A Production Method for Reducing the Occurrence of Edge Folding of Wide Board

A production method and technology of occurrence rate, applied in the field of iron and steel material forming and control, can solve the problems of downgrading and changing judgments, the yield of finished products and the contract fulfillment rate are greatly affected, so as to reduce the amount of blanks, improve the temperature field of the edge, and the thickness of the edge uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example provides a production method for reducing the incidence of wide plate edge folding, structural steel plate S355J, blank size: 260×2070×2792mm; order size: 25×3910×12000mm;

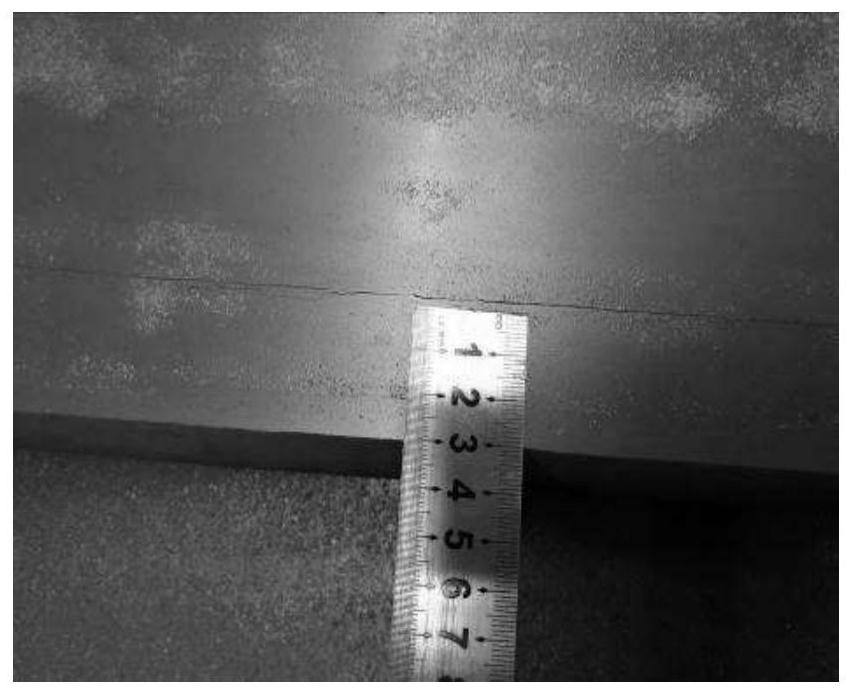

[0027] Rolling method: vertical-horizontal-longitudinal; width ratio: 1.88; the continuous casting billet adopts a large chamfered 34° crystallizer to draw steel, which effectively weakens the two-dimensional cooling of the right-angle billet, improves the temperature uniformity and strain resistance of the corner, After the billet leaves the continuous casting section, perform secondary chamfering, the chamfering pressure is 70bar, and the chamfering size is 15mm, such as figure 2 As shown; the first pass of the rolling process is forming rolling, and after the forming is completed, widening rolling is carried out. There are four widening passes, and the reduction rates are 8%, 9%, 8%, and 8%. Longitudinal rolling and phosphorus removal are the first, fifth and sixth passes respective...

Embodiment 2

[0033] This example provides a production method for reducing the occurrence of wide plate edge folding, high-strength steel Q690, blank size: 260×2570×2792mm; order size: 25×4210×12000mm;

[0034] Rolling method: vertical-horizontal-longitudinal; width ratio: 1.63; the continuous casting billet adopts a large chamfered 34° crystallizer to draw steel, which effectively weakens the two-dimensional cooling of the right-angle billet, improves the temperature uniformity and strain resistance of the corner, After the billet leaves the continuous casting section, the second chamfering is carried out. The chamfering pressure is 80bar, and the chamfering size is 13mm; 9%, 9%, 8%, and 8%, respectively. After the end of the widening, full longitudinal rolling is carried out, and the phosphorus removal is the first, fifth, and sixth passes;

[0035] Pre-straightening is carried out after rolling, and ultra-fast cooling is carried out. After the steel plate reaches the cooling bed, warm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com