Microfeeding system for precisive grinding

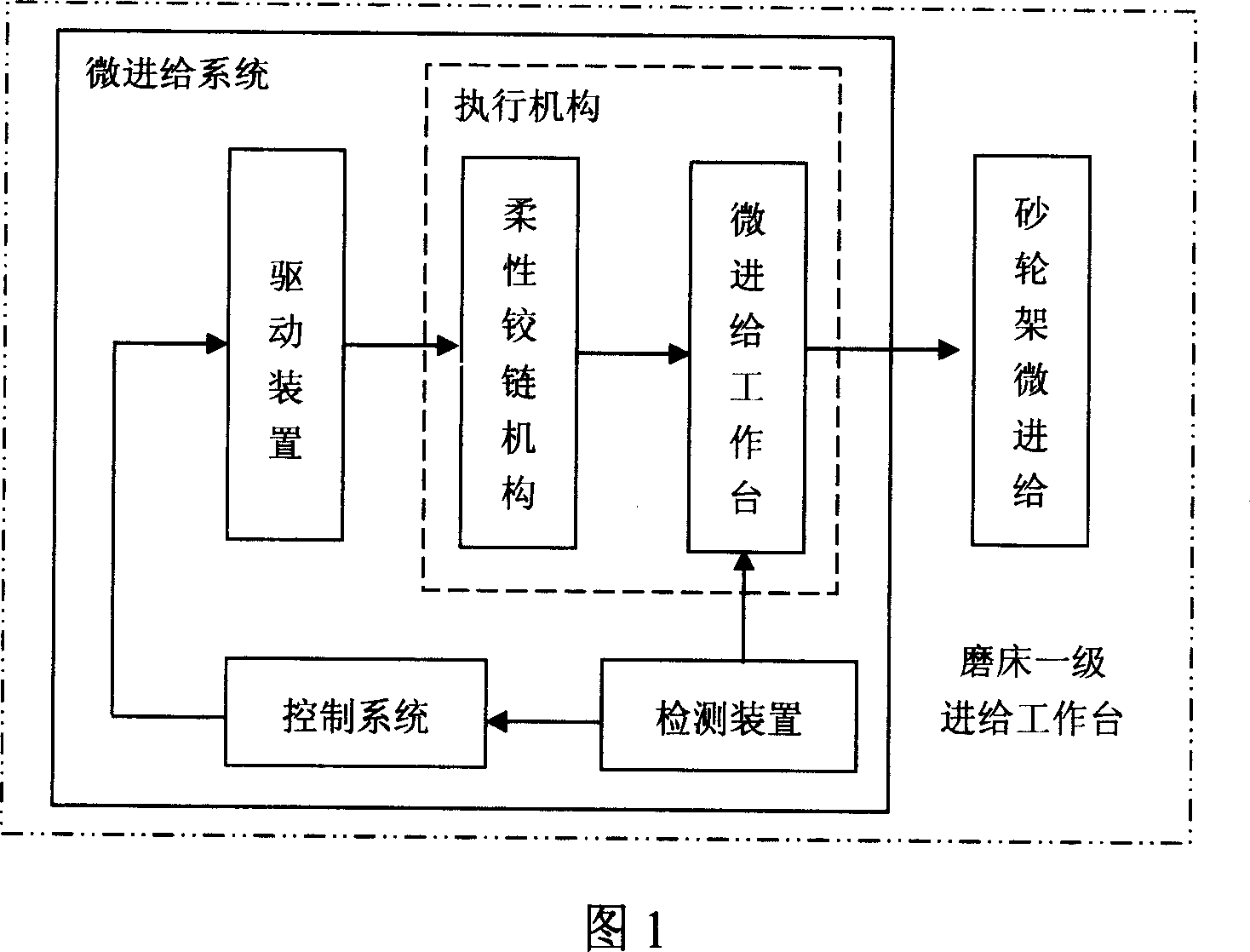

A precision grinding and micro-feeding technology, which is applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of low response frequency, impossibility and difficulty of dynamic compensation, and achieve the goal of research and development Increased success rate, reduced cycle time, and standardized appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Ceramic radome grinding machine, its technical index requirements are: grinding diameter ≤ Φ500mm, the minimum setting unit of the grinding wheel frame is 0.1μm, the actual grinding allowance is <10μm, but the grinding machine including the micro-feeding system is required to have good rigidity and work stability. Based on the MG1520 precision grinding machine, the minimum setting unit of the grinding wheel frame of the grinding machine is 1 μm.

