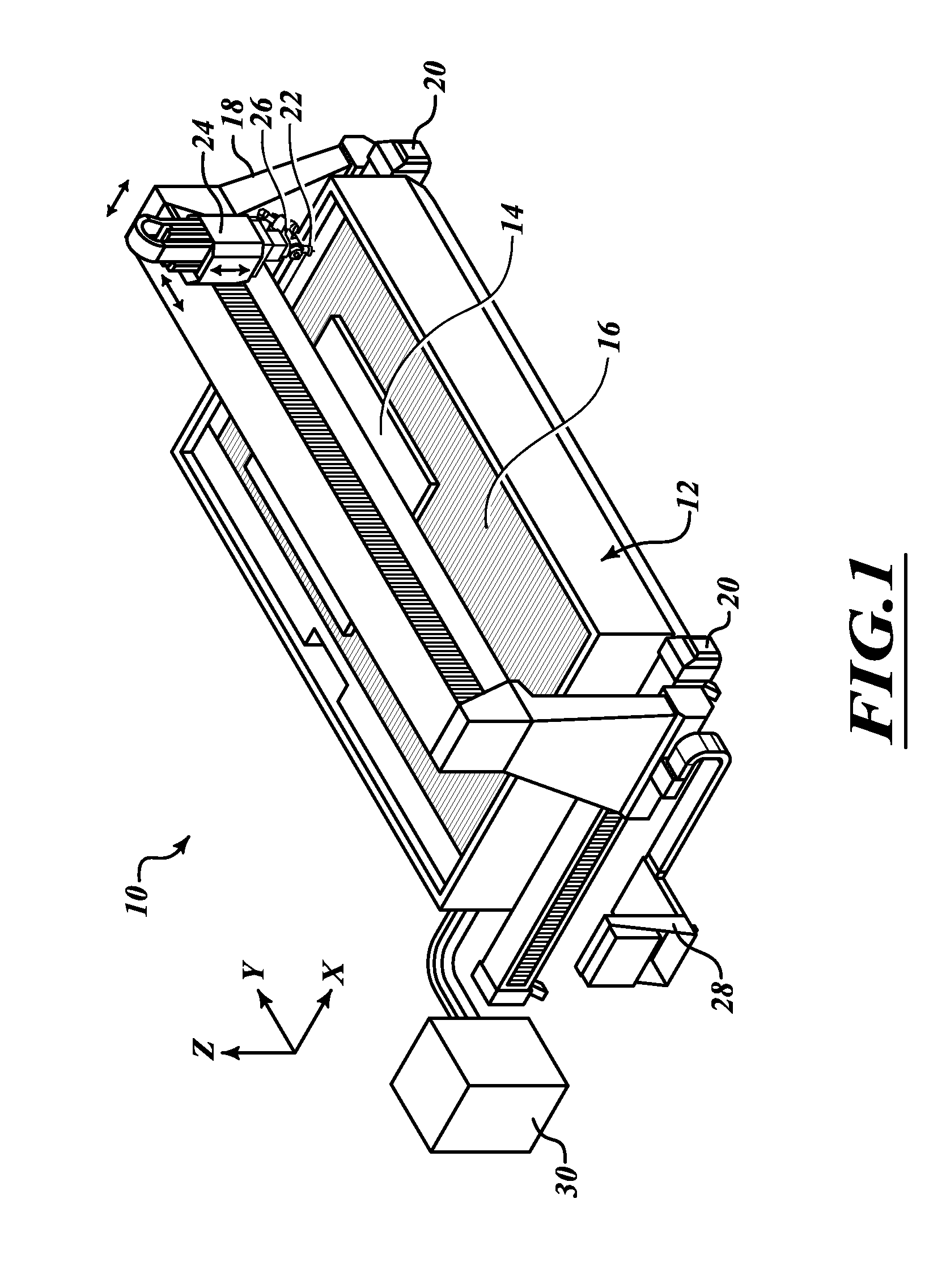

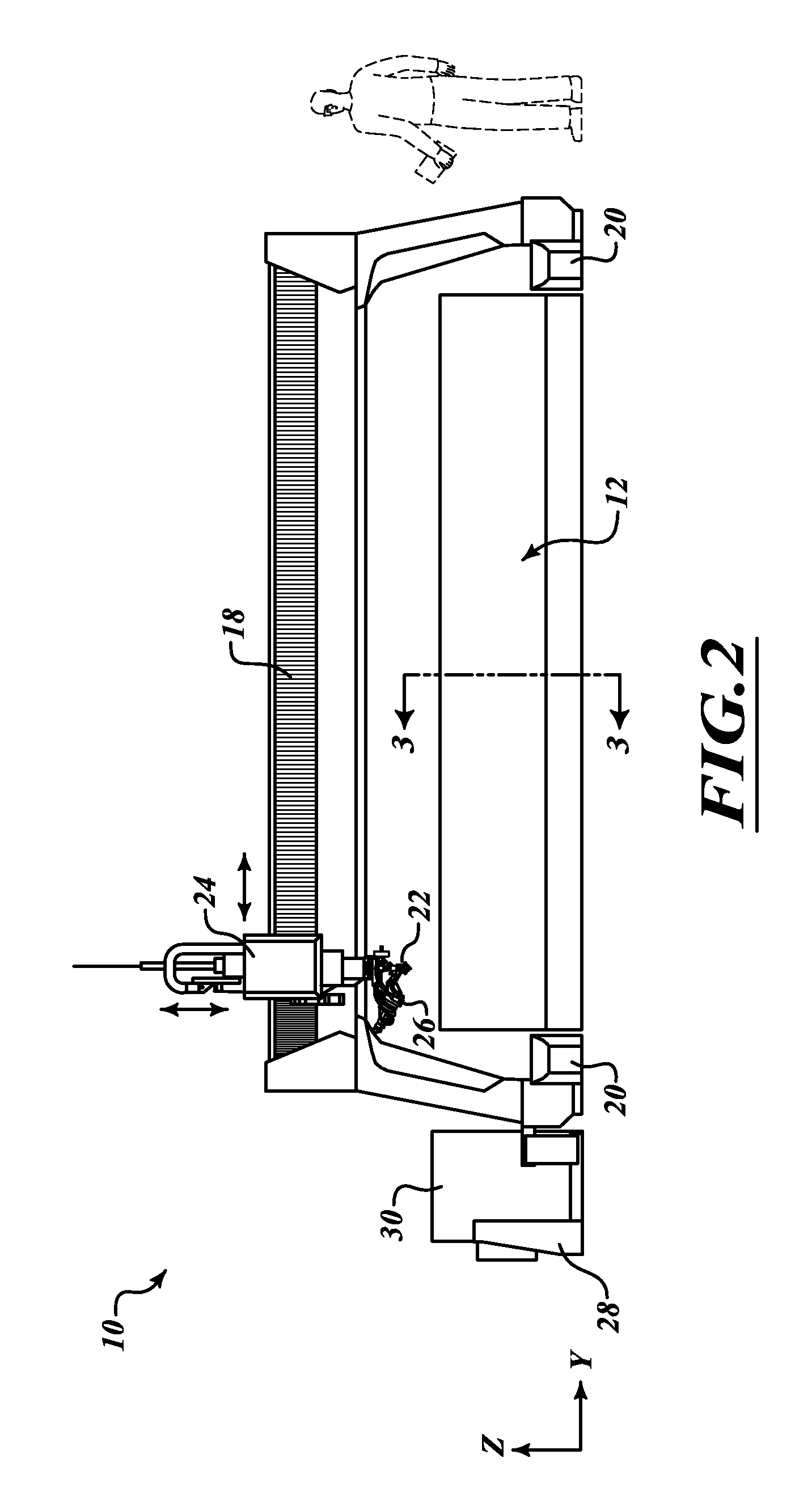

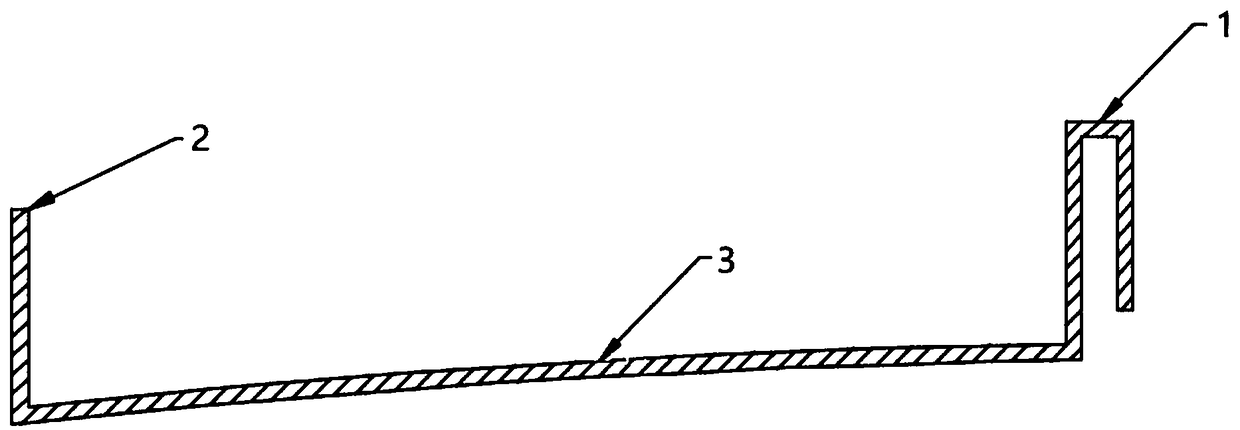

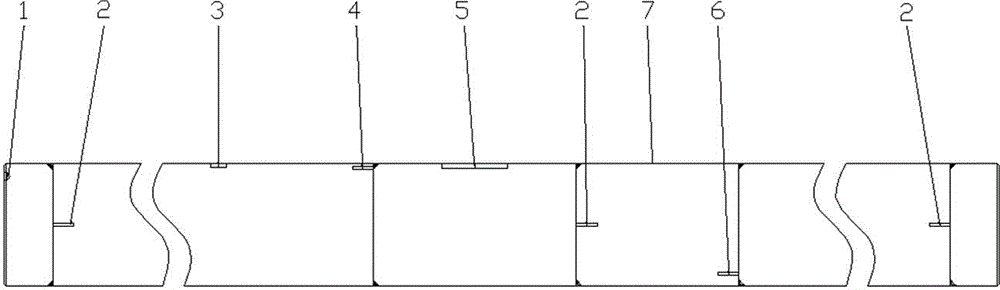

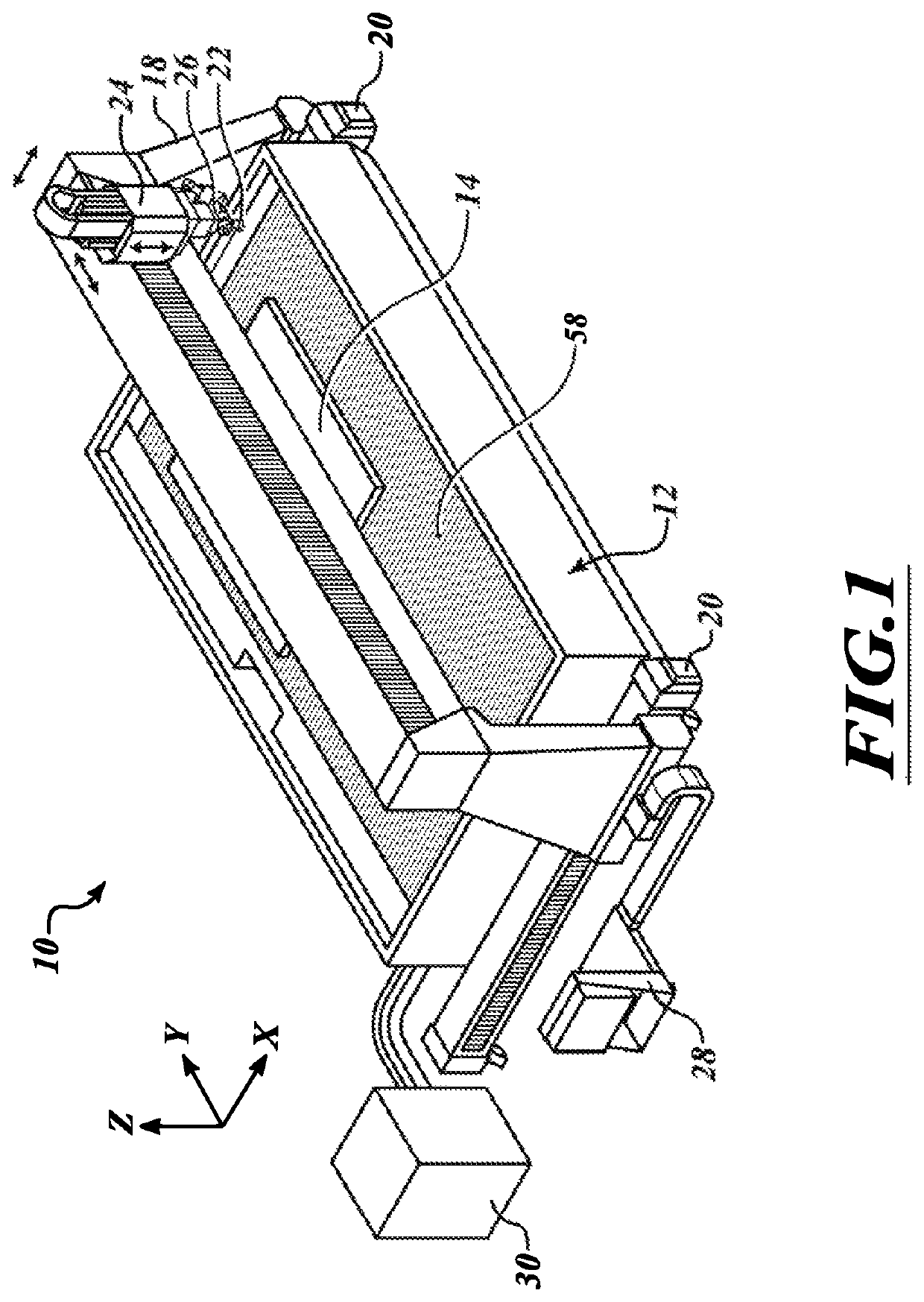

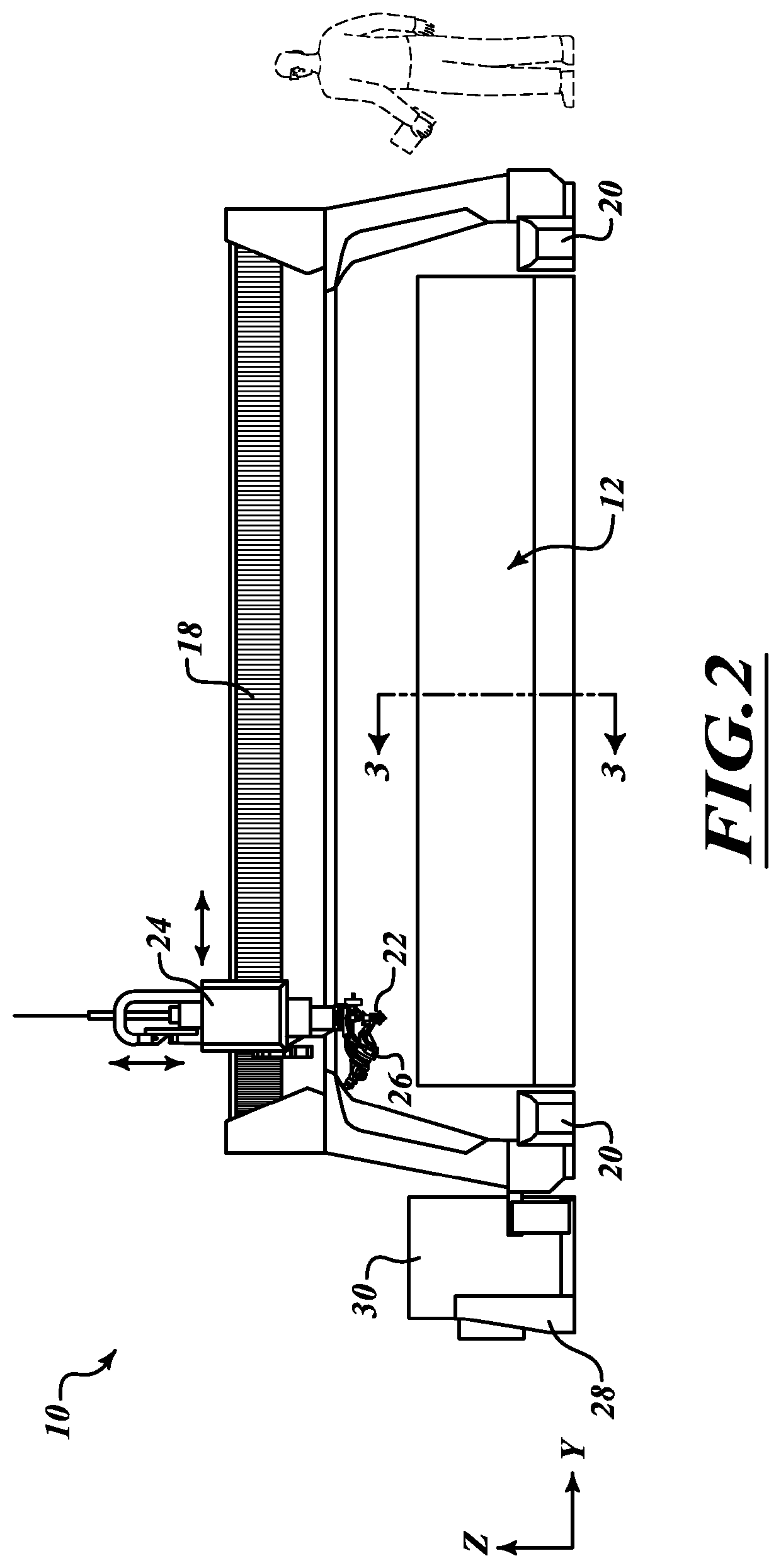

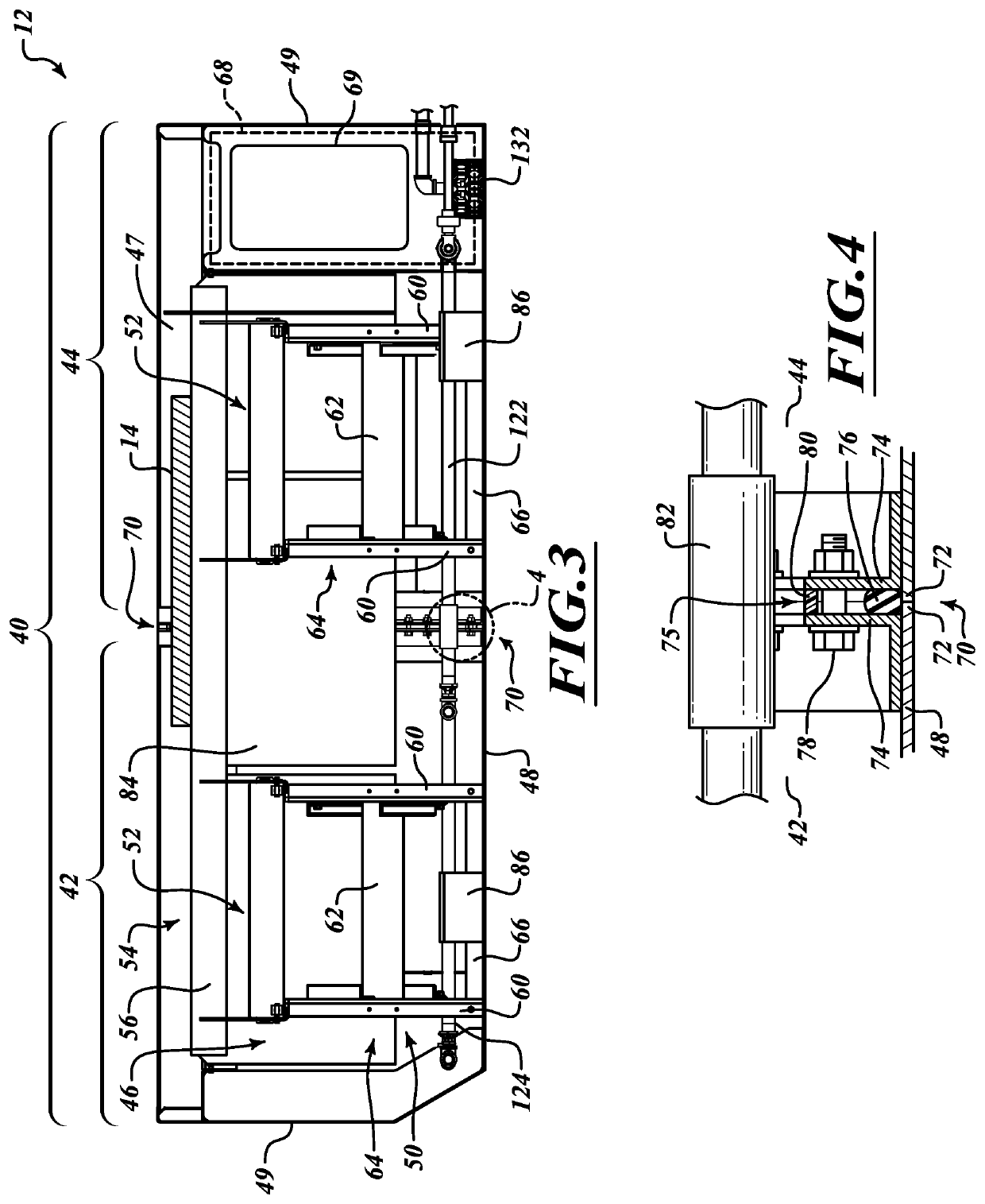

Catcher tank assembly of waterjet cutting system

ActiveUS20130025425A1Versatile form factorConvenient shipmentLarge containersMetal working apparatusSupporting systemEngineering

A catcher tank assembly is provided for a waterjet cutting machine. The catcher tank assembly includes a catcher tank having a plurality of tank sections detachably coupleable together in a side-by-side manner to collectively define a catcher tank having a desired configuration. The catcher tank assembly further includes a workpiece support system detachably coupleable to an interior cavity of the catcher tank. The workpiece support system may include a plurality of workpiece support modules arrangeable in an array to support a workpiece platform of the waterjet cutting machine. The workpiece platform may be formed, for example, by a series of slats supported transversely to parallel rows of the workpiece support modules. Methods and systems which relate to or include the aforementioned catcher tank assembly are also provided.

