A heat-insulating pipe shell and its installation method

A technology of thermal insulation tube shell and thermal insulation material, which is applied in the directions of thermal insulation, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of high labor intensity of thermal insulation engineering site construction, large heat dissipation of high-temperature pipelines, and unsatisfactory thermal insulation effect, etc. The effect of excellent thermal insulation, improved energy saving, and reduced risk and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

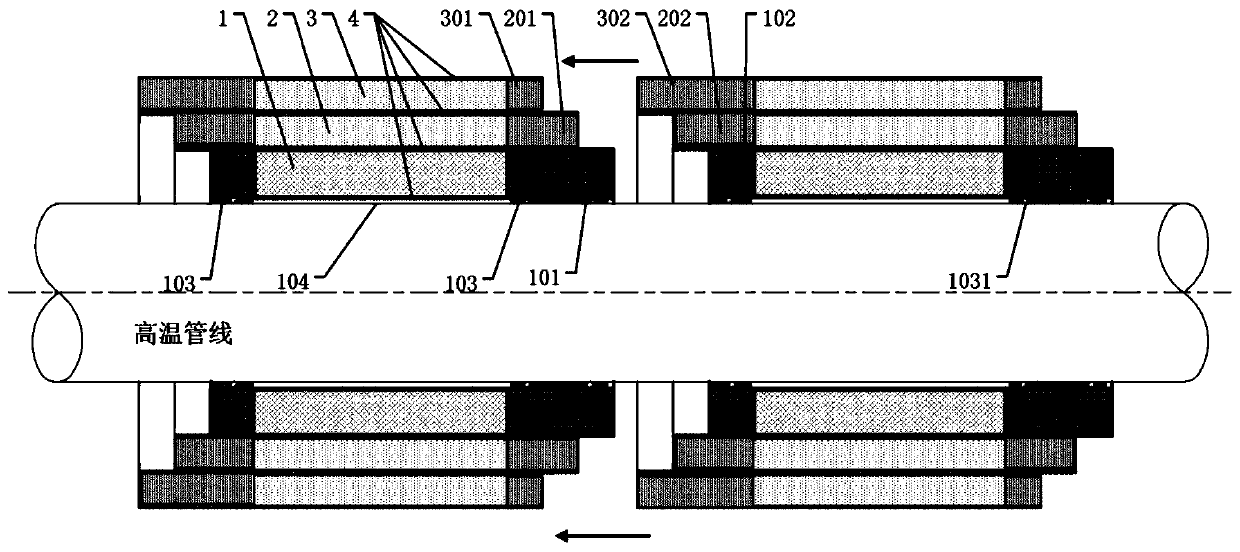

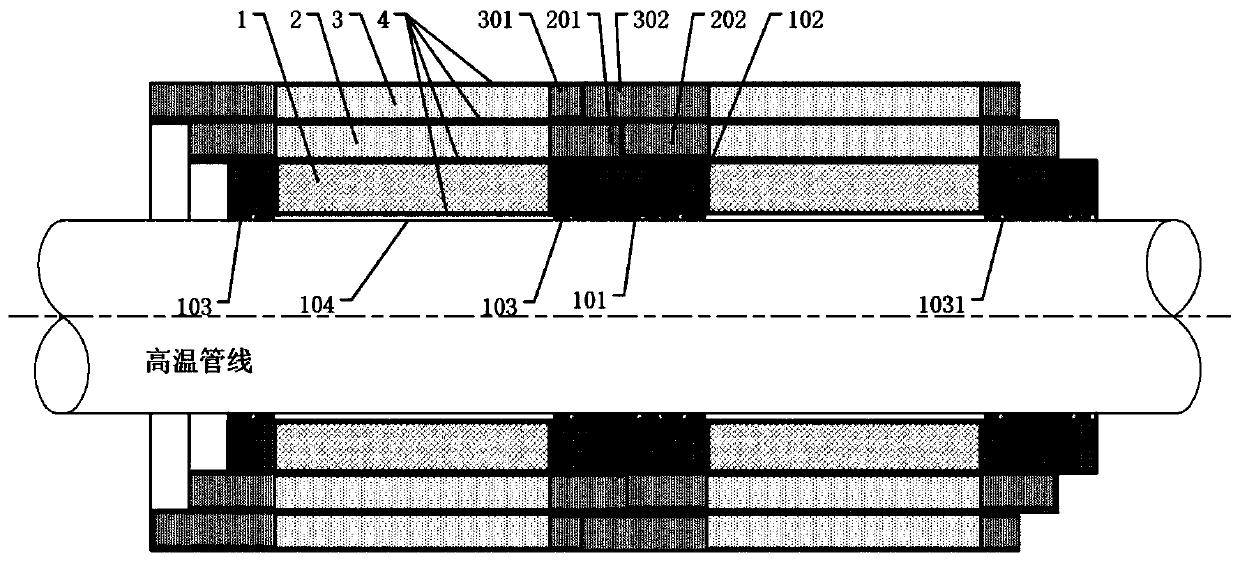

[0050] The bottom thermal insulation structure 1 is 5 cm thick rock wool.

[0051] The middle layer insulation structure 2 is two layers of 5 cm thick aluminum silicate.

[0052] The outer thermal insulation structure 3 is two layers of 5 cm thick glass wool.

[0053] The reinforced substrate structure 4 is a 1 cm thick aerogel substrate.

Embodiment 2

[0055] The bottom thermal insulation structure 1 is 5 cm thick rock wool.

[0056] The middle layer insulation structure 2 is three layers of 5 cm thick glass wool.

[0057] The outer insulation structure 3 is two layers of 5 cm thick aerogel.

[0058] The reinforced substrate structure 4 is a 1 cm thick aerogel substrate.

Embodiment 3

[0060] The bottom thermal insulation structure 1 is 5 cm thick rock wool.

[0061] The middle layer insulation structure 2 is two layers of 5 cm thick aluminum silicate.

[0062] The outer thermal insulation structure 3 is three layers of 3 cm thick aerogel.

[0063] The reinforced substrate structure 4 is a 1 cm thick aerogel substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com