[0081] The basic configuration of the micro-feeding system is given as follows:

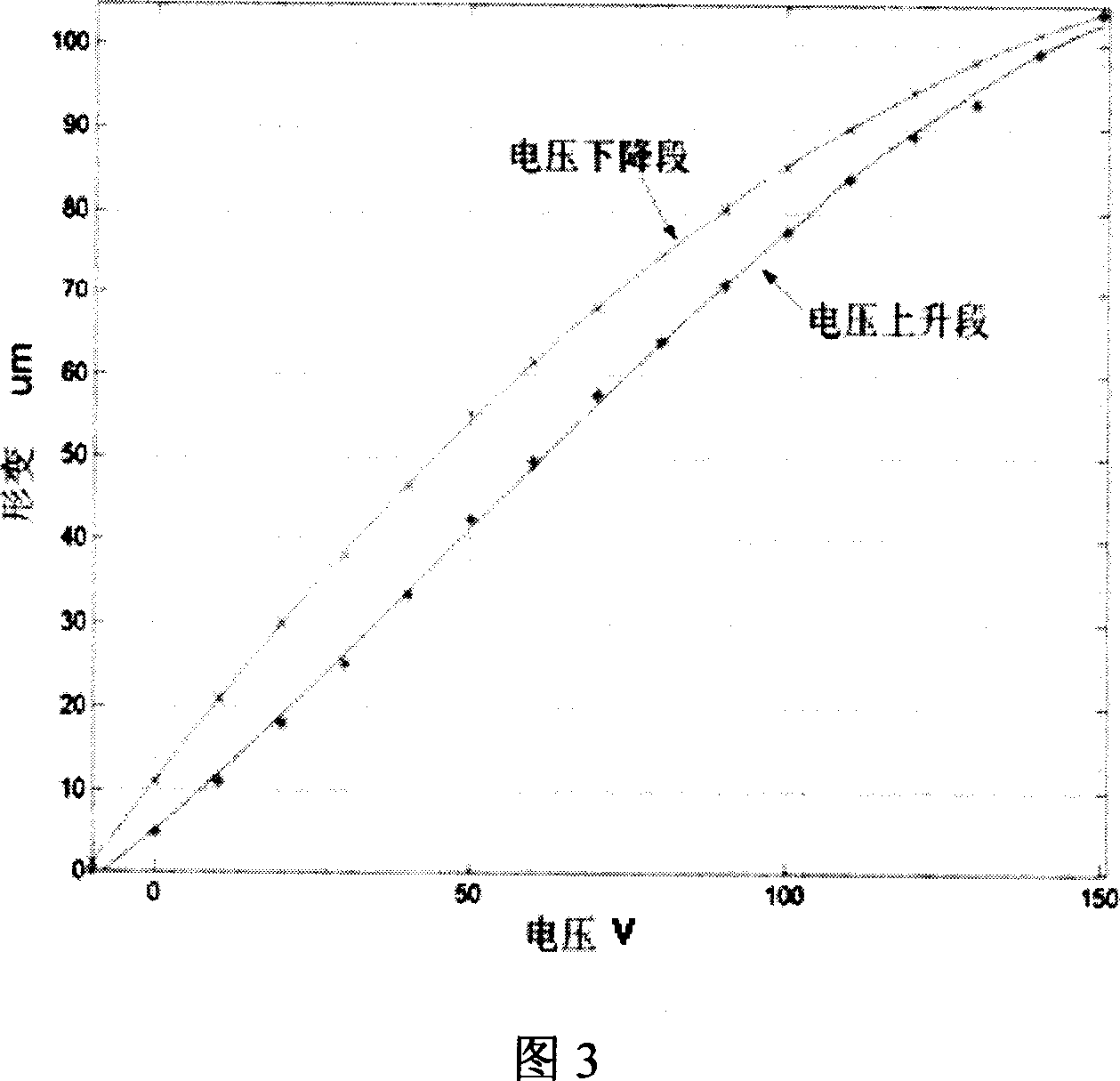

[0082] (1) The main technical characteristics and related parameters of the driving device: the driving power supply voltage is 0-150V, the maximum output force of piezoelectric ceramics is 3600N, and the maximum output displacement is 60μm;