Owner:FLOW INT

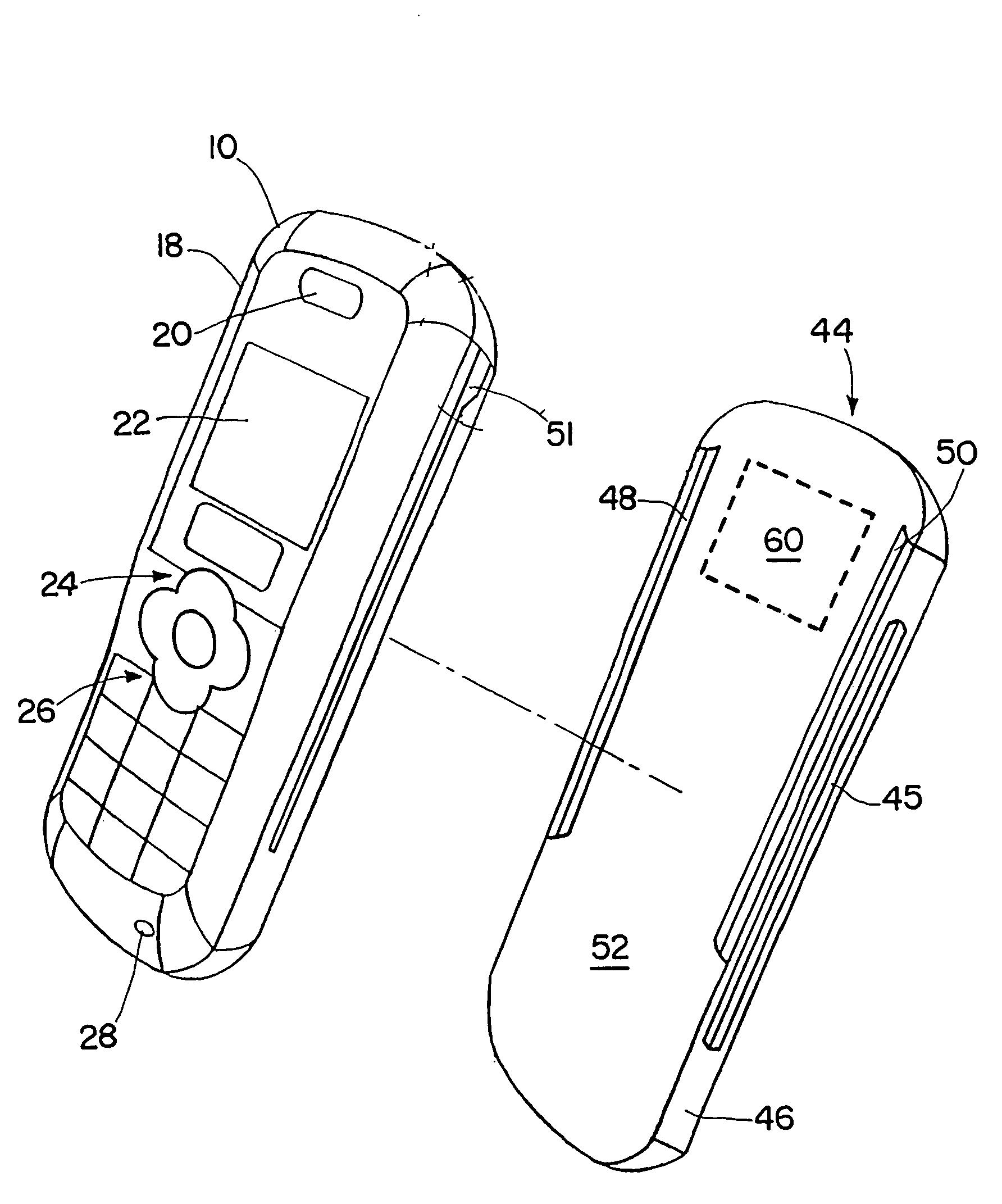

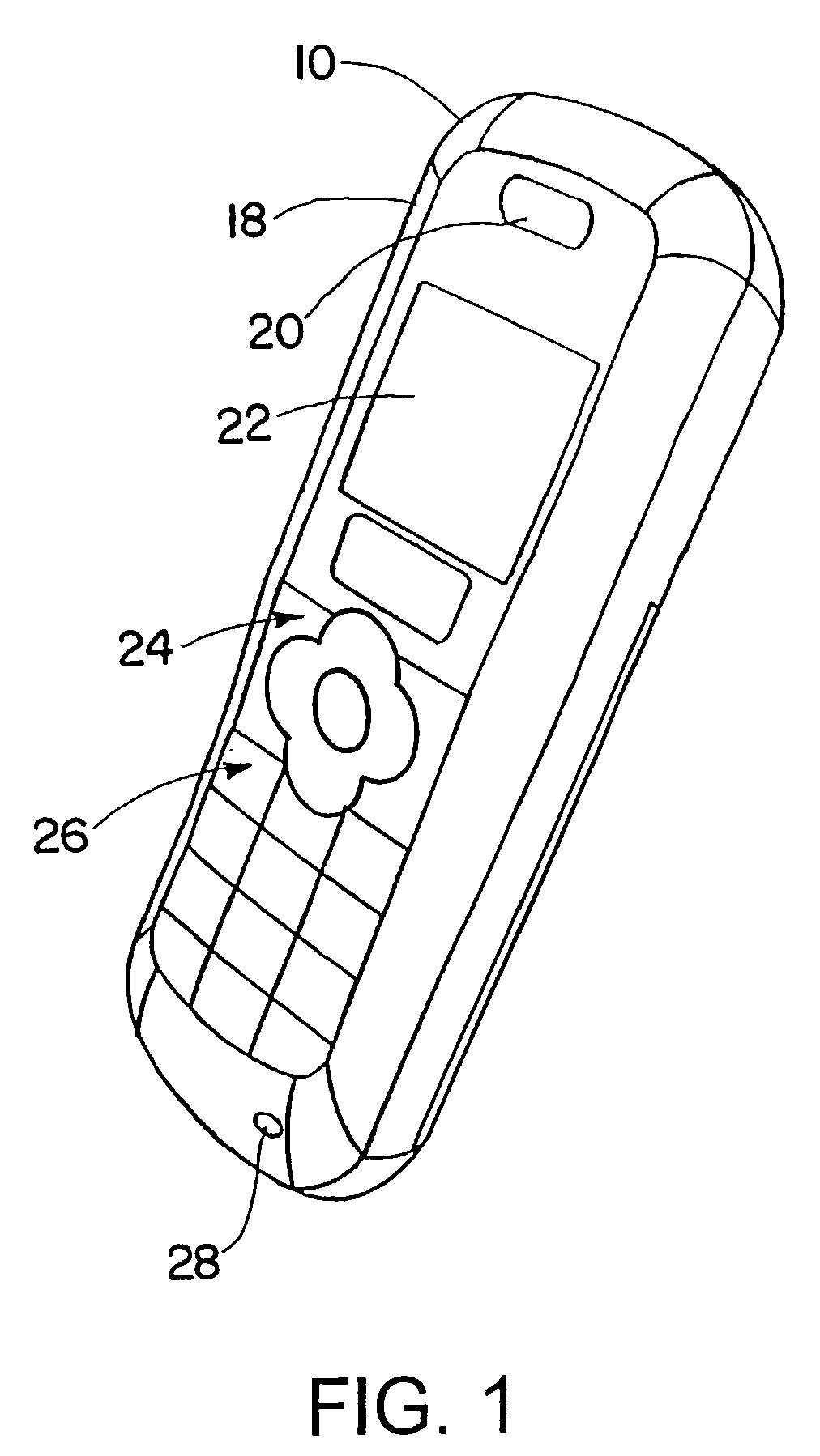

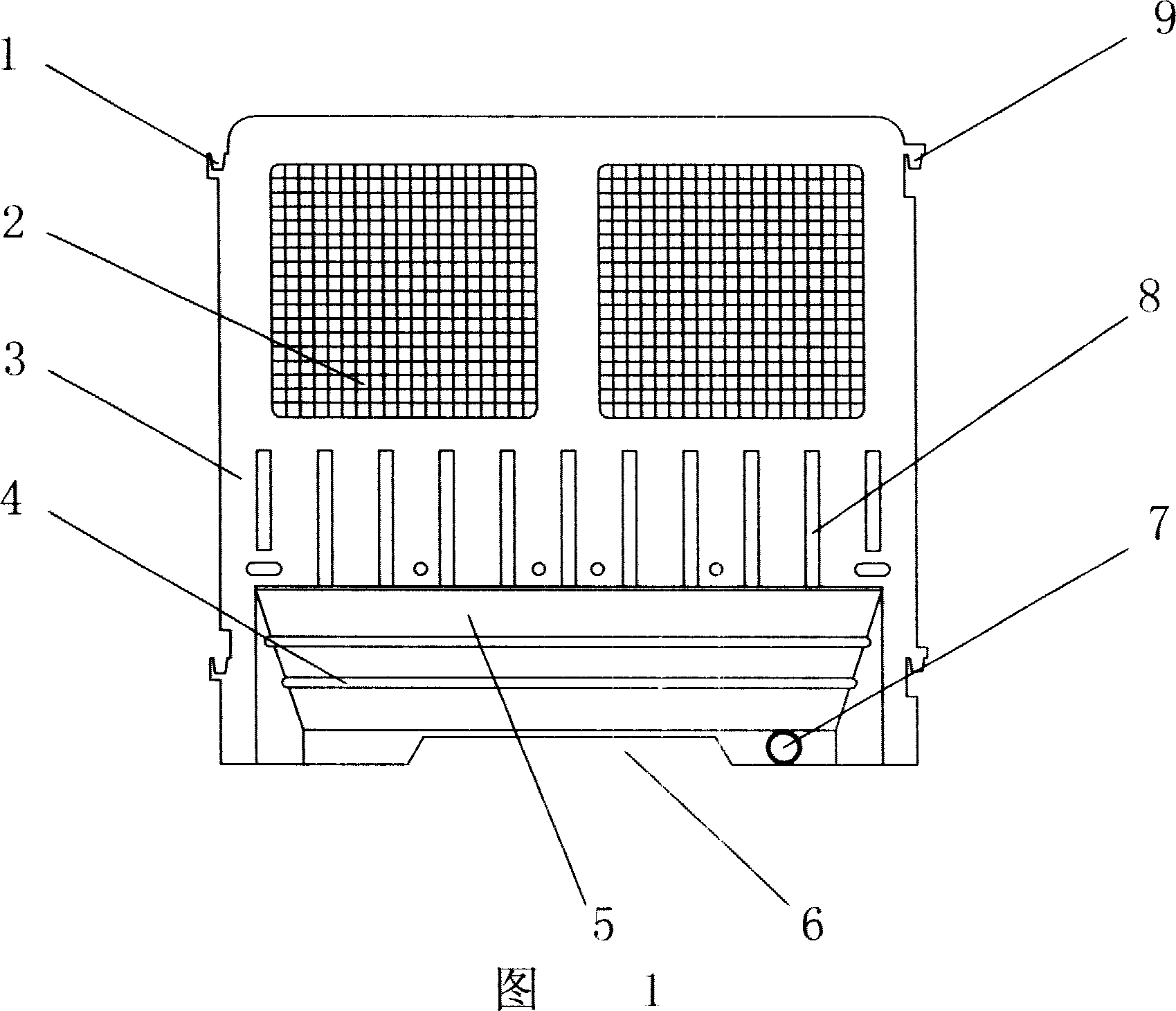

External heat sink for electronic device

InactiveUS20080310108A1Improve performanceImprove reliabilitySubstation equipmentCooling/ventilation/heating modificationsEngineeringLoudspeaker

An external heat sink device that can be attached to an electronic device during periods of excess heat generation, such as during a gaming session, for example. The external heat sink device can be removed from the electronic device during times of relatively lower heat generation. Other external accessories can be associated with the external heat sink device, such as an external antenna, speakers, game input device, power supply, etc.

Owner:SONY ERICSSON MOBILE COMM AB

Compact eye imaging and eye tracking apparatus

ActiveUS20140071400A1Minimal distortionSuperior optical qualityPrismsAcquiring/recognising eyesOptical powerPrism

An optical system for eye tracking is disclosed. The system includes a light guiding prism that guides light from an ocular object to an imaging system through multiple internal reflections. The light guiding prism may include one or more freeform surfaces having optical power.

Owner:AUGMENTED VISION

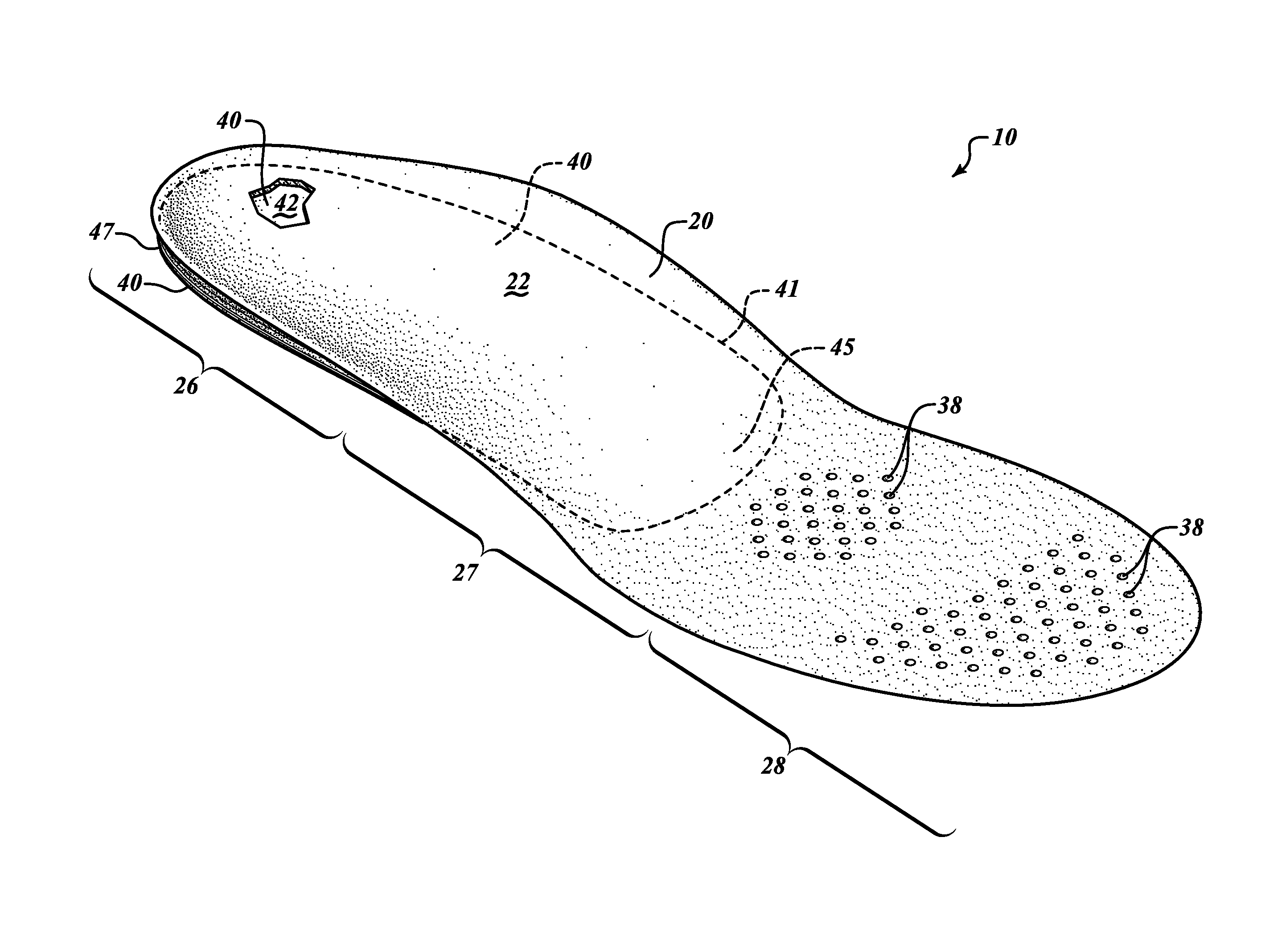

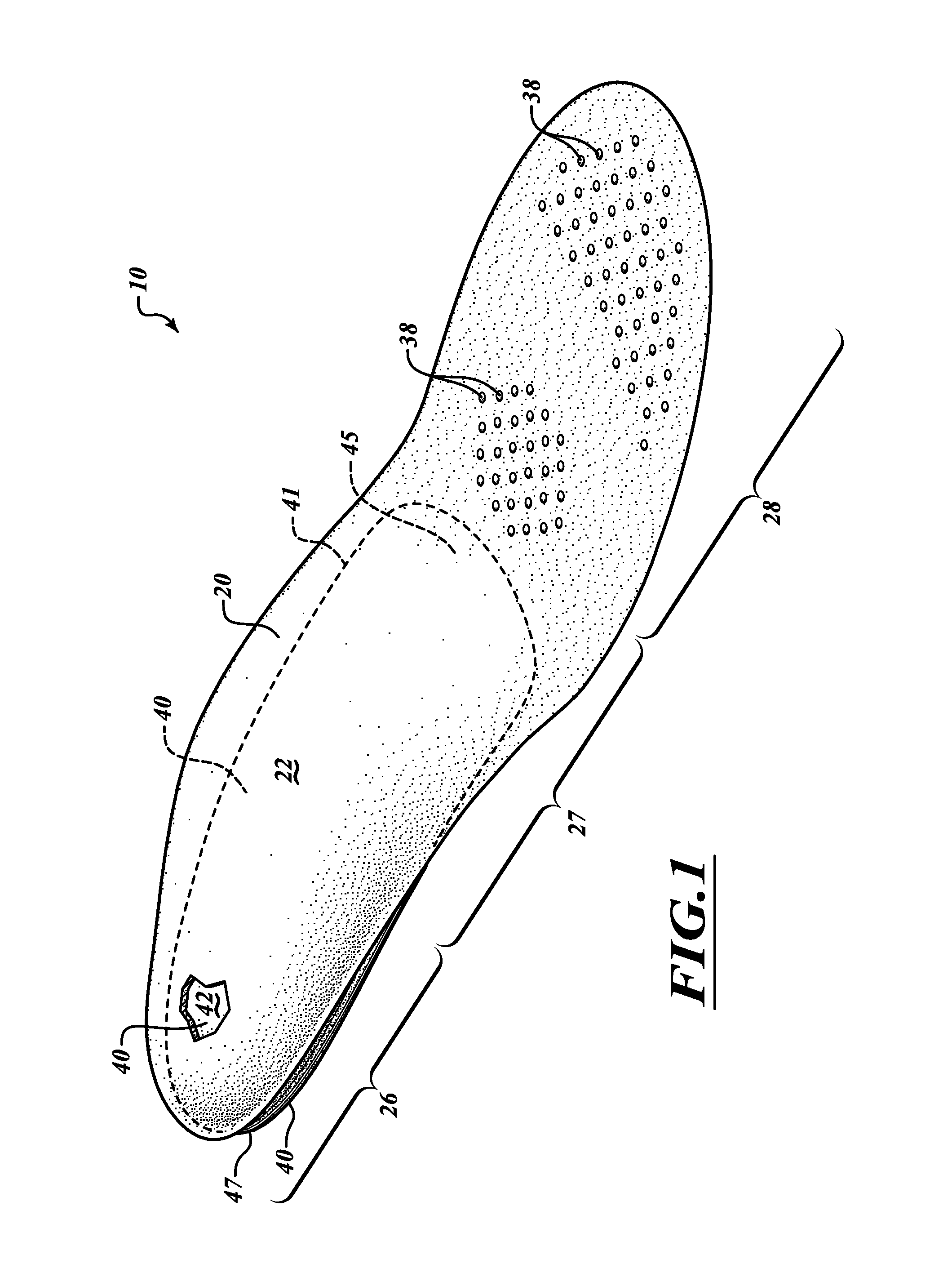

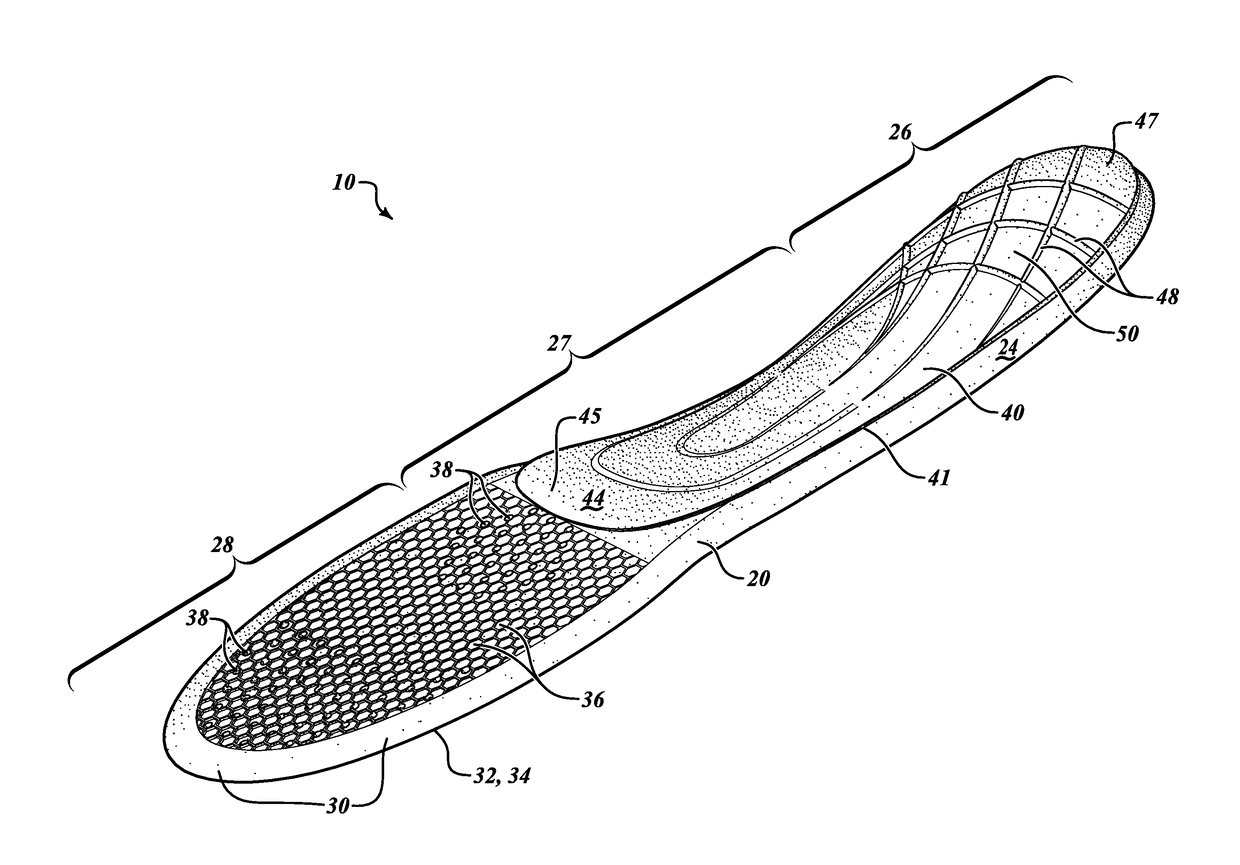

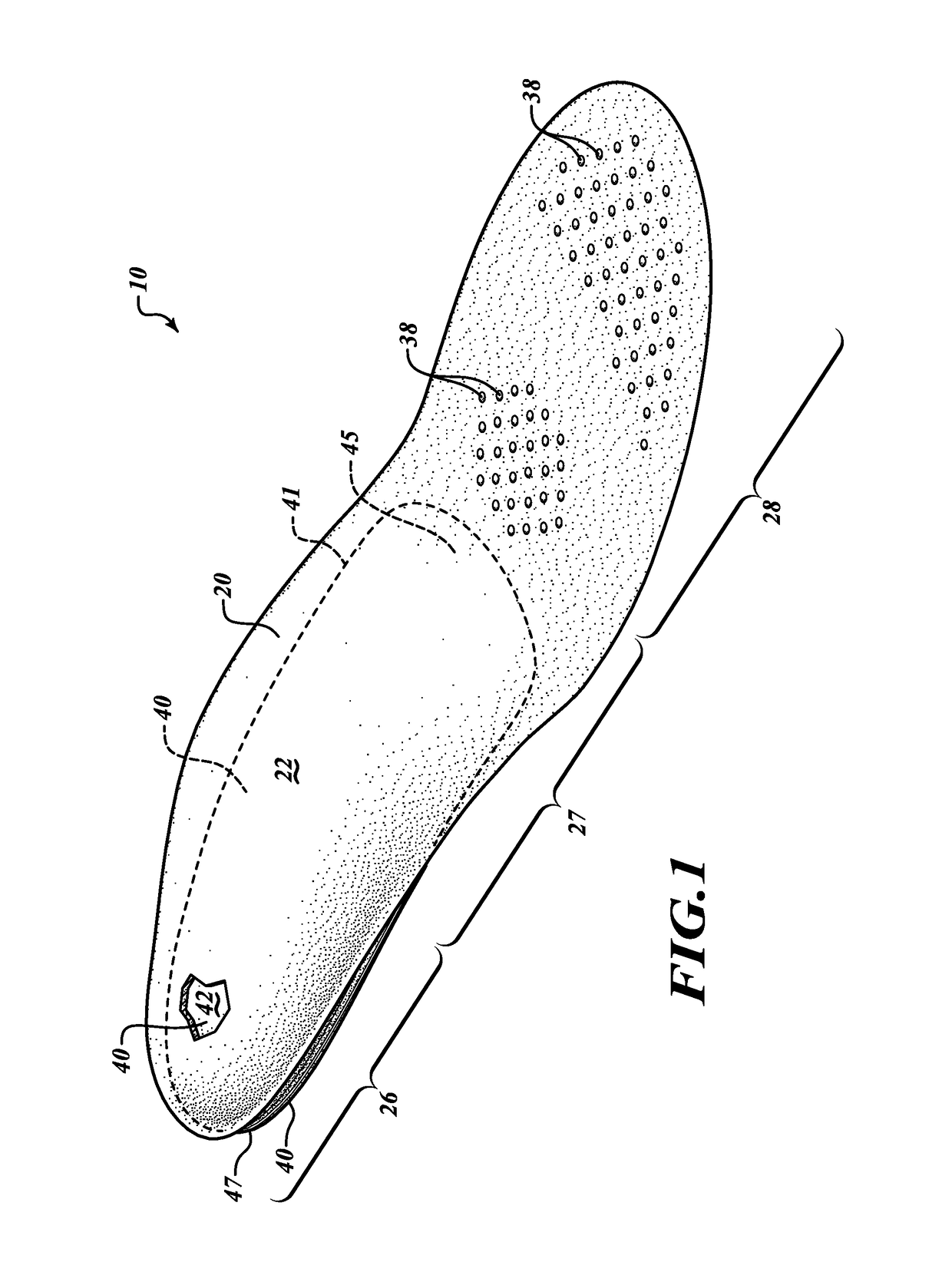

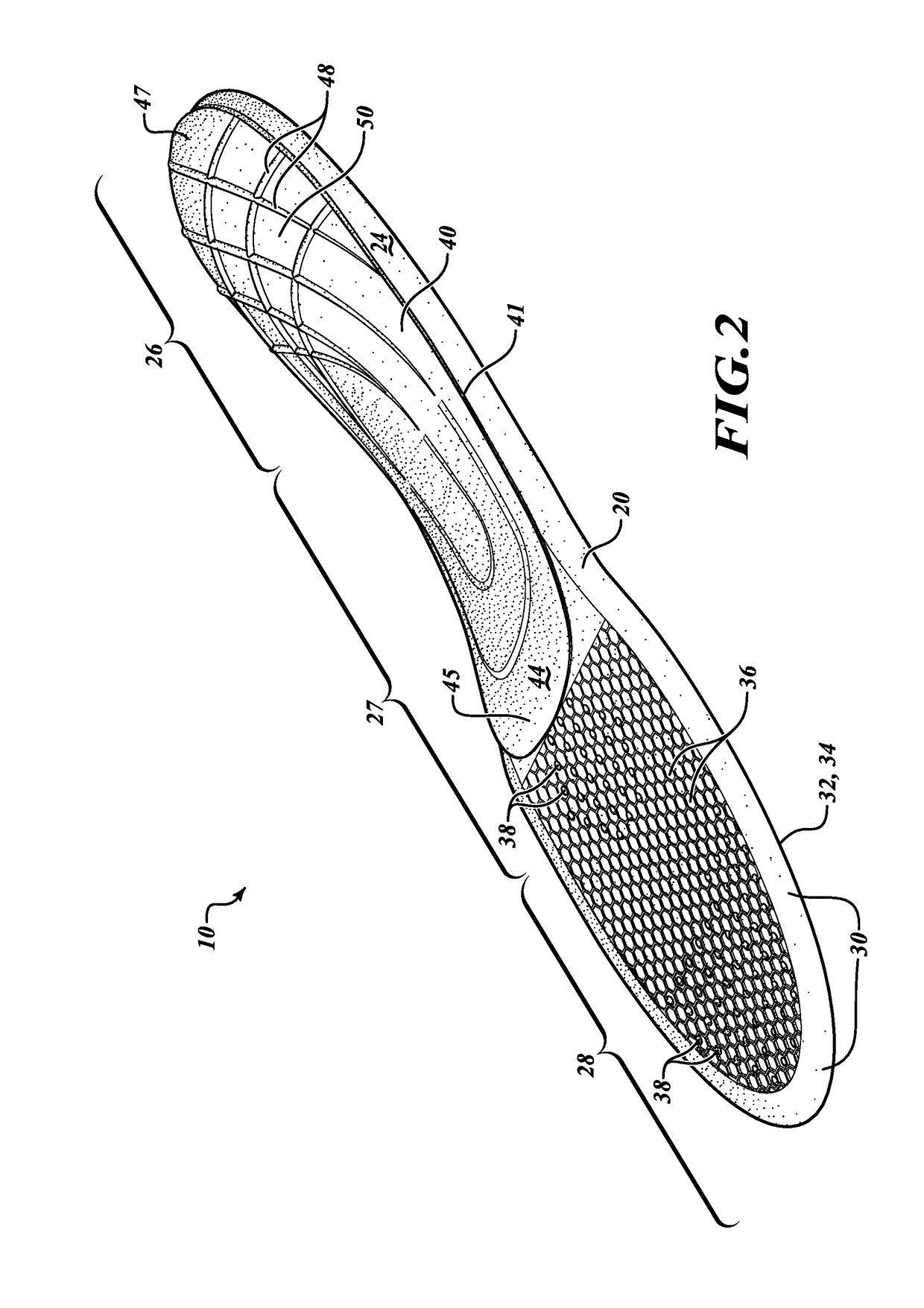

Contoured insoles for footwear

An insole assembly for use in footwear is provided. The insole assembly generally includes a full-length insole base made of a flexible and resilient material (e.g., resiliently compressible foam), and a heel cap made of a generally rigid material (e.g., a carbon fiber reinforced polymer) which is attached to the insole base and mimics the contours thereof to provide proper biomechanical support of the heel and arch areas of a foot in a particularly lightweight and sleek form factor.

