Model rod for bar automatic-rotation supersonic wave detection and use method thereof

An automatic rotation and ultrasonic technology, which is applied in the direction of material analysis, measuring devices, and analysis materials using sound waves/ultrasonic waves/infrasonic waves, and achieves the effects of standard shape, easy operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is further described.

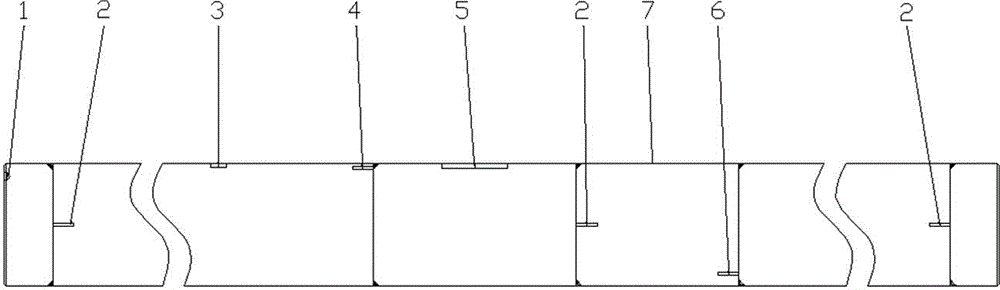

[0012] see figure 1 , a sample rod for automatic rotating ultrasonic testing of rods, comprising a cylindrical rod body 7, a blind hole 1 is opened at the upper end of one side of the rod body 7, and a blind hole 1 is located in the middle of the rod body 7 at the rear end of the blind hole 1 A central horizontal hole 2 is provided, and on the rear side of the central horizontal hole 2, a surface short shallow groove 3 located on the upper surface of the rod body 7 is provided. Horizontal hole 4, the rear side of subcutaneous horizontal hole 4 is provided with a surface long and deep groove 5 that is positioned at upper surface, and the rear side of surface long and deep groove 5 is provided with a center horizontal hole 2 that is positioned at the middle part of rod body 7, and in the center horizontal The rear end of the hole 2 is provided with a near-surface horizontal hole 6 located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com