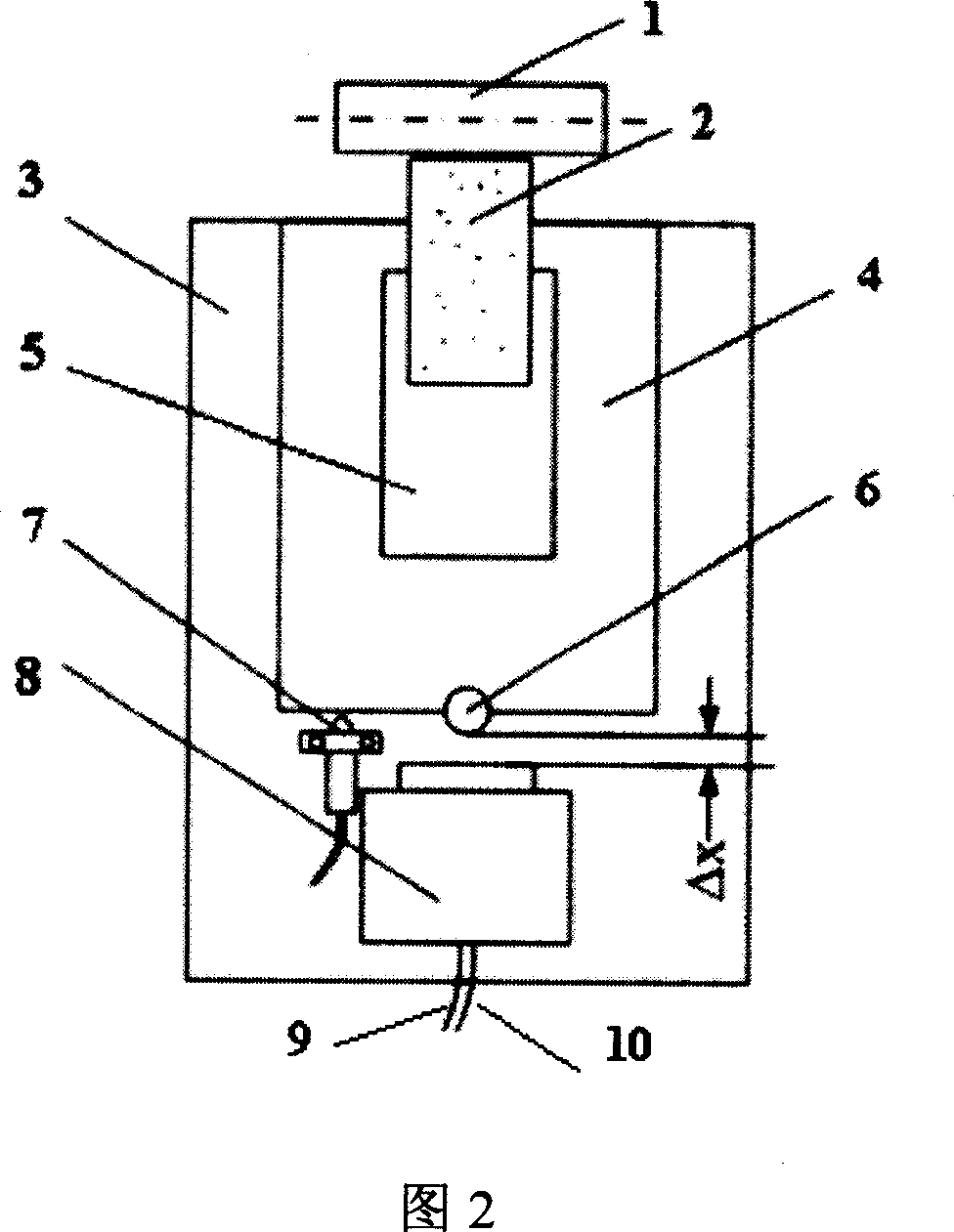

[0083] (2) The main technical characteristics and related parameters of the actuator are that the flexible hinge adopts a parallelogram structure composed of straight circles and double levers, and the sca...

Embodiment 2

[0089] The technical index requirements of the precision grinding machine for the spindle rod bearing gear are: the grinding diameter is less than or equal to Φ300mm, the minimum setting unit of the grinding wheel frame is 0.5μm, and the grinding accuracy of the spindle rod bearing gear is IT5 (the tolerance corresponding to the maximum size of the bearing gear The value is 0.023μm), and the consistency of bearing stall diameter during batch grinding is less than 10μm. However, the minimum setting unit of the grinding wheel frame of the existing MG1320E precision grinding machine is 1 μm. For this reason, based on the MG1320E precision grinding machine, the micro-feeding system of the present invention is added.

[0090] The basic configuration of the micro-feeding system is:

[0091] (1) The main technical characteristics and related parameters of the driving device: the driving power supply voltage is 0-150V, the maximum output force of piezoelectric ceramics is 3500N, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com