Owner:SUPERFEET WORLDWIDE LLC

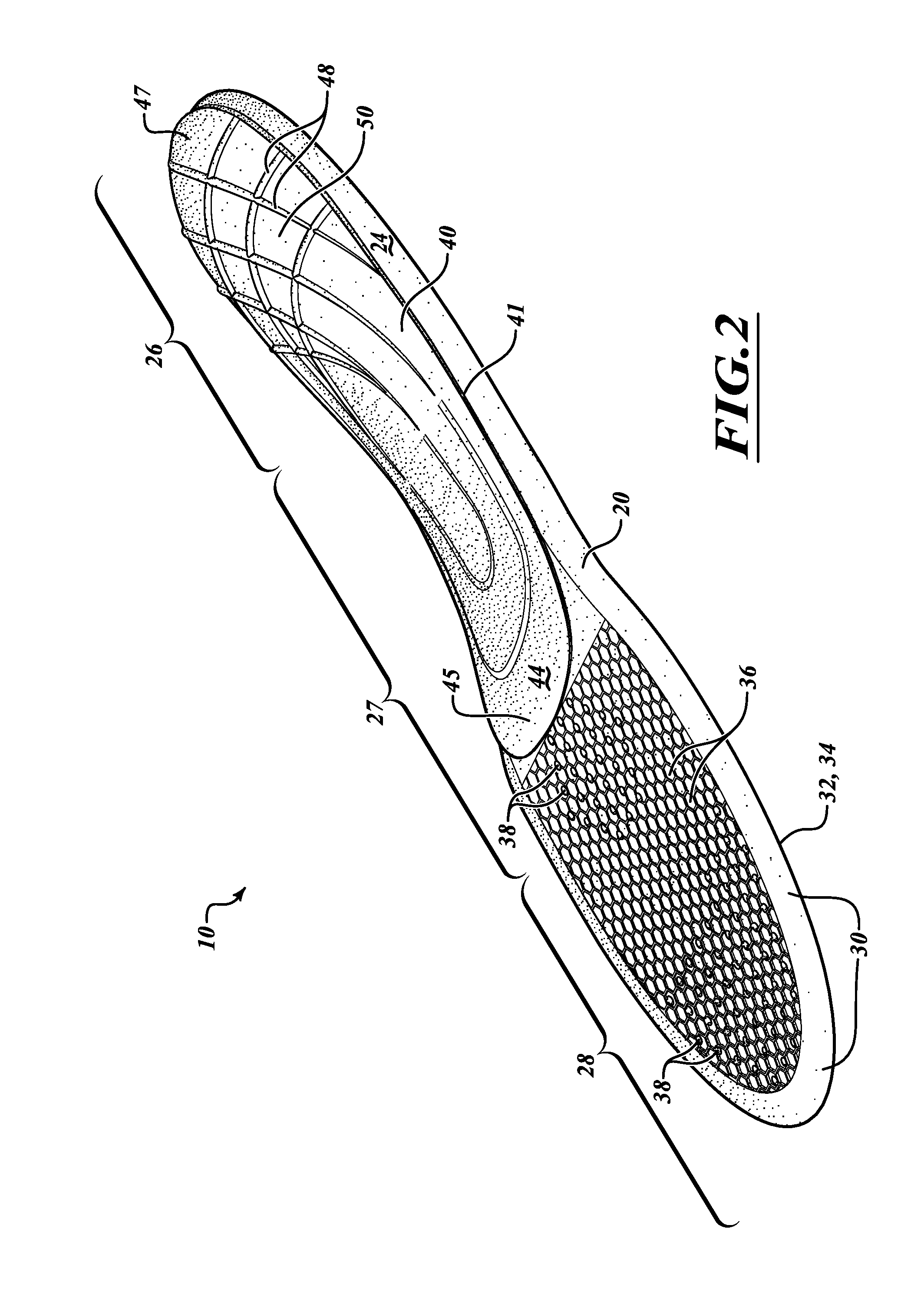

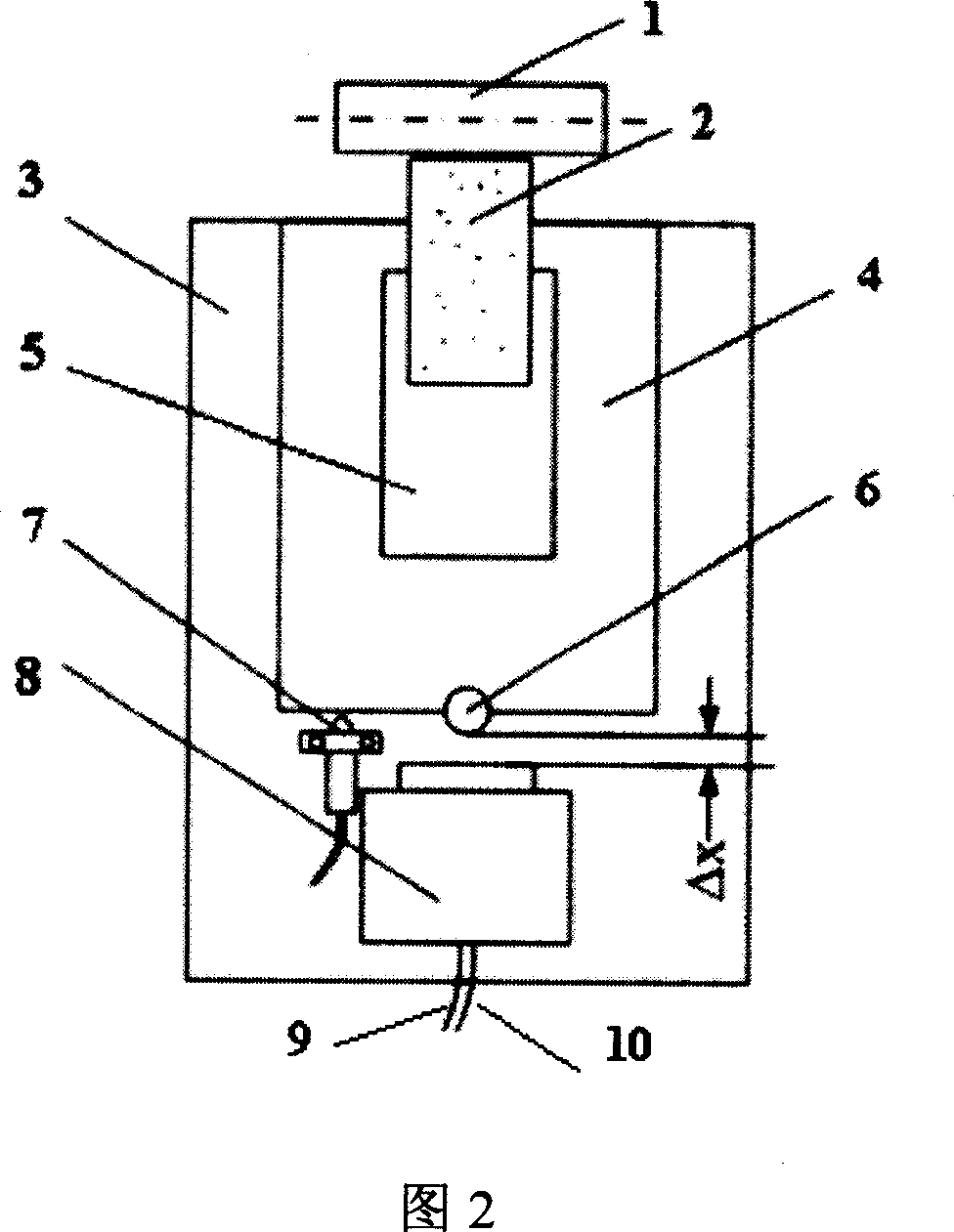

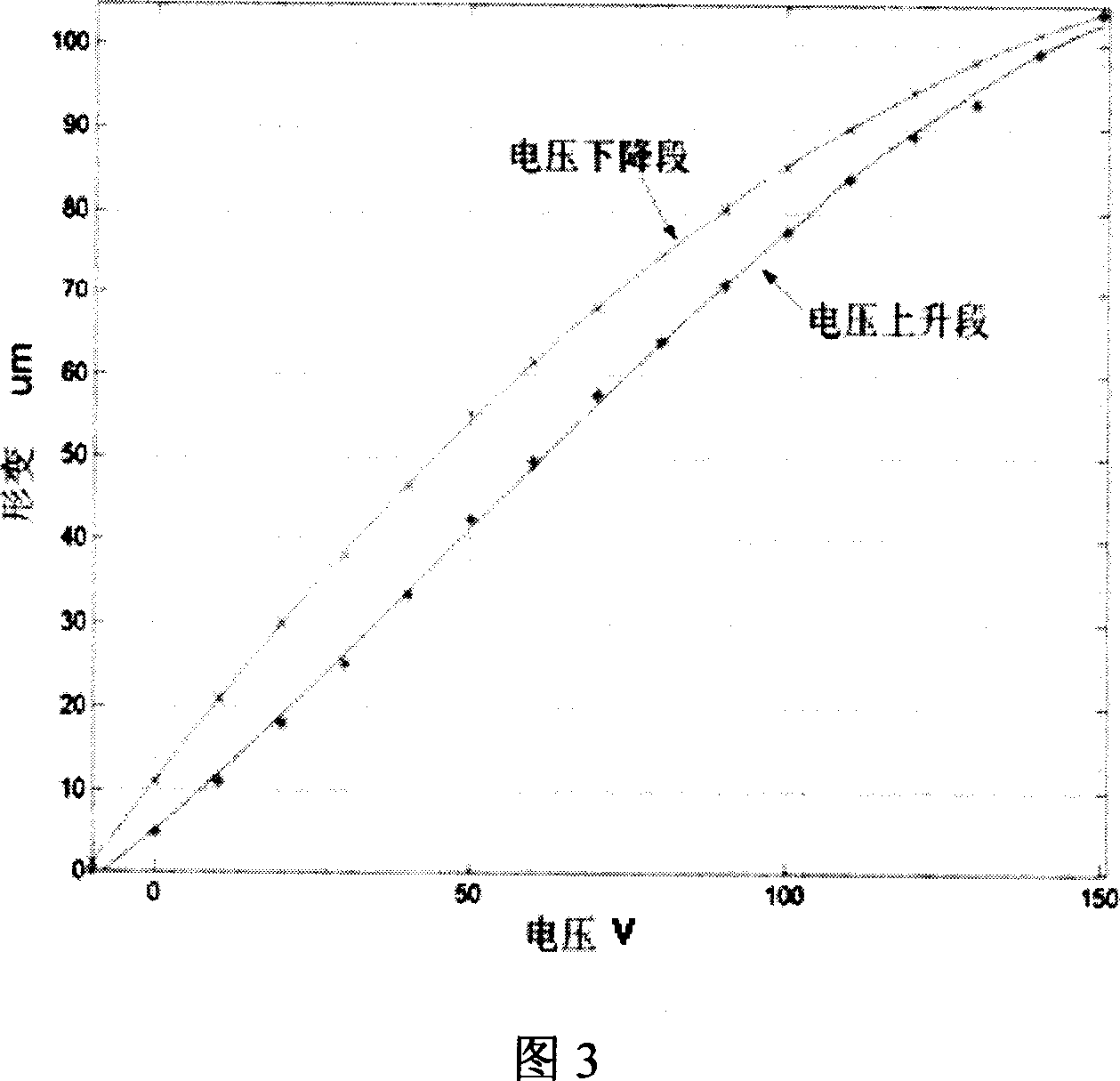

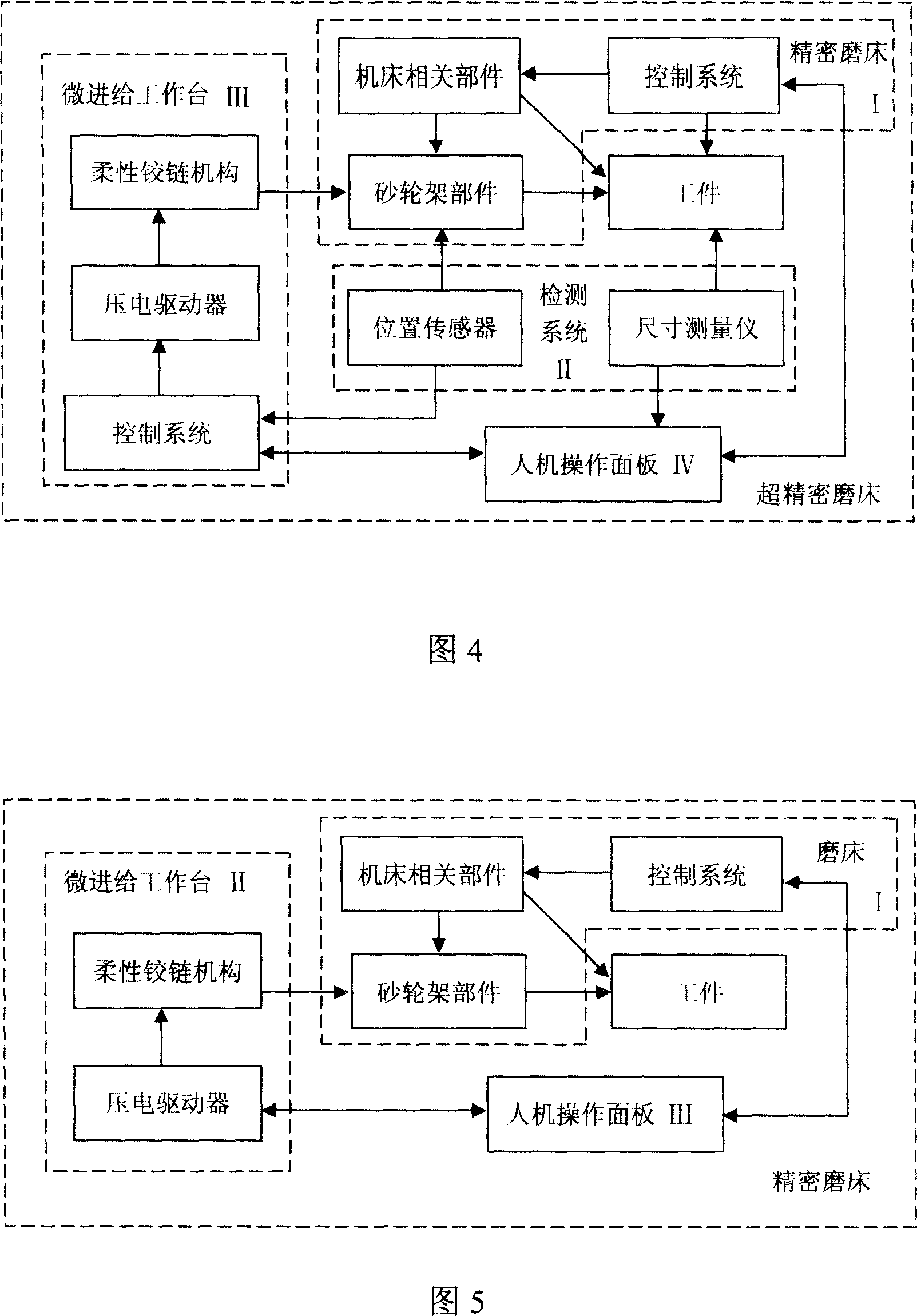

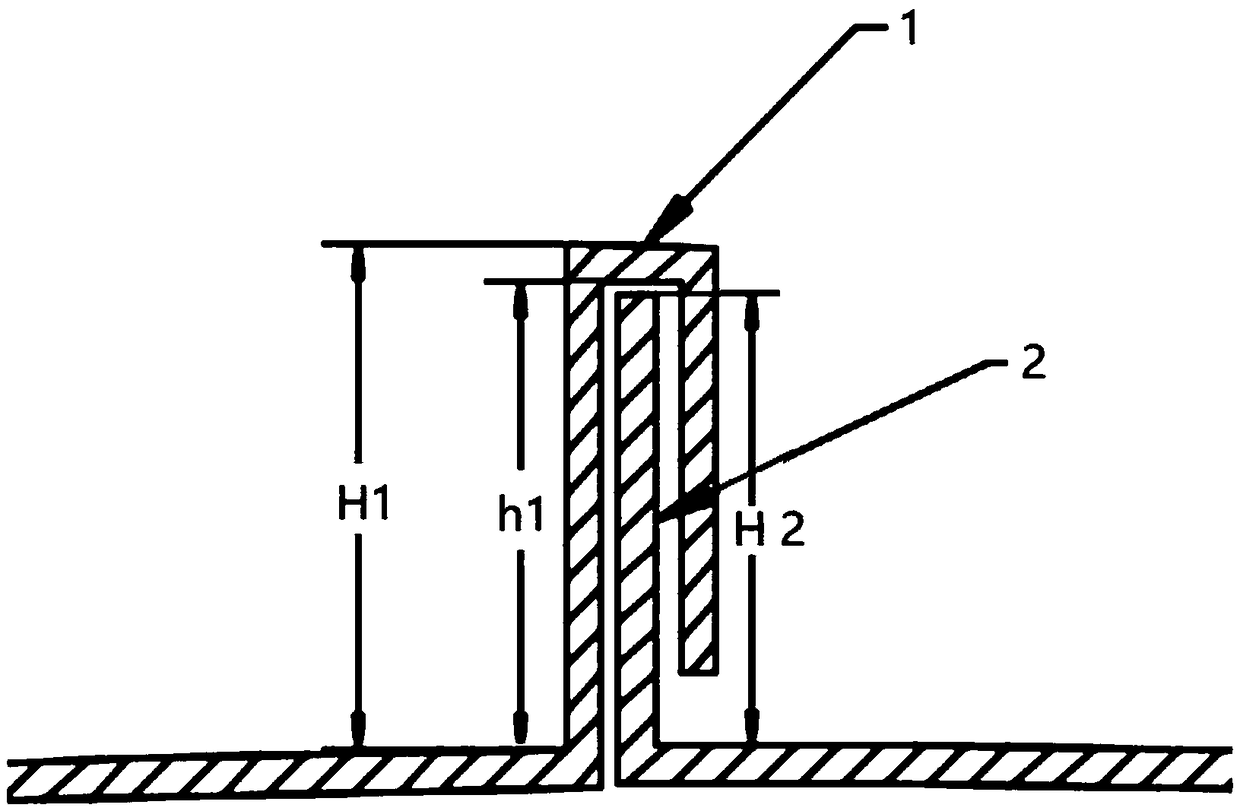

Microfeeding system for precisive grinding

InactiveCN101028702ARealize and guarantee micro-feeding precision requirementsMeeting precision feeding needsGrinding drivesGrinding feed controlDisplay deviceEngineering

A microadvance system for accurate grinding machine is composed of a drive unit consisting of piezoelectric drive power supply, piezoelectric ceramics, man-machine interface type input device, and displacement-voltage table, an executing unit consisting of flexible hinge mechanism and microadvance bench, a detecting unit consisting of inductance-type position sensor or raster rule, detection signal acquiring module, displacement-voltage compensation data table, and signal processing-outputting module, and a control system consisting of microprocessor, D / A and A / D converters, data I / O display, signal amplifier, information integrating interface, and signal processing reference model and algorithm.

Owner:DONGHUA UNIV

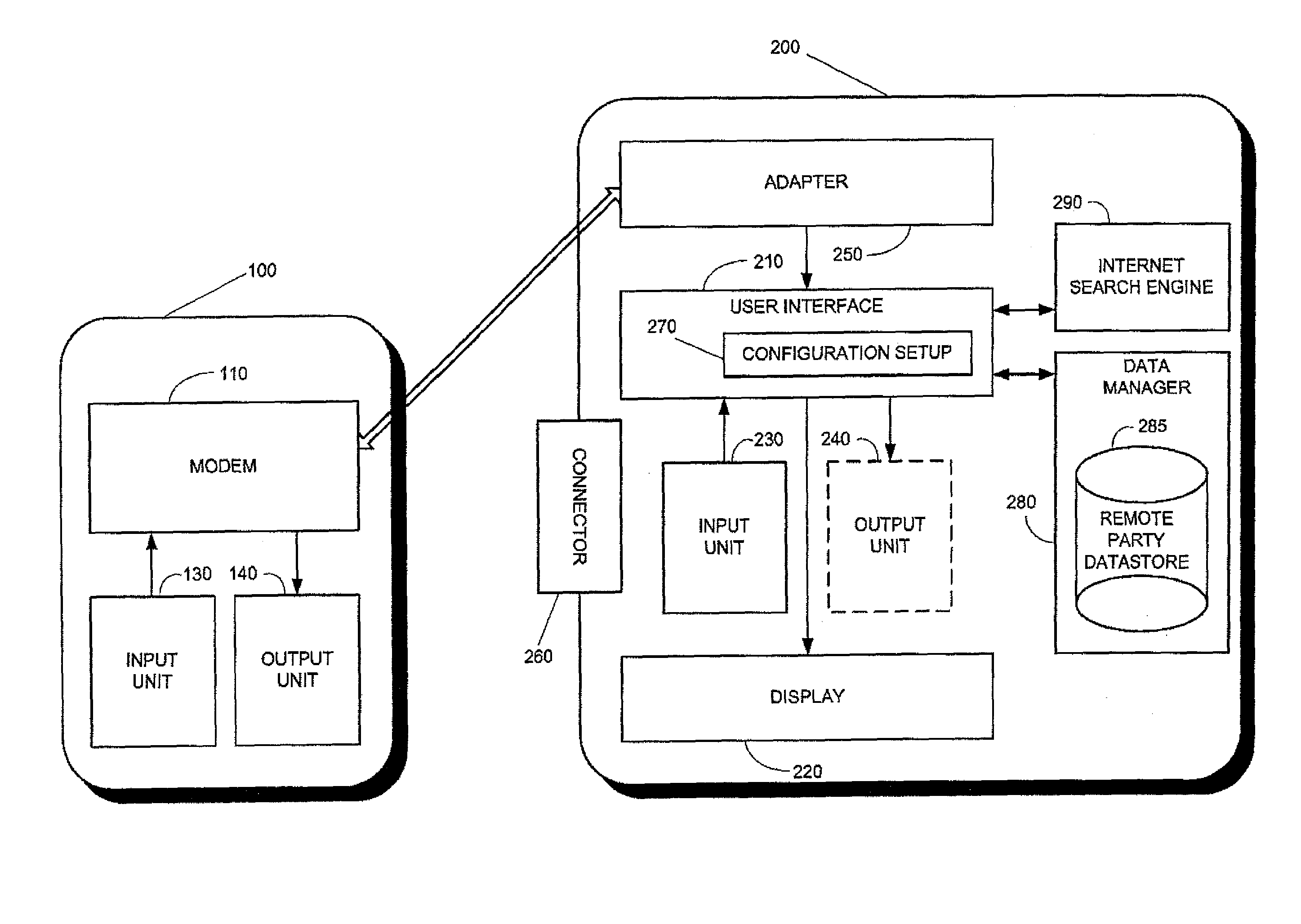

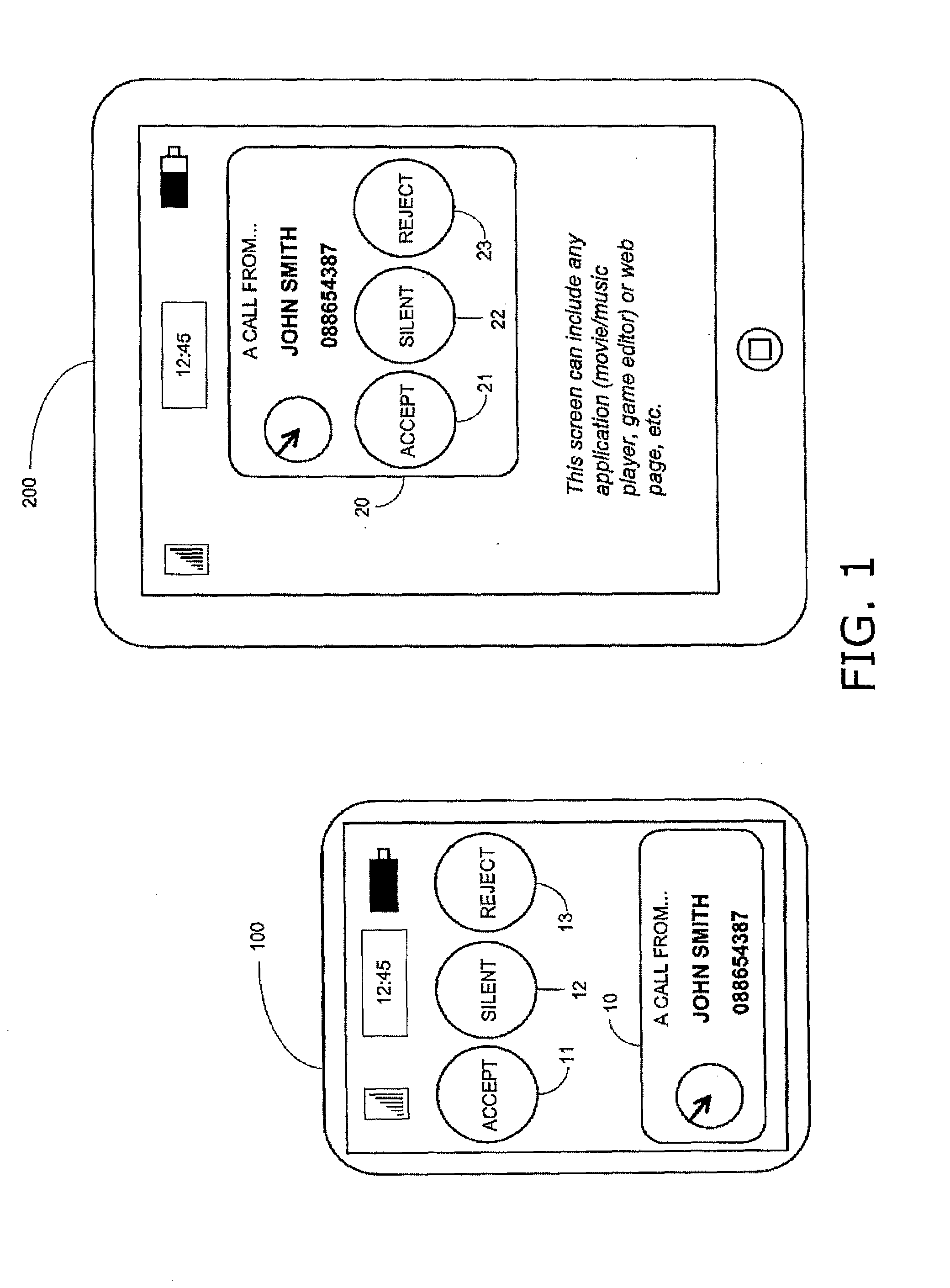

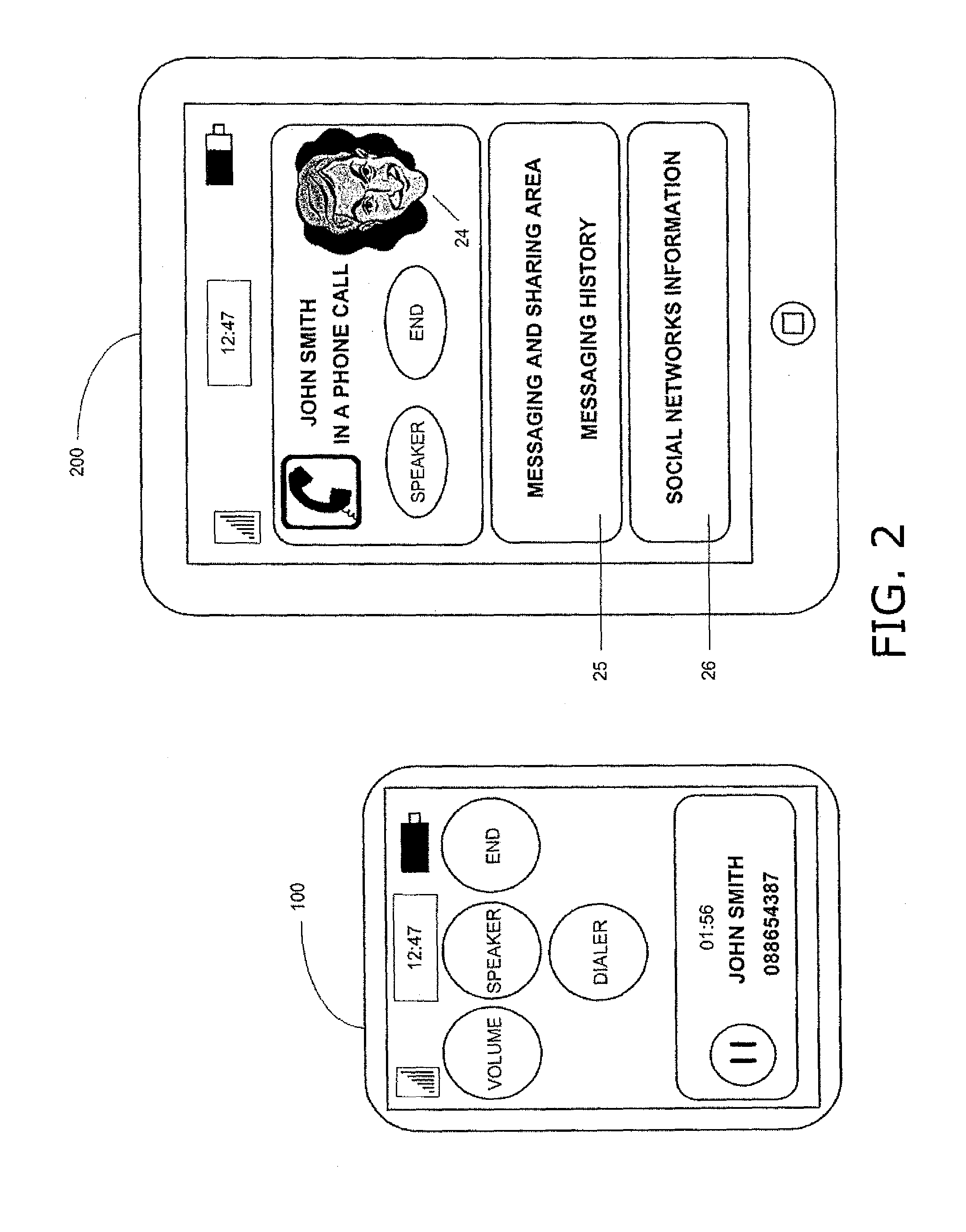

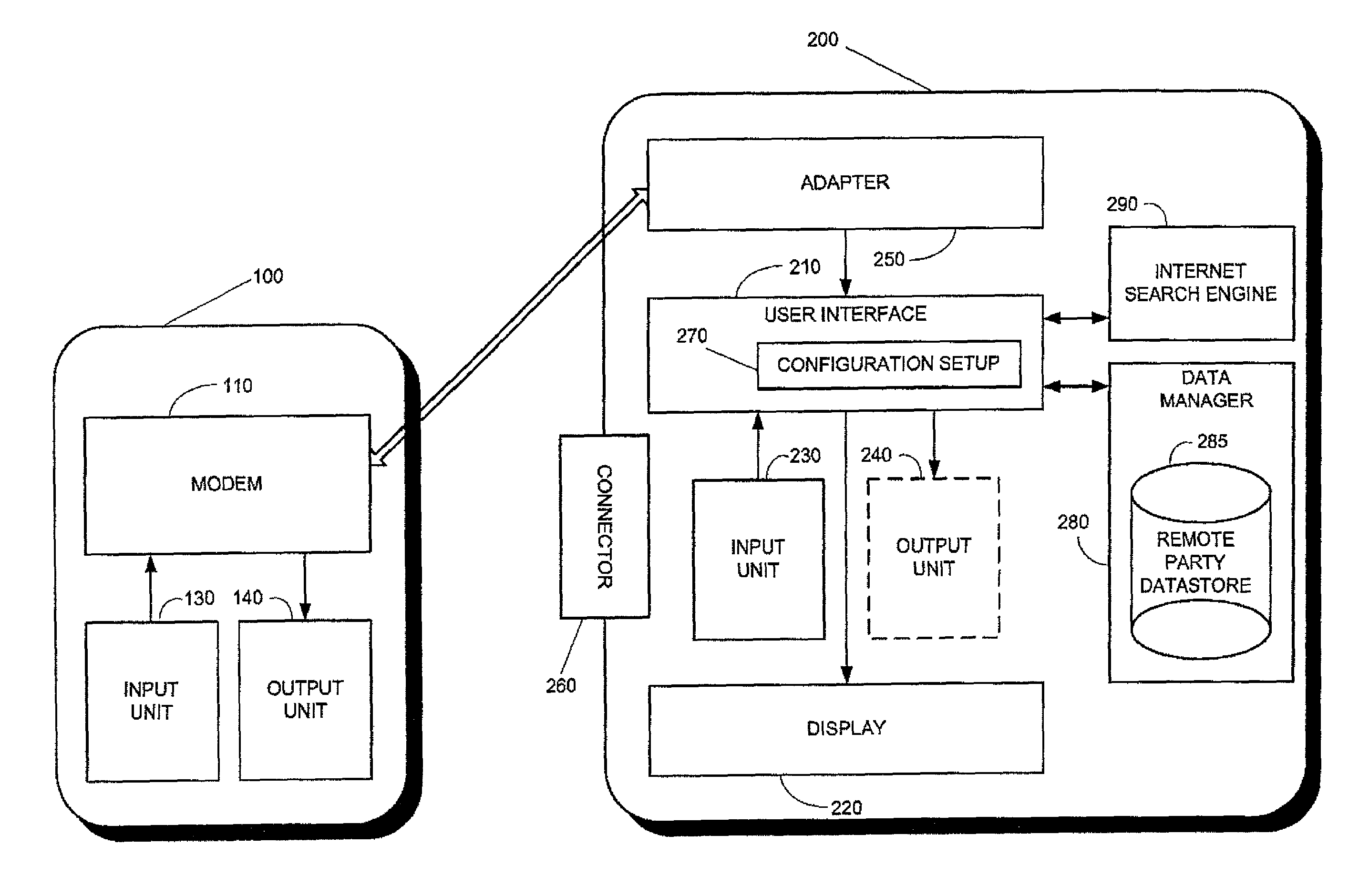

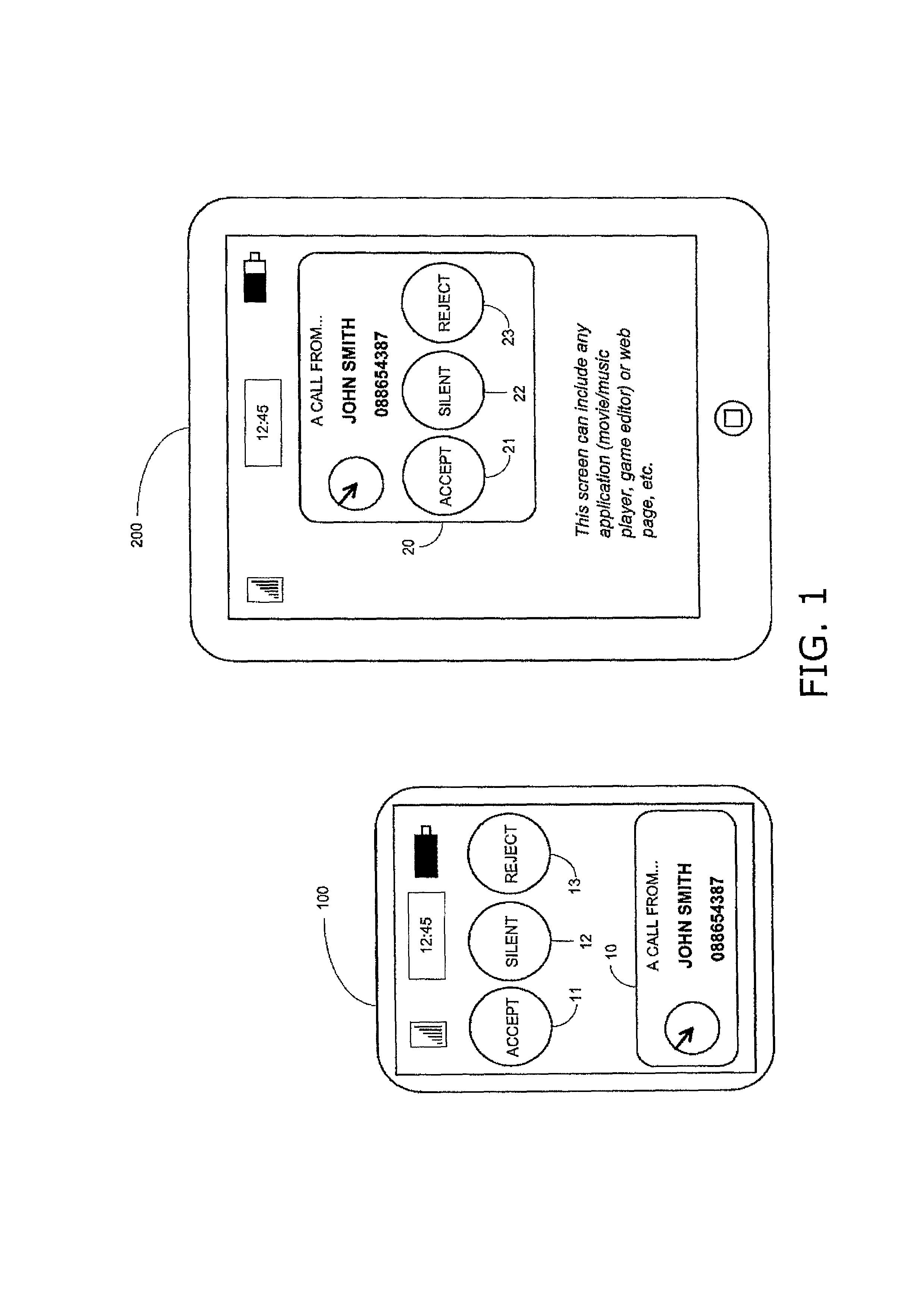

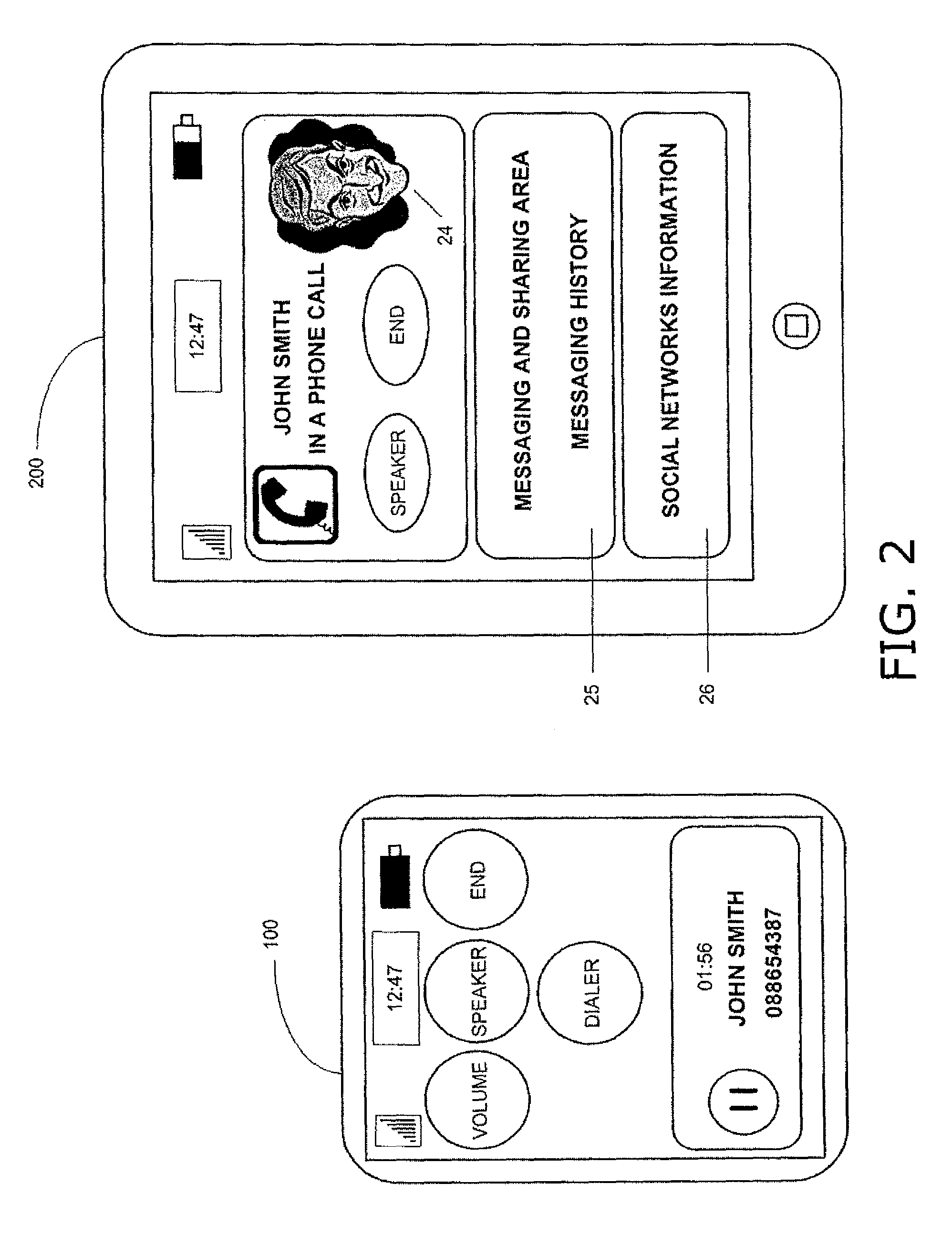

Cooperative tablet computer and mobile communicator

ActiveUS20130225139A1Simple batteryLow costDevices with multiple display unitsSpecial service for subscribersTablet computerCommunications system

A communication system, including a mobile communicator including a modem for conducting a communication with a remote party, an input unit for inputting communication data to the modem, and an output for outputting communication data from the modem, a display device including an input unit, an output unit, a connector for engaging the mobile communicator and for exchanging data with the mobile communicator, and a display for displaying party-specific information about the remote party involved in the communication, wherein the modem switches to receive its communication input via the display device input unit and directs its communication output to the display output unit when the mobile communicator is engaged with the connector, and wherein the modem switches back to receive its communication input via the mobile communicator input unit and directs its communication output to the mobile communicator output unit when the mobile communicator is disengaged from the connector.

Owner:GOOGLE LLC

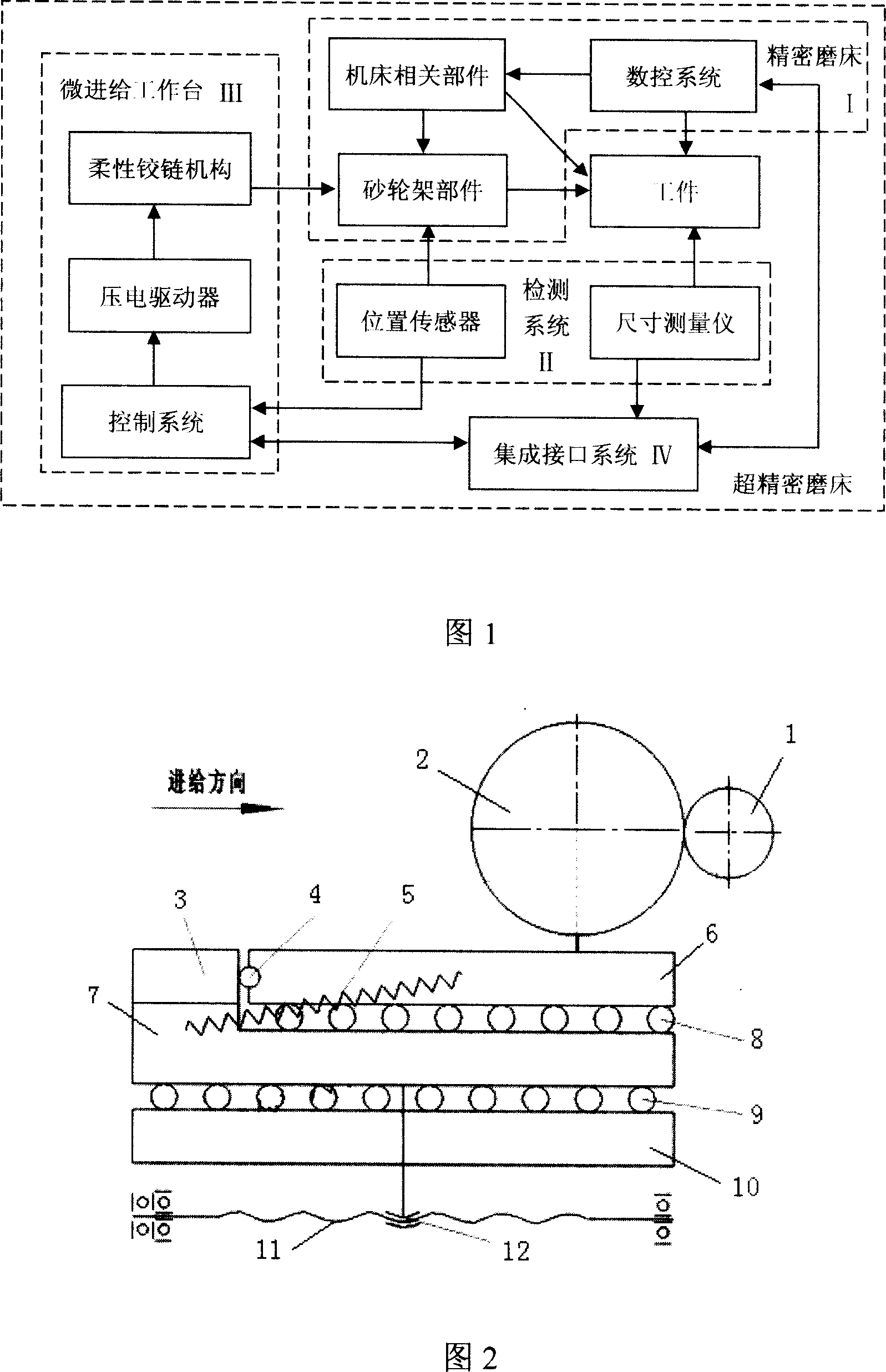

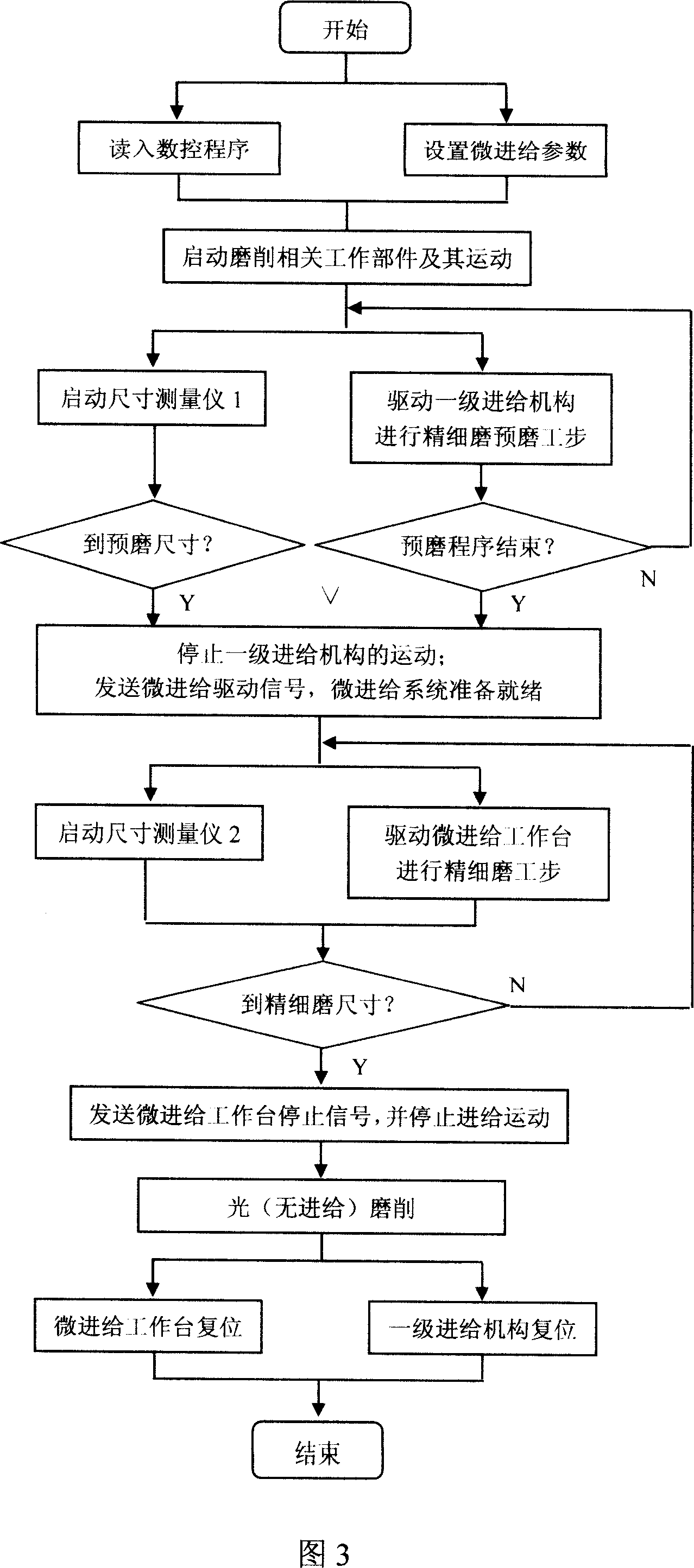

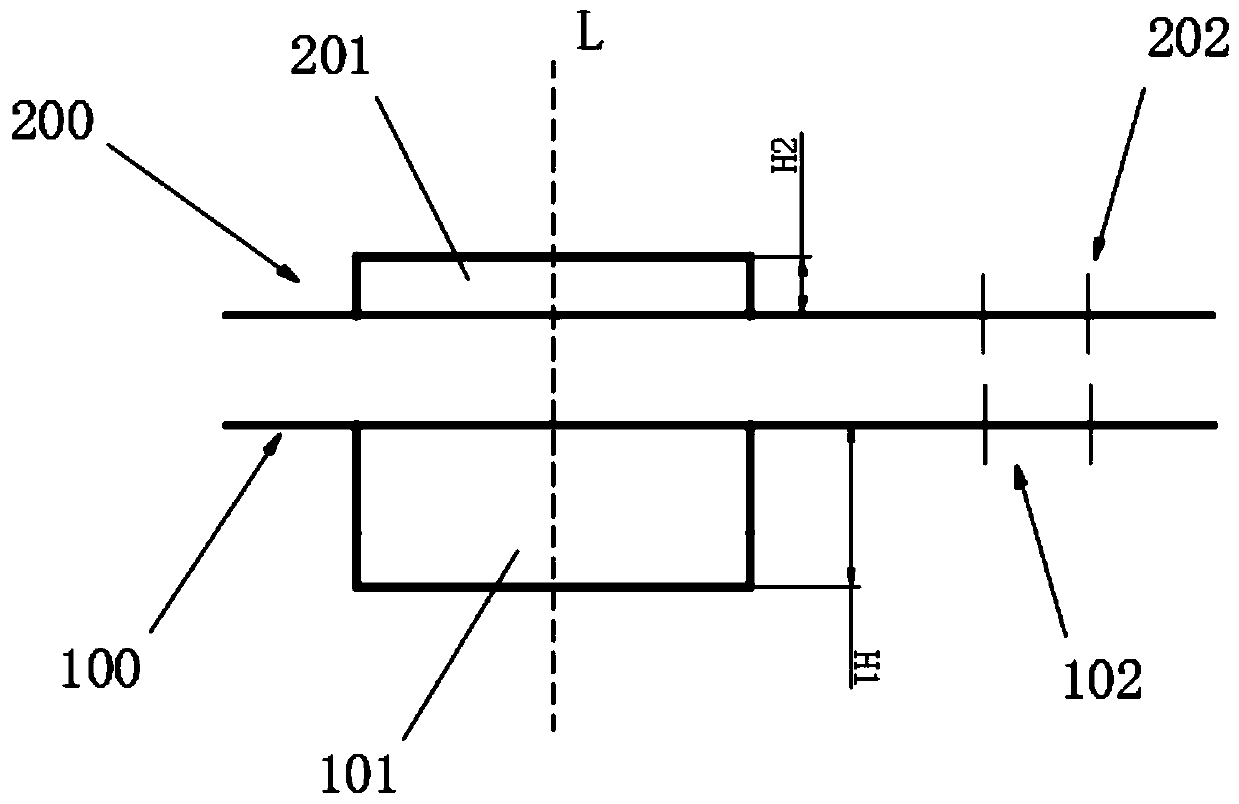

Ultraprecise grinder with two stages of feeding mechanism and its control method

InactiveCN1986156AMeet the needs of ultra-precision grindingIncreased R&D success rateGrinding drivesGrinding feed controlSize measurementControl system

The present invention relates to ultra precise numerically controlled grinder with two stages of feeding mechanism and its control method. The grinder includes an ultra precise numerically controlled grinder; a micro feeding bench comprising a piezoelectric driver, a flexible hinge mechanism and a control system; a detection system comprising a position sensor and a size measurer; and an integrated interface system for transmitting the pulse signals to realize the integrated control of the grinder. The grinder has numerically controlling system, and increased micro feeding bench control system, monitoring system and integrated interface system. The present invention is for completing the coarse, semi-precise and precise grinding of high precision parts of optical glass, ceramic and other hard and fragile material.

Owner:DONGHUA UNIV +1

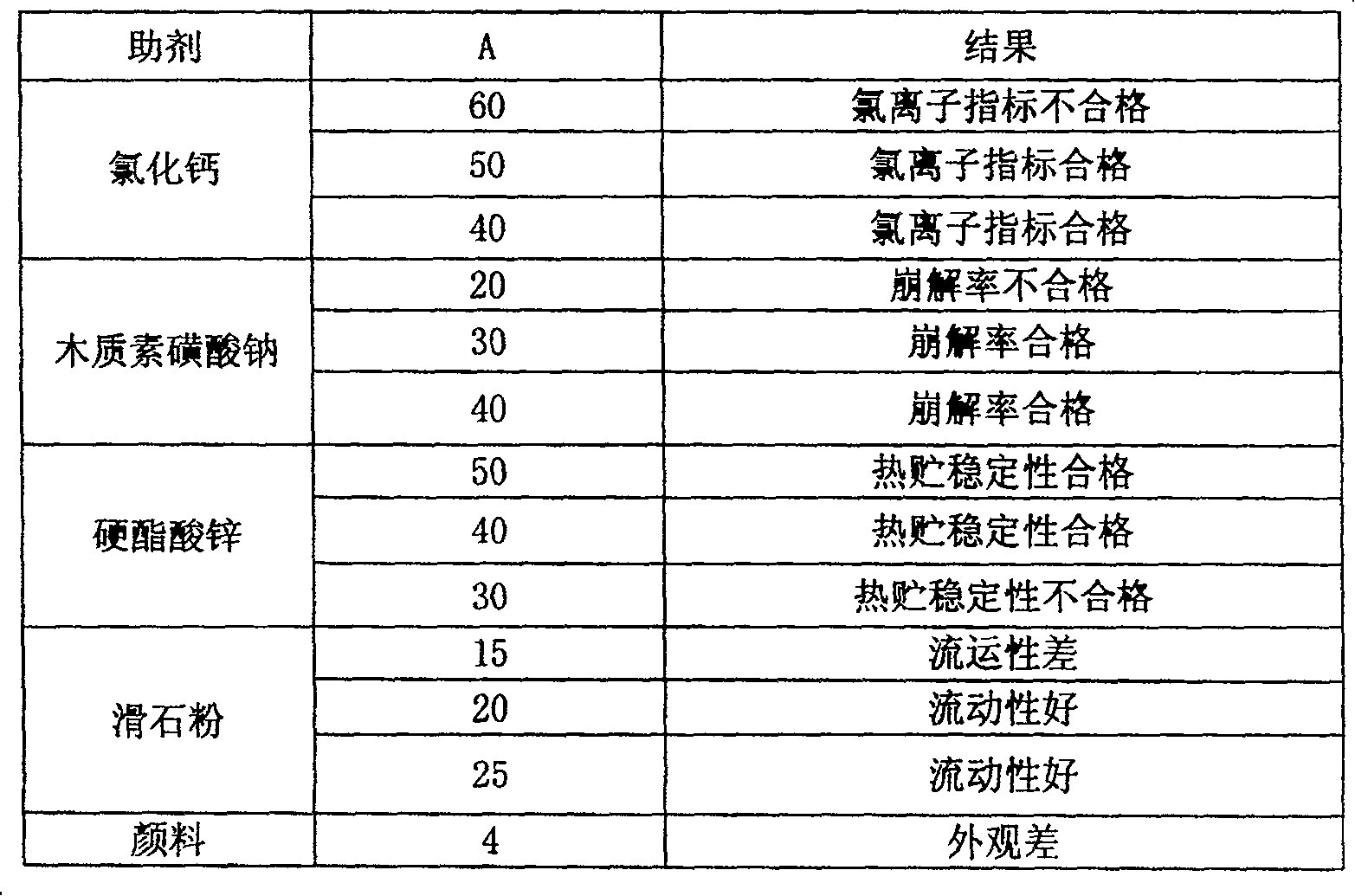

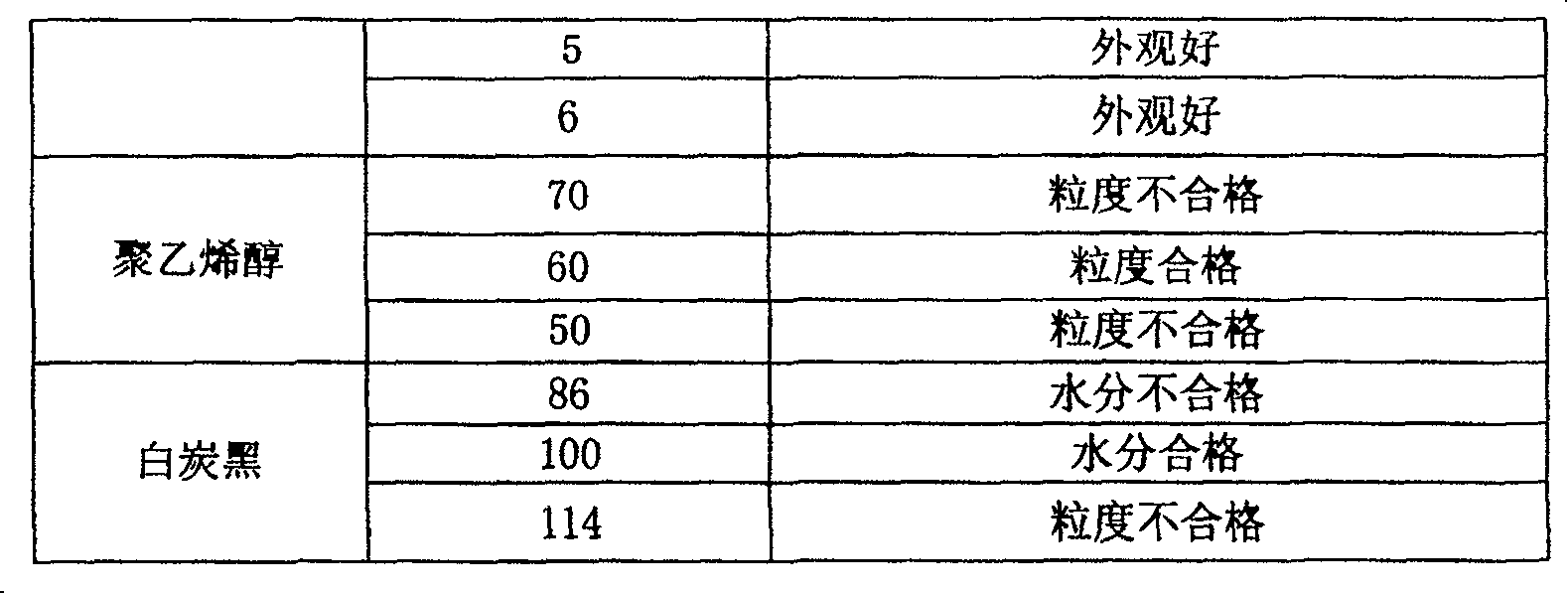

Pharmaceutical bottom fertilizer granule for preventing cotton sprout plant diseases and insect pests

InactiveCN101016219AGood insecticidal effectImprove nutritional conditionsBiocideAnimal repellantsAdjuvantPotassium

The invention discloses a drug substrate fertilizer particle agent to prevent cotton seeding pest, which is characterized by the following: adopting nitrogen, phosphor, potassium or composite fertilizer as carrier; allocating imidacloprid, thiram, triazole ketone and adjuvant according to certain proportion; making the drug particle agent; modifying the nourishing condition and seeding growing environment; reinforcing pest-proof and growing property.

Owner:HUBEI NONGBEI CHEM IND

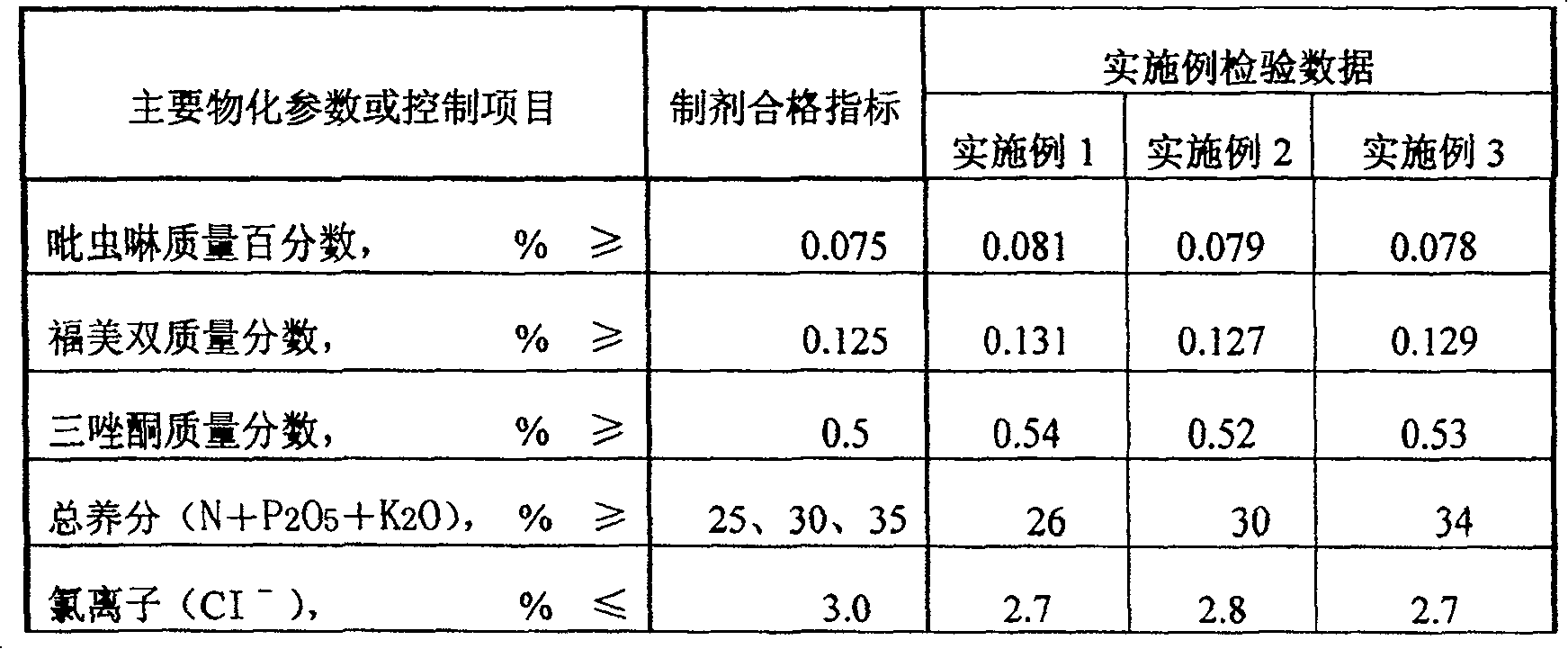

Production method capable of reducing side part folding occurrence rate of wide plate

ActiveCN110076207AAddresses manufacturing defects with edge foldsFix Manufacturing DefectsMetal rolling arrangementsSheet steelUltimate tensile strength

The invention discloses a production method capable of reducing a side part folding occurrence rate of a wide plate, and relates to the technical field of steel material forming and control. Continuously-cast casting blank adopts big-chamfer crystallizer drawn steel, and the big-chamfer casting blank is subjected to secondary chamfering after a continuous casting section is discharged, wherein secondary chamfering pressure is set to be 70-80 bar, and a secondary chamfering dimension is 13-15 mm; according to a rolling schedule, a widening-pass single-pass pressing rate is set to be smaller than 10%, and phosphorous removal operation is not performed in a widening process; after forming pass and widening, phosphorous removal operation is a performed in fine-rolling pass; a widening ratio isgreater than 1.5 times, trimming amount of a rolled steel plate is greater than or equal to 80 mm, a widening ratio of all steel types is lower than or equal to 2.0 time; and a widening ratio is setto be lower than or equal to 1.8 times if the strength grade of the steel type is greater than 500 MPa, and trimming amount of the rolled steel plate is greater than or equal to 100 mm if a widening ratio is greater than 1.5 times. The production method solves the manufacturing defect of side part folding in a production process of an extra-wide steel plate.

Owner:NANJING IRON & STEEL CO LTD

Manufacturing method of soft button lithium battery and soft button lithium battery

ActiveCN110783615ALow costThe overall thickness is thinFinal product manufactureCylindrical casing cells/batteryButton batteryCell fabrication

The invention provides a manufacturing method of a soft button lithium battery and the soft button lithium battery. The manufacturing method comprises the steps that a deep groove and a positioning part are formed by punching a lower aluminum plastic film; a shallow groove which matches the deep groove and a positioning matching part are formed by punching an upper aluminum plastic film; a roll-upbattery core is put into the deep groove for packaging; the upper aluminum plastic film covers the lower aluminum plastic film through the positioning part and the positioning matching part, and twoend faces of the roll-up battery core are placed in the deep and shallow grooves respectively; the positions of the positive and negative earpieces of the roll-up battery core and three or half circumferences of the upper aluminum plastic film and the lower aluminum plastic film are heat-sealed; after electrolyte injection, vacuumizing and forming are successively carried out, unsealed sides are heat-sealed; and a single cell is acquired through cutting and forming. The manufacturing method provided by the invention has the advantages of simple manufacturing process and high product quality. In addition, the manufactured button battery has the advantages of small volume and thin thickness.

Owner:松栢投资有限公司 +1

Contoured insoles for footwear

An insole assembly for use in footwear is provided. The insole assembly generally includes a full-length insole base made of a flexible and resilient material (e.g., resiliently compressible foam), and a heel cap made of a generally rigid material (e.g., a carbon fiber reinforced polymer) which is attached to the insole base and mimics the contours thereof to provide proper biomechanical support of the heel and arch areas of a foot in a particularly lightweight and sleek form factor.

Owner:SUPERFEET WORLDWIDE LLC

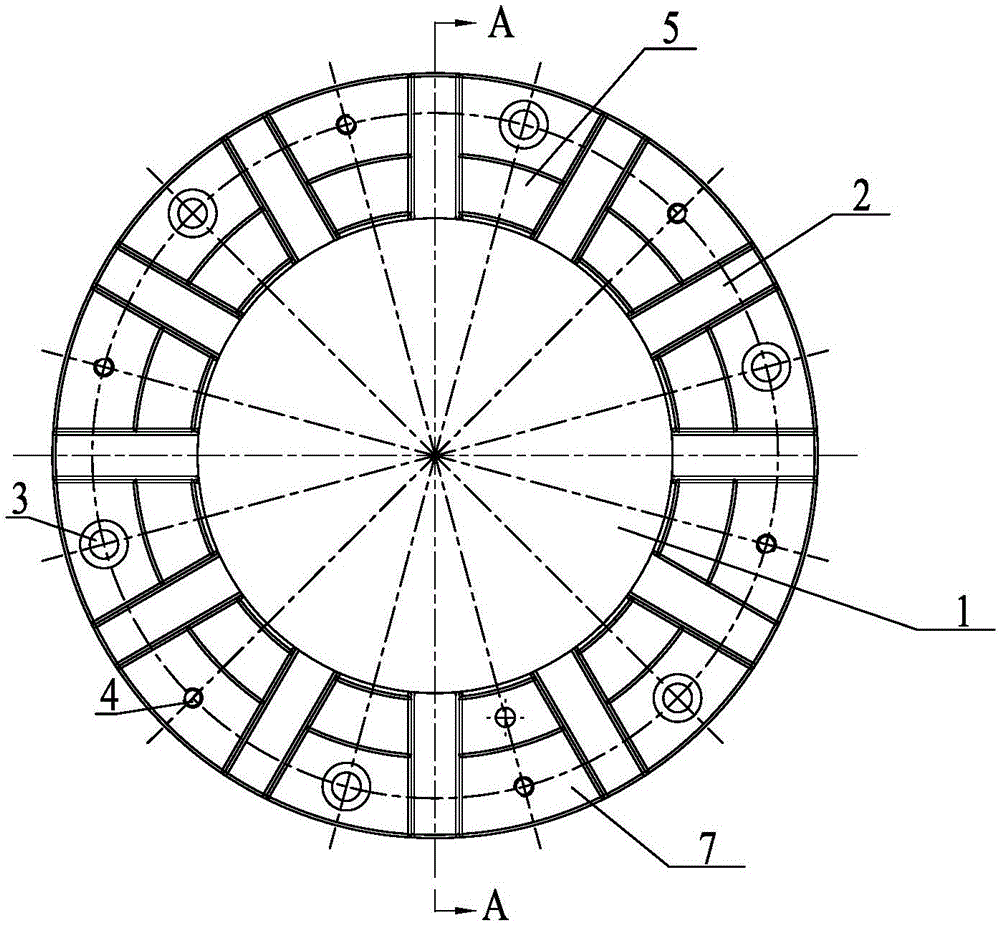

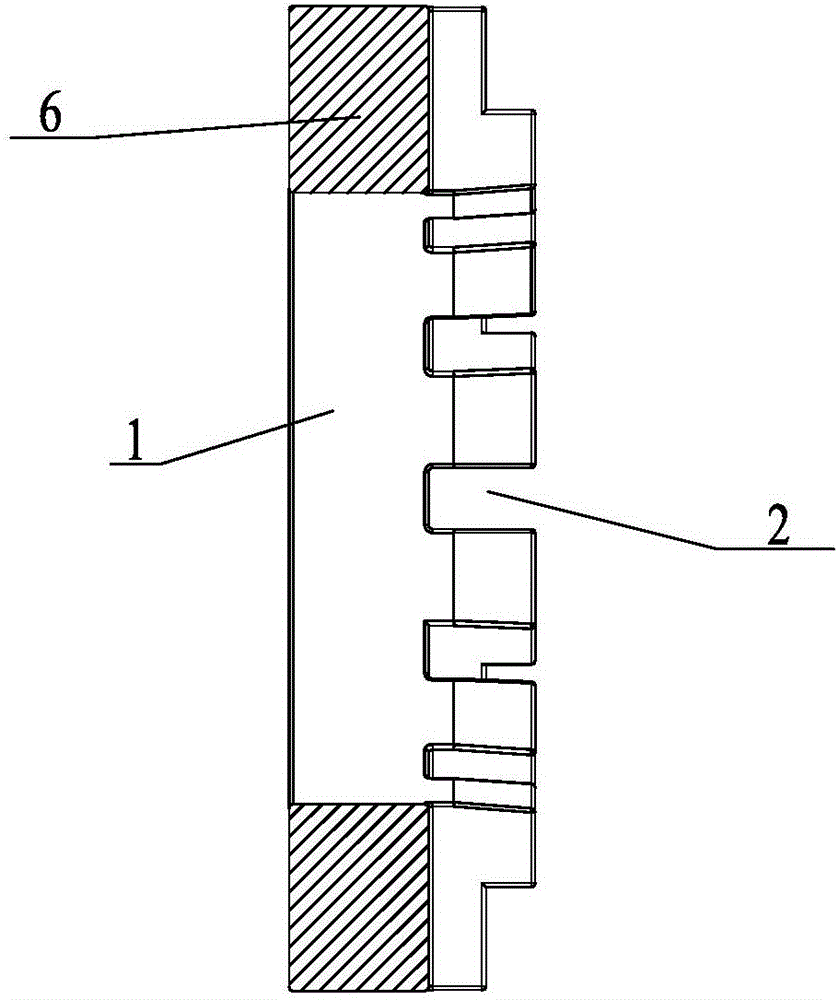

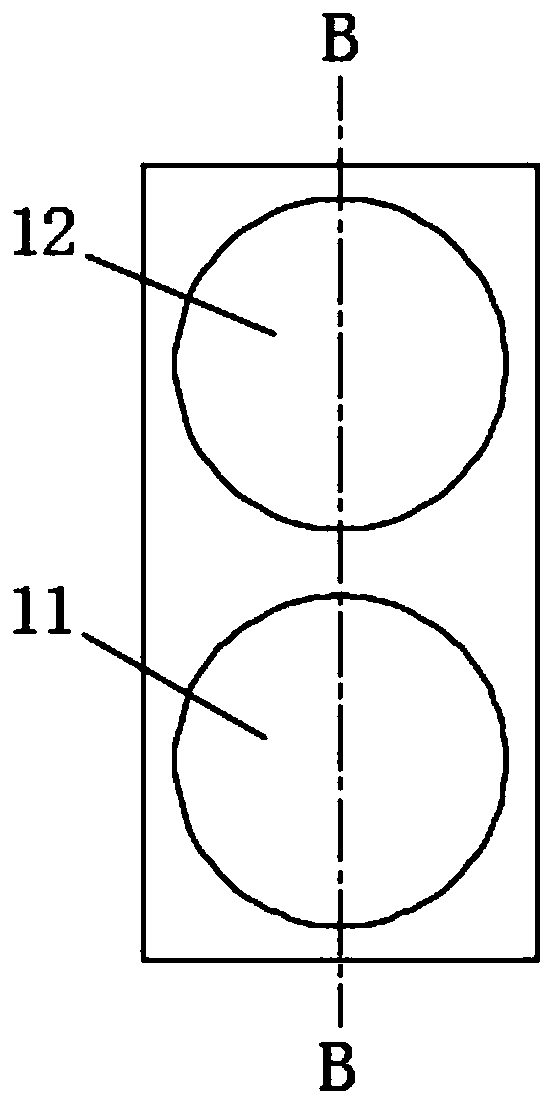

Welding fixed disc

InactiveCN106624543AReduce the overall heightForm factorWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringStator

The invention relates to a welding fixed disc, in particular to a welding fixed disc for an air conditioner stator. According to the technical scheme provided by the invention, the welding fixed disc comprises a disc body; a disc body through hole is formed in a center area of the disc body; multiple cutting grooves are uniformly distributed at the upper end of the disc body; multiple cutting support bodies are uniformly distributed at the upper end of the disc body through the cutting grooves; the cutting support bodies include inner support blocks near the disc body through hole, and outer support tables positioned on the outer sides of the inner support blocks; and the outer support tables are lower than the inner support blocks. The multiple cutting support bodies are uniformly distributed at the upper end of the disc body through the cutting grooves; the cutting support bodies include the inner support blocks near the disc body through hole, and the outer support tables positioned on the outer sides of the inner support blocks; the outer support tables are lower than the inner support blocks; and the welding fixed disc is convenient to use, can support welding of the air conditioner stator, realizes effective limitation of the appearance of the air conditioner stator, and is safe and reliable.

Owner:WUXI CHUANGHENG MACHINERY

Manufacturing method of soft-packed cylindrical battery

InactiveCN109786775ASimple processIncrease productivityFinal product manufactureSmall-sized cells cases/jacketsPunchingSulfur

The invention discloses a manufacturing method of a soft-packed cylindrical battery. According to the method, a first accommodating pit and a second accommodating pit are formed by performing one-timestamping on an aluminum plastic film, and the appearance is standardized. After the aluminum plastic film is punched and cut, a wound core or a laminated core is placed in the first accommodating pitand the second accommodating pit, when electrolyte is injected, electrolyte containing a sulfur element additive is used, and the electrolyte absorbs a generated gas during a formation process. Therefore, no airbag is needed in a pit punching process, and a secondary sealing process is omitted, thereby simplifying the process, improving the production efficiency and reducing the production cost.The preparation of the cylindrical battery can be completed by completing the liquid injection, top sealing and side sealing in a dry environment.

Owner:CHONGQING VDL ELECTRONICS

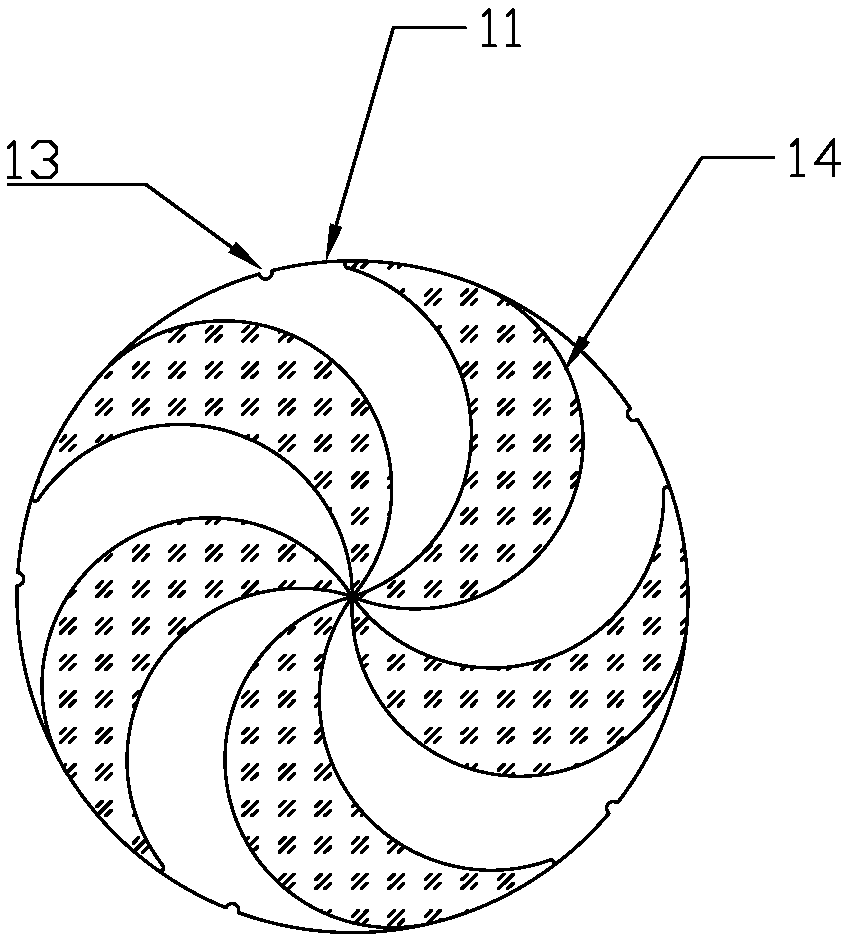

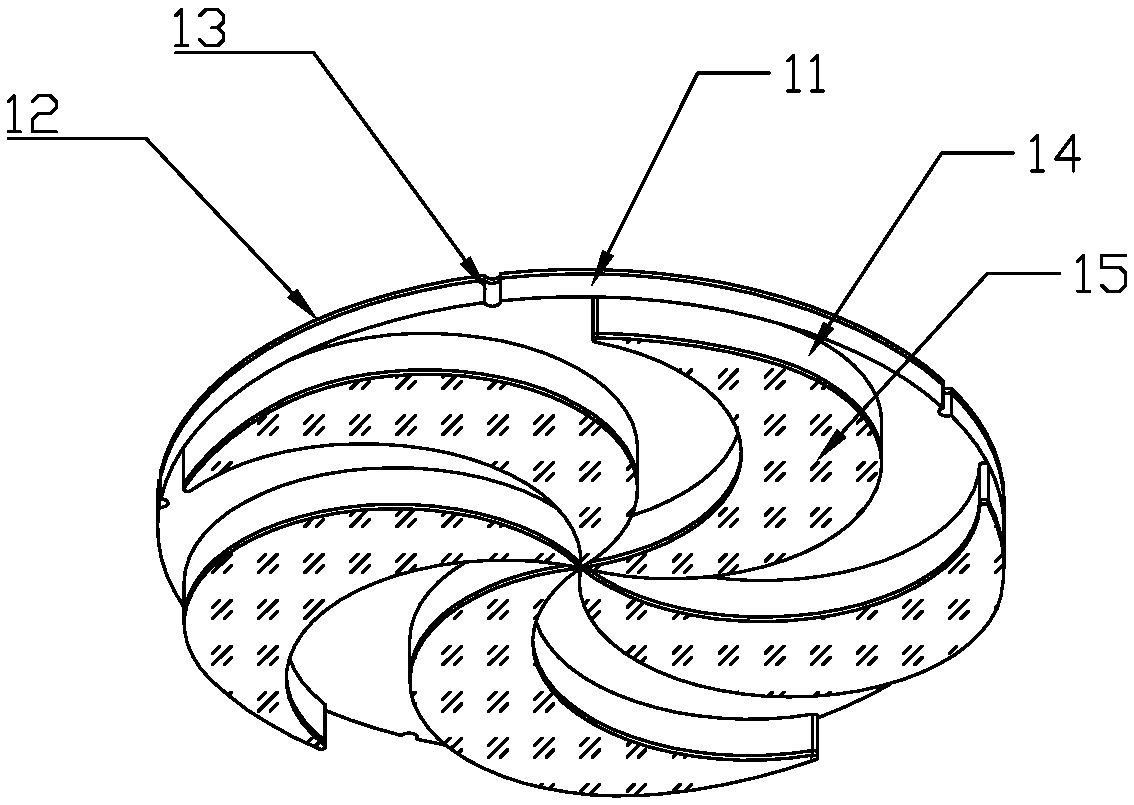

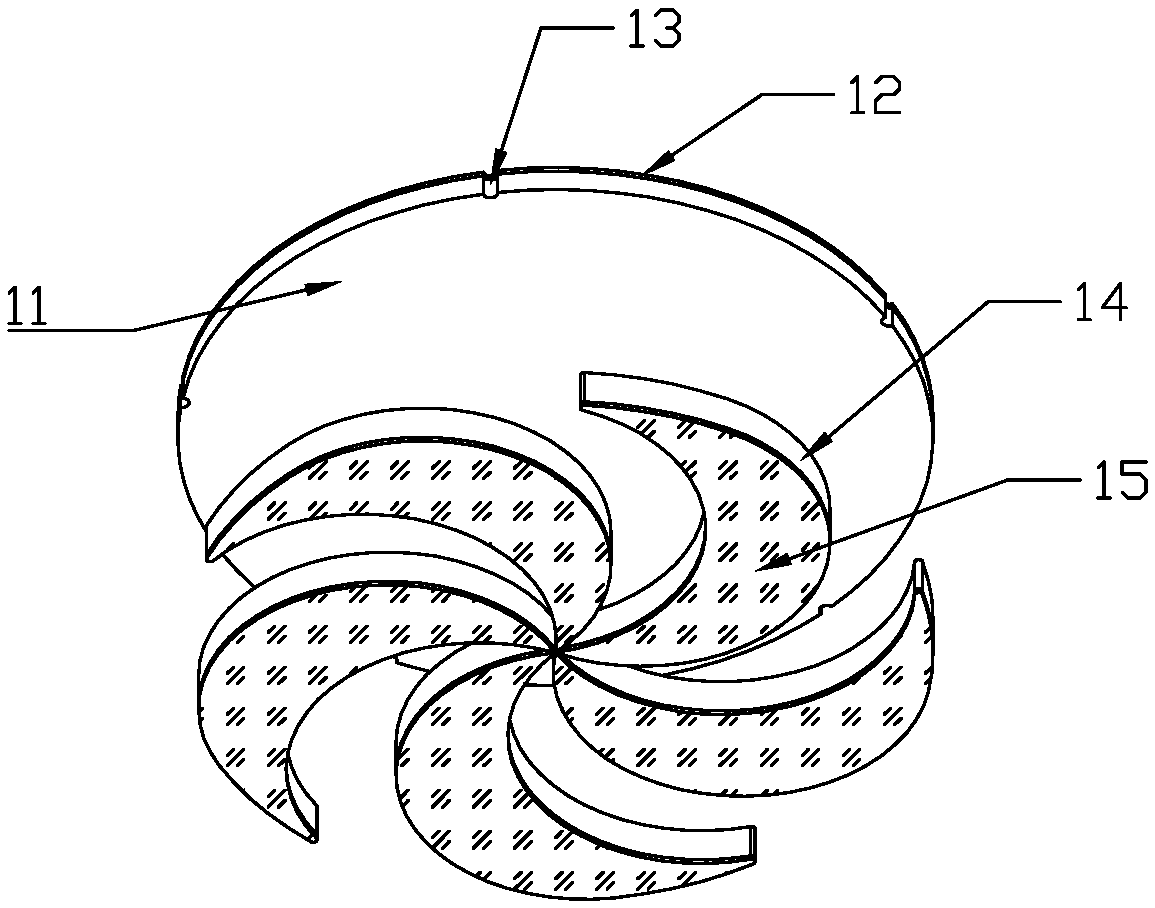

Cleaning head for electric rotating mop

InactiveCN109846426AGood cleaning effectEasy to processCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a cleaning head for an electric rotating mop. The cleaning head comprises a disc and a plurality of cleaning bodies which are arranged under the disc, distributed at intervalsin the circumferential direction and bent in the same direction, wherein the bending direction of the cleaning bodies is consistent with the rotating direction of the cleaning head during work; one ends of the cleaning bodies are connected to the center of the disc; the spacing between every two adjacent cleaning bodies is gradually reduced from outside to inside; garbage on the ground is wiped and gathered by the cleaning bodies into the gap between every two adjacent cleaning bodies and clamped and kept in the gap between every two adjacent cleaning bodies. The cleaning head can be directlyused for replacing a circular mop cloth used by an existing product without changing the existing electric mop, dirt can be gathered, and the garbage left on the ground is reduced.

Owner:阳珉

Method for processing crystal pig head meat

The present invention relates to a processing method of crystal pig's head meat. Said processing method includes the following steps: placing refined pig's head into a flavouring soup to make first stewing procedure, then taking out said pig's head, removing bone and making second stewing procedure; then placing the bone-removed pig's head meat into mould box, forming and thirdly stewing pig's head meat together with mould box; then using clear water to wash said mould box, after said mould box is cooled, taking out the bone-removed pig's head meat from said mould box, finishing and packaging so as to obtain the invented crystal pig's head meat.

Owner:TIANJIN CHINESE & BRITISH NANOMETER TECH DEV

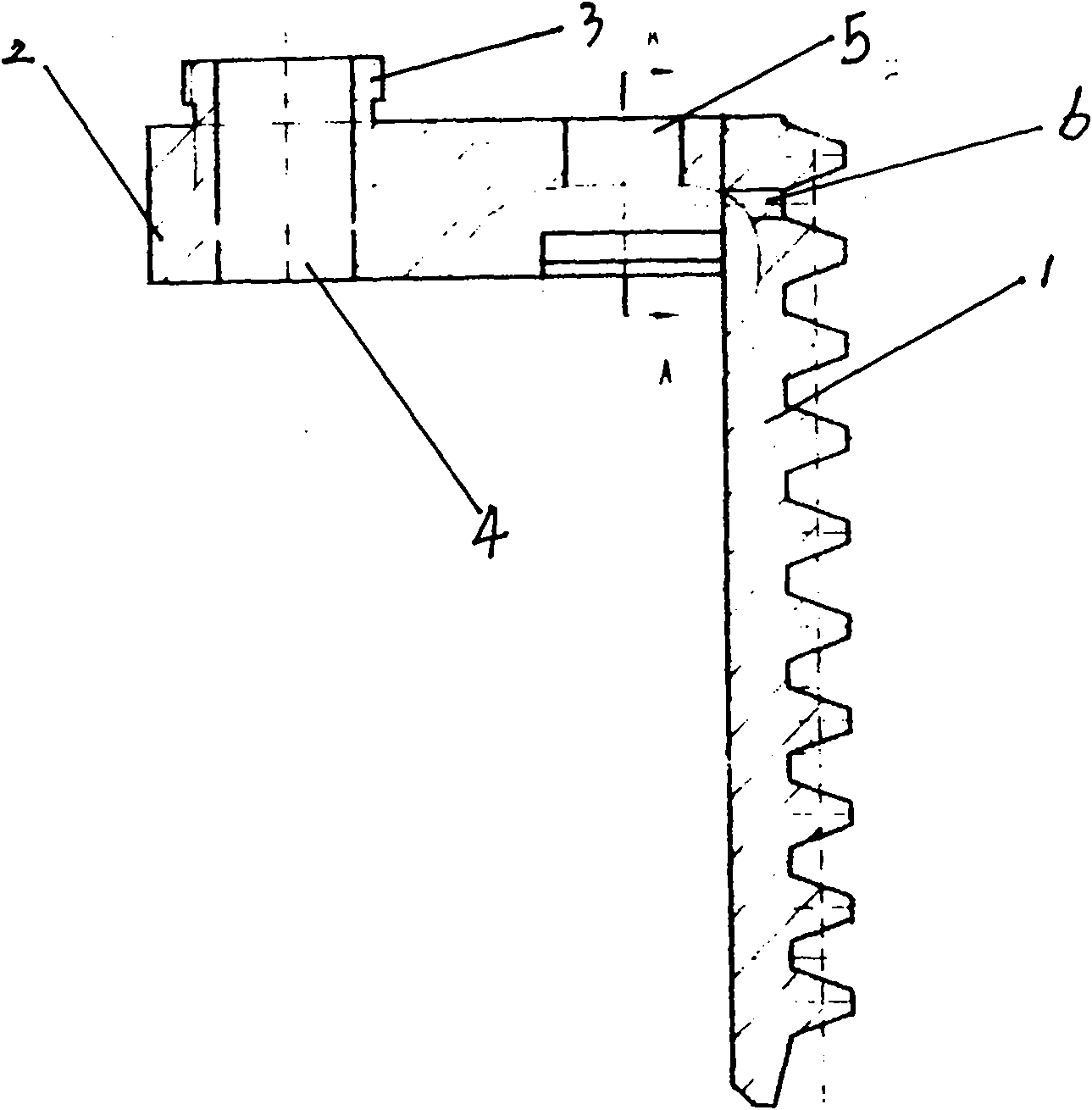

Rack machining process

The invention relates to a rack machining process, which comprises the following steps of: carrying out hot casting to form a rack blank; removing cast burrs; boring and milling a taper hole and a column hole on a cap sect; turning a thread; drilling a pin hole; removing sharp corners and burrs entirely and polishing; soaking for removing oil, passivating and cleaning; and plating chromium. The rack machining process can ensure the manufacturing quality and the product requirement of the component.

Owner:ZHAOYUAN CITY XINDUSNDARD PARTS FACTORY

Full-plastic construction guard fender

InactiveCN1995661ANo pollution in the processMeet environmental requirementsFencingShock resistanceCoal

The invention relates to an all-plastic construction wall for urban municipal engineering road, groove construction and pipeline project such as coal, water, electricity, heat, communication and so on, comprising wall body, substructure and window. Said substructure is hollow cavity. Water inlet is set at the upper of substructure and water outlet is set at the lower of substructure. Bolt and bolt hole are set at two sides of said wall body respectively. Vertical reinforced ribs are set between said substructure and window and transverse reinforced ribs are set on said substructure. Beneficial effects of the invention are that 1) the figuration is beautiful and canonical, it is coincidence with the demand of the whole circumstance in big city, it is easy to clean; 2) working condition of construction is improved and working efficiency is improved; 3) the usage ratio is high and it is applied in the protection of urban municipal facility and building construction; 4) it is provided with high intensity, good tenacity, strong rigidity, heat resistance, cold resistance, acid resistance, alkali resistance, shock resistance and so on; 5) it is the product with energy saving and environmental protection.

Owner:LONGTENGXUANSU TRAFFIC SAFETY INSTALLATION MFG WUHAN +1

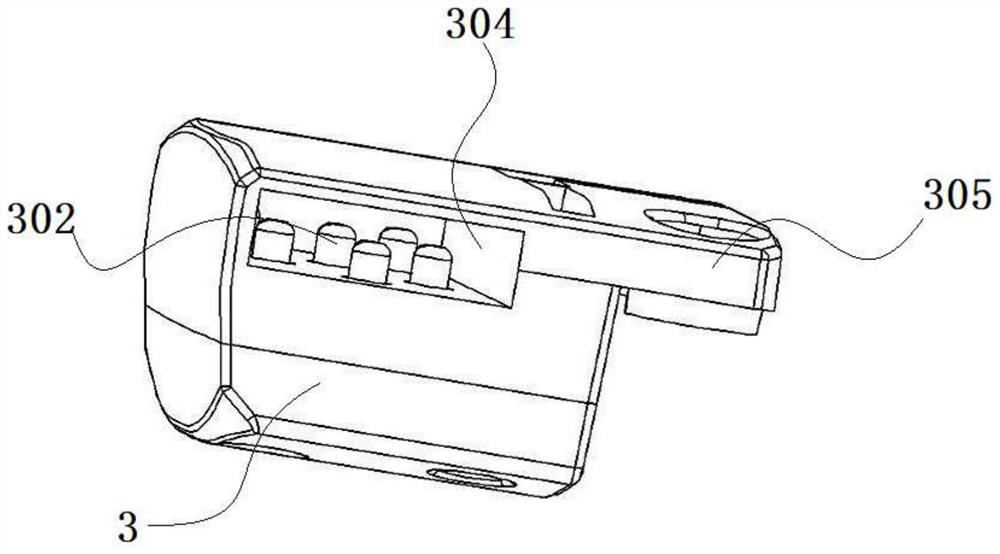

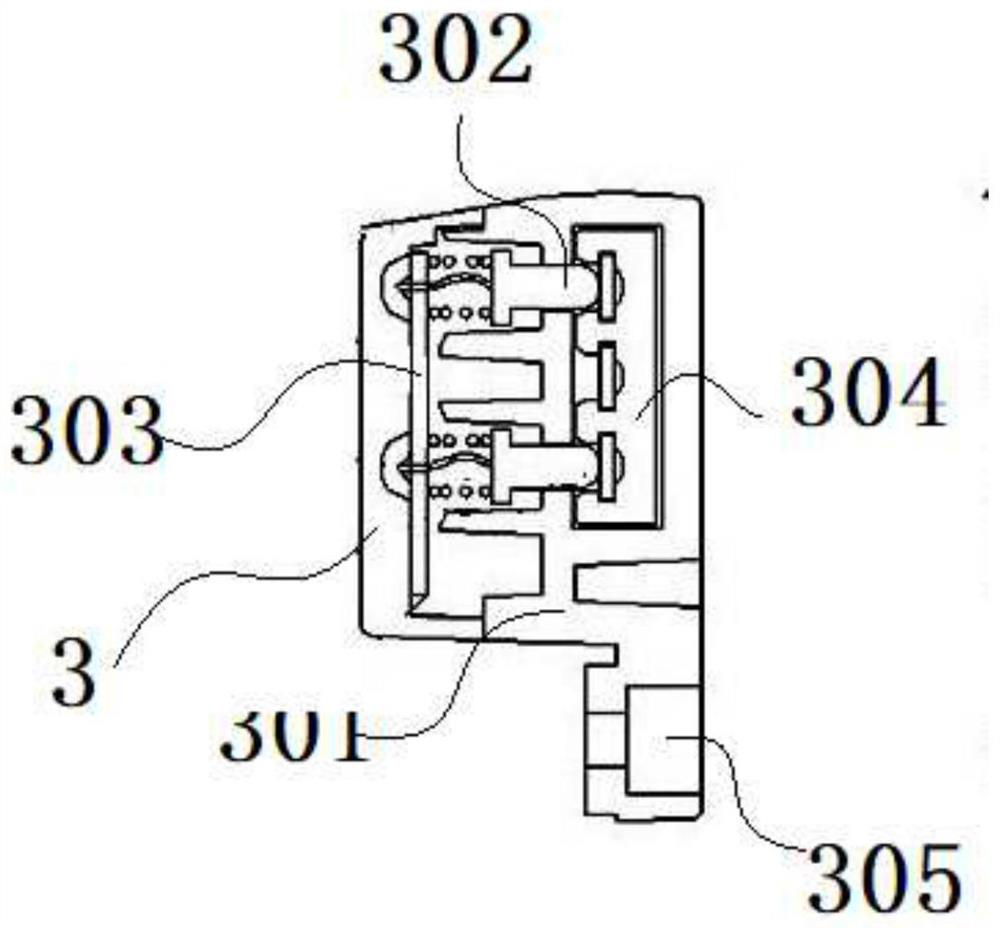

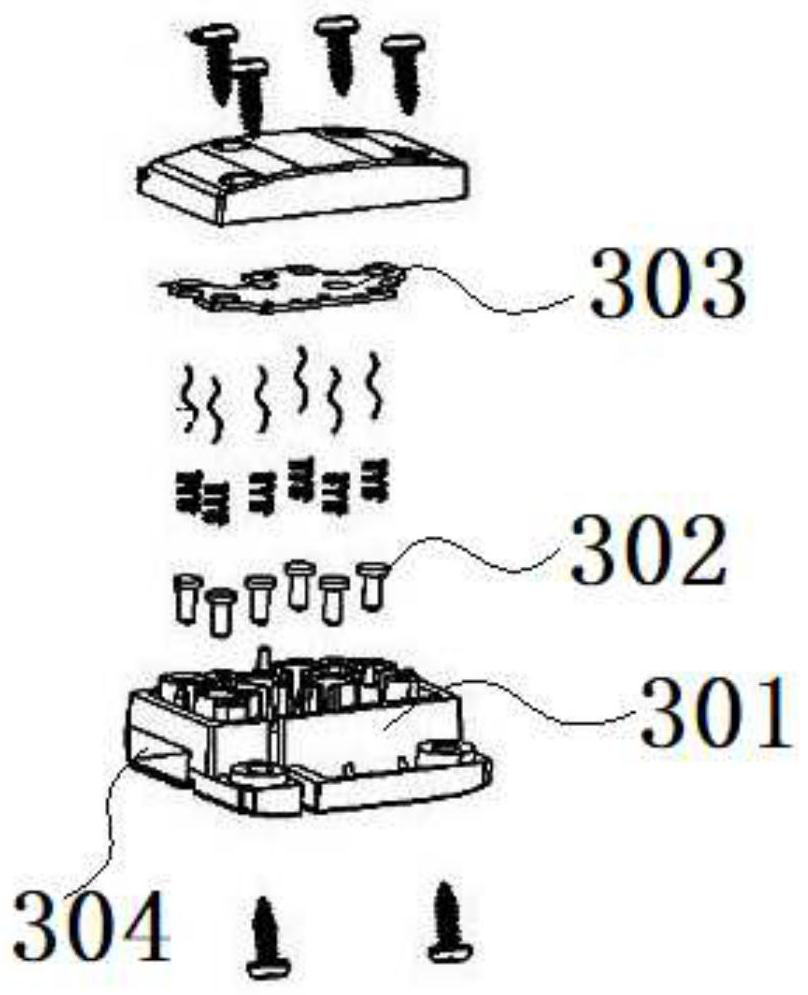

Flexible sliding power supply assembly, massage back cushion and control method of massage back cushion

ActiveCN112510458AImprove adaptabilityStructural specificationProgramme controlPhysical therapies and activitiesMassageElectrical connection

The invention discloses a flexible sliding power supply assembly, a massage back cushion and a control method of the massage back cushion. Two or more fixing grooves are formed in a flexible conductive rail, and conductive strips are installed in the fixing grooves in an embedded mode; a sliding conductive assembly is installed on the flexible conductive rail, the sliding conductive assembly is slidably and electrically connected with the conductive strip, and the conductive strip is correspondingly and electrically connected to the power supply and the controller. The flexible conductive railcan be unidirectionally bent in a large arc manner to adapt to massage chairs in different shapes, is good in adaptability, and can be used for a common back cushion and a curved back cushion; the flexible conductive rail and the tunnel type sliding power transmission assembly can be made into standard parts, and can be universally used for various back cushions, so that the development cost is reduced, and the assembly is convenient; the flexible conductive rail is connected by adopting a tunnel type probe control sleeve structure, and is fixed reliably during sliding guide; and one controller can be connected with a plurality of massage machine cores with tunnel sliding electricity transmission assemblies, the number of wires is reduced, and the problems that wires of a massage cushionare broken and massage heads are twisted are thoroughly solved.

Owner:SHENZHEN MONDIAL TECH CO LTD

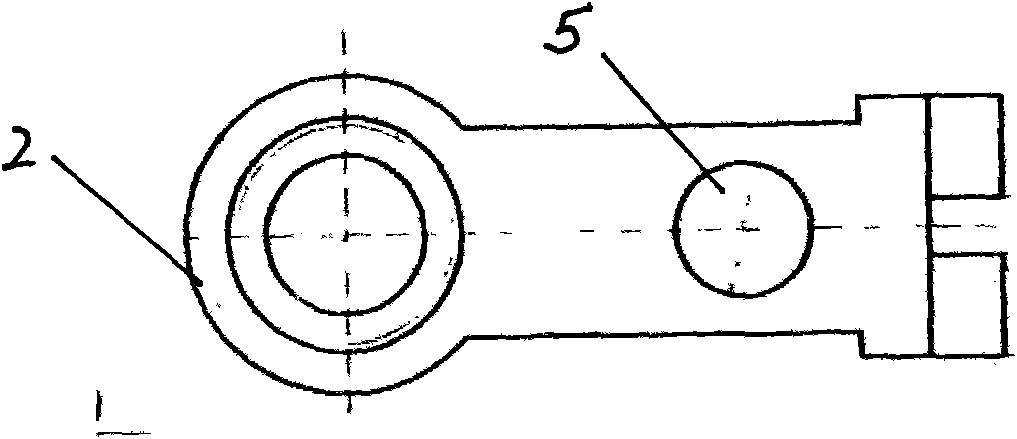

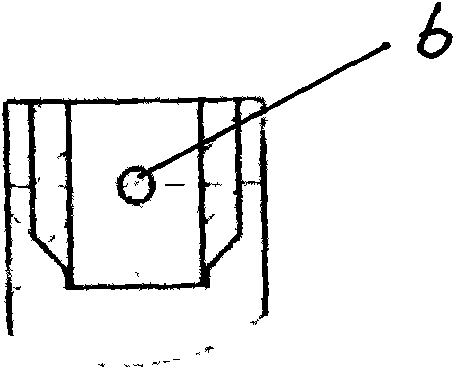

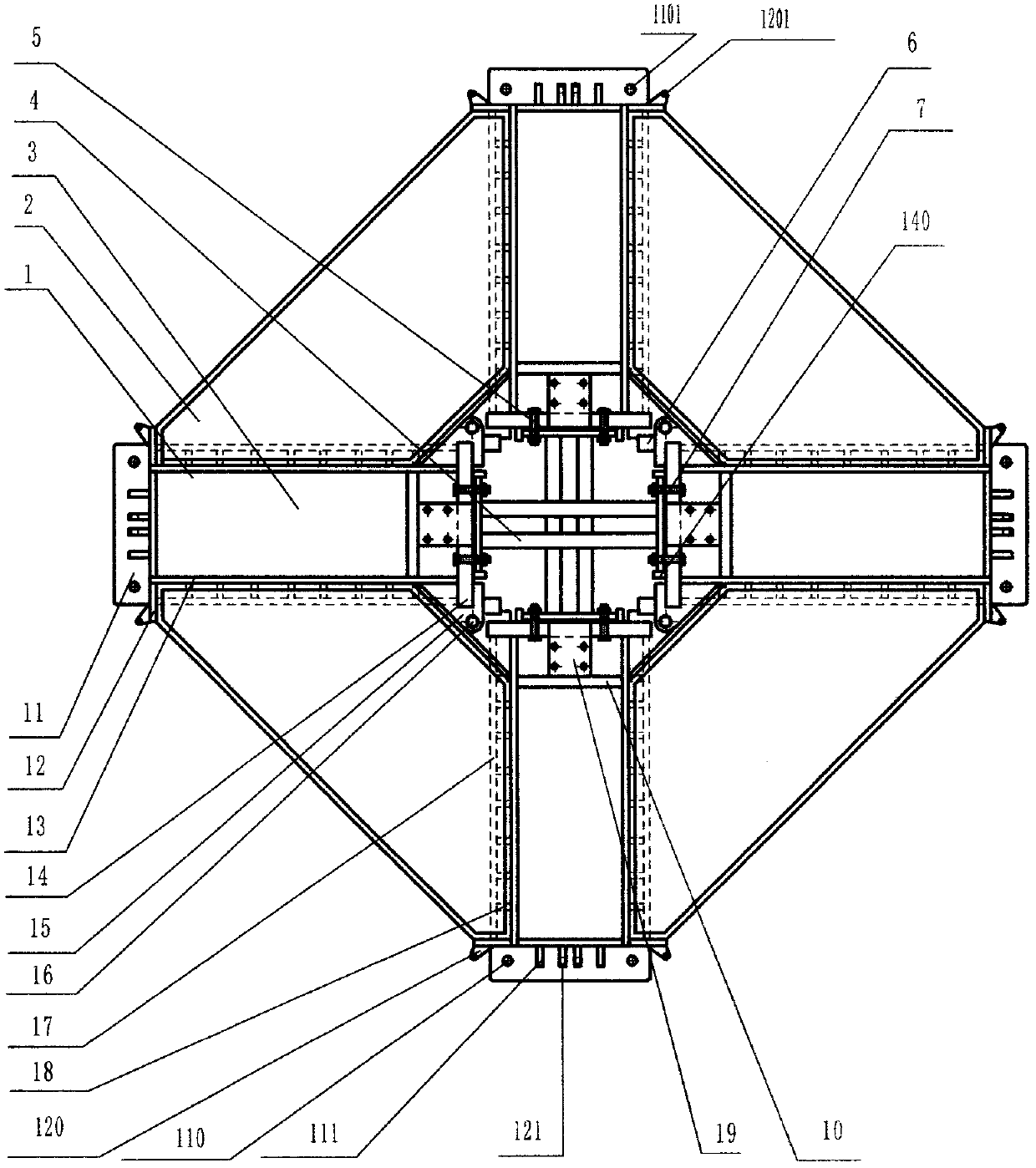

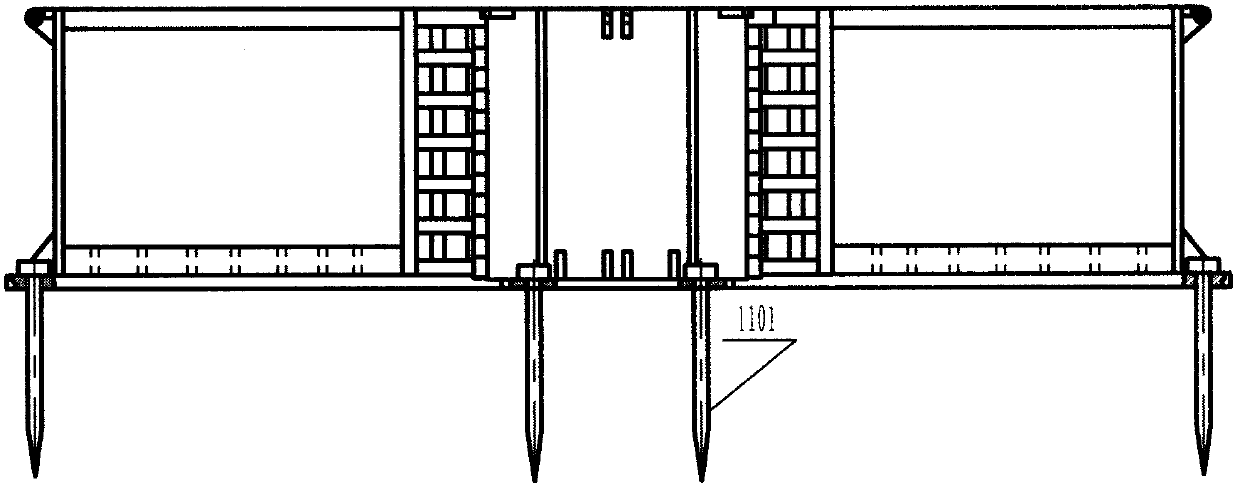

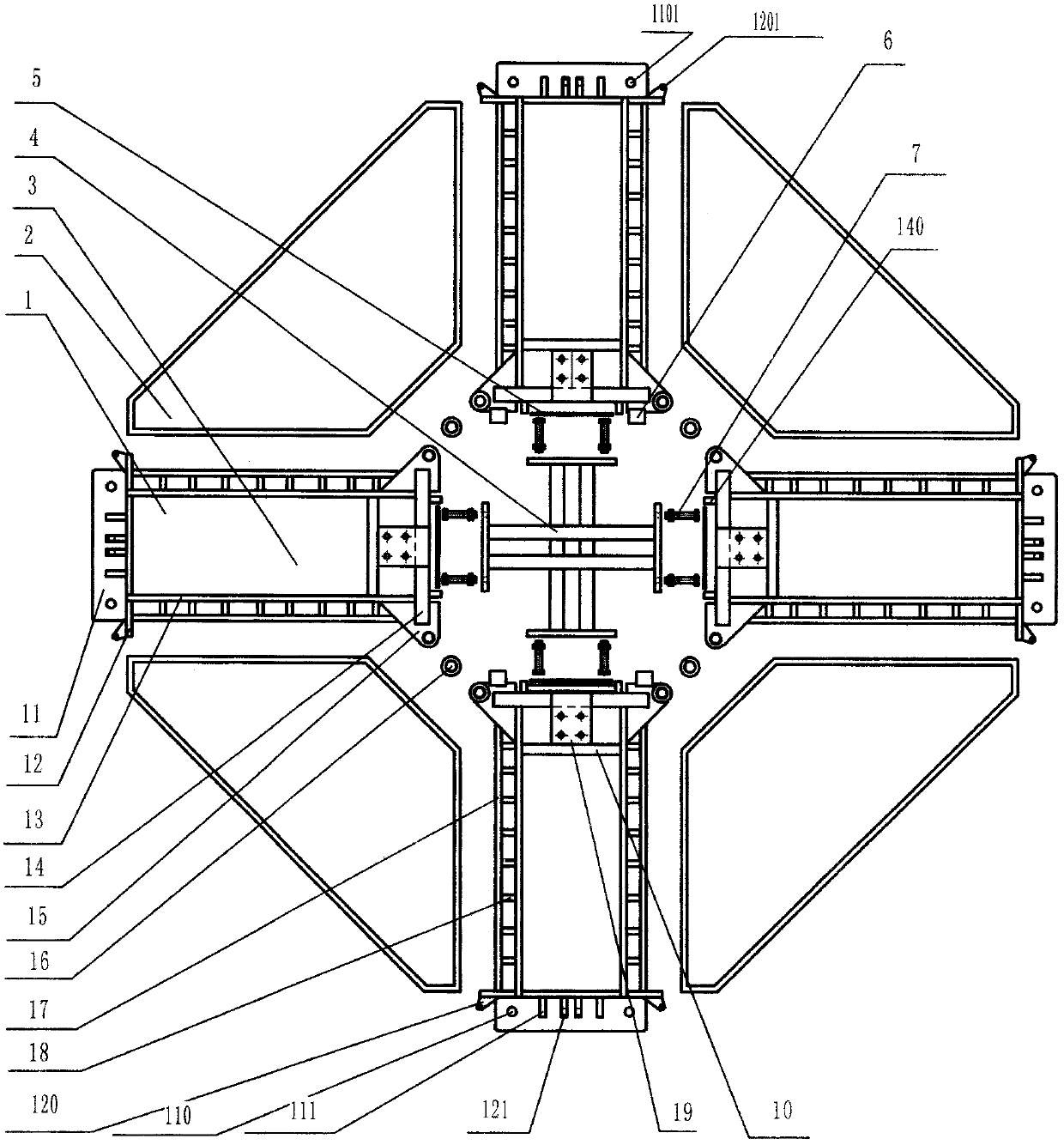

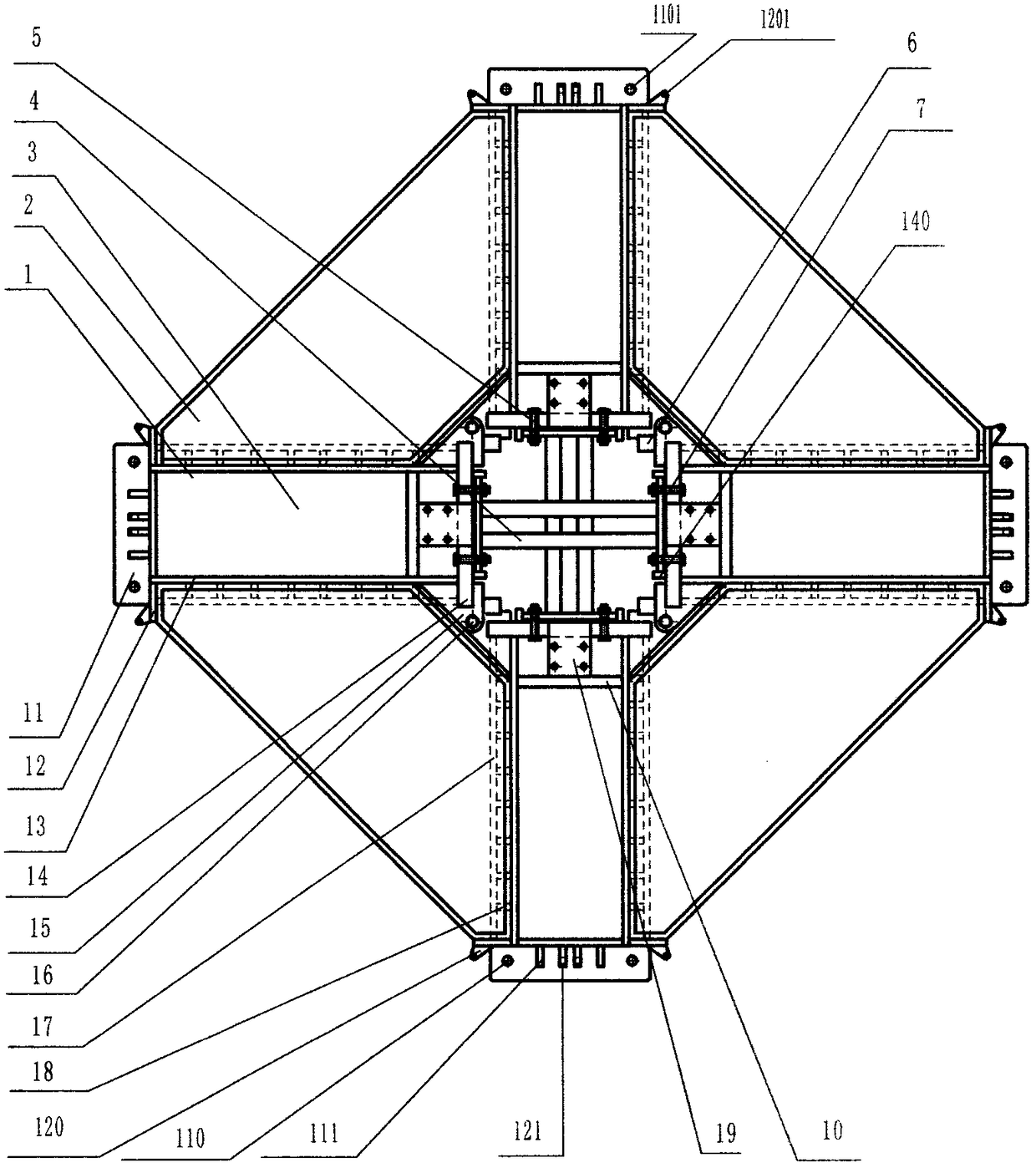

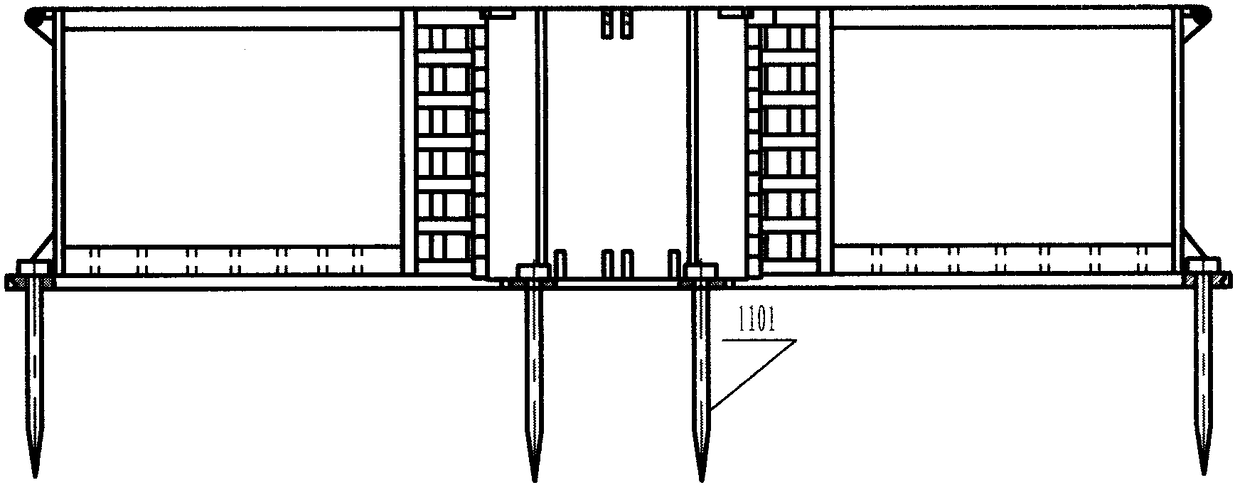

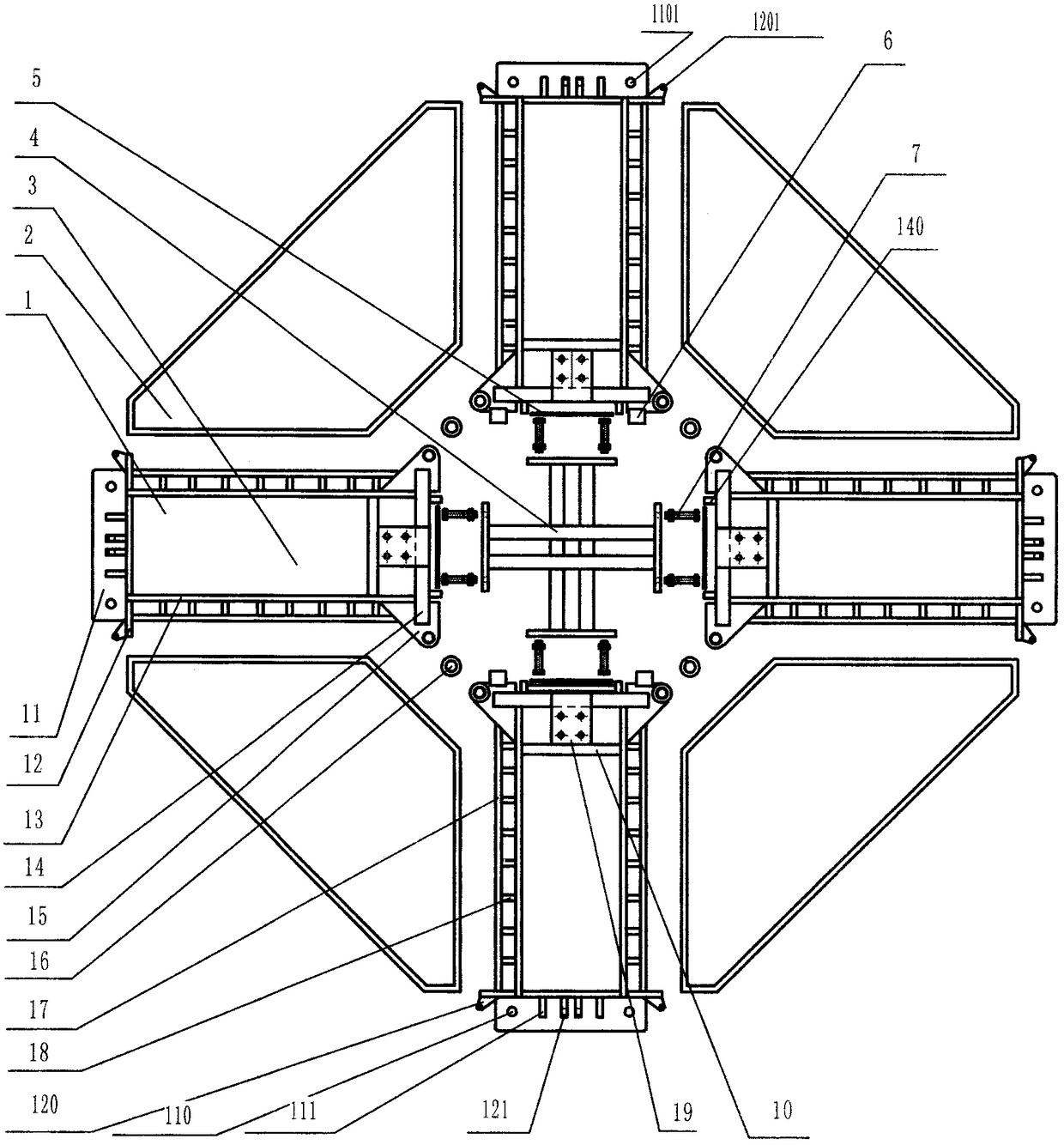

Tower crane foundation with four-beam steel structure and counterweight that can be quickly folded and moved

ActiveCN108086345BProfessional manufacturing unitLearn about performance parametersFoundation engineeringTower craneBolt connection

The invention relates to the field of building construction machines, in particular to a four-beam steel structure tower crane foundation provided with counterweights and capable of being folded and moving quickly. The four-beam steel structure tower crane foundation mainly comprises main beams (1), a cross-shaped supporting frame (4), the main counterweights (2), the main beam counterweights (3)and ground anchors (1101) and is characterized in that the four steel structure main beams (1) and the adjacent main beams are matched through lug plates (15) with holes and hinged through pin shafts(16), wherein the lug plates (15) with the holes are arranged on the two sides of the front ends of the four steel structure main beams (1); the four steel structure main beams are distributed in a cross shape; the cross-shaped supporting frame (4) is arranged among the four main beams and connected with front blocks (14) of the four main beams through bolts (7) correspondingly, and a set of correction sizing blocks (5) is arranged between the cross-shaped supporting frame (4) and the front block (14) of each of the four main beams; and each main counterweight (2) is arranged between the two corresponding adjacent main beams and pressed on rib plates (17 and 18) at the bottoms of the main beams, and the main beam counterweights (3) are arranged in a main beam box body structure. The four-beam steel structure tower crane foundation is stable in structure, simple in manufacturing process, convenient and fast to move and transport and high in repetition utilization rate, compared with anexisting tower crane foundation, resource waste is reduced, the cost is saved, and the environment is protected.

Owner:高文朋

Hook face waterproof structure

The invention relates to a hook face waterproof structure composed of a plurality of waterproof structure units. Each waterproof structure unit is composed of a buckling piece, a supporting piece anda connecting piece, wherein the buckling piece and the supporting piece are connected into a whole through the connecting piece. According to the hook face waterproof structure, the buckling piece ofthe previous waterproof structure unit is engaged with the supporting piece of the rear waterproof structure unit, and accordingly a mutually closed and engaged mouth-shaped structure is formed. The waterproof structure units are sequentially connected, and accordingly the hook face waterproof structure is formed. The hook face waterproof structure is standard in appearance, lasting in heat preservation and capable of achieving the effect of complete water prevention and being applied to connection of any hook face edges needing water prevention. In addition, the hook face waterproof structureis long in service life, the maintaining cost, manpower and material resources are saved, and the structure is reasonable and stable.

Owner:徐正强

Cooperative tablet computer and mobile communicator

ActiveUS9094492B2Simple batteryLow costDevices with multiple display unitsTelephone set constructionsTablet computerCommunications system

A communication system, including a mobile communicator including a modem for conducting a communication with a remote party, an input unit for inputting communication data to the modem, and an output for outputting communication data from the modem, a display device including an input unit, an output unit, a connector for engaging the mobile communicator and for exchanging data with the mobile communicator, and a display for displaying party-specific information about the remote party involved in the communication, wherein the modem switches to receive its communication input via the display device input unit and directs its communication output to the display output unit when the mobile communicator is engaged with the connector, and wherein the modem switches back to receive its communication input via the mobile communicator input unit and directs its communication output to the mobile communicator output unit when the mobile communicator is disengaged from the connector.

Owner:GOOGLE LLC

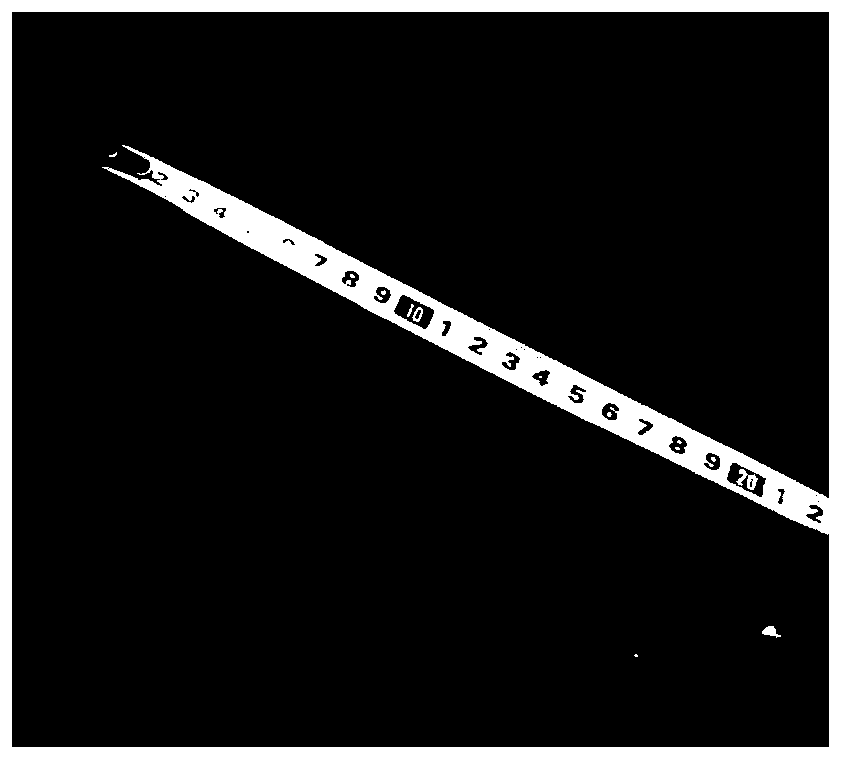

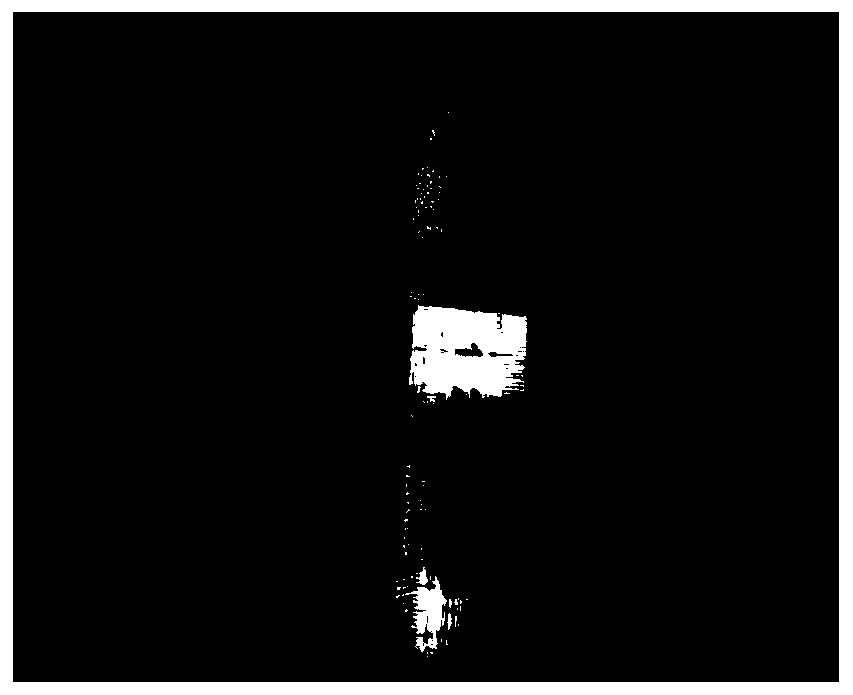

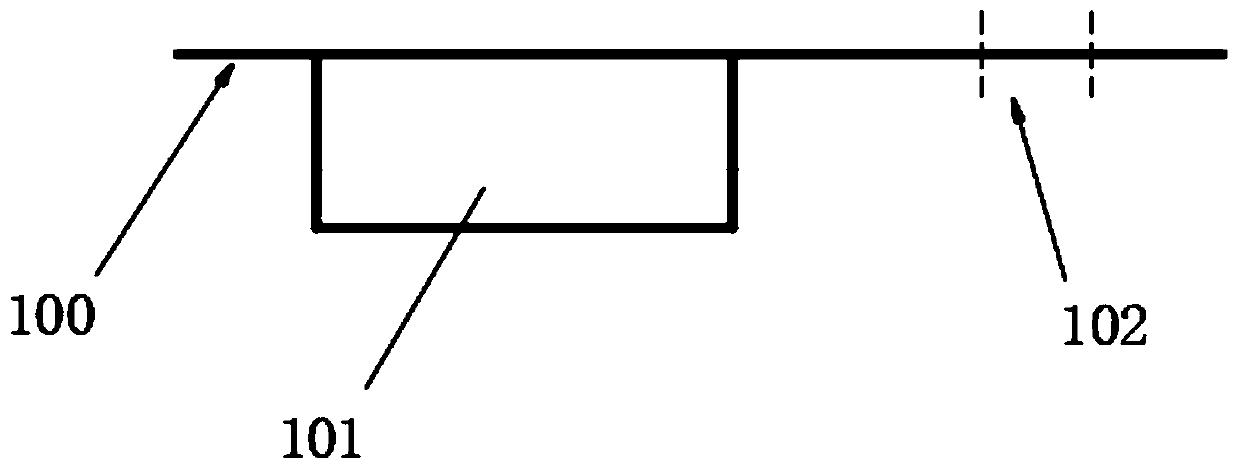

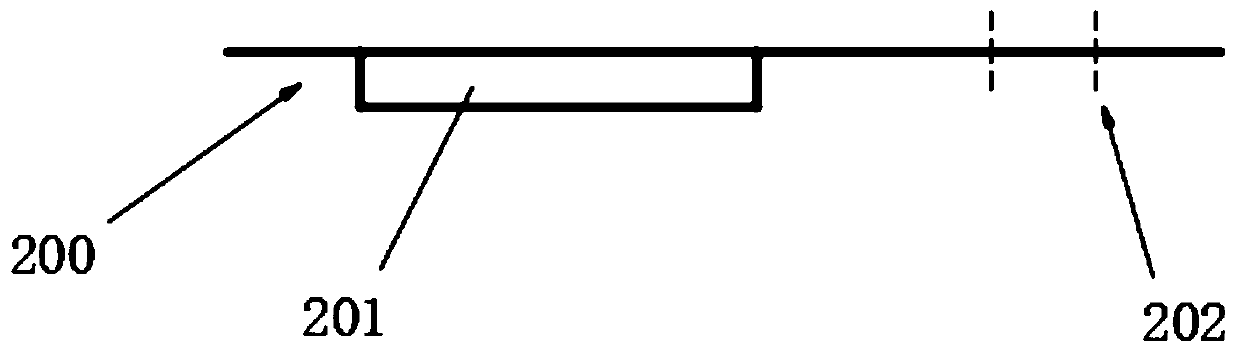

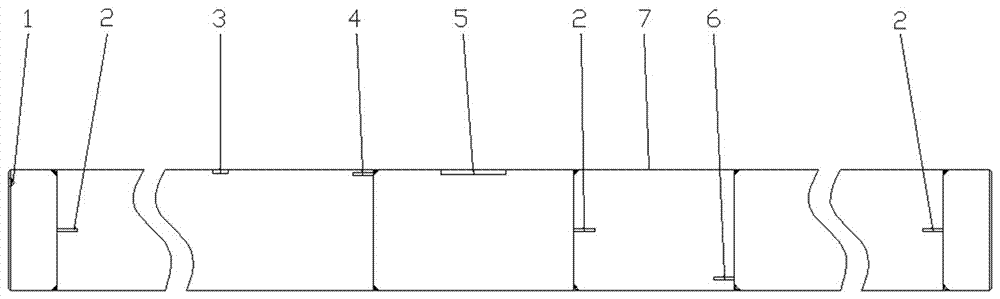

Model rod for bar automatic-rotation supersonic wave detection and use method thereof

ActiveCN104914170AForm factorReasonable arrangementMaterial analysis using sonic/ultrasonic/infrasonic wavesSupersonic wavesEngineering

The invention relates to a model rod for bar automatic-rotation supersonic wave detection. The model rod comprises a cylindrical rod, the upper end of a side of the rod is provided with a blind hole, the middle of the rod in the rear of the blind hole is provided with a central cross bore, the rear side of the central cross bore is provided with a surface short shallow groove on the upper surface of the rod, the rear side of the surface short shallow groove is provided with a subskin cross bore which is located on the upper surface of the rod, the rear side of the subskin cross bore is provided with a surface long deep groove located on the upper surface, the rear side of the surface long deep groove is provided with a central cross bore located at the middle of the rod, the rear end of the central cross bore is provided with a cross bore close to the surface which is located at the lower part of the rod, and a part close to the rear end of the rod is provided with a central cross bore located at the middle of the rod. The model rod has the characteristics of a normative shape, reasonable man made destroy arrangement, clear identification, simple structure, comprehensive functions, operation easiness, accurate verification, safety, practicability and no maintenance.

Owner:SGIS SONGSHAN CO LTD

Four-beam steel structure tower crane foundation provided with counterweights and capable of being folded and moving quickly

ActiveCN108086345AProfessional manufacturing unitLearn about performance parametersFoundation engineeringTower craneSizing

The invention relates to the field of building construction machines, in particular to a four-beam steel structure tower crane foundation provided with counterweights and capable of being folded and moving quickly. The four-beam steel structure tower crane foundation mainly comprises main beams (1), a cross-shaped supporting frame (4), the main counterweights (2), the main beam counterweights (3)and ground anchors (1101) and is characterized in that the four steel structure main beams (1) and the adjacent main beams are matched through lug plates (15) with holes and hinged through pin shafts(16), wherein the lug plates (15) with the holes are arranged on the two sides of the front ends of the four steel structure main beams (1); the four steel structure main beams are distributed in a cross shape; the cross-shaped supporting frame (4) is arranged among the four main beams and connected with front blocks (14) of the four main beams through bolts (7) correspondingly, and a set of correction sizing blocks (5) is arranged between the cross-shaped supporting frame (4) and the front block (14) of each of the four main beams; and each main counterweight (2) is arranged between the two corresponding adjacent main beams and pressed on rib plates (17 and 18) at the bottoms of the main beams, and the main beam counterweights (3) are arranged in a main beam box body structure. The four-beam steel structure tower crane foundation is stable in structure, simple in manufacturing process, convenient and fast to move and transport and high in repetition utilization rate, compared with anexisting tower crane foundation, resource waste is reduced, the cost is saved, and the environment is protected.

Owner:高文朋

Catcher tank assembly of waterjet cutting system

ActiveUS11045969B2Convenient shipmentEasy to assembleLarge containersMetal working apparatusSupporting systemEngineering

A catcher tank assembly is provided for a waterjet cutting machine. The catcher tank assembly includes a catcher tank having a plurality of tank sections detachably coupleable together in a side-by-side manner to collectively define a catcher tank having a desired configuration. The catcher tank assembly further includes a workpiece support system detachably coupleable to an interior cavity of the catcher tank. The workpiece support system may include a plurality of workpiece support modules arrangeable in an array to support a workpiece platform of the waterjet cutting machine. The workpiece platform may be formed, for example, by a series of slats supported transversely to parallel rows of the workpiece support modules. Methods and systems which relate to or include the aforementioned catcher tank assembly are also provided.

Owner:FLOW INT

A sample rod for automatic rotating ultrasonic detection of rods and its use method

ActiveCN104914170BForm factorArrangement of artificial injuries is reasonableMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringUltrasonic testing

Owner:SGIS SONGSHAN CO LTD

Pharmaceutical bottom fertilizer granule for preventing cotton sprout plant diseases and insect pests

InactiveCN100400480CImprove insecticidal effectImprove nutritional conditionsBiocideAnimal repellantsAdjuvantPotassium

The invention discloses a drug substrate fertilizer particle agent to prevent cotton seeding pest, which is characterized by the following: adopting nitrogen, phosphor, potassium or composite fertilizer as carrier; allocating imidacloprid, thiram, triazole ketone and adjuvant according to certain proportion; making the drug particle agent; modifying the nourishing condition and seeding growing environment; reinforcing pest-proof and growing property.

Owner:HUBEI NONGBEI CHEM IND

A Production Method for Reducing the Occurrence of Edge Folding of Wide Board

ActiveCN110076207BForm factorUniform thicknessMetal rolling arrangementsEngineeringUltimate tensile strength

The invention discloses a production method for reducing the occurrence rate of folding at the edge of a wide plate, and relates to the technical field of steel material forming and control. After the pouring section, carry out secondary chamfering, the secondary chamfering pressure is set to 70~80bar, and the secondary chamfering size is 13~15mm; Phosphorus removal operation is not carried out, and phosphorus removal operation is carried out after forming pass and widening, and finishing rolling pass; the width ratio is greater than 1.5 times, the trimming amount of the rolled steel plate is ≥80mm, and the width ratio of all steel grades is ≤2.0 times; the strength level of steel grades If it is greater than 500MPa, the width ratio should be set to be ≤1.8 times, and if the width ratio is greater than 1.5 times, the trimming amount of the rolled steel plate should be greater than or equal to 100mm. The invention solves the manufacturing defect of the edge folding of the extra-wide steel plate in the production process.

Owner:NANJING IRON & STEEL CO LTD

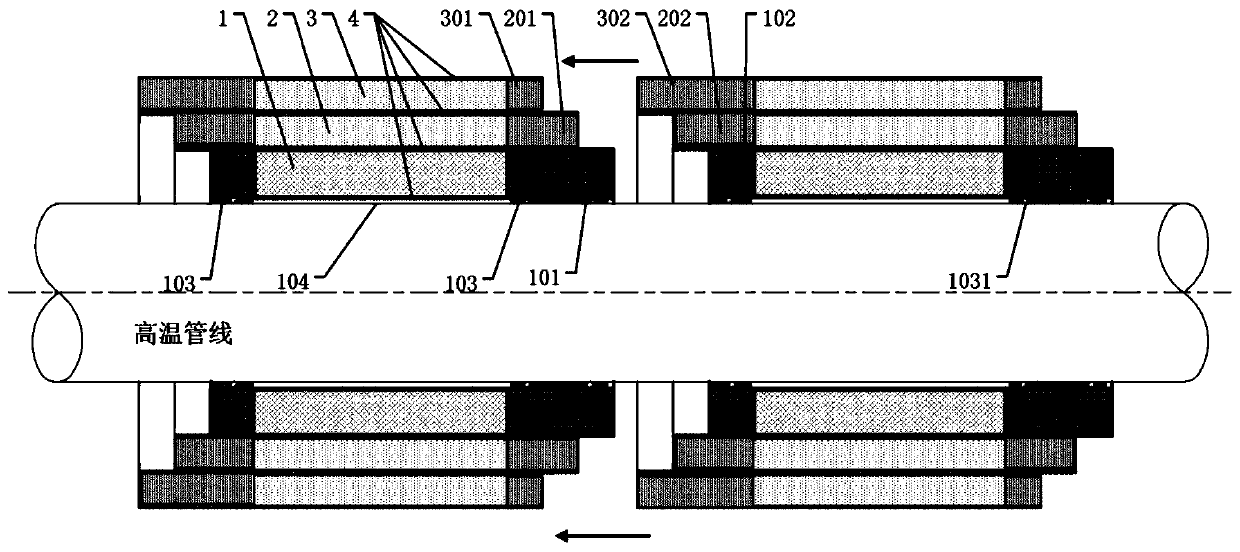

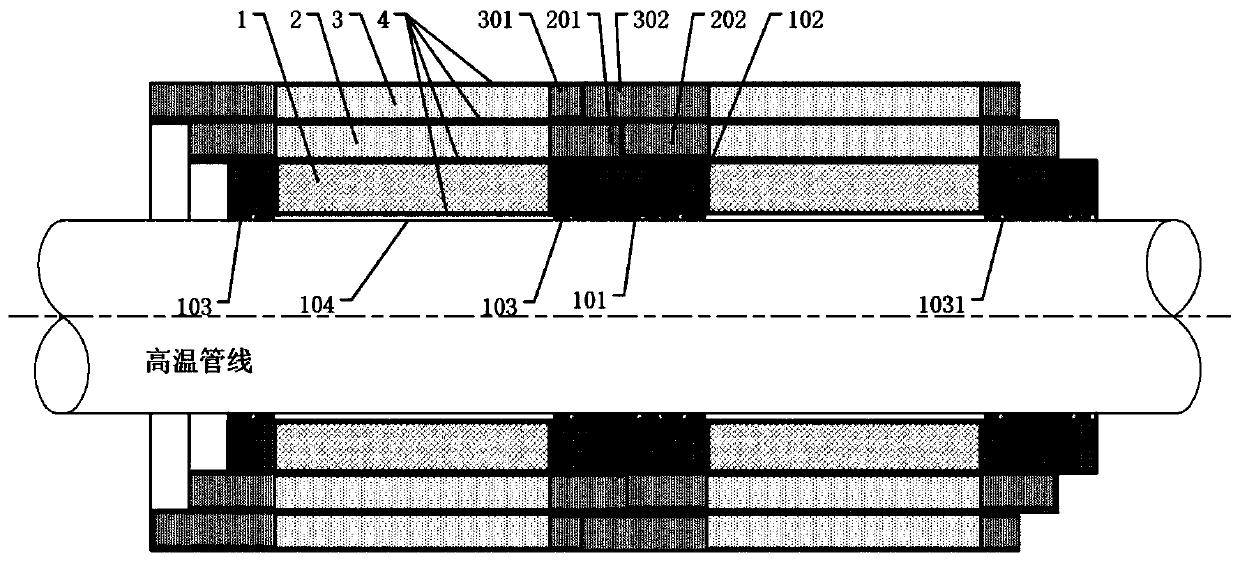

A heat-insulating pipe shell and its installation method

ActiveCN109099262BImprove insulation effectForm factorThermal insulationPipe protection by thermal insulationInsulation layerThermal insulation

The invention relates to a heat-preservation pipe shell and a mounting method thereof. The heat-preservation pipe shell structurally comprises a bottom layer heat-preservation structure, a middle layer heat-preservation structure and an outer layer heat-preservation structure in sequence from inside to outside; reinforcing base material structures are arranged on the inner surface and the outer surface of each layer of heat-preservation structures for fixing heat-preservation layers; and concave-convex modules are arranged at the two ends of each layer of heat-preservation structures, thus thetwo heat-preservation pipe shells can be mutually buckled tightly, and the heat-preservation effect is good. A sliding device and a rolling body are arranged between the two ends of the bottom layerheat-preservation structure and a high-temperature pipeline, the overall heat-preservation pipe shell can be supported to slide on the high-temperature pipeline, the heat-preservation pipe shell can be precast in advance, on-site construction, mounting and dismounting are quick and safe, and the labor intensity, the construction risk and the maintenance cost of on-site construction can be reduced;and a thin air layer is arranged among the bottom layer heat-preservation structure of the heat-preservation pipe shell, the high-temperature pipeline and the sliding device, thus the energy saving effect is greatly improved, the problem that the heat-preservation layer is excessively thick is solved, and the heat-preservation cost can be lowered reasonably.

Owner:北京天济明科技有限公司

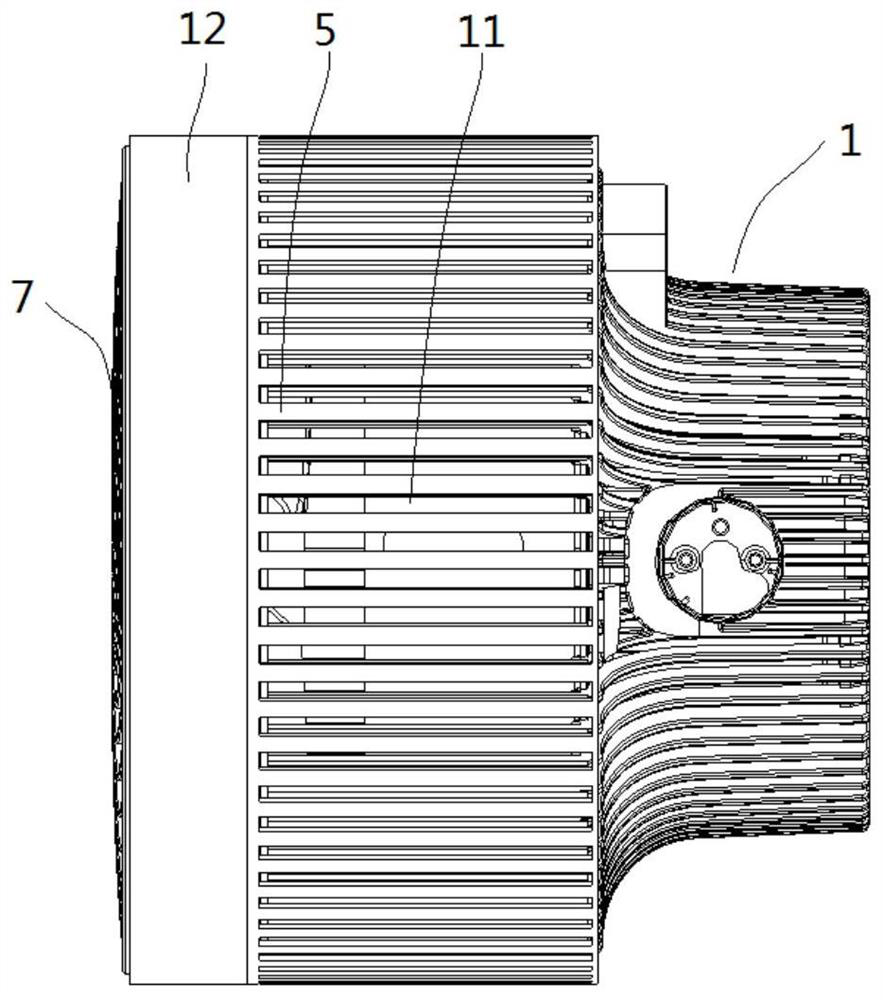

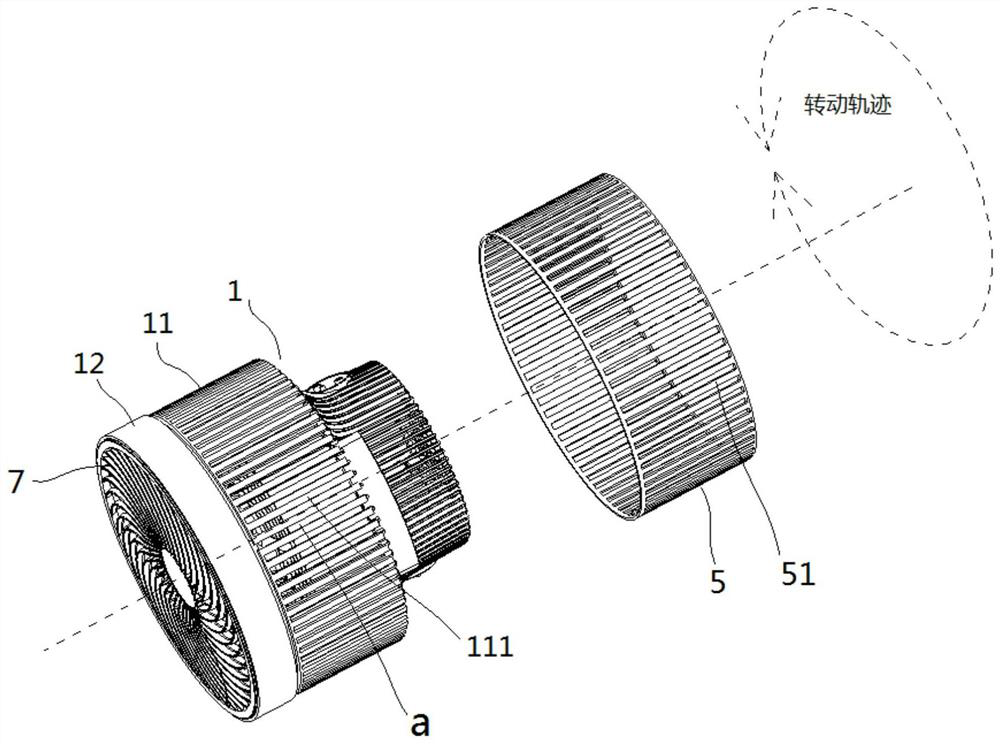

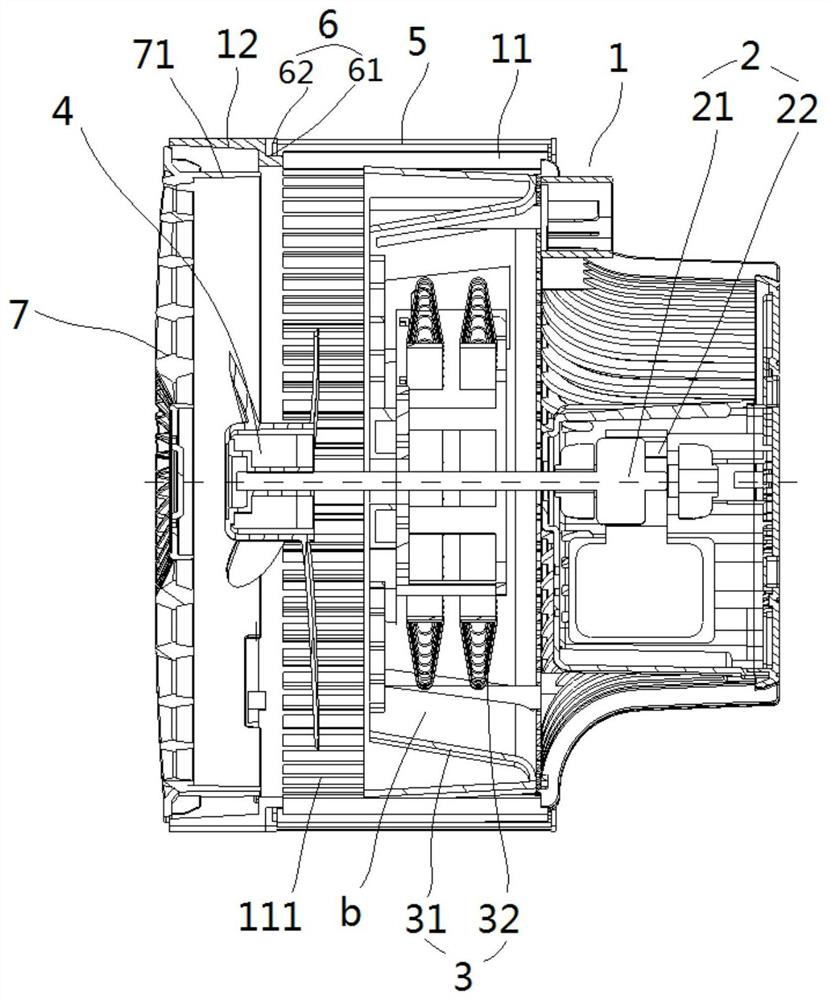

Cooling and heating fan device with adjustable inlet air

PendingCN113639346AEasy to controlFeel goodPump componentsLighting and heating apparatusCold airThermodynamics

The invention discloses a cooling and heating fan device with adjustable inlet air. The cooling and heating fan device is characterized in that a section of radial air inlet channel is further arranged on a rear mesh enclosure located between fan blades and a heating assembly, a section of closed annular air channel is formed in the front end of the rear mesh enclosure and coaxially connected with the radial air inlet channel, a plurality of axially-arranged partition strips are arranged on the radial air inlet channel, a radial air inlet gap is formed between every two adjacent partition strips, a cylindrical air blocking ring is further arranged at the radial air inlet channel, and the air blocking ring is attached to the surface of the whole radial air inlet channel and can rotate along the circumferential surface of the radial air inlet channel; and the air blocking ring is of a grid structure, and a plurality of axially-arranged grid bars are arranged on the air blocking ring. When the grid bars on the air blocking ring rotate to the positions of the radial air inlet gaps, the radial air inlet gaps in the radial air inlet channel are closed, and when the grid bars on the air blocking ring rotate to the positions of the partition strips, the radial air inlet gaps in the radial air inlet channel are opened, the phenomenon that cold air is mixed during warm air can be completely avoided, and the body feeling of a user is effectively improved.

Owner:SHENZHEN LIANCHUANG TECHNOLOGY GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com